Introduction: Navigating the Global Market for how is rubber vulcanized

The global market for rubber products is continuously evolving, and understanding the complexities of how rubber is vulcanized is essential for B2B buyers seeking high-quality materials. Sourcing durable and resilient rubber components, particularly in regions like Africa, South America, the Middle East, and Europe, presents unique challenges. Vulcanization, a chemical process that enhances the strength and elasticity of rubber, is at the heart of producing materials that meet stringent industry standards. This guide will delve into the intricacies of vulcanization, covering various types of rubber, their applications, and the best practices for vetting suppliers.

In the coming sections, readers will gain insights into the latest vulcanization techniques, the benefits of both natural and synthetic rubber, and how to assess costs effectively. We will also explore the environmental implications of vulcanized rubber and its potential for sustainable practices in the industry. By equipping B2B buyers with comprehensive knowledge about vulcanization, this guide aims to empower them to make informed purchasing decisions that align with their operational needs and market demands. Understanding these elements will not only enhance product quality but also foster long-term partnerships with suppliers who can deliver reliable, high-performance rubber solutions.

Índice

- Top 2 How Is Rubber Vulcanized Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how is rubber vulcanized

- Understanding how is rubber vulcanized Types and Variations

- Key Industrial Applications of how is rubber vulcanized

- 3 Common User Pain Points for ‘how is rubber vulcanized’ & Their Solutions

- Strategic Material Selection Guide for how is rubber vulcanized

- In-depth Look: Manufacturing Processes and Quality Assurance for how is rubber vulcanized

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how is rubber vulcanized’

- Comprehensive Cost and Pricing Analysis for how is rubber vulcanized Sourcing

- Alternatives Analysis: Comparing how is rubber vulcanized With Other Solutions

- Essential Technical Properties and Trade Terminology for how is rubber vulcanized

- Navigating Market Dynamics and Sourcing Trends in the how is rubber vulcanized Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how is rubber vulcanized

- Strategic Sourcing Conclusion and Outlook for how is rubber vulcanized

- Aviso importante e termos de utilização

Understanding how is rubber vulcanized Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Sulfur Vulcanization | Involves heating rubber with sulfur to create cross-links. | Tires, industrial belts, seals | Prós: High durability, excellent elasticity. Contras: Requires precise temperature control. |

| Accelerated Vulcanization | Utilizes accelerators to speed up the vulcanization process. | Automotive parts, medical devices | Prós: Faster production times, improved efficiency. Contras: Higher costs due to additives. |

| Thermoplastic Vulcanizates (TPVs) | Combines thermoplastic and vulcanized rubber properties. | Automotive seals, gaskets, soft-touch grips | Prós: Recyclable, versatile. Contras: May have lower heat resistance than traditional vulcanized rubber. |

| Liquid Silicone Rubber (LSR) Vulcanization | Uses heat to cure liquid silicone into solid rubber. | Medical applications, consumer products | Prós: Excellent biocompatibility, high-temperature resistance. Contras: More expensive raw materials. |

| Microwave Vulcanization | Employs microwave energy for rapid vulcanization. | Specialty applications, custom parts | Prós: Quick processing, energy-efficient. Contras: Equipment can be costly, limited material compatibility. |

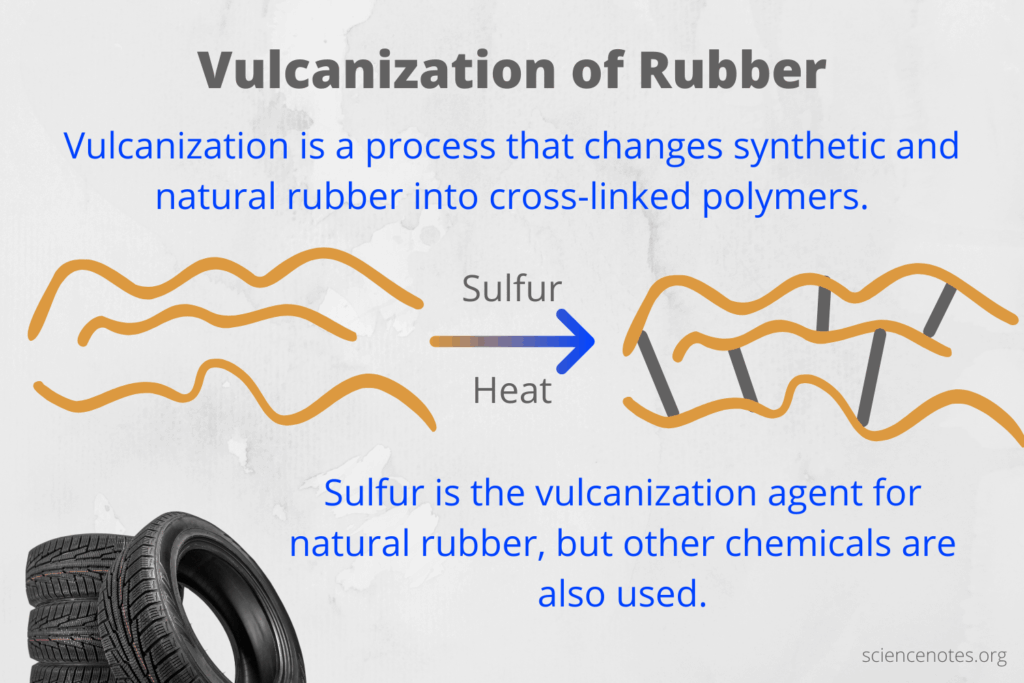

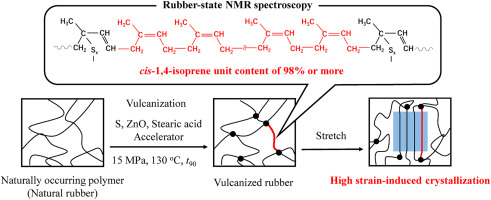

What Are the Characteristics and Suitability of Sulfur Vulcanization?

Sulfur vulcanization is the traditional method of vulcanizing rubber, known for its ability to enhance the mechanical properties of rubber through the formation of cross-links. This method is particularly suitable for manufacturing tires and industrial belts where high durability and elasticity are essential. B2B buyers should consider the need for precise temperature control during the vulcanization process, as fluctuations can significantly affect the final product’s quality. This method remains popular due to its established reliability and performance in demanding applications.

How Does Accelerated Vulcanization Improve Efficiency?

Accelerated vulcanization incorporates chemical accelerators to expedite the vulcanization process, allowing for faster production cycles. This method is especially beneficial in industries such as automotive and medical, where timely delivery is crucial. Buyers should weigh the benefits of improved efficiency against the higher costs associated with the necessary additives. The trade-off often results in a more competitive edge in fast-paced markets, making it a favored choice for manufacturers looking to enhance throughput without compromising quality.

What Makes Thermoplastic Vulcanizates (TPVs) a Versatile Option?

