Introduction: Navigating the Global Market for offshore marine hose

Navigating the complexities of sourcing offshore marine hoses can pose significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These critical components play an essential role in the oil and gas industry, facilitating the safe and efficient transfer of fluids under demanding conditions. As the global market evolves, understanding the various types of offshore marine hoses, their applications, and the specific requirements for each scenario becomes paramount for procurement professionals seeking reliable solutions.

This comprehensive guide delves into the intricacies of offshore marine hoses, covering essential topics such as the different types available, their applications in loading and unloading operations, and key factors to consider when vetting suppliers. It also addresses cost implications, maintenance considerations, and the latest technological advancements in the field. By providing actionable insights and practical recommendations, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and safety standards.

As the demand for efficient fluid transfer continues to grow, particularly in dynamic offshore environments, understanding the nuances of offshore marine hoses is crucial for enhancing operational efficiency and minimizing risks. Equip yourself with the knowledge to navigate this global market effectively, ensuring your business remains competitive and compliant in an ever-changing landscape.

Índice

- Top 8 Offshore Marine Hose Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for offshore marine hose

- Understanding offshore marine hose Types and Variations

- Key Industrial Applications of offshore marine hose

- 3 Common User Pain Points for ‘offshore marine hose’ & Their Solutions

- Strategic Material Selection Guide for offshore marine hose

- In-depth Look: Manufacturing Processes and Quality Assurance for offshore marine hose

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore marine hose’

- Comprehensive Cost and Pricing Analysis for offshore marine hose Sourcing

- Alternatives Analysis: Comparing offshore marine hose With Other Solutions

- Essential Technical Properties and Trade Terminology for offshore marine hose

- Navigating Market Dynamics and Sourcing Trends in the offshore marine hose Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of offshore marine hose

- Strategic Sourcing Conclusion and Outlook for offshore marine hose

- Aviso importante e termos de utilização

Understanding offshore marine hose Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Floating Hose | Designed to float on water; high buoyancy; flexible | Offshore loading/unloading, fluid transfer | Prós: Reduces risk of damage, adaptable to movements. Contras: Higher initial cost compared to rigid hoses. |

| Submarine Hose | Reinforced for deep-sea applications; pressure-resistant | Deep-water oil and gas transfer | Prós: Durable under high pressure, suitable for extreme depths. Contras: Limited flexibility in installation. |

| Drilling Hose | Enhanced abrasion resistance; designed for high-pressure fluids | Offshore drilling operations | Prós: Durable against corrosive materials, reliable performance. Contras: Requires careful handling to avoid kinks. |

| Composite Hose | Made from multiple layers; lightweight and flexible | Chemical transport, LNG transfer | Prós: Lightweight, excellent chemical resistance. Contras: May have a shorter lifespan under harsh conditions. |

| Rigid Hose | Fixed diameter; less flexible; typically metal or PVC | Fixed piping systems in offshore platforms | Prós: Strong structural integrity, suitable for permanent installations. Contras: Difficult to install in dynamic environments. |

What Are the Key Characteristics of Floating Hoses?

Floating hoses are engineered to remain buoyant on the water’s surface, making them essential for offshore loading and unloading operations. Their high buoyancy and flexibility allow for seamless fluid transfer, accommodating the dynamic movements of vessels and platforms. Buyers should consider the initial investment, as floating hoses can be more expensive than traditional rigid hoses. However, their ability to reduce damage risk and enhance safety during operations makes them a valuable asset in offshore applications.

How Do Submarine Hoses Differ From Other Offshore Marine Hoses?

Submarine hoses are specifically reinforced to withstand the high pressures and harsh conditions found in deep-sea environments. These hoses are ideal for transferring oil and gas at significant depths, where durability and resistance to external pressures are critical. For B2B buyers, the strength and reliability of submarine hoses are paramount, but they come with the trade-off of reduced flexibility during installation. Understanding the operational environment is crucial for selecting the right type of hose.

Why Are Drilling Hoses Vital for Offshore Operations?

Drilling hoses are designed to handle high-pressure fluids used in drilling operations, making them indispensable for offshore drilling rigs. Their enhanced abrasion resistance ensures longevity, even when transporting corrosive materials. Buyers should focus on the hose’s ability to withstand harsh environments and the importance of proper handling to prevent kinks or twists. Investing in quality drilling hoses can significantly impact operational efficiency and safety.

What Benefits Do Composite Hoses Offer for Chemical Transport?

Composite hoses are constructed from multiple layers, providing lightweight flexibility while maintaining excellent chemical resistance. This makes them particularly suitable for transporting chemicals and liquefied natural gas (LNG). For B2B buyers, the primary consideration should be the hose’s compatibility with specific chemicals and the expected lifespan in varying conditions. While they offer many advantages, including ease of handling, buyers must weigh these against the potential for shorter lifespans in extreme environments.

When Should Rigid Hoses Be Considered for Offshore Applications?

Rigid hoses, often made from metal or PVC, are ideal for fixed piping systems in offshore platforms. Their strong structural integrity allows for permanent installations, making them suitable for environments where flexibility is not a priority. B2B buyers should assess their operational needs carefully, as rigid hoses can be challenging to install in dynamic environments. While they provide durability, the lack of flexibility may limit their application in certain offshore scenarios.

Key Industrial Applications of offshore marine hose

| Indústria/Setor | Specific Application of offshore marine hose | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Oil and Gas | Fluid transfer between offshore platforms and storage vessels | Ensures safe, efficient transportation of crude oil and gas | Compliance with international safety standards; durability under harsh conditions |

| Processamento químico | Transport of chemicals between vessels and platforms | Reduces risk of spills and contamination | Chemical compatibility; flexibility to accommodate dynamic movements |

| Offshore Drilling | Movement of drilling fluids from rigs to wellbores | Enhances drilling efficiency and safety | Resistance to abrasion and corrosion; proper bending radius |

| Emergency Response | Containment and diversion of spills during incidents | Minimizes environmental impact and protects assets | Quick deployment features; robust construction for reliability |

| LNG Transportation | Loading and unloading of liquefied natural gas | Facilitates safe transfer operations and reduces downtime | High buoyancy rating; flexibility to adapt to vessel movements |

How is Offshore Marine Hose Used in the Oil and Gas Sector?

