Introduction: Navigating the Global Market for fuel hose manufacturers

The global market for fuel hose manufacturers presents a myriad of challenges for international B2B buyers, particularly those navigating the diverse landscapes of Africa, South America, the Middle East, and Europe. With an overwhelming array of products and suppliers, sourcing high-quality fuel hoses that meet specific industry requirements can be daunting. This guide addresses the critical need for buyers to understand the different types of fuel hoses available, their applications across various sectors, and the importance of meticulous supplier vetting to ensure compliance with safety and performance standards.

In this comprehensive resource, we will delve into the nuances of fuel hose manufacturing, exploring the various materials, construction techniques, and certifications that distinguish reputable suppliers. Additionally, we will provide insights into cost considerations, lead times, and logistics, empowering B2B buyers to make informed purchasing decisions. By equipping decision-makers with actionable knowledge, this guide not only streamlines the sourcing process but also enhances the overall supply chain efficiency. Whether you’re based in Germany, Nigeria, or anywhere in between, understanding these dynamics is crucial for optimizing your procurement strategy and ensuring the reliability of your fuel delivery systems.

Índice

- Top 5 Fuel Hose Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fuel hose manufacturers

- Understanding fuel hose manufacturers Types and Variations

- Key Industrial Applications of fuel hose manufacturers

- 3 Common User Pain Points for ‘fuel hose manufacturers’ & Their Solutions

- Strategic Material Selection Guide for fuel hose manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for fuel hose manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fuel hose manufacturers’

- Comprehensive Cost and Pricing Analysis for fuel hose manufacturers Sourcing

- Alternatives Analysis: Comparing fuel hose manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for fuel hose manufacturers

- Navigating Market Dynamics and Sourcing Trends in the fuel hose manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fuel hose manufacturers

- Strategic Sourcing Conclusion and Outlook for fuel hose manufacturers

- Aviso importante e termos de utilização

Understanding fuel hose manufacturers Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Hydraulic Fuel Hoses | Reinforced with wire braiding, high pressure tolerance | Construction, Agriculture, Automotive | Prós: High durability, suitable for high pressure. Contras: Heavier and less flexible than standard hoses. |

| Marine Fuel Hoses | Resistant to saltwater, UV, and extreme temperatures | Marine vessels, Offshore operations | Prós: Excellent weather resistance. Contras: Typically more expensive due to specialized materials. |

| Biofuel-Compatible Hoses | Made from materials resistant to biofuels and ethanol | Renewable energy, Automotive | Prós: Environmentally friendly, prevents degradation. Contras: May have limited availability in some regions. |

| General Purpose Fuel Hoses | Versatile, available in various materials (rubber, PVC, etc.) | Industrial, Foodservice, Agriculture | Prós: Cost-effective, widely available. Contras: May not be suitable for high-pressure applications. |

| Custom Fuel Hoses | Tailored specifications for unique applications | Specialized machinery, Custom vehicles | Prós: Perfect fit for specific needs. Contras: Prazos de entrega mais longos e custos potencialmente mais elevados. |

What Are Hydraulic Fuel Hoses and Their B2B Relevance?

Hydraulic fuel hoses are designed to handle high-pressure applications, often reinforced with wire braiding to enhance durability. They are widely used in sectors such as construction and agriculture, where equipment operates under extreme conditions. B2B buyers should consider the working pressure and temperature ratings when selecting hydraulic hoses, as these factors can significantly impact performance and safety.

How Do Marine Fuel Hoses Stand Out in the Market?

Marine fuel hoses are specifically engineered to resist the harsh conditions of saltwater and UV exposure, making them ideal for marine vessels and offshore operations. Their unique construction ensures longevity and reliability in challenging environments. Buyers in the marine industry must evaluate the hose’s compliance with maritime regulations and its resistance to various fuels, ensuring they meet safety and operational standards.

What Makes Biofuel-Compatible Hoses a Smart Choice?

Biofuel-compatible hoses are crafted from materials that resist degradation from biofuels and ethanol blends. These hoses are increasingly relevant in the renewable energy sector and automotive industries, where sustainability is a priority. When purchasing, B2B buyers should assess the compatibility of the hose materials with their specific biofuel types to avoid performance issues.