Thermoplastic vulcanizates (TPVs) combine the properties of thermoplastics and vulcanized rubber, offering a unique blend of elasticity and recyclability. They are ideal for applications like automotive seals and gaskets, where flexibility and durability are required. B2B buyers should consider the versatility of TPVs, especially in projects that prioritize sustainability. However, it is essential to note that TPVs may exhibit lower heat resistance compared to traditional vulcanized rubber, which could impact their performance in high-temperature environments.

Why Choose Liquid Silicone Rubber (LSR) Vulcanization for Medical Applications?

Liquid silicone rubber (LSR) vulcanization is highly regarded for its biocompatibility and ability to withstand high temperatures, making it an excellent choice for medical applications and consumer products. This method allows for intricate designs and consistent quality, which are critical in the medical field. B2B buyers should factor in the higher material costs associated with LSR, but the long-term benefits of reliability and safety often justify the investment, particularly in regulated industries.

What Are the Benefits of Microwave Vulcanization?

Microwave vulcanization is an innovative approach that utilizes microwave energy for rapid vulcanization, resulting in shorter processing times and reduced energy consumption. This method is suitable for specialty applications and custom parts where speed and efficiency are paramount. Buyers interested in this technology should consider the initial investment in microwave equipment, which can be significant. However, the potential for quicker turnaround times and reduced energy costs can lead to substantial savings over time, making it an attractive option for forward-thinking manufacturers.

Key Industrial Applications of how is rubber vulcanized

| Indústria/Setor | Specific Application of how is rubber vulcanized | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Automóvel | Tires and tire components | Enhanced durability, heat resistance, and improved traction | Sourcing high-quality synthetic rubber and accelerators |

| Industrial Equipment | Conveyor belts | Increased resistance to wear and tear, improved efficiency | Consideration of load capacity and environmental factors |

| Bens de consumo | Footwear (shoe soles) | Greater comfort, durability, and water resistance | Need for lightweight materials with high elasticity |

| Electrical Insulation | Insulating materials for cables | Superior electrical insulation and resistance to aging | Compliance with international safety standards |

| Construção | Seals and gaskets for machinery | Enhanced sealing capabilities and resistance to chemicals | Material compatibility with specific machinery |

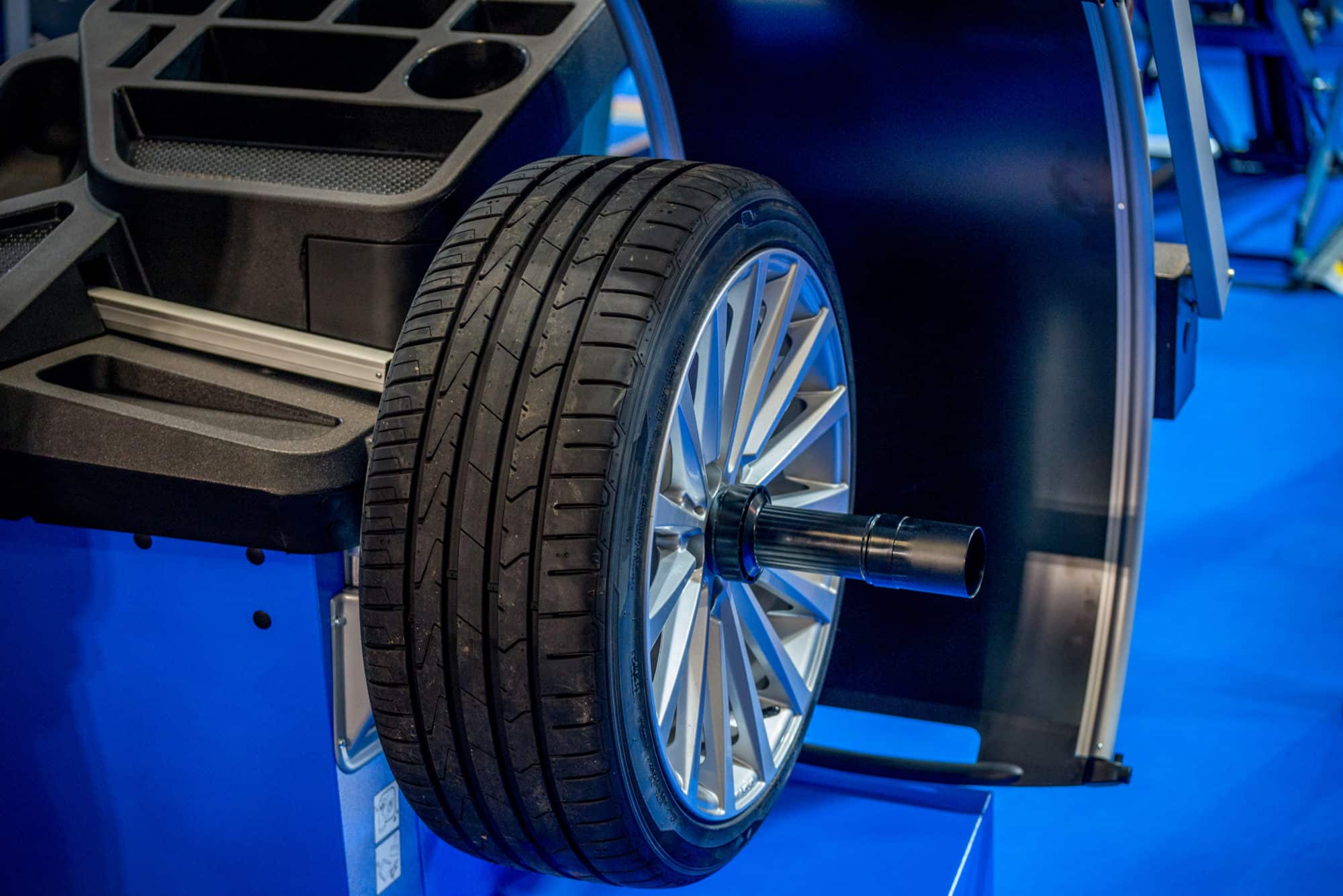

How is Rubber Vulcanization Applied in the Automotive Industry?

In the automotive sector, vulcanized rubber is primarily utilized in the manufacturing of tires and tire components. The vulcanization process enhances the rubber’s strength and elasticity, allowing it to withstand extreme pressures and temperatures. This results in tires that offer better traction, durability, and safety on the road. For B2B buyers in regions like Saudi Arabia and Brazil, sourcing high-quality synthetic rubber and accelerators is crucial, as these materials directly impact the performance and longevity of the tires produced.

What Role Does Vulcanized Rubber Play in Industrial Equipment?

Vulcanized rubber is essential in the production of conveyor belts, which are widely used in various industrial applications. The vulcanization process increases the rubber’s resistance to wear and tear, ensuring that conveyor belts can operate efficiently under heavy loads. B2B buyers must consider factors such as load capacity and environmental conditions when sourcing these belts, particularly in regions with varying climates, to ensure optimal performance and longevity.

