Introduction: Navigating the Global Market for dredge hose

In the ever-evolving landscape of global trade, sourcing the right dredge hose can present a significant challenge for B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe. The demand for high-performance, durable hoses tailored for dredging applications has surged, driven by increased infrastructure projects and resource extraction activities. This comprehensive guide is designed to simplify the complex process of sourcing dredge hoses, offering insights into various types available, their specific applications, and critical factors to consider during supplier vetting.

Throughout this guide, you will discover the diverse range of dredge hoses, from hard-wall to soft-wall constructions, each tailored to withstand the harsh conditions of marine environments and heavy-duty operations. We will delve into essential considerations for selecting the right hose, including material compatibility, flexibility, and resistance to abrasion and wear. Additionally, we will provide actionable insights on cost factors, enabling buyers to make informed purchasing decisions without compromising on quality.

By equipping international B2B buyers with the knowledge and tools necessary for effective sourcing, this guide empowers you to navigate the complexities of the dredge hose market confidently. Whether you are in Germany, Brazil, or beyond, understanding these key elements will ensure you select the most suitable solutions for your operational needs, ultimately enhancing your project outcomes and bottom line.

Índice

- Top 5 Dredge Hose Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for dredge hose

- Understanding dredge hose Types and Variations

- Key Industrial Applications of dredge hose

- 3 Common User Pain Points for ‘dredge hose’ & Their Solutions

- Strategic Material Selection Guide for dredge hose

- In-depth Look: Manufacturing Processes and Quality Assurance for dredge hose

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘dredge hose’

- Comprehensive Cost and Pricing Analysis for dredge hose Sourcing

- Alternatives Analysis: Comparing dredge hose With Other Solutions

- Essential Technical Properties and Trade Terminology for dredge hose

- Navigating Market Dynamics and Sourcing Trends in the dredge hose Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dredge hose

- Strategic Sourcing Conclusion and Outlook for dredge hose

- Aviso importante e termos de utilização

Understanding dredge hose Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Hard-Wall Hose | Rigid construction, excellent for controlled bend radius | Suction and discharge in dredging projects | Prós: Durable, kink-resistant; Contras: Less flexible, heavier. |

| Soft-Wall Hose | Flexible design, can bend easily without kinking | Situations with tight turns in dredging | Prós: Lightweight, versatile; Contras: Less durable under heavy loads. |

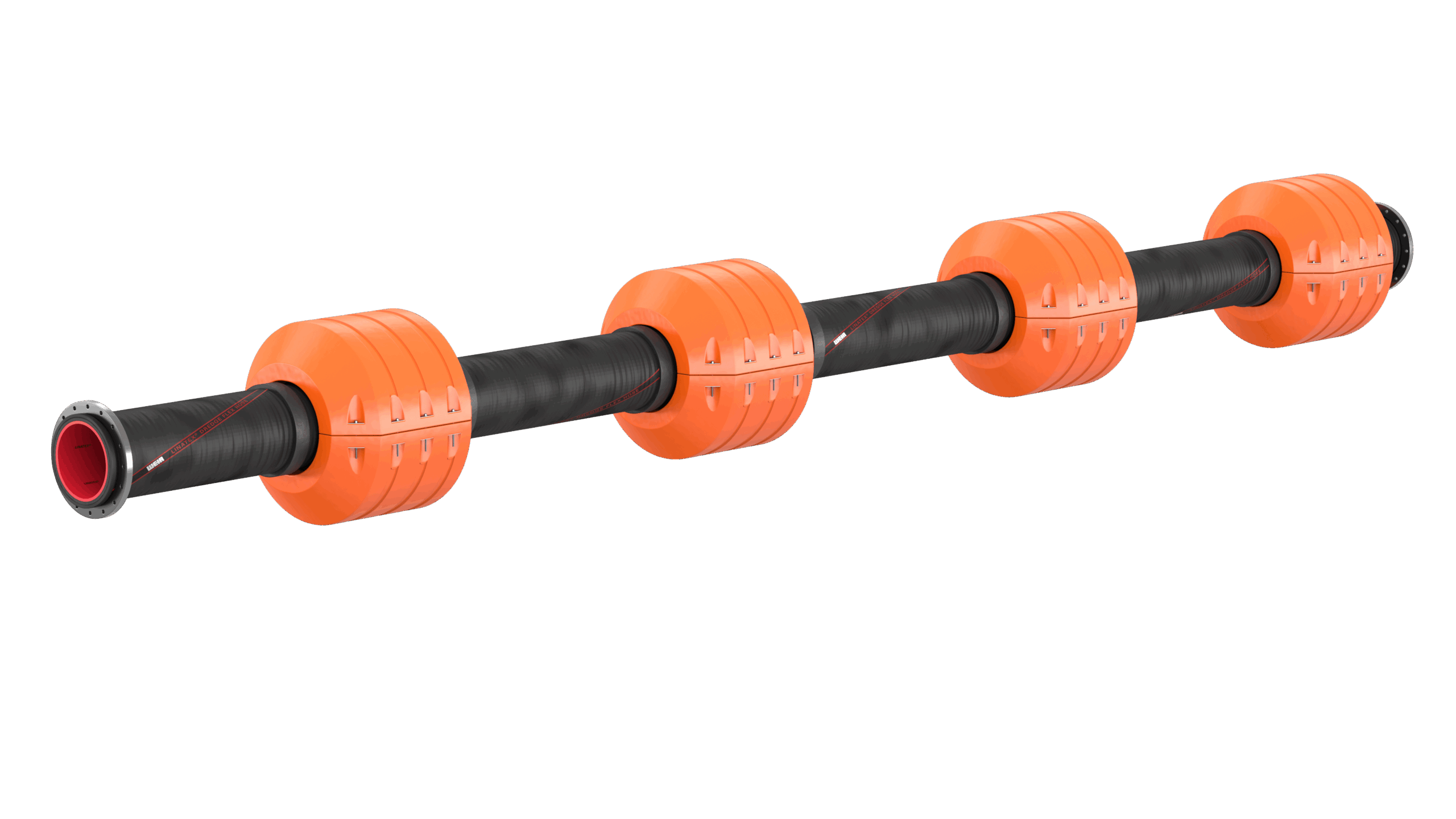

| Floating Hose | Designed to remain buoyant on water | Used in dredging applications where hoses need to float | Prós: Prevents drag, easy maneuverability; Contras: May require additional support. |

| Gimbal Joint Hose | Specialized for dragarm hopper dredges | High-performance dredging operations | Prós: Enhanced flexibility, reduces stress; Contras: Custom manufacturing may increase costs. |

| Custom Hose Variants | Tailored specifications for specific operational needs | Diverse applications across industries | Prós: Meets exact requirements, highly adaptable; Contras: Longer lead times for production. |