In the oil and gas industry, offshore marine hoses are crucial for transferring fluids between production platforms and storage vessels. They handle crude oil and natural gas under high pressure, ensuring a safe and efficient operation. For international buyers, it is essential to source hoses that meet stringent safety regulations and can withstand harsh marine environments. Durability, flexibility, and compliance with international standards are critical factors in selecting the right marine hose.

What Role Do Offshore Marine Hoses Play in Chemical Processing?

In chemical processing, offshore marine hoses facilitate the safe transportation of various chemicals between vessels and offshore platforms. This application is vital for preventing spills and ensuring environmental safety. Buyers must consider the chemical compatibility of the hoses, as well as their ability to maintain flexibility under dynamic conditions. The right marine hose solution can significantly reduce operational risks and enhance overall efficiency in chemical transfer operations.

How Are Offshore Marine Hoses Utilized in Offshore Drilling Operations?

Offshore marine hoses are essential in drilling operations, where they transport drilling fluids from rigs to wellbores. These hoses must be resistant to abrasion and corrosion due to the harsh nature of drilling fluids. Buyers in this sector should prioritize hoses that offer a proper bending radius and can withstand the dynamic movements associated with offshore drilling. Selecting the right marine hose can lead to improved drilling efficiency and enhanced safety measures.

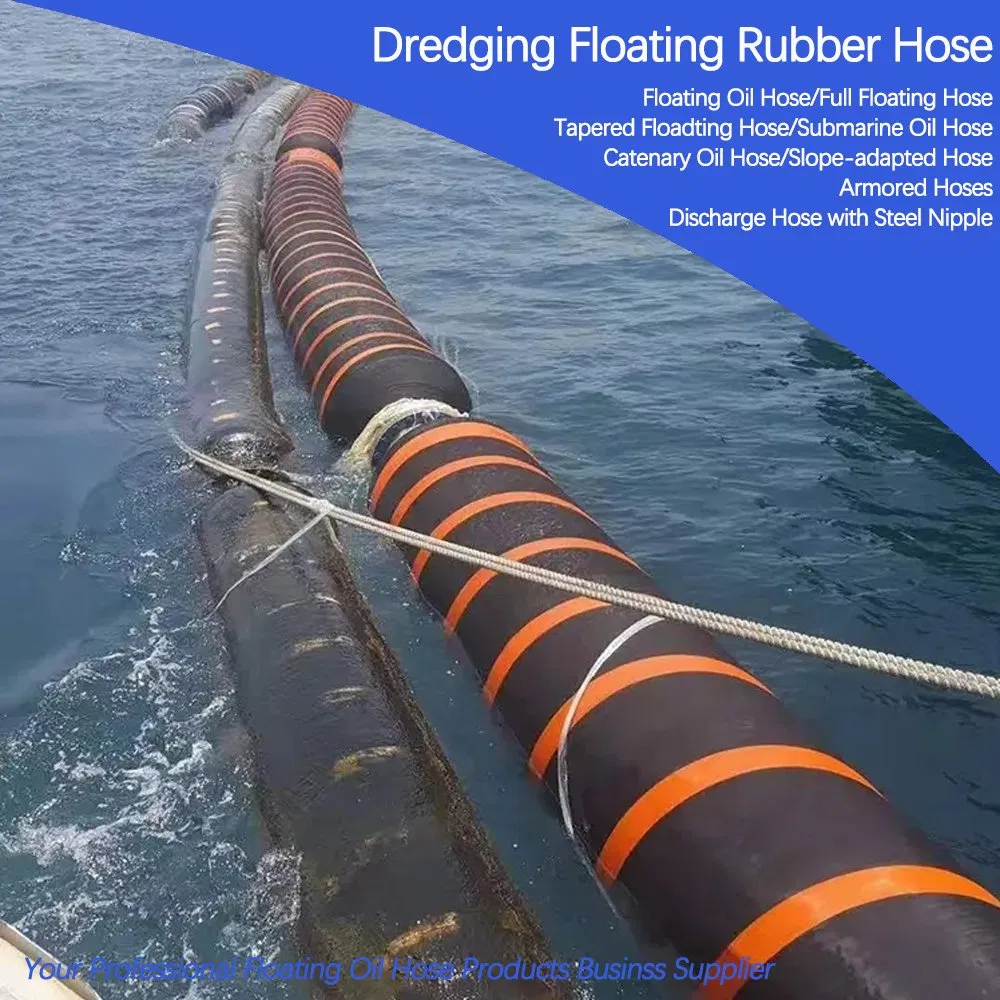

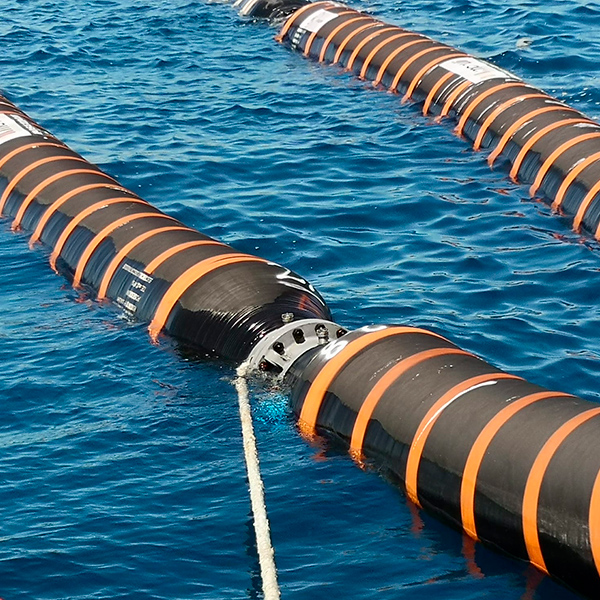

Illustrative image related to offshore marine hose

Why Are Offshore Marine Hoses Important for Emergency Response?

In emergency response scenarios, offshore marine hoses are employed to contain and divert spilled liquids, helping to minimize environmental damage. Their quick deployment features and robust construction make them reliable tools in crisis situations. For businesses, sourcing hoses that can withstand extreme conditions and offer ease of use during emergencies is crucial. Investing in high-quality marine hoses can protect assets and uphold a company’s reputation for environmental responsibility.