How Does Vulcanization Benefit Consumer Goods Manufacturers?

In the consumer goods industry, vulcanized rubber is commonly used in footwear, particularly in shoe soles. The vulcanization process provides increased comfort, durability, and water resistance, making shoes more appealing to consumers. For international B2B buyers, sourcing lightweight materials that maintain high elasticity is vital, as these properties significantly enhance the product’s marketability and consumer satisfaction.

Why is Vulcanized Rubber Important for Electrical Insulation?

Vulcanized rubber is widely used as insulating material for electrical cables due to its superior electrical insulation properties and resistance to aging. This makes it an ideal choice for various applications in the electrical and electronics sectors. Buyers must ensure that the materials comply with international safety standards to mitigate risks associated with electrical failures, particularly in regions where regulations may vary.

How Does Vulcanization Enhance Construction Applications?

In the construction industry, vulcanized rubber is utilized in seals and gaskets for machinery and structural components. The vulcanization process enhances the rubber’s sealing capabilities and resistance to chemicals, which is critical for preventing leaks and ensuring operational efficiency. B2B buyers should prioritize material compatibility with specific machinery to ensure optimal performance and minimize maintenance costs, especially in diverse environments across Africa, South America, and Europe.

3 Common User Pain Points for ‘how is rubber vulcanized’ & Their Solutions

Scenario 1: Ensuring Consistent Quality in Vulcanization Processes

O problema: Many manufacturers face challenges in maintaining consistent quality during the vulcanization of rubber products. Variability in raw materials, temperature fluctuations, and differences in curing times can lead to inconsistencies in rubber properties, such as tensile strength and elasticity. This not only affects the performance of the final product but can also lead to increased waste and rework costs, frustrating B2B buyers who rely on high-quality materials for their applications.

Illustrative image related to how is rubber vulcanized

A solução: To address these quality concerns, B2B buyers should prioritize working with suppliers who offer detailed specifications and testing for their rubber compounds. Implementing a robust quality control system that includes regular monitoring of the vulcanization process is essential. Buyers can specify clear parameters for temperature, curing times, and the proportions of sulfur and accelerators used in the vulcanization process. Additionally, investing in training for production staff on the importance of consistency can significantly improve outcomes. Utilizing advanced technologies like real-time monitoring systems can also help ensure that each batch meets the required standards before it leaves the facility.

Scenario 2: Navigating Supply Chain Disruptions for Vulcanization Materials

O problema: International B2B buyers often encounter supply chain disruptions that affect the availability of key materials needed for vulcanization, such as sulfur and various accelerators. These disruptions can stem from geopolitical tensions, natural disasters, or logistical challenges, resulting in production delays and potential loss of contracts due to unmet demand.

A solução: To mitigate supply chain risks, buyers should consider establishing relationships with multiple suppliers across different regions. This diversification can provide alternative sources for critical materials, ensuring that production can continue even if one supplier faces challenges. Additionally, buyers can negotiate long-term contracts with suppliers that include clauses for prioritized delivery during shortages. Implementing a just-in-time inventory system can help manage stock levels effectively, reducing the impact of delays. Furthermore, collaborating with suppliers to develop a shared understanding of demand forecasts can enhance supply chain resilience and responsiveness.

Scenario 3: Reducing Environmental Impact of Vulcanized Rubber Production

O problema: With increasing pressure from consumers and regulatory bodies to adopt sustainable practices, B2B buyers in the rubber industry are often concerned about the environmental impact of vulcanization processes. The use of certain chemicals and the energy-intensive nature of vulcanization can lead to significant carbon footprints, making it imperative for companies to seek greener alternatives.

A solução: Buyers can tackle this challenge by sourcing eco-friendly vulcanization agents and exploring alternative curing methods that reduce energy consumption. For instance, using bio-based accelerators or employing steam curing instead of traditional methods can significantly lower emissions. Additionally, engaging with suppliers who prioritize sustainability in their production processes can enhance a company’s overall environmental profile. Buyers should also consider investing in research and development to innovate new vulcanization techniques that minimize waste and energy use. By actively pursuing greener options, businesses can meet sustainability goals while maintaining the quality and performance of their products.

Strategic Material Selection Guide for how is rubber vulcanized

What Are the Key Materials Used in Rubber Vulcanization?

When selecting materials for rubber vulcanization, it is essential to consider the properties and performance characteristics of each component. The most common materials used in the vulcanization process include sulfur, accelerators, and fillers. Each of these materials plays a crucial role in determining the final product’s performance, durability, and suitability for various applications.

How Does Sulfur Influence the Vulcanization Process?

Sulfur is the primary vulcanizing agent that forms cross-links between polymer chains, enhancing the rubber’s strength and elasticity. The key properties of sulfur include its ability to withstand high temperatures and its compatibility with various rubber types. However, while sulfur improves elasticity and tensile strength, it can also lead to oxidative degradation if used alone. This limitation necessitates the addition of accelerators to optimize the vulcanization process.

Prós e contras: Sulfur is relatively low-cost and widely available, making it an economical choice for manufacturers. However, the vulcanization process can be slow without accelerators, which may increase production time and costs.

Impacto na aplicação: Products made with sulfur-vulcanized rubber are commonly used in automotive tires and industrial applications where durability is crucial.

Considerações para compradores internacionais: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe and the Middle East should ensure that the sulfur content meets local regulations regarding emissions and environmental impact.

What Role Do Accelerators Play in Rubber Vulcanization?

Accelerators are chemicals added to the vulcanization process to speed up the cross-linking reaction between sulfur and rubber. Common accelerators include thiurams, thiazoles, and guanidines. These materials enhance the efficiency of sulfur, allowing vulcanization to occur at lower temperatures and within shorter time frames.

Prós e contras: The use of accelerators significantly reduces production time and improves the mechanical properties of the final product. However, the complexity of the manufacturing process increases, as the selection of the right accelerator is crucial for achieving the desired properties.

Impacto na aplicação: Accelerators are vital for applications requiring rapid production cycles, such as automotive parts and consumer goods.

Considerações para compradores internacionais: Buyers should be aware of the specific accelerator types that comply with regional regulations, especially in markets like South America and Africa, where chemical regulations may vary.

Illustrative image related to how is rubber vulcanized

How Do Fillers Affect the Vulcanization Process and Final Product?

Fillers, such as carbon black and silica, are added to rubber compounds to enhance properties like strength, durability, and cost-effectiveness. Carbon black, for instance, improves tensile strength and abrasion resistance, making it ideal for tires and industrial applications.

Prós e contras: Fillers can significantly reduce material costs and enhance product performance. However, excessive filler content may lead to reduced flexibility and elasticity, which can be a limitation for certain applications.

Impacto na aplicação: Fillers are particularly important in the tire industry, where they contribute to the rubber’s performance under stress and environmental conditions.