Why Choose General Purpose Fuel Hoses for Versatility?

General-purpose fuel hoses are versatile and available in various materials, including rubber and PVC. They cater to a broad range of applications in industrial, foodservice, and agricultural sectors. While they are cost-effective and readily available, buyers must ensure that these hoses meet the necessary pressure ratings and material specifications for their intended use.

How Do Custom Fuel Hoses Address Unique Needs?

Custom fuel hoses provide tailored solutions for specialized machinery and vehicles, allowing businesses to meet specific operational requirements. These hoses can be designed to accommodate unique dimensions, materials, and pressure ratings. B2B buyers should be prepared for longer lead times and higher costs, but the investment often results in enhanced efficiency and performance tailored to their unique applications.

Key Industrial Applications of fuel hose manufacturers

| Indústria/Setor | Specific Application of fuel hose manufacturers | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Automóvel | Fuel line connections in vehicles | Ensures efficient fuel delivery and engine performance | Compliance with local regulations and material specifications |

| Marine | Fuel delivery systems for boats and ships | Enhances safety and reliability in fuel management | Resistance to marine conditions and compatibility with fuels |

| Aeroespacial | Fuel hoses in aircraft refueling systems | Critical for safety and operational efficiency in aviation | Adherence to stringent aerospace standards and certifications |

| Agricultura | Fuel transfer systems for agricultural machinery | Increases efficiency and reduces downtime in farming operations | Durability against environmental factors and fuel types |

| Construção | Fuel hoses for equipment refueling on construction sites | Minimizes fuel spillage and enhances operational safety | High-pressure tolerance and resistance to wear and tear |

How Are Fuel Hose Manufacturers Used in the Automotive Industry?

Fuel hose manufacturers play a crucial role in the automotive sector by providing reliable fuel line connections. These hoses are designed to withstand high pressures and temperature fluctuations, ensuring efficient fuel delivery to the engine. For international buyers, particularly from regions like Africa and South America, sourcing hoses that meet local regulations and are compatible with various fuel types is essential to prevent engine issues and enhance vehicle performance.