How Do Offshore Marine Hoses Support LNG Transportation?

Offshore marine hoses are pivotal in loading and unloading liquefied natural gas (LNG), ensuring safe and efficient transfer operations. This application is critical for reducing downtime and enhancing supply chain efficiency. When sourcing hoses for LNG applications, buyers should focus on those with high buoyancy ratings and the flexibility needed to adapt to the movements of vessels. Effective LNG transfer solutions can significantly impact operational performance and safety in the marine industry.

3 Common User Pain Points for ‘offshore marine hose’ & Their Solutions

Scenario 1: Navigating Harsh Environmental Conditions

O problema: Offshore marine hose users frequently face the challenge of operating in extreme environmental conditions. High pressure, corrosive seawater, and dynamic movements from waves can lead to hose failure or compromised integrity. This can result in hazardous spills, costly downtime, and potential damage to equipment and the environment. B2B buyers need to ensure that the hoses they procure are designed to withstand these conditions, which is often a complex task involving various specifications.

Illustrative image related to offshore marine hose

A solução: To effectively address these challenges, buyers should prioritize sourcing hoses that are specifically engineered for high-performance in harsh offshore environments. Look for hoses constructed with advanced materials like high-grade rubber or composite materials that can resist abrasion and corrosion. Verify that the hoses meet or exceed industry standards for pressure ratings and flexibility, particularly in terms of Minimum Bending Radius (MBR) to prevent kinking. Consulting with manufacturers or suppliers who specialize in offshore marine hoses can provide insights into the best products suited for your specific operational conditions. Implementing a rigorous quality control process during installation and maintenance can also help ensure the longevity and reliability of the hoses.

Scenario 2: Reducing Downtime During Loading and Unloading Operations

O problema: B2B buyers in the oil and gas sector often encounter significant downtime during loading and unloading operations due to inefficient or failing marine hoses. Delays in fluid transfer can disrupt supply chains, leading to financial losses and missed deadlines. Furthermore, improper installation or the wrong type of hose can exacerbate these issues, creating a need for constant monitoring and replacement.

A solução: To mitigate downtime, it is essential to conduct a thorough assessment of your operational needs before selecting marine hoses. Choose hoses that are specifically designed for the types of fluids being transferred and the specific loading and unloading equipment in use. Employing flexible hoses with high buoyancy can enhance fluid transfer efficiency while accommodating the movements of vessels. Additionally, invest in training for your operational staff on proper hose handling, installation, and maintenance practices. Regular inspections and proactive maintenance schedules can catch wear and tear before they lead to failures, ensuring seamless operations.

Illustrative image related to offshore marine hose

Scenario 3: Ensuring Compliance and Safety in Emergency Scenarios

O problema: Compliance with safety regulations and environmental standards is a major concern for B2B buyers in the offshore marine sector. In emergencies, such as spills or leaks, the failure of hoses can lead to severe environmental damage and hefty penalties. Buyers are often anxious about selecting hoses that not only meet operational requirements but also adhere to safety standards mandated by regulatory bodies.

A solução: To ensure compliance and safety, buyers must prioritize selecting hoses that are certified by recognized industry standards, such as API or ISO certifications. These certifications guarantee that the hoses have undergone rigorous testing for safety and performance. Buyers should also engage with suppliers who can provide detailed documentation of compliance and safety features of their products. Implementing a robust emergency response plan that includes the use of marine hoses specifically designed for containment and diversion during spills can further enhance safety. Regular training sessions on emergency procedures and hose management for employees can prepare teams to respond effectively in crisis situations.

Strategic Material Selection Guide for offshore marine hose

What Are the Key Materials Used in Offshore Marine Hoses?

When selecting offshore marine hoses, understanding the materials used is crucial for ensuring optimal performance and compliance with industry standards. Here, we analyze four common materials: rubber, thermoplastic, composite, and metal. Each material has distinct properties, advantages, and limitations that can significantly impact application suitability.

How Does Rubber Perform in Offshore Marine Hoses?

Rubber is a traditional choice for offshore marine hoses due to its excellent flexibility and resilience. It typically offers a good temperature rating, capable of withstanding pressures up to 20 bar. Rubber hoses exhibit strong corrosion resistance against a variety of fluids, including crude oil and chemicals.

Prós: The primary advantage of rubber is its durability and flexibility, allowing it to handle dynamic movements without compromising structural integrity. It is also relatively cost-effective, making it a popular choice for many applications.

Illustrative image related to offshore marine hose

Contras: However, rubber can degrade under UV exposure and may not be suitable for extreme temperature variations. Its manufacturing process can be complex, and sourcing high-quality rubber that meets international standards can be challenging.

For international buyers, especially in regions like Africa and South America, compliance with standards such as ASTM or DIN is crucial. Buyers should ensure that the rubber used meets these specifications to avoid operational failures.

What Are the Benefits of Thermoplastic Materials in Marine Hoses?

Thermoplastic materials, particularly thermoplastic elastomers (TPE), are gaining traction in offshore applications. They offer excellent chemical resistance and can handle temperatures ranging from -40°C to +80°C, making them suitable for a wide range of fluids.

Prós: TPEs are lightweight and flexible, which eases installation and reduces shipping costs. They also exhibit good abrasion resistance and can be manufactured in various colors for easy identification.

Contras: On the downside, thermoplastics may have lower pressure ratings compared to rubber, which could limit their use in high-pressure applications. Their cost can also be higher than traditional rubber options.

Illustrative image related to offshore marine hose

International buyers should consider the local availability of thermoplastic materials and ensure they comply with relevant standards like JIS in Japan or EN in Europe. This is particularly important for projects in the Middle East and Europe, where regulatory compliance is stringent.

Why Choose Composite Materials for Offshore Marine Hoses?

Composite materials are increasingly utilized in offshore marine hoses due to their superior strength-to-weight ratio. They can withstand extreme pressures and temperatures while offering excellent corrosion resistance.

Prós: The key advantage of composites is their durability, which significantly reduces maintenance costs over time. They are also resistant to a wide range of chemicals, making them suitable for various applications, including LNG transfer.

Contras: However, composite hoses can be more expensive to manufacture, which may deter some buyers. Additionally, their complex manufacturing process may lead to longer lead times.