What are the Key Characteristics of Hard-Wall Dredge Hoses?

Hard-wall dredge hoses are characterized by their rigid construction, which enables them to maintain a specific bend radius during operation. This type of hose is ideal for applications requiring high durability and resistance to abrasion, making it suitable for suction and discharge operations in dredging projects. Buyers should consider the weight and flexibility of hard-wall hoses, as they can be heavier and less adaptable in tight spaces compared to softer alternatives.

How Do Soft-Wall Hoses Benefit Dredging Operations?

Soft-wall hoses feature a flexible design that allows them to bend easily without kinking, making them particularly useful in scenarios where tight turns are unavoidable. They are lightweight, which can reduce handling costs and facilitate easier installation. However, buyers should be aware that while soft-wall hoses offer versatility, they may not withstand the same heavy loads as their hard-wall counterparts.

Why Choose Floating Hoses for Dredging Applications?

Floating hoses are specifically designed to remain buoyant on water, making them essential for dredging applications where hoses must float to minimize drag and enhance maneuverability. These hoses are particularly useful in maintaining efficient dredging operations. While floating hoses facilitate easier movement, buyers should consider that they may require additional support structures to ensure optimal performance.

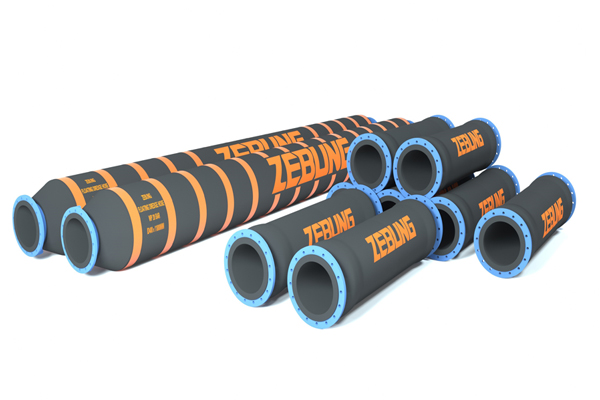

Illustrative image related to dredge hose

What Advantages Do Gimbal Joint Hoses Offer?

Gimbal joint hoses are engineered for use in dragarm hopper dredges, providing enhanced flexibility and reducing stress on the hose during operation. This design allows for better alignment with the dredge’s movement, which can improve efficiency and longevity. However, the customization required for gimbal joint hoses may lead to increased production costs, which buyers should factor into their purchasing decisions.

How Do Custom Hose Variants Meet Specific Needs?

Custom hose variants are tailored to meet specific operational requirements, allowing businesses to address unique challenges in various industries. These hoses can be designed with particular materials, wall thicknesses, and reinforcement options to suit the intended application. While offering significant advantages in terms of adaptability, buyers should be prepared for potentially longer lead times in production, which could impact project timelines.

Key Industrial Applications of dredge hose

| Indústria/Setor | Specific Application of dredge hose | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Exploração mineira | Slurry transportation in mineral extraction | Efficient material transfer, reducing operational downtime | Durability, flexibility, and resistance to abrasion |

| Dredging | Sediment and debris removal from waterways | Enhanced environmental management and compliance | Custom lengths, flexibility, and compatibility with pumps |

| Construção | Dewatering and drainage in excavation sites | Improved site safety and reduced project delays | Resistance to kinking, pressure ratings, and custom fittings |

| Gestão de resíduos | Transfer of sludge and waste materials | Streamlined waste processing and reduced environmental impact | Chemical resistance and adaptability to various waste types |

| Agricultura | Irrigation and water management systems | Optimized water usage and crop yield improvement | Compatibility with existing irrigation systems and UV resistance |

How is Dredge Hose Used in Mining Applications?

In the mining sector, dredge hoses play a crucial role in the transportation of slurries, which consist of water mixed with minerals. These hoses are designed to withstand extreme conditions, including abrasion and pressure, ensuring continuous material flow without interruptions. For international buyers, particularly in regions like Africa and South America, sourcing hoses that can handle the specific mineral types and conditions of local mining operations is essential. Additionally, selecting hoses with high flexibility can facilitate easier installation and maneuverability within tight spaces typical of mining sites.

What Role Does Dredge Hose Play in Dredging Operations?

Dredging operations utilize dredge hoses for the efficient removal of sediment and debris from waterways, which is vital for maintaining navigable channels and supporting environmental restoration efforts. These hoses must be robust enough to handle abrasive materials while being flexible to navigate the underwater environment. Buyers in Europe and the Middle East should consider the specific length and diameter requirements of their dredging equipment, ensuring compatibility for optimal performance. The ability to customize hoses for specific dredging applications can significantly enhance operational efficiency and compliance with environmental regulations.

How is Dredge Hose Beneficial in Construction Projects?

In construction, dredge hoses are employed for dewatering and drainage during excavation activities, helping to manage groundwater levels and prevent flooding at job sites. The use of high-quality hoses reduces the risk of kinking and bursting, which can lead to costly delays and safety hazards. International buyers, particularly those in regions prone to heavy rainfall, should prioritize sourcing hoses with high-pressure ratings and robust construction to ensure reliability. Custom fittings may also be necessary to integrate seamlessly with existing drainage systems, enhancing overall site safety and efficiency.