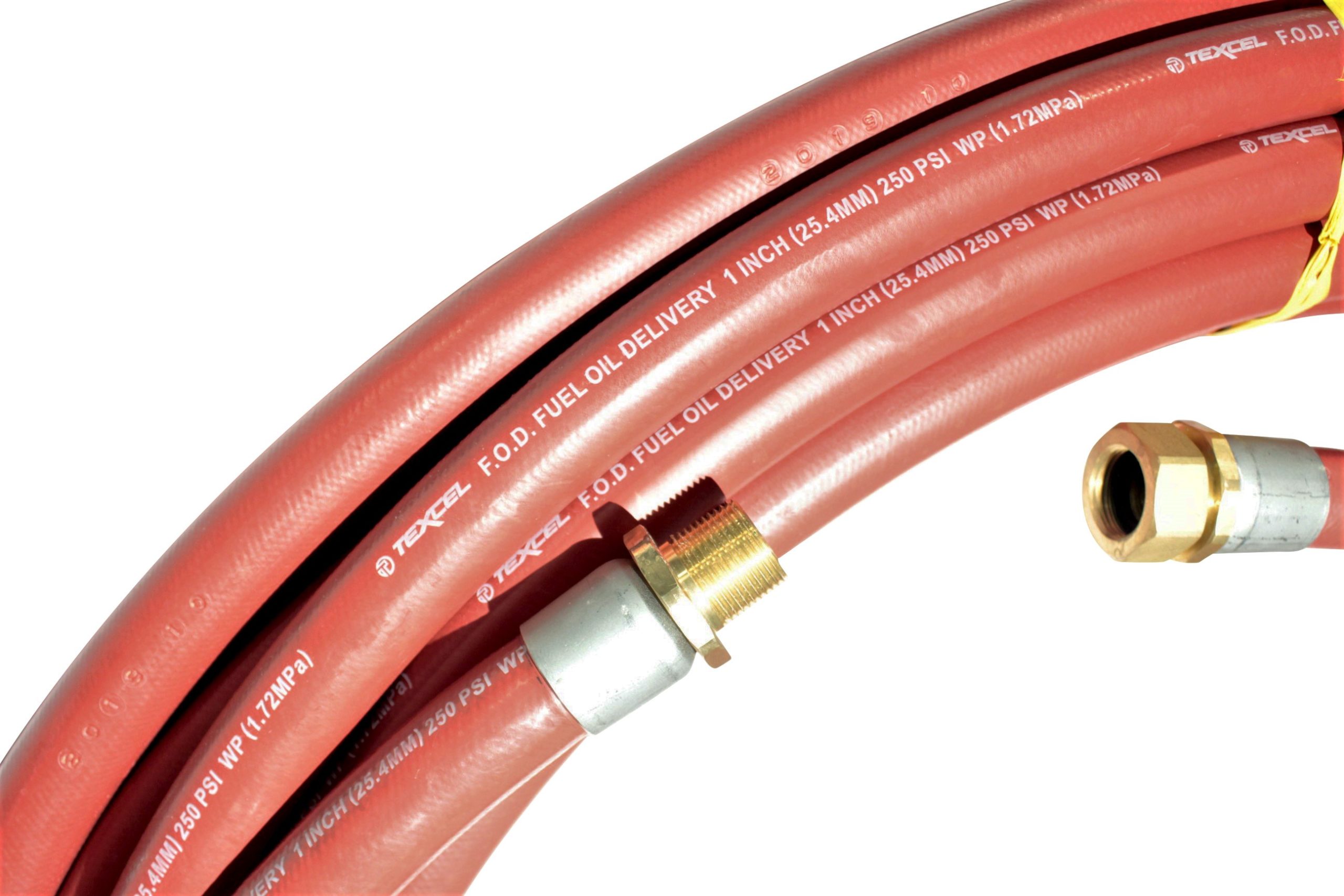

Illustrative image related to fuel hose manufacturers

What Role Do Fuel Hose Manufacturers Play in Marine Applications?

In the marine industry, fuel hose manufacturers supply hoses that facilitate safe and efficient fuel delivery systems for boats and ships. These hoses are engineered to resist harsh marine conditions, including saltwater exposure and extreme temperatures. Buyers in the Middle East and Europe must prioritize sourcing hoses that meet maritime safety standards to prevent leaks and ensure safe operations while protecting the marine environment.

Why Are Fuel Hose Manufacturers Essential in Aerospace?

Aerospace applications require specialized fuel hoses for aircraft refueling systems, where safety and reliability are paramount. Fuel hose manufacturers produce hoses that adhere to strict aerospace regulations, ensuring they can withstand extreme conditions and prevent fuel leaks. International buyers, particularly from European nations such as Germany, must ensure that sourced hoses are certified to meet aviation standards, thus safeguarding flight safety.

How Do Fuel Hose Manufacturers Support Agricultural Operations?

In agriculture, fuel hose manufacturers provide hoses for transferring fuel to machinery such as tractors and harvesters. These hoses enhance operational efficiency by ensuring quick and safe refueling, which is critical during peak seasons. Buyers from regions like Africa must consider the durability of hoses against environmental factors and the specific types of fuel used in agricultural machinery to minimize downtime and maintenance costs.

What Importance Do Fuel Hose Manufacturers Hold in Construction?

Fuel hoses are vital in the construction industry for refueling equipment on-site, where efficiency and safety are crucial. Manufacturers provide hoses designed to minimize fuel spillage and enhance operational safety, thereby reducing the risk of accidents. Buyers in South America and other developing regions should focus on high-pressure tolerance and wear resistance when sourcing these hoses to ensure longevity and reliability in demanding construction environments.