Illustrative image related to offshore marine hose

For B2B buyers from regions like Europe and the Middle East, understanding the specific composite formulations and ensuring they meet industry standards is critical. This ensures that the hoses can perform reliably in harsh offshore environments.

What Role Do Metal Hoses Play in Offshore Applications?

Metal hoses are often used in applications requiring high pressure and temperature resistance. They are typically constructed from stainless steel or other alloys, providing excellent durability and resistance to corrosion.

Prós: The primary advantage of metal hoses is their ability to handle extreme conditions, making them ideal for high-pressure applications. They also provide excellent leak-proof performance, which is vital in offshore operations.

Illustrative image related to offshore marine hose

Contras: The downside is that metal hoses can be heavy and less flexible than rubber or thermoplastic options. This can complicate installation and increase shipping costs.

International buyers should ensure that metal hoses comply with industry standards such as ASME or API, particularly in regions like Germany, where regulations are strict. Understanding the specific alloy compositions is also essential for ensuring compatibility with the fluids being transported.

Summary Table of Material Selection for Offshore Marine Hoses

| Material | Typical Use Case for offshore marine hose | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha | General fluid transfer in offshore ops | High flexibility and durability | UV degradation and temperature sensitivity | Médio |

| Termoplástico | Chemical transfer and low-pressure applications | Lightweight and good chemical resistance | Lower pressure ratings compared to rubber | Elevado |

| Compósito | LNG and high-pressure fluid transfer | Excellent strength-to-weight ratio | Higher manufacturing costs | Elevado |

| Metal | Aplicações de alta pressão e alta temperatura | Leak-proof and durable | Heavy and less flexible | Médio |

This strategic material selection guide provides valuable insights for international B2B buyers, allowing them to make informed decisions based on application requirements, cost considerations, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for offshore marine hose

What Are the Main Stages in the Manufacturing Process of Offshore Marine Hoses?

The manufacturing process of offshore marine hoses is intricate, designed to ensure the highest quality and reliability under extreme conditions. The process typically encompasses several key stages: material preparation, forming, assembly, and finishing.

Preparação do material

The first step involves sourcing and preparing the raw materials. Offshore marine hoses are typically constructed from high-quality rubber compounds, reinforced with layers of synthetic fibers and steel wire for added strength. Manufacturers often use advanced elastomer materials that can withstand harsh environmental conditions, including UV exposure, corrosive chemicals, and extreme temperatures. Properly assessing and selecting materials based on their mechanical properties and resistance to environmental factors is crucial. This stage also includes rigorous quality checks to ensure that all materials meet international standards.

How Are Offshore Marine Hoses Formed?

Once materials are prepared, the next stage is forming. This process often employs techniques such as extrusion and molding. Extrusion allows for the continuous production of hose lengths, ensuring uniformity in diameter and wall thickness. Molding is typically used for creating specialized components or fittings that will be attached to the hoses. During this stage, manufacturers pay close attention to the hose’s Minimum Bending Radius (MBR) to ensure flexibility without compromising structural integrity.

What Does the Assembly Stage Involve?

Following the forming process, assembly begins. This involves integrating the various components of the hose, including the inner lining, reinforcement layers, and outer cover. Advanced techniques such as vulcanization are employed to bond the layers together, enhancing the hose’s durability and performance. The assembly process may also involve installing additional features like buoyancy modules for floating hoses, which are critical for offshore applications.

What Finishing Techniques Are Used in Offshore Marine Hoses?

The final stage of manufacturing is finishing, which includes trimming, surface treatment, and quality checks. Hoses are often subjected to surface treatments that enhance their resistance to abrasion and environmental damage. Final inspections are conducted to ensure that each hose meets specific performance criteria and is free from defects. This stage also includes marking hoses with relevant certifications and specifications, making it easier for B2B buyers to verify compliance with industry standards.

What Quality Assurance Standards Are Relevant for Offshore Marine Hoses?

Quality assurance is paramount in the production of offshore marine hoses. Various international and industry-specific standards guide manufacturers in establishing quality control measures.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized international quality standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer maintains consistent quality in their products and services. Additionally, industry-specific standards such as the American Petroleum Institute (API) specifications and the Conformité Européenne (CE) marking are critical for ensuring that offshore marine hoses meet the rigorous safety and performance requirements of the oil and gas sector.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) in offshore marine hose manufacturing typically involves several checkpoints, including:

- Controlo de qualidade de entrada (IQC): This initial inspection assesses raw materials upon arrival to ensure they meet specified standards.

- Controlo de qualidade durante o processo (IPQC): Conducted during various manufacturing stages, IPQC checks ensure that processes are being followed correctly and that any deviations are addressed promptly.

- Controlo de qualidade final (FQC): This thorough inspection occurs before the product is shipped, confirming that the finished hoses meet all regulatory and performance standards.

How Are Offshore Marine Hoses Tested for Quality Assurance?

Quality assurance testing is vital to ensuring the reliability and safety of offshore marine hoses. Common testing methods include:

Illustrative image related to offshore marine hose

- Hydrostatic Testing: This test evaluates the hose’s ability to withstand high-pressure conditions by filling it with water and monitoring for leaks.

- Bend Testing: To assess flexibility and the Minimum Bending Radius (MBR), hoses are bent at specific angles to ensure they do not kink or fail.

- Ensaio de abrasão: This method simulates wear and tear to evaluate the hose’s durability against physical damage.

- Environmental Resistance Testing: Hoses are exposed to various environmental conditions (UV light, saltwater, chemicals) to ensure they can withstand offshore environments.

Como podem os compradores B2B verificar o controlo de qualidade dos fornecedores?

When sourcing offshore marine hoses, B2B buyers should take proactive steps to verify the quality control measures of their suppliers. This can be accomplished through:

- Auditorias a fornecedores: Conducting on-site audits helps buyers assess the manufacturing processes, quality control measures, and adherence to standards.

- Pedido de relatórios de qualidade: Suppliers should provide detailed quality reports that outline testing methods, results, and compliance with international standards.

- Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes and product reliability.

What Are the Nuances of Quality Control and Certification for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality control and certification. Different countries may have varying regulations and standards for marine hoses. It is essential for buyers to understand the local compliance requirements and ensure that their suppliers can meet these regulations.