Why is Dredge Hose Important for Waste Management?

Dredge hoses are essential in the waste management sector for transferring sludge and other waste materials from collection points to treatment facilities. The durability and chemical resistance of these hoses are critical in handling various waste types, ensuring safe and efficient processing. For buyers in developing regions, where waste management infrastructure may be limited, sourcing hoses that can withstand harsh conditions and provide reliable service is vital. Additionally, understanding the specific waste types being handled can guide the selection of appropriate materials and construction methods for the hoses.

Illustrative image related to dredge hose

How Does Dredge Hose Enhance Agricultural Water Management?

In agriculture, dredge hoses are used in irrigation systems to transport water efficiently to crops. This application optimizes water usage, contributing to improved crop yields and sustainable farming practices. For international buyers, especially in arid regions of Africa and South America, the selection of hoses that are UV resistant and compatible with various irrigation systems is crucial. Customization options, such as specific lengths and diameters, can also help tailor solutions to unique agricultural needs, enhancing overall water management strategies.

3 Common User Pain Points for ‘dredge hose’ & Their Solutions

Scenario 1: Managing Wear and Tear on Dredge Hoses

O problema: B2B buyers in industries such as mining or construction often face the challenge of high wear rates on dredge hoses due to abrasive materials being transported. This can lead to frequent hose replacements, resulting in unexpected downtime and increased operational costs. For example, a dredging operation in a riverine environment might experience accelerated wear due to sand and gravel, which can damage the internal lining of the hose. This situation not only disrupts workflow but can also compromise the safety of the operation.

A solução: To mitigate wear and extend the lifespan of dredge hoses, buyers should invest in hoses made from high-quality, wear-resistant materials. When sourcing dredge hoses, look for products that feature advanced rubber compounds specifically designed to withstand abrasion. For instance, hoses with a hard-wall construction can offer better resistance to cutting and wear compared to soft-wall alternatives. Additionally, consider implementing a regular inspection and maintenance schedule to identify any signs of wear early. Ensuring that the hoses are correctly installed and supported can also prevent unnecessary stress and damage during operation. By prioritizing the quality of materials and adhering to best practices for maintenance, companies can significantly reduce replacement frequency and associated costs.

Scenario 2: Ensuring Compatibility with Various Materials

O problema: Many B2B buyers encounter issues when their dredge hoses are not compatible with the specific materials they are transporting. This could lead to chemical reactions that degrade the hose, leaking hazardous materials, or even complete hose failure. For example, transporting corrosive materials without proper lining can quickly erode the internal surface, leading to safety hazards and environmental concerns.

Illustrative image related to dredge hose

A solução: To avoid compatibility issues, buyers should thoroughly assess the chemical properties of the materials they intend to transport. When selecting dredge hoses, look for manufacturers that offer customization options, including specific linings designed for various applications. It’s advisable to consult with the manufacturer’s technical team to ensure that the chosen hose material is suitable for the intended application. Additionally, buyers should consider conducting compatibility tests in controlled environments prior to full-scale deployment. Investing time in material compatibility assessments can prevent costly failures and enhance operational safety.

Scenario 3: Addressing Flexibility and Maneuverability Issues

O problema: In many dredging operations, flexibility and maneuverability of hoses can be a significant concern, especially in complex setups where hoses must navigate tight bends or transitions. This inflexibility can lead to kinks and blockages, which not only halt operations but can also cause strain on the equipment. For example, a dredging operation in a confined area may find that rigid hoses cannot adapt to the required angles, leading to inefficiencies and increased wear.

A solução: To improve flexibility and maneuverability, buyers should consider using soft-wall dredge hoses that are specifically designed for applications requiring tighter bends. These hoses typically feature enhanced flexibility and can withstand the dynamic movements associated with dredging operations. It’s also crucial to evaluate the hose’s bend radius specifications when selecting hoses for complex applications. Additionally, integrating swivel connections can help minimize stress on the hose during operation, allowing for smoother transitions and reducing the risk of kinking. By choosing the right type of hose and employing smart design choices, companies can enhance the efficiency and reliability of their dredging operations.

Strategic Material Selection Guide for dredge hose

What Are the Key Materials Used in Dredge Hose Manufacturing?

Dredge hoses are critical components in various industries, particularly in marine and mining applications. Selecting the right material is essential for ensuring performance, durability, and cost-effectiveness. Below, we explore four common materials used in dredge hose manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Natural Rubber Perform in Dredge Hose Applications?

Natural rubber is renowned for its excellent elasticity and resilience, making it a popular choice for dredge hoses. It can withstand a wide range of temperatures and pressures, with a typical temperature rating of up to 70°C (158°F) and good resistance to abrasion.

Prós: Natural rubber offers high tensile strength and flexibility, which allows for easy maneuverability in challenging environments. It is also relatively cost-effective compared to synthetic alternatives.

Contras: However, natural rubber has limitations in terms of chemical resistance and can degrade when exposed to oils, solvents, and extreme weather conditions. Its lifespan may be shorter in harsh environments, necessitating more frequent replacements.

Impacto na aplicação: Natural rubber is best suited for transporting water, sand, and other non-corrosive materials. Buyers in regions with diverse environmental conditions, such as Africa and South America, should consider these factors when selecting natural rubber hoses.

Illustrative image related to dredge hose

What Advantages Do Synthetic Rubber Materials Provide?

Synthetic rubber, including neoprene and EPDM, is engineered for superior performance in abrasive and corrosive environments. It typically withstands higher temperatures (up to 100°C or 212°F) and offers excellent resistance to chemicals and UV exposure.

Prós: The durability of synthetic rubber makes it ideal for applications involving harsh chemicals or extreme conditions. Its consistent performance under stress can lead to reduced downtime and lower maintenance costs.