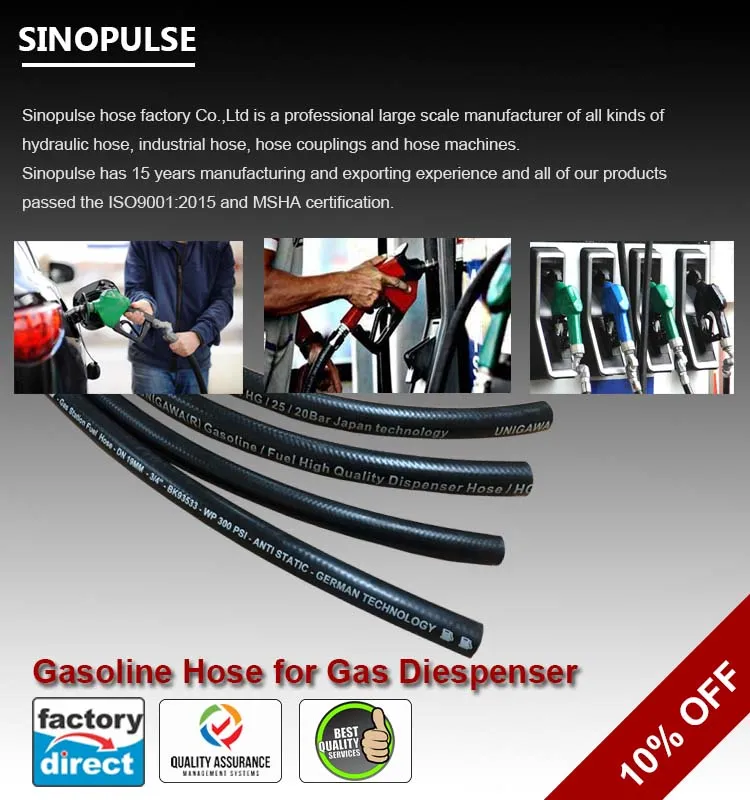

Illustrative image related to fuel hose manufacturers

3 Common User Pain Points for ‘fuel hose manufacturers’ & Their Solutions

Scenario 1: Ensuring Compliance with Industry Standards

O problema: B2B buyers often face the challenge of navigating the complex regulatory landscape associated with fuel hoses. Different regions have varying standards for safety, environmental impact, and material specifications. For instance, manufacturers in Europe must comply with REACH regulations, while those in the Middle East may have different certification requirements. This complexity can lead to costly delays and compliance issues if the wrong materials or specifications are used.

A solução: To mitigate these compliance challenges, buyers should conduct thorough research on the specific regulations applicable in their region and industry. Collaborating with reputable fuel hose manufacturers who possess certifications relevant to your locale is crucial. Request documentation and proof of compliance with local regulations, such as ISO certifications or material safety data sheets (MSDS). Additionally, consider establishing a long-term partnership with a manufacturer that provides ongoing support and updates regarding regulatory changes, ensuring that your operations remain compliant and efficient.

Scenario 2: Addressing Material Durability Concerns

O problema: Another common pain point for B2B buyers is the durability and longevity of fuel hoses. Many buyers are concerned about the wear and tear on hoses due to exposure to harsh environments, including extreme temperatures, chemicals, and abrasion. A fuel hose that deteriorates quickly can lead to operational downtime, safety hazards, and increased costs for replacements.

A solução: When sourcing fuel hoses, it is essential to focus on the materials and construction methods used by manufacturers. Look for hoses made from high-quality synthetic rubber or reinforced thermoplastics that offer enhanced resistance to temperature fluctuations and chemical exposure. Additionally, inquire about the hose’s specifications, such as bend radius and pressure ratings, to ensure they meet your operational needs. Manufacturers should provide data on the expected lifespan of their products and any warranties that back their durability claims. Conducting regular inspections and maintenance on hoses can also help identify wear early, allowing for timely replacements before failures occur.

Scenario 3: Managing Supply Chain Disruptions

O problema: Supply chain disruptions can significantly impact fuel hose procurement, particularly in the wake of global events such as pandemics or geopolitical tensions. Buyers may experience delays in delivery, increased costs, or even shortages of critical components needed for their operations. These disruptions can lead to unanticipated downtime and affect overall business productivity.

Illustrative image related to fuel hose manufacturers

A solução: To effectively manage supply chain risks, buyers should diversify their supplier base by sourcing from multiple fuel hose manufacturers across different regions. This strategy helps reduce dependency on a single supplier and mitigates the risk of disruptions affecting your operations. Additionally, consider implementing vendor-managed inventory (VMI) programs with your manufacturers, where they monitor your inventory levels and automatically replenish stock as needed. This proactive approach can ensure that you maintain adequate supplies even during unexpected disruptions. Regular communication with suppliers about their production capabilities and any potential issues can further enhance your ability to respond to supply chain challenges swiftly.