Additionally, considering the logistics of international shipping, buyers should confirm that the hoses are adequately packaged and labeled to prevent damage during transit. Collaborating with suppliers who have experience in international trade can also facilitate smoother transactions and compliance with import regulations.

In summary, the manufacturing processes and quality assurance measures for offshore marine hoses are critical to ensuring safety and reliability in challenging environments. By understanding these processes and verifying supplier quality controls, B2B buyers can make informed decisions that enhance their operational efficiency and protect their investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore marine hose’

In the competitive landscape of offshore operations, sourcing high-quality marine hoses is crucial for ensuring safe and efficient fluid transfer. This guide provides a practical checklist for B2B buyers aiming to procure offshore marine hoses. By following these steps, buyers can make informed decisions that align with their operational needs and compliance standards.

Illustrative image related to offshore marine hose

Passo 1: Definir as suas especificações técnicas

Before initiating the procurement process, it’s essential to have a clear understanding of your technical requirements. Consider factors such as the type of fluid being transported (e.g., crude oil, natural gas, chemicals), the operating pressure, and the environmental conditions (e.g., temperature, salinity) where the hoses will be used.

– Key Specifications to Include:

– Minimum Bending Radius (MBR) to prevent kinking.

– Maximum Rated Buoyancy (MRB) to ensure safe flotation during operations.

Passo 2: Pesquisa de potenciais fornecedores

Invest time in identifying reputable suppliers with a proven track record in the offshore marine hose market. Look for companies that specialize in marine hoses and have experience with your specific application needs.

– What to Look For:

– Supplier’s history and years in operation.

– Client testimonials and case studies relevant to your industry.

Passo 3: Avaliar as certificações dos fornecedores

It is critical to verify that potential suppliers hold the necessary certifications and comply with international quality standards. Certifications such as ISO 9001 indicate a commitment to quality management, while industry-specific certifications ensure adherence to safety and performance standards.

– Important Certifications to Check:

– API (American Petroleum Institute) certifications for oil and gas applications.

– CE marking for compliance with European safety standards.

Passo 4: Request Samples for Testing

Before finalizing your order, request samples of the marine hoses to conduct performance testing. This step is vital to ensure that the hoses meet your technical specifications and can withstand the operational demands of your projects.

– Testing Considerations:

– Assess flexibility and durability under simulated operational conditions.

– Check for resistance to abrasion and chemical compatibility.

Passo 5: Negociar termos e condições

Once you have selected a preferred supplier, engage in negotiations to clarify terms and conditions. This includes pricing, payment terms, delivery schedules, and warranty conditions.

– Key Points to Discuss:

– Bulk purchase discounts or long-term contract options.

– Penalties for late delivery or non-compliance with specifications.

Illustrative image related to offshore marine hose

Passo 6: Plan for Logistics and Delivery

Effective logistics planning is essential to ensure timely delivery of the marine hoses. Coordinate with the supplier to establish a clear delivery timeline and shipping method that aligns with your project schedules.

– Logistics Considerations:

– Customs clearance processes if importing from international suppliers.

– Local regulations regarding the transport of hazardous materials.

Passo 7: Implement a Quality Control Process

Finally, establish a quality control process to monitor the performance of the marine hoses once they are in use. Regular inspections and maintenance checks can help prevent issues that may arise during operations.

– Quality Control Checklist:

– Regularly inspect for signs of wear or damage.

– Ensure compliance with operational standards throughout the hose’s lifecycle.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for offshore marine hoses, ensuring they select the best products that meet their operational requirements and safety standards.

Comprehensive Cost and Pricing Analysis for offshore marine hose Sourcing

What Are the Key Cost Components in Offshore Marine Hose Manufacturing?

When sourcing offshore marine hoses, understanding the cost structure is vital for effective budgeting and negotiations. The primary cost components include:

-

Materiais: The choice of materials significantly influences cost. High-quality synthetic rubber, steel wire reinforcements, and buoyant materials are essential for durability and performance in harsh marine environments. Premium materials often come with a higher price tag but are crucial for meeting safety standards.

-

Trabalho: Skilled labor is necessary for the specialized manufacturing processes involved in producing offshore marine hoses. Labor costs can vary based on location and the level of expertise required.

-

Despesas gerais de fabrico: This includes costs related to factory operations, utilities, and equipment maintenance. Facilities that employ advanced manufacturing technologies may incur higher overhead but also produce hoses with superior quality and reliability.

-

Ferramentas: Investment in molds, dies, and other tools is necessary for producing hoses in various sizes and configurations. Custom tooling can add to initial costs but is essential for meeting specific requirements.

-

Controlo de qualidade (CQ): Rigorous testing and quality assurance processes are critical in this industry to prevent failures that could lead to environmental disasters. The costs associated with QC processes should be factored into the overall pricing structure.

-

Logística: Transportation and shipping costs can vary significantly based on the destination and delivery terms. For international buyers, factors like shipping distances and customs duties will impact overall costs.

-

Margem: Suppliers typically include a profit margin in their pricing. Understanding the standard margins in the industry can help buyers evaluate if a price is fair.

What Influences Pricing for Offshore Marine Hoses?

Several factors can affect the pricing of offshore marine hoses, making it essential for buyers to be aware of these influences:

-

Volume e quantidade mínima de encomenda (MOQ): Bulk purchases often result in lower unit costs. Establishing long-term contracts with suppliers may also lead to more favorable pricing.

-

Especificações e personalização: Customized hoses tailored to specific operational needs may incur additional costs due to the unique manufacturing requirements. Buyers should weigh the benefits of customization against potential price increases.

-

Qualidade dos materiais e certificações: Hoses that meet international safety and quality certifications (e.g., API, ISO) generally command higher prices. However, investing in certified products can mitigate risks and ensure compliance with industry standards.

-

Factores do fornecedor: Established suppliers with a strong reputation for quality and reliability may charge a premium. However, their products often provide better long-term value, reducing the risk of failures.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) can significantly impact pricing. Buyers should carefully assess which terms best align with their logistical capabilities and cost expectations.

What Are the Best Tips for Buyers in Negotiating Offshore Marine Hose Prices?