Contras: The primary drawback of synthetic rubber is its higher cost compared to natural rubber. Manufacturing complexity can also be greater, which may lead to longer lead times for custom orders.

Impacto na aplicação: Synthetic rubber hoses are suitable for dredging operations that involve transporting abrasive materials or chemicals. International buyers from the Middle East and Europe should ensure compliance with local standards, such as ASTM or DIN, when selecting synthetic options.

Why Is PVC a Viable Option for Dredge Hoses?

Polyvinyl chloride (PVC) is often used in dredge hoses due to its lightweight nature and versatility. PVC hoses can handle moderate pressure and offer good chemical resistance, making them suitable for various applications.

Prós: PVC is cost-effective and can be manufactured in various colors and sizes, allowing for customization. Its lightweight nature makes installation and handling easier.

Contras: However, PVC hoses may not perform well under extreme temperatures, with a typical limit of around 60°C (140°F). They can also be less flexible than rubber options, leading to kinking in certain applications.

Impacto na aplicação: PVC hoses are ideal for lighter dredging tasks and for transporting less abrasive materials. Buyers in Europe and South America may favor PVC for its compliance with local regulations and standards.

How Do Composite Materials Enhance Dredge Hose Performance?

Composite materials, often a blend of rubber and synthetic fibers, provide unique advantages in dredge hose applications. These hoses can be designed to meet specific performance criteria, including high pressure and abrasion resistance.

Illustrative image related to dredge hose

Prós: Composite hoses are highly durable and can be engineered for specific applications, offering excellent flexibility and resistance to kinking. They are also capable of handling a variety of media, from water to hazardous materials.

Contras: The complexity of manufacturing composite hoses can lead to higher costs and longer production times. Additionally, they may require specialized fittings and connectors, which can complicate procurement.

Impacto na aplicação: Composite hoses are particularly beneficial for dredging operations that involve diverse materials and conditions. International buyers should consider the compatibility of composite hoses with local standards and their specific operational requirements.

Summary Table of Dredge Hose Materials

| Material | Typical Use Case for dredge hose | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha natural | Transporting non-corrosive materials | High elasticity and cost-effective | Limited chemical resistance; shorter lifespan | Baixa |

| Borracha sintética | Abrasive and chemical transport | Superior durability and chemical resistance | Higher cost and manufacturing complexity | Elevado |

| PVC | Lighter dredging tasks | Lightweight and customizable | Poor performance under extreme temperatures | Baixa |

| Compósito | Diverse material handling | Excellent flexibility and tailored performance | Higher costs and potential fitting complexity | Médio |

In conclusion, understanding the properties and implications of different materials used in dredge hoses is crucial for B2B buyers. Each material offers unique advantages and limitations that can significantly impact performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dredge hose

What Are the Key Stages in the Manufacturing Process of Dredge Hose?

The manufacturing of dredge hoses involves several critical stages that ensure the final product meets the rigorous demands of the dredging industry. Each stage is meticulously designed to produce hoses that are durable, flexible, and capable of handling abrasive materials.

Illustrative image related to dredge hose

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is the selection and preparation of raw materials. High-quality natural and synthetic rubber compounds are chosen for their wear resistance and durability. Additionally, fabric reinforcements, such as high-tensile synthetic fibers, are selected to enhance the hose’s structural integrity. These materials are then processed, which may include mixing, heating, and forming into specific blends that are tailored for different applications.

How Are Dredge Hoses Formed and Assembled?

Once the materials are prepared, the next stage involves forming the hose. This typically includes extrusion, where the rubber compound is forced through a die to create the desired shape and diameter. For hoses that require specific wall thicknesses or flexibility, custom molds may be used.

After forming, the hoses are assembled, which can involve adding end fittings, such as flanges or gimbals, that allow for easy connection to other equipment. This stage is crucial, as it dictates how well the hose will perform under operational conditions. Manufacturers often employ automated machinery to ensure precision in this process.

What Finishing Techniques Are Used to Enhance Dredge Hose Quality?

The final stage in the manufacturing process is finishing, which may include curing (vulcanization) to enhance the strength and elasticity of the rubber. After curing, hoses may undergo additional treatments, such as applying protective covers or coatings that enhance wear resistance and chemical compatibility. The finished hoses are then cut to specified lengths and prepared for quality assurance testing.

What Quality Assurance Measures Are Essential for Dredge Hoses?

Quality assurance is a critical component in the manufacturing of dredge hoses, ensuring that products meet both international and industry-specific standards. B2B buyers should be familiar with these measures to guarantee the reliability of their suppliers.

Which International Standards Should Buyers Look For?

Key international standards for quality assurance in manufacturing include ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 indicates that the manufacturer has a systematic approach to managing processes and meeting customer requirements. Additionally, for specific applications, buyers should consider certifications like CE marking, which signifies conformity with health, safety, and environmental protection standards, and API specifications for petroleum products.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to ensuring that dredge hoses meet required specifications. Common checkpoints include:

- Controlo de qualidade de entrada (IQC): This involves assessing raw materials upon arrival to ensure they meet pre-established criteria.

- Controlo de qualidade durante o processo (IPQC): During the manufacturing process, various tests are conducted to monitor the quality of the hoses. This may include measuring wall thickness, flexibility, and tensile strength at different stages of production.

- Controlo de qualidade final (FQC): Once the hoses are completed, final inspections and tests are performed to ensure they meet all specifications before they are shipped.

What Testing Methods Are Commonly Used for Dredge Hoses?

Testing methods for dredge hoses can include:

- Hydrostatic Testing: To assess the hose’s ability to withstand internal pressure.

- Abrasion Resistance Testing: To evaluate how well the hose will perform when exposed to abrasive materials.

- Flexibility and Kink Resistance Tests: To ensure the hose can bend without kinking or losing functionality.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality assurance processes of their suppliers.

What Steps Can Buyers Take to Ensure Compliance with QC Standards?

-

Auditorias a fornecedores: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This may involve site visits or reviews of their quality management systems.