Strategic Material Selection Guide for fuel hose manufacturers

What Are the Key Properties of Common Materials Used in Fuel Hose Manufacturing?

Fuel hoses are critical components in various industries, and the selection of materials significantly affects performance, durability, and compliance with international standards. Here, we analyze four common materials used in fuel hose manufacturing: Nitrile Rubber, Polyurethane, PVC, and Silicone.

How Does Nitrile Rubber Perform as a Fuel Hose Material?

Nitrile rubber, known for its excellent resistance to petroleum-based fuels, is a popular choice among fuel hose manufacturers. It typically operates effectively within a temperature range of -40°F to 257°F and can handle pressures up to 300 psi. Its resistance to abrasion and weathering makes it suitable for outdoor applications.

Prós: Nitrile rubber is durable, cost-effective, and offers good flexibility, which aids in installation. It is also resistant to oils and fuels, making it an ideal choice for automotive and industrial applications.

Contras: While nitrile rubber is effective against petroleum products, it may not perform well against certain chemicals, such as ketones or strong acids. Additionally, prolonged exposure to UV light can degrade its properties.

Impacto na aplicação: Nitrile hoses are commonly used in automotive fuel lines, industrial machinery, and marine applications, where compatibility with gasoline and diesel is crucial.

Considerações para compradores internacionais: Buyers from regions like Africa and South America should ensure that nitrile hoses meet local compliance standards, such as ASTM or ISO certifications, to avoid issues related to quality and safety.

Illustrative image related to fuel hose manufacturers

What Advantages Does Polyurethane Offer in Fuel Hose Applications?

Polyurethane hoses are increasingly favored due to their superior flexibility and resistance to abrasion, oils, and fuels. They typically handle a temperature range of -40°F to 140°F and can withstand pressures up to 300 psi.

Prós: Polyurethane is lightweight, flexible, and resistant to weathering, making it suitable for a variety of applications, including those requiring frequent movement.

Contras: While polyurethane offers excellent mechanical properties, it may be more expensive than other materials. Its chemical resistance can also vary, necessitating careful selection for specific fuel types.

Impacto na aplicação: This material is often utilized in applications requiring high flexibility, such as in fuel transfer systems in agricultural machinery.

Considerações para compradores internacionais: Buyers should consider the specific fuel compatibility of polyurethane hoses and ensure they adhere to local standards, particularly in regions with stringent regulations like Germany.

Why Is PVC a Common Choice for Fuel Hoses?

Polyvinyl Chloride (PVC) is a versatile material that is often used for fuel hoses, especially for low-pressure applications. It generally operates within a temperature range of -10°F to 150°F and can handle pressures up to 150 psi.

Prós: PVC is cost-effective, lightweight, and easy to manufacture, making it a popular choice for low-cost applications. Its resistance to corrosion and chemicals also enhances its usability.

Contras: PVC hoses may lack the flexibility and durability of rubber or polyurethane alternatives, especially under extreme temperatures or pressures. They are also less suitable for high-performance applications.

Impacto na aplicação: PVC hoses are commonly used in fuel transfer for agricultural and light industrial applications where cost is a primary concern.

Considerações para compradores internacionais: Buyers should ensure that PVC hoses comply with relevant standards, such as DIN or JIS, particularly in Europe and Asia, where compliance is rigorously enforced.

What Role Does Silicone Play in Fuel Hose Manufacturing?

Silicone hoses are known for their excellent temperature resistance, typically ranging from -100°F to 500°F, and can handle pressures up to 200 psi. They are also resistant to aging and degradation.

Prós: Silicone is highly flexible and maintains its properties over a wide temperature range, making it suitable for extreme environments. It is also non-toxic and can handle various fluids.

Contras: Silicone hoses can be more expensive than other materials, and their compatibility with certain fuels may be limited. They may also require additional reinforcement for high-pressure applications.

Impacto na aplicação: Silicone is often used in high-performance automotive applications and specialized industrial settings where temperature extremes are common.

Considerações para compradores internacionais: Buyers should verify that silicone hoses meet relevant safety and performance standards, particularly in regions with stringent regulations.