Navigating the procurement of offshore marine hoses can be complex, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe. Here are some actionable tips:

-

Negociar as condições: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules. Building a relationship with suppliers can lead to better deals over time.

-

Foco no custo total de propriedade (TCO): Consider not just the initial purchase price, but also maintenance, operational costs, and potential downtime associated with lower-quality hoses. A higher upfront cost may lead to savings in the long run.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import duties, and shipping costs can all impact the final price. International buyers should account for these variables in their budget.

-

Request Detailed Quotations: Ask suppliers for breakdowns of their pricing to understand where costs are allocated. This transparency can aid in negotiations and help identify areas for cost savings.

-

Stay Informed on Market Trends: Keep abreast of developments in the offshore marine hose market, including technological advancements and shifts in material costs. This knowledge can enhance your negotiating power.

Conclusão

Sourcing offshore marine hoses requires a thorough understanding of cost structures, pricing influences, and effective negotiation strategies. By considering these factors, international buyers can make informed decisions that align with their operational needs and budget constraints. Always consult multiple suppliers to ensure competitive pricing and quality assurance. Keep in mind that the prices indicated by suppliers may vary, and it’s essential to validate all quotes through a detailed review of the costs involved.

Alternatives Analysis: Comparing offshore marine hose With Other Solutions

Introduction: Exploring Alternatives to Offshore Marine Hoses

In the dynamic landscape of fluid transfer solutions in the offshore oil and gas industry, selecting the right technology is crucial for operational efficiency and safety. While offshore marine hoses are widely recognized for their flexibility and resilience in harsh environments, there are alternative solutions that may better suit specific operational needs. This analysis examines two viable alternatives—rigid piping systems and flexible composite hoses—offering B2B buyers a comprehensive comparison to facilitate informed decision-making.

Illustrative image related to offshore marine hose

Comparison Table

| Aspeto de comparação | Offshore Marine Hose | Rigid Piping System | Flexible Composite Hose |

|---|---|---|---|

| Desempenho | High flexibility; ideal for dynamic environments | Excellent pressure handling; less flexible | Good flexibility; suitable for various fluids |

| Custo | Higher initial cost; long-term savings through durability | Lower initial cost; potential higher maintenance costs | Moderate cost; competitive with marine hoses |

| Facilidade de implementação | Requires specialized installation | Generally easier to install | Quick installation; requires less support |

| Manutenção | Low maintenance; periodic inspections needed | High maintenance; prone to corrosion | Moderate maintenance; less prone to damage |

| Melhor caso de utilização | Offshore fluid transfer and emergency response | Fixed installations with minimal movement | Temporary installations or areas with vibration |

Análise pormenorizada das alternativas

Rigid Piping Systems

Rigid piping systems are a traditional method for transporting fluids, particularly in fixed offshore installations. They are designed to handle high pressure and flow rates effectively, making them suitable for permanent setups. However, these systems can be less adaptable to the dynamic movements of offshore platforms, which can lead to stress and potential failure at connection points. Maintenance can be a challenge, as corrosion and leaks may require frequent inspections and repairs. The lower initial cost might be appealing, but the long-term operational expenses can add up, especially in corrosive environments.

Flexible Composite Hoses

Flexible composite hoses are another alternative that offers a blend of flexibility and durability. They are constructed from multiple layers of materials, allowing them to handle a variety of fluids, including aggressive chemicals. Their flexibility allows for ease of handling and installation, making them ideal for temporary or mobile applications. However, while they are generally resistant to damage, they may not provide the same level of pressure handling as offshore marine hoses. The initial cost is moderate, and they can be a cost-effective solution in scenarios where high flexibility is required, though their lifespan may not be as extensive as that of marine hoses.

Conclusão: Escolher a solução certa para as suas necessidades

Selecting the right fluid transfer solution requires careful consideration of operational requirements, budget constraints, and environmental conditions. Offshore marine hoses excel in dynamic offshore environments, offering high flexibility and durability, making them ideal for fluid transfer and emergency response. Rigid piping systems, while cost-effective initially, may lead to higher maintenance costs in the long run, particularly in corrosive settings. Flexible composite hoses present a middle ground, providing good adaptability for temporary installations but may not match the performance of marine hoses under all conditions. B2B buyers should assess their specific operational demands and conduct a thorough cost-benefit analysis to choose the solution that best aligns with their needs.

Essential Technical Properties and Trade Terminology for offshore marine hose

Understanding the technical properties and terminology associated with offshore marine hoses is essential for B2B buyers in the oil and gas industry. This knowledge not only aids in making informed purchasing decisions but also ensures compliance with industry standards and enhances operational efficiency.

Illustrative image related to offshore marine hose

What Are the Key Technical Properties of Offshore Marine Hoses?

-

Grau do material

Offshore marine hoses are typically constructed from specialized rubber compounds and reinforced with steel wire. The material grade determines the hose’s resistance to abrasion, corrosion, and extreme temperatures. Selecting the appropriate material grade is crucial for ensuring longevity and performance, particularly in harsh marine environments where exposure to chemicals and fluctuating weather conditions is common. -

Pressão nominal

The pressure rating indicates the maximum pressure the hose can safely handle during operation. This specification is vital for preventing catastrophic failures that can lead to environmental disasters and costly downtime. Buyers must ensure that the pressure rating aligns with the operational requirements of their offshore facilities, particularly for high-pressure fluid transfer applications. -

Minimum Bending Radius (MBR)

The MBR is the smallest radius at which a hose can bend without damaging its integrity. Understanding the MBR is essential for installation and operational flexibility, as it ensures that hoses can be routed without kinking or twisting. This property is particularly important in dynamic offshore environments where movement is constant, and any compromise in hose integrity can lead to leaks or failures. -

Maximum Rated Buoyancy (MRB)

The MRB refers to the maximum buoyant force a hose can exert when submerged. This characteristic is crucial for floating hoses used in offshore loading and unloading operations. A proper understanding of MRB helps buyers select hoses that will remain afloat even when filled with fluids, thus minimizing the risk of spills and ensuring safe operations. -

Temperature Tolerance

Offshore marine hoses must be able to withstand a range of temperatures, both high and low. The temperature tolerance specification is critical for ensuring that the hose can handle the thermal stresses associated with transporting heated fluids or operating in cold marine environments. Buyers need to consider temperature tolerance to avoid premature wear or failure.