-

Requesting QC Reports: Buyers should ask for quality control reports that detail the results of testing and inspections performed on the dredge hoses. These reports should be comprehensive and cover all QC checkpoints.

-

Inspecções por terceiros: Engaging independent third-party inspectors can provide an unbiased assessment of the supplier’s quality assurance practices. This can be particularly important for buyers who may not have the resources to conduct thorough audits themselves.

Quais são as nuances do controlo de qualidade para os compradores internacionais B2B?

International buyers need to be aware of specific nuances that can affect quality control. For instance, variations in manufacturing standards and practices across different countries may impact the quality of dredge hoses. Buyers should ensure that suppliers adhere to both local and international standards to mitigate risks.

Additionally, communication is key; buyers should clearly outline their quality expectations and specifications to avoid misunderstandings. Building a strong relationship with suppliers can also facilitate better quality assurance, as suppliers are more likely to prioritize the needs of trusted partners.

In summary, understanding the manufacturing processes and quality assurance measures in the production of dredge hoses is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dredge hose’

To facilitate effective procurement of dredge hoses, this guide offers a structured checklist that outlines essential steps for B2B buyers. The aim is to ensure that your sourcing process is thorough, efficient, and aligned with your operational needs.

Passo 1: Definir as suas especificações técnicas

Before reaching out to suppliers, it’s vital to have a clear understanding of your requirements. This includes the size, length, wall thickness, and type of dredge hose needed.

– Consider the specific application, such as suction or discharge, and any environmental factors like temperature and chemical exposure.

– Documenting these specifications will help you communicate effectively with potential suppliers and avoid costly mistakes.

Passo 2: Pesquisa de potenciais fornecedores

Conduct a thorough investigation of suppliers specializing in dredge hoses. This includes checking their market presence and reputation.

– Look for companies with a proven track record and relevant experience, especially in your geographical region (Africa, South America, the Middle East, or Europe).

– Utilize industry forums, trade shows, and online reviews to gauge supplier reliability and customer satisfaction.

Passo 3: Evaluate Supplier Certifications and Compliance

Before finalizing your supplier choice, ensure they meet industry standards and certifications.

– Verify compliance with ISO standards, which can indicate quality assurance in manufacturing processes.

– Check if the supplier follows environmental regulations and safety standards relevant to dredging operations.

Passo 4: Request Samples and Test Quality

Request samples from shortlisted suppliers to evaluate the quality of their dredge hoses.

– Perform tests to assess durability, flexibility, and resistance to abrasion or chemicals based on your operational conditions.

– This step is crucial to ascertain that the hoses will withstand the specific demands of your projects.

Passo 5: Assess Customization Capabilities

Depending on your unique operational needs, consider suppliers that offer customization options for dredge hoses.

– Inquire about the ability to produce custom lengths, wall thicknesses, and cover materials tailored to your application.

– Customization can enhance performance and longevity, particularly in challenging environments.

Passo 6: Rever os preços e as condições de pagamento

Analyze the pricing structure of the suppliers to ensure it aligns with your budget while reflecting the quality of the product.

– Discuss payment terms and conditions, including any upfront costs or financing options that may be available.

– Ensure transparency in pricing to avoid hidden costs that could impact your procurement budget.

Passo 7: Establish Clear Delivery and Warranty Terms

Clarify the delivery timelines and warranty terms before making a purchase.

– Ensure the supplier can meet your project deadlines and discuss penalties for delays to safeguard your operations.

– A robust warranty can provide peace of mind, ensuring you are covered for defects or performance issues post-purchase.

By following this checklist, B2B buyers can streamline their sourcing process for dredge hoses, ensuring that they select the right products and suppliers that meet their operational requirements efficiently.

Comprehensive Cost and Pricing Analysis for dredge hose Sourcing

Analyzing the cost structure and pricing for dredge hose sourcing is crucial for international B2B buyers looking to optimize their procurement strategies. Understanding the various components that influence cost can lead to better decision-making and overall savings.

Illustrative image related to dredge hose

What Are the Key Cost Components in Dredge Hose Production?

The cost structure for dredge hoses encompasses several critical components:

-

Materiais: The primary cost driver in dredge hose manufacturing is the raw materials, which include natural and synthetic rubber, textiles, and metal reinforcements. The quality and sourcing of these materials significantly affect the final product price, as premium materials can enhance durability and performance.

-

Trabalho: Labor costs vary based on the manufacturing location and the complexity of the hose design. Skilled labor is essential for tasks like vulcanization and assembly, particularly in custom applications.

-

Despesas gerais de fabrico: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, which may be passed on to the buyer.

-

Ferramentas: Custom tooling is often required for specialized hose designs. While this is a one-time cost, it can significantly affect pricing for custom orders, as tooling costs are amortized over production runs.

-

Controlo de qualidade (CQ): Rigorous QC processes are essential to ensure product reliability, especially for hoses subjected to harsh conditions. Investments in quality assurance can lead to higher upfront costs but can save buyers from future failures and associated costs.

-

Logística: Shipping and handling costs can vary widely based on distance, freight method, and volume. For international buyers, understanding logistics costs is critical, as they can substantially impact total procurement costs.

-

Margem: Suppliers will typically apply a margin to cover their costs and ensure profitability. The margin can vary based on the supplier’s market position, competition, and perceived value of the product.

What Influences Dredge Hose Pricing?

Several factors can influence the pricing of dredge hoses:

-

Volume/MOQ: Larger orders often benefit from economies of scale, resulting in lower per-unit costs. Understanding minimum order quantities (MOQs) can help buyers negotiate better pricing.

-

Especificações e personalização: Hoses tailored to specific applications or environments may come at a premium. Buyers should be clear about their specifications to avoid unnecessary costs.

-

Qualidade e certificações: Hoses meeting industry standards or specific certifications may command higher prices. Buyers should weigh the benefits of certified products against cost.

-

Factores do fornecedor: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and higher quality assurance standards.