Summary Table of Material Selection for Fuel Hose Manufacturers

| Material | Typical Use Case for fuel hose manufacturers | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Nitrile Rubber | Automotive fuel lines | Excellent oil and fuel resistance | Poor UV resistance | Médio |

| Poliuretano | Flexible fuel transfer systems | Superior flexibility and durability | Higher cost than alternatives | Elevado |

| PVC | Low-pressure fuel transfer | Económica e leve | Limited flexibility and durability | Baixa |

| Silicone | High-performance automotive applications | Wide temperature range | Higher cost and limited fuel compatibility | Elevado |

This guide provides essential insights into material selection for fuel hose manufacturing, helping international B2B buyers make informed decisions based on their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fuel hose manufacturers

What Are the Key Stages in the Manufacturing Process of Fuel Hoses?

Manufacturing fuel hoses involves several critical stages, each designed to ensure that the final product meets strict performance and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

Preparação do material

The first step is selecting high-quality materials suitable for fuel hose applications. Common materials include synthetic rubber, thermoplastics, and specialized fabrics that provide flexibility and chemical resistance. Manufacturers often source materials from certified suppliers to guarantee consistency and quality. Before processing, raw materials undergo inspection to ensure they meet the specified technical standards.

Formação

Once materials are prepared, they are shaped into the desired hose form. This process may involve extrusion, where heated material is forced through a die to create a continuous hose, or molding for specialized components. Techniques such as spiral reinforcement can be applied during this stage to enhance strength and flexibility. For instance, braiding wire around the hose can significantly improve pressure resistance, which is essential for high-performance fuel applications.

Montagem

After forming, hoses require assembly, which may involve attaching fittings, couplings, or other components. This stage is critical, as improper assembly can lead to leaks or failures under pressure. Automated systems are often used to ensure precision in the fitting process, reducing human error. Additionally, manufacturers may offer customization options, allowing buyers to specify particular lengths, diameters, and connection types.

Illustrative image related to fuel hose manufacturers

Acabamento

The final stage involves applying protective coatings or treatments to enhance durability. This may include weather-resistant layers or anti-abrasive finishes. The hoses are then cut to specified lengths, coiled, and prepared for shipment. Quality checks are performed to ensure that each hose meets the design specifications and performance criteria.

How Is Quality Assurance Ensured in Fuel Hose Manufacturing?

Quality assurance is integral to the manufacturing process, ensuring that products meet international standards and customer expectations. Key components of a robust quality assurance program include adherence to international standards, various quality control checkpoints, and comprehensive testing methods.

Normas internacionais e específicas do sector

Manufacturers often comply with ISO 9001, which focuses on quality management systems, ensuring consistent product quality. Additionally, industry-specific certifications such as CE marking for European markets or API standards for petroleum products are crucial. These certifications reassure B2B buyers that the products have met rigorous safety and quality benchmarks.

Pontos de controlo de qualidade

Quality control involves several checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: This stage involves inspecting incoming materials to confirm they meet specified standards before production begins.

- IPQC: Continuous monitoring during production ensures that any deviations from quality standards are identified and corrected promptly.

- FQC: At this final stage, finished products undergo rigorous testing to verify their performance against specifications.

Métodos de teste comuns

Testing methods vary depending on the intended application of the fuel hoses. Common methods include pressure testing, where hoses are filled with fluid and subjected to pressure to detect leaks; tensile testing to assess material strength; and exposure tests to evaluate resistance to chemicals and environmental factors. These tests provide critical data that help manufacturers ensure that their products can withstand the conditions they will face in use.

Como podem os compradores B2B verificar as práticas de controlo de qualidade dos fornecedores?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Several strategies can be employed to ensure due diligence.

Supplier Audits

Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. These audits can be performed by the buyers themselves or through third-party inspection agencies. An effective audit will assess compliance with international standards and the effectiveness of the supplier’s quality management system.

Quality Reports

Requesting quality reports from suppliers can offer transparency regarding their quality control measures. These reports should detail testing methodologies, results, and any corrective actions taken in response to quality issues. Consistent documentation of quality control practices is a good indicator of a supplier’s commitment to maintaining high standards.