Considerações para compradores internacionais: Buyers should ensure that fillers meet local environmental standards, as regulations regarding carbon black and silica usage can differ significantly across regions, particularly in Europe and the Middle East.

Summary Table of Common Materials for Rubber Vulcanization

| Material | Typical Use Case for how is rubber vulcanized | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Sulfur | Automotive tires, industrial rubber products | Enhances strength and elasticity | Slow vulcanization without accelerators | Baixa |

| Accelerators | Consumer goods, automotive parts | Speeds up vulcanization process | Increased manufacturing complexity | Médio |

| Fillers (Carbon Black) | Tires, industrial applications | Reduces costs and improves durability | May reduce flexibility | Baixa |

| Fillers (Silica) | High-performance tires, specialty applications | Enhances wet traction and durability | Higher cost compared to carbon black | Médio |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in rubber vulcanization, helping them make informed decisions that align with their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how is rubber vulcanized

The process of rubber vulcanization is essential for producing high-quality rubber products used in various industries. Understanding the manufacturing processes and quality assurance measures can help B2B buyers make informed decisions when selecting suppliers. This section provides an in-depth overview of the typical manufacturing stages, key techniques, and quality control checkpoints associated with rubber vulcanization.

What Are the Main Stages of the Rubber Vulcanization Manufacturing Process?

How Is Material Prepared for Rubber Vulcanization?

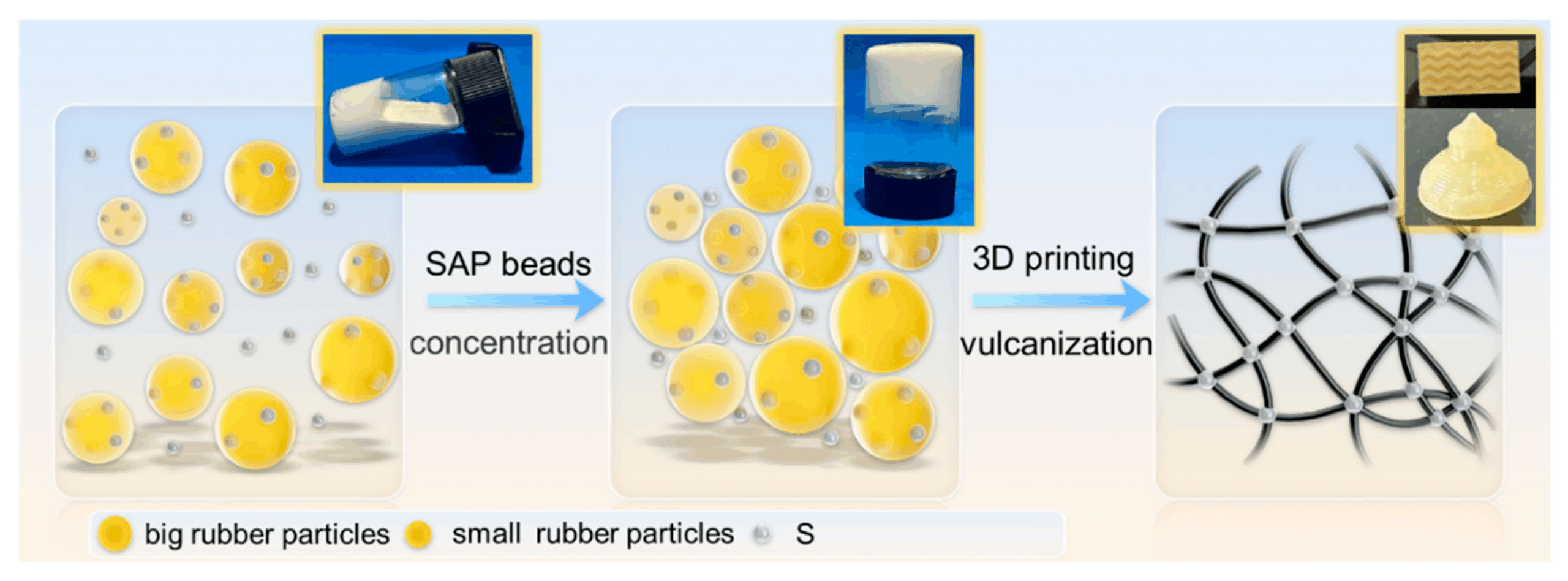

The first stage in the rubber vulcanization process involves careful material preparation. This includes selecting the appropriate type of rubber—natural or synthetic—based on the intended application. The rubber is then mixed with various additives, including sulfur, accelerators, activators, and fillers, to enhance its properties.

The mixing process is critical; it must be conducted under controlled conditions to ensure uniform distribution of the additives. Advanced mixing technologies, such as internal mixers and open mills, are often employed to achieve the desired consistency. Precise control over temperature and time during this stage is vital to prevent premature vulcanization, which can adversely affect the quality of the final product.

What Techniques Are Used in the Forming Stage of Vulcanization?

Once the rubber is properly mixed, it undergoes the forming stage. This involves shaping the rubber into the desired form, which can range from sheets to complex components like tires or seals. Techniques such as compression molding, transfer molding, and injection molding are commonly used, each with its unique advantages depending on the complexity of the product.

Illustrative image related to how is rubber vulcanized

Compression molding is particularly popular for simpler shapes, while injection molding is favored for intricate designs that require high precision. During this stage, manufacturers must ensure that the molds are clean and properly prepared to prevent defects in the final product.

How Is the Assembly and Finishing Process Conducted?

Following the forming stage, the rubber components may require assembly, especially if they consist of multiple parts. This could involve bonding different rubber components or integrating non-rubber materials, such as metal or fabric, to enhance performance.

The finishing process may include trimming excess material, surface treatment, or applying coatings to improve durability and aesthetics. This stage is crucial for ensuring that the final product meets the required specifications and quality standards.

Illustrative image related to how is rubber vulcanized

What Quality Control Measures Are Commonly Used in Rubber Vulcanization?

Which International Standards Should Be Followed?

Quality assurance in rubber vulcanization is paramount for ensuring product reliability and safety. Many manufacturers adhere to international standards such as ISO 9001, which provides a framework for effective quality management systems. Additionally, industry-specific standards like CE marking for products sold in Europe or API specifications for oil and gas applications may apply, depending on the end-use of the rubber products.

These standards guide manufacturers in maintaining consistent quality and compliance throughout the production process, from raw material sourcing to final inspection.

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the manufacturing process to ensure that products meet defined quality criteria:

-

Controlo de qualidade de entrada (IQC): This initial checkpoint evaluates the quality of raw materials and additives before they enter the production line. Suppliers must provide certificates of analysis and compliance with relevant standards.

-

Controlo de qualidade durante o processo (IPQC): During the manufacturing stages, IPQC monitors critical parameters such as temperature, pressure, and time. Regular checks help identify deviations early, reducing the risk of defects in the final product.