What Are Common Trade Terms Related to Offshore Marine Hoses?

-

OEM (Fabricante de Equipamento Original)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of offshore marine hoses, understanding whether the supplier is an OEM can influence the quality and reliability of the hoses purchased. -

MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers who need to manage inventory effectively. Knowing the MOQ helps in budgeting and ensures that procurement meets operational needs without incurring excess costs. -

RFQ (Pedido de Cotação)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ is a standard practice that allows for competitive pricing and helps in evaluating supplier capabilities before making a purchase decision. -

Incoterms (Termos Comerciais Internacionais)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They delineate the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers as they affect shipping costs, insurance, and liability. -

Prazo de execução

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for planning and ensuring that operations are not disrupted due to delays in the supply chain.

In summary, a solid grasp of the essential technical properties and trade terminology associated with offshore marine hoses empowers B2B buyers to make informed decisions that can significantly impact operational efficiency and safety in the oil and gas industry.

Navigating Market Dynamics and Sourcing Trends in the offshore marine hose Sector

What Are the Key Market Dynamics and Trends in the Offshore Marine Hose Sector?

The offshore marine hose sector is experiencing significant growth, driven by the increasing demand for oil and gas in emerging markets and the global shift towards renewable energy sources. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are navigating a landscape shaped by technological advancements and changing regulatory environments. Key trends include the integration of digital technologies such as IoT for real-time monitoring and predictive maintenance, which enhance operational efficiency and safety in offshore operations. Moreover, the industry is witnessing a rise in the use of composite materials that provide better resilience against harsh environmental conditions, thereby extending the lifespan of marine hoses.

Another notable trend is the increased focus on flexible and lightweight marine hose designs that facilitate easier handling and installation, catering to the dynamic needs of offshore operations. As environmental regulations tighten globally, there is a growing emphasis on sourcing hoses that meet stringent quality and safety standards. For international buyers, staying ahead of these trends is crucial for maintaining competitive advantage, ensuring compliance, and optimizing supply chain processes.

How Is Sustainability Influencing the Sourcing of Offshore Marine Hoses?

Sustainability has become a cornerstone of sourcing strategies in the offshore marine hose sector. The environmental impact of oil and gas operations is under scrutiny, prompting B2B buyers to prioritize ethical sourcing and sustainable practices. A commitment to sustainability not only enhances a company’s brand reputation but also aligns with the increasing expectations of stakeholders for responsible environmental stewardship.

Buyers are increasingly seeking suppliers that offer ‘green’ certifications and materials, such as hoses made from recycled or biodegradable components. These products not only reduce environmental footprints but also contribute to compliance with international sustainability standards. Implementing ethical supply chains can mitigate risks associated with environmental regulations and promote long-term viability in the market. By focusing on sustainable sourcing, companies can enhance their operational efficiency while contributing to broader environmental goals.

What Is the Historical Context of Offshore Marine Hoses Relevant to B2B Buyers?

The evolution of offshore marine hoses reflects the broader trends in the oil and gas industry, marked by technological advancements and increasing operational complexities. Initially developed for basic fluid transfer, marine hoses have transformed significantly since their inception in the mid-20th century. Early designs were primarily rigid and less adaptable to the dynamic nature of offshore environments.

As offshore drilling and production activities expanded, the need for more flexible and resilient hoses became apparent. Innovations in materials science and engineering led to the development of hoses that could withstand extreme pressures, corrosive substances, and harsh weather conditions. This evolution not only improved safety and reliability but also paved the way for a diverse range of applications, from fluid transfer to emergency response scenarios. For B2B buyers, understanding this historical context is crucial for making informed decisions about the sourcing and selection of marine hoses that meet current and future operational demands.

Frequently Asked Questions (FAQs) for B2B Buyers of offshore marine hose

1. How do I choose the right offshore marine hose for my operations?

Selecting the appropriate offshore marine hose involves understanding your specific operational requirements, including the type of fluids being transferred (crude oil, chemicals, etc.), pressure conditions, and environmental factors. Assess the hose’s Minimum Bending Radius (MBR) and Maximum Rated Buoyancy (MRB) to ensure it can withstand dynamic movements and remain buoyant. Additionally, consider the hose’s flexibility, durability, and compatibility with your existing infrastructure. Collaborating with a reputable supplier who can provide tailored recommendations based on your operational context is essential.

2. What are the key features to look for in offshore marine hoses?

Key features to consider include resistance to high pressures, flexibility for dynamic offshore movements, and compatibility with the specific fluids you are handling. Look for hoses made from high-quality materials that can withstand harsh environmental conditions, such as UV exposure and saltwater. Buoyancy is crucial for floating hoses, so ensure they have adequate buoyant materials. Also, evaluate the hose’s certifications and compliance with industry standards to guarantee safety and performance.

3. What is the standard lead time for offshore marine hose orders?

Lead times for offshore marine hose orders can vary significantly depending on the supplier, customization requirements, and order volume. Generally, standard orders may take anywhere from 4 to 12 weeks for delivery. However, for customized hoses or larger quantities, expect longer lead times. It’s advisable to communicate your project timelines clearly to the supplier and inquire about their production capacity to ensure timely delivery aligned with your operational needs.

Illustrative image related to offshore marine hose

4. How can I verify the reliability of an offshore marine hose supplier?

To vet a supplier, check their industry experience, certifications, and customer reviews. Request references from previous clients and assess their track record in fulfilling orders on time and meeting quality standards. Additionally, inquire about their manufacturing processes, quality control measures, and the materials used in their hoses. A reliable supplier should also provide technical support and be responsive to inquiries, demonstrating their commitment to customer satisfaction.

5. Are there customization options available for offshore marine hoses?

Yes, many suppliers offer customization options to meet specific operational needs. This may include variations in length, diameter, material composition, and additional features like anti-static properties or specialized fittings. Discuss your requirements with the supplier to explore the customization possibilities. It’s essential to ensure that any modifications do not compromise the hose’s integrity or performance standards.