Illustrative image related to fuel hose manufacturers

Third-Party Inspection

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality assurance practices. These services can verify compliance with international standards and provide objective testing results. This step is particularly important for buyers in regions where regulatory compliance may vary.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers must be aware of certain nuances when it comes to quality control, especially when sourcing from diverse markets.

Cultural and Regulatory Differences

Different countries may have varying regulations regarding quality standards. Buyers should familiarize themselves with these differences and ensure that their suppliers comply with both local and international standards. This is particularly relevant for buyers in Africa and South America, where local regulations may differ significantly from European or North American standards.

Communication and Documentation

Effective communication with suppliers is essential. Buyers should ensure that suppliers can provide clear documentation of quality assurance processes and certifications. Language barriers and differing business practices can complicate this, so establishing a strong communication channel is vital.

Building Long-Term Relationships

Establishing long-term partnerships with suppliers can facilitate better quality control. Regular interactions and feedback loops allow buyers to communicate their quality expectations and collaborate on improvements. This relationship can lead to enhanced product quality and innovation over time.

In conclusion, understanding the manufacturing processes and quality assurance measures of fuel hose manufacturers is essential for B2B buyers. By focusing on the key stages of production and implementing robust quality verification practices, buyers can ensure they are sourcing reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fuel hose manufacturers’

To assist B2B buyers in the procurement of fuel hose manufacturers, this guide provides a practical checklist. Following these steps will help ensure that you find reliable suppliers who meet your specific needs, ultimately leading to successful procurement.

Passo 1: Definir as suas especificações técnicas

Before initiating the sourcing process, it is essential to clearly outline the technical requirements for your fuel hoses. This includes specifications such as the type of materials (e.g., rubber, polyurethane), temperature ranges, pressure ratings, and compliance with industry standards. Defining these specifications upfront helps narrow down potential suppliers and ensures that the products will meet your operational needs.

Illustrative image related to fuel hose manufacturers

Passo 2: Research and Identify Potential Suppliers

Conduct thorough research to identify manufacturers that specialize in fuel hoses. Utilize online directories, industry publications, and trade shows to compile a list of potential suppliers. Look for companies with a proven track record in your industry and those that serve similar markets, as they will better understand your specific requirements.

Passo 3: Avaliar as certificações dos fornecedores

Before engaging with a supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001, ITAR registration, or specific automotive industry standards (like SAE) indicate a commitment to quality and safety. Ensuring that suppliers meet these standards minimizes risks associated with product quality and regulatory compliance.

Passo 4: Request Samples and Technical Data Sheets

Once you have shortlisted potential suppliers, request samples of their fuel hoses along with technical data sheets. Evaluating samples allows you to assess the quality, flexibility, and durability of the hoses. Additionally, technical data sheets provide crucial information regarding performance metrics, compatibility with fuels, and maintenance requirements.

Passo 5: Rever os preços e as condições de pagamento

Pricing is a critical factor in supplier selection. Request detailed quotations from your shortlisted suppliers, including pricing for different quantities and any additional costs such as shipping. Pay attention to payment terms; favorable conditions can improve cash flow and overall project viability. Ensure that the pricing aligns with your budget while maintaining the necessary quality standards.

Illustrative image related to fuel hose manufacturers

Passo 6: Check References and Customer Feedback

Before making a final decision, reach out to other businesses that have worked with the suppliers you are considering. Ask for references and read customer reviews to gain insights into the supplier’s reliability, customer service, and overall satisfaction. Positive feedback from similar industries can provide confidence in your choice.

Passo 7: Negotiate Contracts and Delivery Terms

Once you have selected a supplier, negotiate the terms of the contract, focusing on delivery schedules, warranties, and after-sales support. Clear agreements on these aspects help prevent misunderstandings and ensure that both parties are aligned on expectations. Establishing strong terms can also facilitate a smoother procurement process and foster a long-term partnership.

By following this checklist, B2B buyers can systematically approach the sourcing of fuel hose manufacturers, ensuring that they select suppliers who meet their technical requirements and offer reliable service.

Comprehensive Cost and Pricing Analysis for fuel hose manufacturers Sourcing

What Are the Key Cost Components for Fuel Hose Manufacturers?