-

Controlo de qualidade final (FQC): This final checkpoint assesses the finished product against established specifications. It includes visual inspections, physical testing (such as tensile strength and hardness), and performance evaluations to ensure the rubber meets the required standards.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed during the QC process to evaluate the properties of vulcanized rubber. Common tests include:

Illustrative image related to how is rubber vulcanized

- Tensile Testing: Measures the rubber’s strength and elasticity.

- Hardness Testing: Assesses the material’s resistance to indentation.

- Compression Set Testing: Evaluates the rubber’s ability to return to its original shape after compression.

- Aging Tests: Determine how the rubber performs under prolonged exposure to heat, light, and ozone.

These tests provide critical data that B2B buyers can use to assess product quality and suitability for their specific applications.

Como podem os compradores B2B verificar as práticas de controlo de qualidade dos fornecedores?

What Steps Can Buyers Take to Audit Suppliers?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Conducting regular audits is one of the most effective methods. These audits can include:

- On-site Visits: Buyers can assess the manufacturing facilities, equipment, and processes firsthand.

- Document Reviews: Requesting and reviewing quality control documentation, such as inspection reports and compliance certificates, can provide insights into the supplier’s quality management practices.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further enhance the verification process. These independent entities can conduct thorough assessments of the manufacturing processes and quality control measures, providing an unbiased evaluation of the supplier’s capabilities. This is particularly important for international B2B buyers who may face challenges in assessing suppliers from different regions, including Africa, South America, the Middle East, and Europe.

Quais são as nuances do controlo de qualidade para os compradores internacionais B2B?

International buyers must be aware of various nuances that can affect quality control. Regional differences in standards, regulations, and manufacturing practices can lead to variations in product quality. It is essential for buyers to understand the specific requirements for their target markets and ensure that suppliers comply with these standards.

Illustrative image related to how is rubber vulcanized

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear, documented agreements and maintaining open lines of communication with suppliers can help mitigate these challenges.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with rubber vulcanization is crucial for B2B buyers. By focusing on material preparation, forming techniques, and robust quality control practices, buyers can ensure they source high-quality rubber products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how is rubber vulcanized’

This guide aims to equip B2B buyers with a practical checklist for sourcing rubber vulcanization services or materials. Understanding the vulcanization process is essential for ensuring the quality and durability of rubber products, which are critical in various industries. Here’s a step-by-step approach to guide your sourcing decisions effectively.

Illustrative image related to how is rubber vulcanized

Passo 1: Definir as suas especificações técnicas

Before initiating the procurement process, clearly outline your technical requirements for vulcanized rubber. This includes specifying the type of rubber (natural or synthetic), desired physical properties (such as tensile strength, elasticity, and abrasion resistance), and the applications intended for the final product. Having precise specifications will enable suppliers to provide accurate quotes and samples that meet your needs.

Passo 2: Pesquisa de potenciais fornecedores

Conduct thorough research to identify suppliers specializing in rubber vulcanization. Utilize industry directories, trade shows, and online platforms to compile a list of potential candidates. Focus on suppliers with a proven track record in your industry, as they are more likely to understand specific needs and challenges.

Passo 3: Avaliar as certificações dos fornecedores

It is crucial to verify that suppliers hold relevant certifications that demonstrate compliance with industry standards. Look for certifications like ISO 9001 for quality management systems or ISO 14001 for environmental management. These certifications indicate that the supplier adheres to best practices in manufacturing and sustainability, which can significantly impact product quality.

Passo 4: Request Samples and Test Quality

Once you have shortlisted potential suppliers, request samples of their vulcanized rubber products. Testing these samples will help assess their performance against your defined specifications. Look for attributes such as flexibility, durability, and resistance to environmental factors. This step is vital to ensure that the products will perform as expected in their intended applications.

Illustrative image related to how is rubber vulcanized

Passo 5: Assess Production Capabilities

Evaluate the production capabilities of each supplier to ensure they can meet your volume requirements and timelines. Inquire about their manufacturing processes, equipment, and technology used for vulcanization. Suppliers with advanced technology may offer more efficient production and higher quality results, impacting your overall supply chain effectiveness.

Passo 6: Rever os preços e as condições de pagamento

After assessing quality and capabilities, compare pricing structures among suppliers. Consider not just the unit price but also payment terms, bulk order discounts, and any additional costs (like shipping or handling). A clear understanding of the total cost will help you make informed purchasing decisions while maintaining budget constraints.

Passo 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan to facilitate ongoing collaboration. Define points of contact, frequency of updates, and preferred communication channels. Effective communication is essential to address any issues promptly and ensure that production aligns with your expectations throughout the partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing vulcanized rubber efficiently, ensuring that they select suppliers who can meet their technical and business needs.

Comprehensive Cost and Pricing Analysis for how is rubber vulcanized Sourcing

Understanding the cost structure and pricing for sourcing vulcanized rubber is essential for B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. This analysis will break down key cost components, price influencers, and offer practical tips for negotiating favorable terms.

What Are the Key Cost Components in Rubber Vulcanization?

-

Materiais: The primary materials for vulcanization include natural and synthetic rubber, sulfur, accelerators, and various additives like zinc oxide and anti-oxidants. The choice of materials significantly affects cost; for instance, synthetic rubber, while more resistant to heat, may be more expensive than natural rubber. The prices of these materials fluctuate based on global oil prices and supply chain dynamics.

-

Trabalho: Labor costs vary by region and the level of expertise required for the vulcanization process. Skilled labor may command higher wages, especially in countries with advanced manufacturing capabilities. Additionally, training costs for staff to handle complex machinery can contribute to overall labor expenses.

-

Despesas gerais de fabrico: This includes utilities, maintenance of machinery, and facility costs. Efficient manufacturing processes can help reduce overhead, making it essential for buyers to assess a supplier’s operational efficiency.

-

Ferramentas: The initial investment in molds and machinery for vulcanization can be significant. Custom tooling for unique rubber products can further increase costs, so understanding tooling expenses is vital for buyers considering specialized products.

-

Controlo de qualidade (CQ): Implementing rigorous QC processes ensures product consistency and compliance with international standards. Costs associated with testing and certifications can add to the final price of vulcanized rubber products.

-

Logística: Shipping costs are particularly crucial for international buyers. Factors such as distance, mode of transport, and local regulations can heavily influence logistics expenses. Incoterms also play a significant role in defining responsibilities and costs between buyers and suppliers.

-

Margem: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s reputation, market demand, and the complexity of the product.

What Influences Pricing for Vulcanized Rubber?

Several factors can influence the pricing structure of vulcanized rubber:

-

Volume e quantidade mínima de encomenda (MOQ): Larger orders often lead to reduced per-unit costs. Negotiating MOQs can lead to better pricing, but buyers should balance volume with their demand forecasts.