6. What are the minimum order quantities (MOQ) for offshore marine hoses?

Minimum order quantities for offshore marine hoses can vary widely among suppliers. Some may have a low MOQ for standard products, while others might require larger quantities for customized hoses. Generally, MOQs range from a few units to several hundred, depending on the hose specifications and the supplier’s production capabilities. Always confirm the MOQ with your supplier before placing an order to avoid any unexpected costs or delays.

Illustrative image related to offshore marine hose

7. What payment terms should I expect when sourcing offshore marine hoses?

Payment terms can differ significantly based on the supplier’s policies and your negotiation. Common arrangements include upfront payments, partial payments upon order confirmation, and the balance upon delivery. For larger orders, some suppliers may offer extended payment terms or financing options. It’s crucial to discuss payment terms early in the negotiation process and ensure they align with your budget and cash flow requirements.

8. How do I ensure quality assurance (QA) for my offshore marine hose purchases?

To ensure quality assurance, request documentation on the hoses’ manufacturing standards and certifications. Many suppliers conduct rigorous testing for pressure tolerance, flexibility, and environmental resistance. You can also ask for third-party testing reports or conduct your inspections upon delivery. Establishing a clear QA protocol with the supplier can help mitigate risks and ensure that the hoses meet your operational standards before deployment.

Top 8 Offshore Marine Hose Manufacturers & Suppliers List

1. Offshore Marine Hoses – Essential Fluid Transfer Solutions

Domínio: offshoremarinehoses.com

Registered: 2023 (2 years)

Introdução: Offshore marine hoses are essential in the oil and gas industry for the safe and effective transfer of fluids such as crude oil, natural gas, and chemicals between offshore platforms, vessels, and terminals. They are designed to withstand harsh environmental conditions, including high pressure and dynamic movements. Key applications include fluid transfer, loading and unloading operations, emergen…

2. Trelleborg – Marine Hose Range

Domínio: trelleborg.com

Registada: 1996 (29 anos)

Introdução: The Trelleborg marine hose range includes SEALINE, KLELINE, REELINE, and TRELLINE, designed for long-life offshore applications. The selection guide provides a simple application guide for these hoses, which are suitable for offshore oil and gas transfer. Additional products mentioned include breakaway couplings, connections, composite hoses, expansion joints, industrial hoses, couplings, accessor…

3. Ridderflex – Offshore Hoses

Domínio: ridderflex.com

Registada: 2007 (18 anos)

Introdução: Ridderflex supplies a wide range of hoses for the offshore industry, applicable in offshore platforms and vessels. The product range includes: Bulk transfer hose, Bunkering hose, Chemical hose, Discharge hose, Fire rated hose, Floating hose, High pressure hose, Hydraulic hose, Marine hose, RIG Supply hose, Sea-water intake systems, STS hose (ship-to-ship), Suction hose, Utility hose. Hoses can be …

4. Yokohama – Offshore Marine Hoses

Domínio: y-yokohama.com

Registered: 2014 (11 years)

Introdução: Yokohama offers a complete line of GMPHOM 2009 certified offshore marine hoses. Key design features include superior durability, flexibility, and weight reduction in the double carcass hose. The hoses are manufactured by a highly skilled workforce in state-of-the-art facilities located in Japan and Indonesia.

5. Titeflex – Marine Hose Solutions

Domínio: titeflex.com

Registered: 1995 (30 years)

Introdução: Marine Titeflex US Hose provides solutions based on decades of experience in the marine industry. Key products include:

– Braided metallic hose assemblies

– Composite hose assemblies

– Fluoropolymer hose assemblies

– Willcox Hose ‘MarineMaster’ and HD Oilmaster hydrocarbon transfer assemblies

– Cryoflex® 200 LNG transfer hose assemblies, engineered for LNG transfers since the early 1970s

– Monel 4…

6. The Hose Company – 1/2 SAE 100-R2 SN Hydraulic Hose

Domínio: thehosecompany.com

Registada: 2015 (10 anos)

Introdução: {“product_name”:”1/2″ SAE 100-R2 SN 2-WIRE HYDRAULIC HOSE”,”cost_per_foot”:”$2.86″,”assembly_fee”:”$5.00″,”pressure_rating”:”3950 psi”}

7. China Rubber Hose – Floating Hoses for Offshore Mooring Systems

Domínio: chinarubberhose.com

Registered: 2009 (16 years)

Introdução: Floating hoses for offshore mooring systems, including double carcass and single carcass options. Designed for various applications such as tanker rail, tail, reducer, and mainline hoses. Suitable for transferring mediums like natural gas, LPG, and oil. Features resistance to abrasion, sunlight, and sea water corrosion. Available in both single and double carcass configurations.

8. Alien Drill – Mainline Floating Hose for Offshore Moorings

Domínio: aliendrill.com

Registered: 2024 (1 years)

Introdução: Mainline Floating Hose for Offshore Moorings is designed for delivering, handling, storage, or transferring crude oil and liquid petroleum products between loading and unloading vessels at offshore mooring systems. It features an independent PE foam layer to prevent water absorption, an outer cover made of rubber compound for high resistance to UV, corrosion, and wear, and a compact construction f…

Strategic Sourcing Conclusion and Outlook for offshore marine hose

In the dynamic landscape of offshore marine hose procurement, strategic sourcing emerges as a pivotal factor for success. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, must prioritize sourcing high-quality marine hoses that meet rigorous safety and performance standards. Understanding essential attributes like Minimum Bending Radius (MBR) and Maximum Rated Buoyancy (MRB) is critical, ensuring that the selected hoses can withstand the harsh offshore conditions while maintaining operational efficiency.

The value of strategic sourcing extends beyond mere cost savings; it encompasses risk management, supply chain reliability, and enhanced operational performance. As the oil and gas industry evolves, leveraging innovative technologies and materials in marine hose production will be crucial. Buyers are encouraged to foster partnerships with reputable suppliers who demonstrate a commitment to quality, sustainability, and innovation.

Illustrative image related to offshore marine hose

Looking ahead, the offshore marine hose market is poised for growth, driven by increasing energy demands and advancements in offshore technology. By adopting a forward-thinking approach to sourcing, international B2B buyers can not only secure their supply chains but also position themselves as leaders in a competitive marketplace. Engage with reliable suppliers today to ensure your operations are equipped for the future.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Illustrative image related to offshore marine hose

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, pedir amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.