-

Incoterms: The agreed-upon Incoterms can significantly affect the total cost of ownership. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to accurately assess their total expenditure.

How Can Buyers Optimize Their Dredge Hose Procurement?

To achieve cost efficiency in dredge hose procurement, buyers should consider the following strategies:

-

Negociação: Engage suppliers in discussions about pricing, especially when purchasing in bulk. Don’t hesitate to seek volume discounts or flexible payment terms.

-

Custo total de propriedade (TCO): Evaluate not just the upfront cost but the TCO, which includes maintenance, replacement, and operational efficiency. High-quality hoses may have a higher initial price but can save costs in the long run through increased durability.

-

Nuances de preços para compradores internacionais: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local regulations that can impact pricing. Building relationships with local suppliers can also lead to better deals and insights into market conditions.

Disclaimer on Indicative Prices

It is essential to note that prices for dredge hoses can vary widely based on the factors discussed. Buyers should seek quotes from multiple suppliers to ensure competitive pricing and assess the specific needs of their projects before finalizing any agreements.

Alternatives Analysis: Comparing dredge hose With Other Solutions

Exploring Alternatives to Dredge Hose Solutions

In the industrial sector, particularly in dredging applications, selecting the right material handling solution is crucial for operational efficiency. While dredge hoses are widely recognized for their durability and reliability in transporting slurries and abrasives, it is essential to consider alternative solutions that may offer different advantages depending on specific operational requirements. This analysis compares dredge hoses with two viable alternatives: slurry pipelines and submersible pumps.

| Aspeto de comparação | Dredge Hose | Slurry Pipeline | Submersible Pump |

|---|---|---|---|

| Desempenho | High abrasion resistance, flexible | Continuous flow, long distances | High efficiency in lifting slurries |

| Custo | Moderate initial investment; long lifespan | High upfront costs; lower operating costs | Lower initial costs; potential for higher maintenance |

| Facilidade de implementação | Relatively easy to deploy; requires minimal infrastructure | Requires extensive installation; may need right-of-way | Simple installation; needs power source |

| Manutenção | Moderate; periodic inspections needed | Low; mostly passive operation | High; regular maintenance required |

| Melhor caso de utilização | Short to medium distances, flexible routing | Long-distance transport, fixed locations | Situations needing high vertical lift |

Understanding Slurry Pipelines as an Alternative

Slurry pipelines are a robust alternative to dredge hoses, particularly suited for transporting large volumes of slurries over long distances. These pipelines offer a continuous flow, making them ideal for operations where high throughput is essential. However, they involve significant upfront costs related to installation and infrastructure development. Once established, slurry pipelines generally have low operating costs, but they can be inflexible in routing and require more extensive planning and maintenance compared to dredge hoses.

Evaluating Submersible Pumps

Submersible pumps provide another alternative, especially in scenarios where lifting slurries from lower elevations is necessary. They are relatively easy to install and can be integrated into various systems with minimal infrastructure. However, while the initial investment may be lower than that of dredge hoses or slurry pipelines, submersible pumps can entail higher ongoing maintenance costs due to wear from abrasive materials. They are best used in applications requiring high vertical lift and where flexibility in deployment is needed.

Illustrative image related to dredge hose

Making the Right Choice for Your Business Needs

When evaluating whether to use dredge hoses or consider alternatives such as slurry pipelines or submersible pumps, B2B buyers should carefully assess their operational needs, including the specific materials being transported, distances involved, and budget constraints. Dredge hoses excel in flexibility and wear resistance, making them ideal for shorter distances and variable routing. Conversely, for long-distance transport, slurry pipelines may offer efficiency despite higher initial costs. Submersible pumps can be advantageous for operations requiring vertical lifting but may require a more frequent maintenance schedule.

Ultimately, the right choice will depend on a thorough analysis of operational requirements, costs, and long-term maintenance capabilities. Prioritizing these factors ensures that buyers select the most effective solution for their dredging and material handling needs.

Essential Technical Properties and Trade Terminology for dredge hose

What Are the Key Technical Properties of Dredge Hose?

Understanding the essential technical properties of dredge hoses is crucial for B2B buyers involved in dredging operations. These properties impact performance, durability, and suitability for specific applications. Here are some critical specifications:

-

Grau do material

Dredge hoses are typically made from high-quality natural and synthetic rubber, which provides excellent abrasion resistance and flexibility. The choice of material grade affects the hose’s ability to withstand harsh environments, such as those found in mining and marine applications. Higher-grade materials can lead to longer service life and reduced downtime, ultimately saving costs. -

Wall Thickness

The wall thickness of a dredge hose varies based on its intended use and the materials being transported. A thicker wall enhances durability and pressure resistance, while a thinner wall may offer greater flexibility. Understanding the required wall thickness is vital for ensuring that the hose can handle the specific stress and wear associated with your operations. -

Raio de curvatura

The bend radius is the minimum radius a hose can be bent without compromising its integrity. This property is crucial for applications where space is limited or where hoses must navigate around obstacles. A smaller bend radius can facilitate easier installation and routing, but it may also increase the risk of kinking or damage. -

Vacuum Rating

This specification indicates the hose’s ability to maintain suction under various conditions. A higher vacuum rating is essential for suction applications, ensuring that the hose can effectively transport materials without collapsing. Buyers must match the vacuum rating to the operational requirements to avoid performance issues. -

Reinforcement Layer

Dredge hoses often include reinforcement layers made from synthetic fabrics or steel wire to enhance tensile strength and kink resistance. The type and arrangement of reinforcement affect the hose’s overall durability and flexibility. This property is particularly important for hoses that will experience frequent movement or vibration. -

Temperature Resistance

Dredge hoses may be exposed to extreme temperatures, depending on the materials being transported. Knowing the temperature resistance of the hose material is critical for ensuring it maintains performance and safety during operation. Hoses that can withstand higher temperatures may be necessary for certain industrial applications.

What Are Common Trade Terms in the Dredge Hose Industry?