-

Especificações e personalização: Customized rubber products that meet specific performance criteria will typically incur higher costs. Buyers should be clear about their specifications to avoid unexpected charges.

-

Qualidade dos materiais e certificações: Higher quality materials and relevant certifications (e.g., ISO, ASTM) can increase costs but may be necessary for compliance in certain industries, especially automotive and aerospace.

-

Factores do fornecedor: The reputation and reliability of a supplier can affect pricing. Established suppliers with a track record of quality and timely delivery may charge higher prices, but their reliability can mitigate risks.

-

Incoterms: The terms of sale can significantly impact total costs. Understanding whether costs include shipping, insurance, and tariffs can help buyers make informed decisions.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Bulk Purchasing: If feasible, consolidating orders can lead to better pricing and terms. Discussing long-term contracts can also incentivize suppliers to offer discounts.

-

Analyze Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, maintenance, and logistics. A lower upfront price might lead to higher costs down the line if quality is compromised.

-

Understand Regional Pricing Nuances: Prices for vulcanized rubber can vary by region due to labor costs, material availability, and local economic conditions. Buyers should research and understand these factors to negotiate effectively.

-

Establish Clear Communication: Communicate your needs and concerns clearly with suppliers. Building a strong relationship can lead to better deals and terms.

-

Stay Informed on Market Trends: Keeping abreast of global trends in rubber pricing, material costs, and supply chain issues can provide leverage during negotiations.

Declaração de exoneração de responsabilidade

Prices and cost structures mentioned are indicative and may vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for accurate and up-to-date pricing.

Alternatives Analysis: Comparing how is rubber vulcanized With Other Solutions

Introduction: Exploring Alternatives to Rubber Vulcanization

Rubber vulcanization is a well-established process that enhances the properties of rubber, making it suitable for a variety of demanding applications. However, alternative methods exist that can achieve similar goals, each with its own set of advantages and disadvantages. Understanding these alternatives can empower international B2B buyers to make informed decisions based on performance needs, cost considerations, and application requirements.

Comparison Table: How Does Rubber Vulcanization Stack Up Against Alternatives?

| Aspeto de comparação | How Is Rubber Vulcanized | Alternative 1: Thermoplastic Elastomers (TPE) | Alternative 2: Silicone Rubber |

|---|---|---|---|

| Desempenho | Excellent elasticity and durability; resistant to abrasion and heat. | Good elasticity and flexibility; less durable than vulcanized rubber. | Superior temperature and chemical resistance; less elastic. |

| Custo | Moderate initial investment; long-term savings due to durability. | Generally lower cost; suitable for low-volume applications. | Higher initial cost; cost-effective for specialized applications. |

| Facilidade de implementação | Requires specialized equipment and expertise for vulcanization. | Easier to process; can be molded and reshaped with standard equipment. | Requires specialized equipment for curing; relatively complex. |

| Manutenção | Low maintenance due to durability; long lifecycle. | Moderate maintenance; wear and tear may occur over time. | Low maintenance; excellent longevity under extreme conditions. |

| Melhor caso de utilização | Ideal for tires, hoses, and heavy-duty applications. | Suitable for consumer goods, seals, and gaskets. | Best for high-temperature applications and medical devices. |

Análise pormenorizada das alternativas

Alternative 1: Thermoplastic Elastomers (TPE)

Thermoplastic elastomers provide a blend of rubber-like elasticity and the processing advantages of plastics. They are easier to mold and can be reshaped multiple times, making them ideal for applications requiring flexibility and custom shapes. However, TPEs typically do not match the durability and heat resistance of vulcanized rubber, which may limit their use in high-stress environments. B2B buyers in sectors like consumer goods may find TPEs a cost-effective solution for lower-volume production needs.

Alternative 2: Silicone Rubber

Silicone rubber is renowned for its exceptional temperature stability and resistance to chemicals, making it ideal for applications that endure extreme conditions. While silicone offers low maintenance and long-lasting performance, its initial cost is generally higher than that of vulcanized rubber. Silicone’s mechanical properties, particularly its lower elasticity compared to traditional rubber, may limit its use in applications where flexibility is critical. Businesses in the medical or food processing industries often prefer silicone due to its biocompatibility and resilience.

Conclusion: Making the Right Choice for Your Business Needs

When evaluating rubber vulcanization against alternative solutions, B2B buyers should consider their specific application requirements, budget constraints, and the operational environment. Vulcanization remains a superior choice for high-performance applications requiring durability and elasticity, such as tires and industrial hoses. However, alternatives like TPEs and silicone rubber can offer viable solutions for specialized applications where cost and flexibility are more critical. By carefully assessing these factors, businesses can select the most appropriate material and processing method to meet their needs effectively.

Essential Technical Properties and Trade Terminology for how is rubber vulcanized

Quais são as principais propriedades técnicas da borracha vulcanizada?

Vulcanized rubber exhibits a range of essential technical properties that enhance its performance and usability in various industrial applications. Understanding these specifications is crucial for B2B buyers when selecting materials for manufacturing processes.

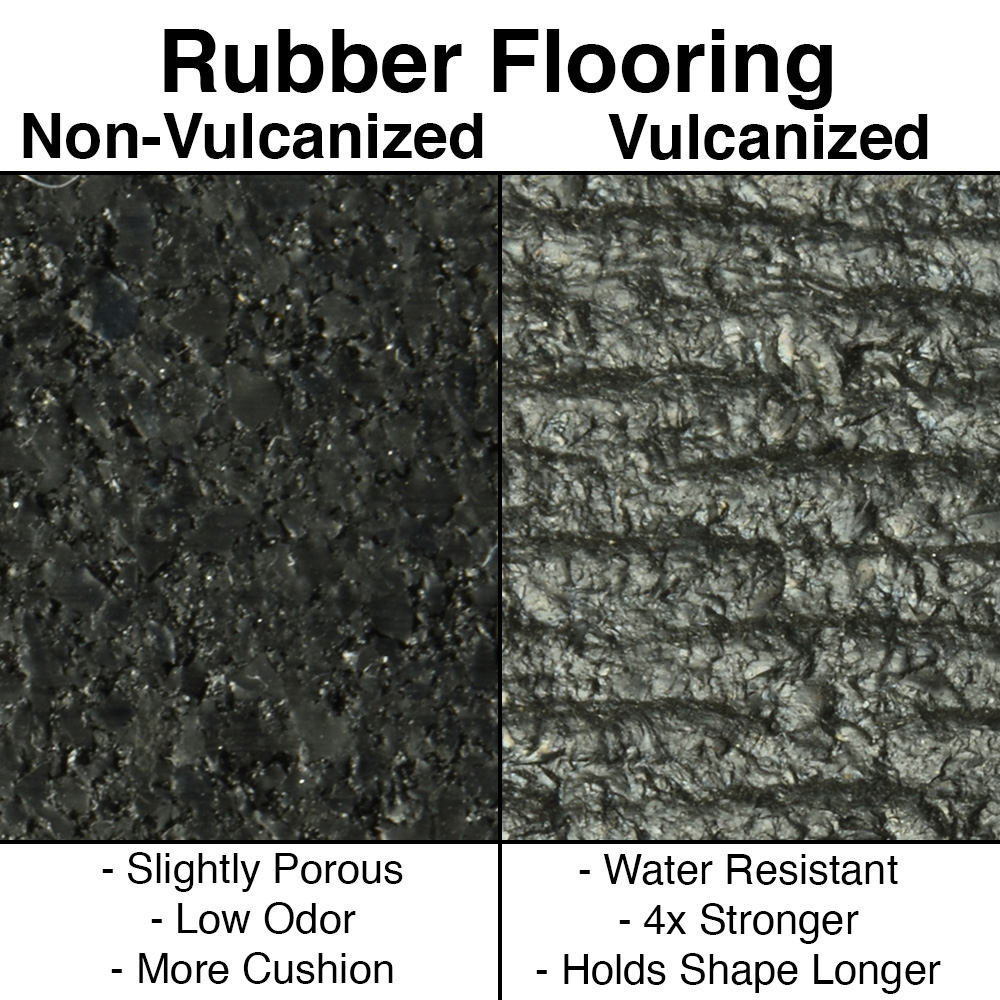

1. Tensile Strength

Tensile strength refers to the maximum stress that a material can withstand while being stretched or pulled before failing. For vulcanized rubber, this property is vital as it ensures durability under mechanical loads. High tensile strength is particularly important for applications such as automotive tires, where resistance to wear and tear is critical.

2. Elasticity

Elasticity is the ability of rubber to return to its original shape after being deformed. This property is crucial for applications requiring repeated flexing or stretching, such as rubber seals and gaskets. In a B2B context, high elasticity translates to longer product life and reduced replacement costs, making it an attractive feature for manufacturers.

3. Resistência à abrasão

Abrasion resistance measures how well a material can withstand surface wear from friction and contact with other materials. Vulcanized rubber is often used in environments where it is exposed to harsh conditions, such as conveyor belts and tire tread. Businesses should prioritize this property to ensure longevity and reliability in their products.

Illustrative image related to how is rubber vulcanized

4. Heat Resistance

Heat resistance indicates a material’s ability to maintain its properties at elevated temperatures. Vulcanized rubber typically exhibits improved heat resistance compared to unvulcanized rubber, which is essential in applications like automotive components that are exposed to high temperatures. For B2B buyers, selecting heat-resistant materials can prevent premature failure and improve safety.

5. Resistência química

This property pertains to a material’s ability to resist degradation when exposed to various chemicals, including oils and solvents. Vulcanized rubber’s chemical resistance makes it suitable for use in environments where it may encounter aggressive substances, such as in industrial machinery. Understanding this property helps businesses mitigate risks associated with chemical exposure.

Which Trade Terms Are Important in the Vulcanization Process?

Navigating the terminology associated with rubber vulcanization can enhance communication and negotiations between B2B buyers and suppliers. Familiarity with these terms is essential for informed decision-making.

Illustrative image related to how is rubber vulcanized

1. OEM (Fabricante de Equipamento Original)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. Understanding OEM relationships is important for buyers seeking specific rubber components that meet their quality standards and specifications.

2. MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest amount of product a supplier is willing to sell. This term is critical for B2B buyers to understand, as it affects inventory management and cash flow. Knowing the MOQ helps companies plan their purchasing strategies effectively.

3. RFQ (Pedido de Cotação)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers use RFQs to compare costs, ensuring they receive competitive pricing for vulcanized rubber materials. This process is essential for budgeting and financial planning.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B transactions to avoid misunderstandings and ensure smooth logistics in the supply chain.

5. Curing

Curing refers to the chemical process of hardening rubber through vulcanization. Understanding the curing process is vital for buyers, as it affects the final properties of the rubber, including strength, elasticity, and durability. This knowledge helps in selecting the right vulcanization method for specific applications.

6. Cross-linking

Cross-linking is a chemical reaction that bonds polymer chains together, enhancing the structural integrity of vulcanized rubber. This term is essential for buyers to understand, as it directly relates to the performance characteristics of the rubber products they are sourcing.

By familiarizing themselves with these properties and terms, B2B buyers can make more informed decisions when sourcing vulcanized rubber, ultimately leading to better product outcomes and business success.

Navigating Market Dynamics and Sourcing Trends in the how is rubber vulcanized Sector

What Are the Key Market Trends Influencing Rubber Vulcanization?

The global rubber vulcanization market is experiencing significant growth, driven by increasing demand for durable and high-performance rubber products across various sectors. Key market drivers include the automotive industry’s continuous expansion, particularly in regions such as Africa, South America, the Middle East, and Europe, where demand for tires and automotive components is surging. Additionally, the rise of electric vehicles is creating new opportunities for rubber manufacturers as they adapt their products to meet the unique requirements of this evolving market.

Emerging technologies in rubber processing, such as advanced mixing and curing techniques, are enhancing the efficiency of vulcanization processes. The integration of automation and IoT in manufacturing is also gaining traction, allowing for real-time monitoring of production quality and improving operational efficiency. B2B buyers should pay close attention to suppliers that leverage these technologies, as they can offer superior product quality and cost-effectiveness.

Sourcing trends are shifting towards strategic partnerships and collaborations between suppliers and manufacturers. This approach helps streamline supply chains and enhances the ability to respond to market fluctuations rapidly. In regions like Saudi Arabia and Brazil, where natural rubber supply can be impacted by environmental factors, establishing reliable partnerships can mitigate risks and ensure consistent product availability.

How Can Sustainability and Ethical Sourcing Impact the Rubber Vulcanization Sector?

Sustainability is becoming a critical consideration for B2B buyers in the rubber vulcanization sector. The environmental impact of rubber production, including deforestation and biodiversity loss, has prompted a shift towards sustainable sourcing practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmental stewardship, which includes using responsibly harvested natural rubber and recycled materials.

Ethical supply chains not only enhance a company’s brand reputation but also align with the growing consumer demand for environmentally friendly products. Certifications such as the Forest Stewardship Council (FSC) and the Global Organic Textile Standard (GOTS) are becoming essential for suppliers aiming to attract conscientious buyers. These certifications ensure that rubber is sourced from sustainable practices that minimize environmental harm.

Furthermore, innovations in ‘green’ vulcanization processes are emerging, such as the use of alternative curing agents that reduce the reliance on sulfur and harmful chemicals. These eco-friendly approaches not only lessen the environmental footprint but can also improve the mechanical properties of vulcanized rubber, making it more appealing to businesses focused on sustainability.

What Is the Historical Context of Rubber Vulcanization and Its Relevance Today?