Familiarity with industry terminology can facilitate smoother negotiations and transactions. Here are some common trade terms you should know:

-

OEM (Fabricante de Equipamento Original)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of dredge hoses, understanding the OEM can help buyers ensure compatibility with existing equipment and standards. -

MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest order size that a supplier is willing to accept. This term is crucial for buyers to understand, as it can affect inventory management and financial planning. Higher MOQs may be justified by lower per-unit costs but can also tie up capital. -

RFQ (Pedido de Cotação)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This process allows buyers to compare offers and make informed purchasing decisions. Including detailed specifications in the RFQ can lead to more accurate quotes. -

Incoterms

International Commercial Terms (Incoterms) are a set of standardized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risks, and liability, ensuring smoother logistics. -

Prazo de execução

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This term is essential for planning project timelines and managing operational schedules. Buyers should inquire about lead times to avoid delays in critical projects. -

Custom Hose Assembly

This term refers to hoses that are tailored to meet specific customer requirements, including length, diameter, and end fittings. Custom hose assemblies can provide enhanced performance and compatibility with unique operational conditions, making them a valuable option for specialized applications.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing dredge hoses, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the dredge hose Sector

What Are the Key Trends Shaping the Dredge Hose Market?

The dredge hose market is experiencing significant transformation driven by several global factors. Increasing demand for natural resources, particularly in mining and construction, is propelling the need for efficient dredging operations. Countries in Africa and South America are seeing heightened activity in mineral extraction and infrastructure projects, leading to a surge in dredging requirements. Additionally, technological advancements in materials science are paving the way for more durable and flexible hose solutions. Manufacturers are increasingly focusing on creating hoses that can withstand harsh conditions while minimizing downtime.

Emerging B2B technologies such as IoT-enabled monitoring systems are becoming prevalent in the dredging sector. These systems allow for real-time tracking of hose performance, helping buyers optimize their operations and reduce costs. Furthermore, the trend toward customization is gaining momentum; businesses are seeking tailored solutions that meet specific project requirements, including unique lengths, diameters, and materials. This shift towards bespoke solutions is particularly relevant for international buyers from regions like Europe and the Middle East, where diverse environmental conditions necessitate specialized products.

How Is Sustainability Influencing Dredge Hose Sourcing Decisions?

Sustainability is increasingly becoming a critical factor in the sourcing of dredge hoses. The environmental impact of dredging activities is under scrutiny, prompting companies to seek hoses that minimize ecological disruption. Ethical supply chains that prioritize sustainable practices are becoming a competitive advantage in the market. Buyers are looking for manufacturers that adhere to rigorous environmental standards and demonstrate a commitment to reducing their carbon footprint.

Moreover, the use of ‘green’ materials in the production of dredge hoses is gaining traction. Hoses made from recyclable or biodegradable materials not only mitigate environmental impact but also appeal to businesses aiming to enhance their sustainability credentials. Certifications such as ISO 14001 for environmental management and adherence to REACH regulations can further assure buyers of the supplier’s commitment to responsible sourcing. As international regulations tighten, especially in Europe, buyers must prioritize suppliers who can demonstrate compliance with these standards, ensuring that their procurement choices align with global sustainability goals.

How Has the Dredge Hose Sector Evolved Over Time?

The dredge hose sector has undergone considerable evolution since its inception, moving from rudimentary designs to sophisticated engineering solutions. Initially, dredge hoses were constructed using basic rubber materials, limiting their durability and flexibility. Over the decades, advancements in material science have introduced high-performance synthetic rubbers and composite materials, significantly enhancing the hoses’ resistance to abrasion, pressure, and environmental factors.

Today, manufacturers like Salem-Republic Rubber and Novaflex are at the forefront of this evolution, offering customized solutions that cater to the unique demands of various industries. With over 30 years of experience, these companies have refined their manufacturing processes, ensuring that every component of the hose is designed to meet rigorous standards. This evolution not only reflects the changing demands of the market but also underscores the importance of innovation in maintaining competitiveness in the dredge hose sector.

Illustrative image related to dredge hose

By understanding these dynamics, international B2B buyers can make informed decisions that align with both their operational needs and sustainability objectives, ensuring a successful procurement strategy in the dredge hose market.

Frequently Asked Questions (FAQs) for B2B Buyers of dredge hose

-

1. How do I select the right dredge hose for my application?

Selecting the right dredge hose involves assessing the specific requirements of your application, including the type of material being transported, the environmental conditions, and the required flexibility. Evaluate the hose’s construction materials—look for options that feature wear-resistant rubber and textile reinforcements for durability. Additionally, consider whether you need hard-wall or soft-wall hoses, depending on the bend radius and pressure conditions. Consulting with suppliers who offer customization can help you tailor the hose to your operational needs. -

2. What are the key factors to consider when sourcing dredge hoses internationally?

When sourcing dredge hoses internationally, consider factors such as supplier reputation, quality certifications, and compliance with international standards. It’s crucial to vet suppliers thoroughly by checking their production capabilities, experience, and customer reviews. Additionally, assess logistical aspects, including shipping times and costs, to ensure timely delivery. Understanding local regulations and import duties in your country is also essential to avoid unexpected expenses. -

3. What customization options are available for dredge hoses?

Customization options for dredge hoses can include variations in length, diameter, wall thickness, and material composition. Many manufacturers offer tailored solutions based on specific operational conditions and the type of materials being transported. You can also request special features like reinforced ends, specific color coding for identification, and customized linings to enhance chemical resistance. Discuss your requirements with potential suppliers to explore all available options. -

4. What is the typical minimum order quantity (MOQ) for dredge hoses?

The minimum order quantity (MOQ) for dredge hoses can vary significantly between suppliers and may depend on the customization level required. Typically, MOQs can range from a few units for standard hoses to larger quantities for customized products. It’s advisable to communicate your needs directly with suppliers to negotiate favorable terms. Some manufacturers may be willing to accommodate smaller orders, especially for first-time buyers or trial runs. -