The history of rubber vulcanization dates back to the 19th century when Charles Goodyear discovered the process that would revolutionize the rubber industry. His accidental formulation combined rubber with sulfur, leading to the creation of a durable and elastic material that could withstand varying temperatures and stresses. This breakthrough laid the foundation for modern rubber manufacturing, allowing for the production of high-quality products used in numerous applications, from automotive tires to industrial components.

Understanding the evolution of vulcanization is crucial for B2B buyers today, as it highlights the continuous advancements in rubber technology. The modern vulcanization process has evolved significantly, incorporating innovative additives and accelerators that enhance the efficiency and effectiveness of production. This historical context underscores the importance of sourcing from suppliers that not only understand traditional methods but also embrace cutting-edge technologies to meet the demands of today’s dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of how is rubber vulcanized

-

How is rubber vulcanized and why is it important for my business?

Rubber vulcanization is a chemical process that enhances the properties of rubber, making it stronger, more elastic, and resistant to heat, aging, and abrasion. By adding sulfur and applying heat, the rubber undergoes cross-linking, which creates a robust molecular network. This process is crucial for businesses requiring high-performance materials, such as tire manufacturing or industrial applications. Understanding vulcanization helps you select the right rubber products for durability and performance, ensuring your products meet industry standards. -

What are the main types of rubber used in vulcanization?

The primary types of rubber utilized in vulcanization are natural rubber, derived from the latex of rubber trees, and synthetic rubber, produced from petroleum by-products. Natural rubber offers superior elasticity and strength, while synthetic rubber is more resistant to environmental factors like heat and chemicals. Choosing the right type depends on your specific application and performance requirements. Many industries, including automotive and manufacturing, often favor synthetic rubber for its versatility and durability. -

What should I consider when sourcing vulcanized rubber suppliers internationally?

When sourcing vulcanized rubber suppliers, consider their experience, production capacity, and quality certifications (like ISO). Evaluate their ability to meet your specific requirements, such as material type, customization options, and minimum order quantities (MOQs). It’s also important to assess their logistics capabilities and lead times to ensure timely delivery. Building a strong relationship with your supplier can facilitate better communication and understanding of your needs, leading to more favorable terms and conditions. -

How can I ensure the quality of vulcanized rubber products?

To ensure the quality of vulcanized rubber products, look for suppliers that implement stringent quality assurance (QA) protocols. Request product samples and certifications to verify their compliance with industry standards. Regular audits of the manufacturing process and materials used can also help maintain quality. Additionally, inquire about their testing methods, such as tensile strength and abrasion resistance, to confirm that the products will meet your performance expectations. -

Que opções de personalização estão disponíveis para os produtos de borracha vulcanizada?

Many suppliers offer customization options for vulcanized rubber products, including variations in compound formulations, colors, and shapes to meet specific application needs. You can also request modifications in physical properties like hardness or elasticity. Discussing your requirements with potential suppliers early in the sourcing process can help you identify the best customization options. Be prepared to share detailed specifications to ensure that the final product aligns with your expectations. -

What are typical payment terms when importing vulcanized rubber?

Payment terms can vary widely depending on the supplier and the region. Common practices include upfront deposits, letters of credit, or payment upon delivery. Establishing clear payment terms upfront is crucial to avoid misunderstandings. Consider negotiating terms that align with your cash flow needs, such as staggered payments tied to production milestones. Understanding local payment norms can also facilitate smoother transactions and strengthen supplier relationships. -

Qual é a quantidade mínima de encomenda (MOQ) para produtos de borracha vulcanizada?

Minimum order quantities (MOQs) for vulcanized rubber products can vary significantly between suppliers and depend on factors like production capacity and material costs. Typically, MOQs may range from a few hundred to several thousand units. Discussing your specific needs with potential suppliers can help you find a partner willing to accommodate smaller orders, especially if you are a new business or testing new product lines. Keep in mind that larger orders often result in better pricing. -

How can logistics impact my sourcing of vulcanized rubber?

Logistics play a critical role in the sourcing of vulcanized rubber, affecting lead times, shipping costs, and overall supply chain efficiency. Evaluate potential suppliers’ logistics capabilities, including their experience with international shipping and customs clearance processes. Understanding their shipping methods and timelines can help you plan your inventory needs effectively. Collaborating closely with your logistics provider can also minimize delays and ensure that you receive your products on time, maintaining your production schedules.

Top 2 How Is Rubber Vulcanized Manufacturers & Suppliers List

1. Walker Rubber – Custom Rubber Extrusions

Domínio: walker-rubber.co.uk

Registada: 1999 (26 anos)

Introdução: Extrusões de borracha, Extrusões de borracha personalizadas, Extrusão de ângulos, Vedantes de borracha para janelas de barcos, Garras de tijolo, Pneus de cabina, Proteção de cabos de borracha, Extrusões coloridas, Extrusão de vedação de porta de contentor, Rodapé lateral de transportador, Vedantes de borracha para portas, Extrusões EPDM, Vedantes de expansão de borracha, Extrusões de vedação de fachada de borracha, Extrusões retardadoras de chama, Extrusões de qualidade alimentar, Vedantes de borracha para portões, Vedantes de borracha para vidros, H Pr...

2. WARE – Boiler Rentals & Services

Domínio: wareinc.com

Registada: 2000 (25 anos)

Introdução: WARE is an industrial & commercial boiler rental and service company specializing in sales, service, valve repair, rentals, parts, turnkey solutions, and boiler training. Key offerings include:

– Boiler Rentals: A wide range of rental boilers for various applications and industries.

– Boiler Sales: New, used, and remanufactured boiler equipment with over 70 years of experience.

– Aux Equipment: In…

Strategic Sourcing Conclusion and Outlook for how is rubber vulcanized

What Are the Key Takeaways from the Rubber Vulcanization Process?

Understanding the rubber vulcanization process is crucial for international B2B buyers looking to enhance product durability and performance. Vulcanization transforms raw rubber into a robust material that offers superior elasticity, tear strength, and resistance to various environmental factors. This process is essential for industries that rely on high-quality rubber products, such as automotive, construction, and manufacturing.

Illustrative image related to how is rubber vulcanized

How Does Strategic Sourcing Play a Role in Rubber Procurement?

Effective strategic sourcing allows businesses to identify reliable suppliers of vulcanized rubber, ensuring consistent quality and cost-effectiveness. By leveraging global supply chains, buyers from Africa, South America, the Middle East, and Europe can access advanced vulcanization technologies and materials that meet their specific needs. Engaging with manufacturers who utilize modern techniques and additives will help mitigate risks associated with product failure and enhance overall performance.

What’s Next for B2B Buyers in the Rubber Industry?

As the demand for high-performance rubber products continues to grow, now is the time to evaluate your sourcing strategies. Explore partnerships with reputable suppliers who prioritize innovation in the vulcanization process. By investing in quality materials, businesses can position themselves for success in competitive markets. Take action today to secure a sustainable and resilient rubber supply chain that meets the evolving needs of your industry.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, pedir amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.