5. How do I ensure quality assurance (QA) when purchasing dredge hoses?

To ensure quality assurance when purchasing dredge hoses, request detailed product specifications and certifications from your suppliers. Inquire about their manufacturing processes, including material sourcing and testing methods. Many reputable manufacturers conduct rigorous QA testing for durability, flexibility, and resistance to wear and chemicals. Consider asking for samples or visiting the production facility if possible, as this can provide insight into their quality control practices. -

6. What payment terms should I expect when ordering dredge hoses?

Payment terms for ordering dredge hoses typically vary by supplier but can include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for custom orders, with the balance due upon completion. It’s essential to discuss payment terms during the negotiation phase and ensure that they align with your financial processes. Familiarize yourself with any currency exchange implications if sourcing internationally. -

7. What logistics considerations should I keep in mind when sourcing dredge hoses?

Logistics considerations when sourcing dredge hoses include shipping methods, lead times, and customs clearance processes. Evaluate the supplier’s shipping options and choose a method that balances cost with delivery speed. Ensure you understand the documentation required for customs clearance to avoid delays. Additionally, consider warehousing solutions in your region if you plan to order in bulk, as this can help manage inventory effectively. -

8. How can I establish long-term partnerships with dredge hose suppliers?

Establishing long-term partnerships with dredge hose suppliers involves clear communication, mutual trust, and consistent order patterns. Start by building a strong rapport through regular interactions and feedback on product performance. Consider collaborating on future projects or innovations to foster a sense of partnership. Additionally, demonstrating loyalty through repeat business can incentivize suppliers to prioritize your needs and offer better terms or customization options.

Top 5 Dredge Hose Manufacturers & Suppliers List

1. Novaflex – Dredge Sleeves/Sand Discharge Hose

Domínio: novaflex.com

Registada: 2001 (24 anos)

Introdução: Part Number: Novaflex 5331

Type: Dredge Sleeves/Sand Discharge Hose

Construction:

– Tube: Black abrasion resistant synthetic rubber

– Reinforcement: Polyester tire cord

– Cover: Black abrasion and weather resistant synthetic rubber

Length: 20 ft

Temperature Range: Up to +180°F

Features: Abrasive resistant and static conductive tube, manufactured to very close O.D. tolerances.

2. Keene Engineering – 2 Clearflow Suction Hose

Domínio: keene.store

Registered: 2021 (4 years)

Introdução: {“name”: “2” Clearflow Suction Hose”, “code”: “SH2”, “price_per_foot”: “$6.51”, “description”: “This 2 inch ‘Clearflow’ Suction Hose is made especially for Keene Engineering to withstand extreme temperature changes and hold up against deterioration from exposure to sunlight, ozone and mildew. Extremely flexible and lightweight with a smooth interior that is conducive to any dredging operation.”, “…

3. Trelleborg – Rubber Hoses for Material Handling

Domínio: trelleborg.com

Registada: 1996 (29 anos)

Introdução: Trelleborg’s engineered products operation specializes in rubber hoses for material handling, providing design engineering development, production, and technical support in-house. Key market focus includes the international dredging industry, emphasizing high service levels and guaranteed product quality. The product range includes high-quality hoses for the oil sands market, featuring wear resist…

4. Gold Fever – Suction Hose for Dredging

Domínio: goldfeverprospecting.com

Registada: 2003 (22 anos)

Introdução: Suction Hose for Dredging

– Item #: dredgehose-kesh

– Regular price: $5.95

– Available diameters (price is per foot):

– 1.25 inch (+$0)

– 1.5 inch (+$1)

– 2 inch (+$2)

– 2.5 inch (+$3)

– 3 inch (+$8)

– 4 inch (+$14)

– 5 inch (+$25)

– 6 inch (+$31)

– 6 inch HD (+$35)

– 8 inch (+$69)

– 8 inch HD (+$77)

– Availability: Usually ships in 5-7 business days

– Description: “Clearflow…

5. Dredge Brokers – 16 Rubber Floating Dredge Hose

Domínio: dredgebrokers.com

Registada: 2005 (20 anos)

Introdução: [{‘type’: ’16” Rubber Floating Dredge Hose’, ‘price’: ‘2,500 USD’, ‘location’: ‘Alabama’, ‘details’: ’16” Floating rubber dredge hose for sale. 14 Sections available. Purchase will include racks. Includes all nuts and bolts. 35′ and 39′ lengths. Older hose that has never been used and has been on racks and covered.’}, {‘type’: ’24” Rubber Dredge Hose’, ‘price’: ‘2,500 USD’, ‘location’: ‘Alabama’, …

Strategic Sourcing Conclusion and Outlook for dredge hose

Why is Strategic Sourcing Essential for Dredge Hose Procurement?

In the competitive landscape of dredging operations, strategic sourcing is vital for ensuring the reliability and durability of dredge hoses. By selecting suppliers who offer customized solutions tailored to specific operational requirements, businesses can enhance performance while minimizing downtime. Key takeaways include the importance of leveraging high-quality materials, understanding the unique needs of your projects, and collaborating with manufacturers who can provide tailored designs and robust support.

How Can International Buyers Benefit from Strategic Sourcing?

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, strategic sourcing presents an opportunity to not only optimize costs but also to ensure compliance with local standards and regulations. Engaging with manufacturers that have a proven track record and extensive experience in the dredge hose industry can yield significant advantages, including improved operational efficiency and increased safety.

What’s Next for Dredge Hose Procurement?

As the global demand for dredging services continues to rise, the need for innovative and resilient dredge hose solutions will only grow. Buyers should actively seek partnerships with suppliers who prioritize research and development, ensuring they stay ahead of industry trends. By embracing strategic sourcing practices now, businesses can position themselves for future success in the evolving dredging market. Engage with trusted suppliers today to secure the best solutions for your operational needs and ensure a sustainable competitive edge.

Illustrative image related to dredge hose

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, pedir amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.