Understanding the cost structure of fuel hose manufacturers is crucial for B2B buyers. The primary cost components include:

-

Materiais: The choice of raw materials significantly impacts pricing. Common materials such as synthetic rubber, polyurethane, and specialized fabrics can vary in cost based on quality and availability. For instance, hoses designed for high-pressure applications may require more expensive materials.

-

Trabalho: Labor costs encompass both skilled and unskilled labor involved in manufacturing, assembly, and quality control. Countries with higher labor costs may reflect this in the pricing of their hoses.

-

Despesas gerais de fabrico: This includes costs associated with factory operations, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Ferramentas: Investment in specialized tools and machinery can also affect pricing. Custom hoses typically require unique tooling, increasing upfront costs but potentially lowering per-unit costs in high-volume runs.

-

Controlo de qualidade (CQ): Implementing stringent QC processes ensures product reliability but adds to overall costs. Certifications such as ISO or industry-specific standards can further influence pricing.

-

Logística: Transportation costs, including shipping and handling, are crucial, especially for international buyers. The distance from the manufacturing facility to the buyer can add significant costs.

-

Margem: Manufacturers typically apply a markup to cover operational risks and profit margins. This varies by company and market conditions.

How Do Price Influencers Impact Fuel Hose Pricing?

Several factors influence the pricing of fuel hoses, particularly for international B2B buyers:

-

Volume/MOQ (Quantidade mínima de encomenda): Bulk orders often lead to discounts. Buyers should evaluate their needs to negotiate better pricing based on quantity.

-

Especificações e personalização: Custom hoses tailored to specific applications usually come at a premium. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications enhance product reliability but increase costs. Buyers should assess the trade-offs between price and quality.

-

Factores do fornecedor: Supplier reputation, reliability, and market position can affect pricing. Established suppliers may charge more due to perceived quality and service levels.

-

Incoterms: Understanding delivery terms is essential. Different Incoterms (e.g., FOB, CIF) can significantly alter landed costs, affecting the total price.

What Buyer Tips Can Enhance Cost-Efficiency in Fuel Hose Sourcing?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should consider the following strategies for cost-efficient sourcing:

-

Negotiate Effectively: Building strong relationships with suppliers can lead to better pricing. Open discussions about volume and future orders can yield favorable terms.

-

Assess Total Cost of Ownership (TCO): Beyond initial costs, consider maintenance, replacement, and potential downtime associated with lower-quality hoses. A cheaper initial price may lead to higher long-term costs.

-

Compreender as nuances dos preços: Be aware of regional pricing trends and economic factors that may influence costs. For example, currency fluctuations can impact international purchases.

-

Evaluate Multiple Suppliers: Always compare quotes from various manufacturers. This not only helps in finding competitive pricing but also provides insight into market standards.

-

Stay Informed on Market Trends: Keeping abreast of industry developments, such as material shortages or shifts in demand, can provide leverage in negotiations and help anticipate pricing changes.

Declaração de exoneração de responsabilidade

The prices discussed herein are indicative and can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. It’s advisable to consult directly with manufacturers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing fuel hose manufacturers With Other Solutions

Understanding Alternatives in Fuel Hose Solutions

In the quest for efficient fuel transfer solutions, B2B buyers often explore various options beyond traditional fuel hose manufacturers. While fuel hoses are essential for safe and effective fuel handling, alternatives may offer distinct advantages or cater to specific operational needs. This analysis compares fuel hoses with alternative solutions, helping buyers make informed decisions based on performance, cost, and other critical factors.

Illustrative image related to fuel hose manufacturers

| Aspeto de comparação | Fuel Hose Manufacturers | Composite Fuel Lines | Metal Hose Solutions |

|---|---|---|---|

| Desempenho | High flexibility and resistance to various fuels | Excellent chemical resistance and lightweight | High durability and heat resistance |

| Custo | Moderate to high, depending on material and customizations | Generally higher due to advanced materials | Higher initial investment but longer lifespan |

| Facilidade de implementação | Straightforward installation with standard fittings | Requires specialized fittings and installation | Complex installation requiring skilled labor |

| Manutenção | Moderate; regular checks needed for wear | Low; less frequent replacement | Low; resistant to wear and tear |

| Melhor caso de utilização | General fuel transfer in automotive and marine applications | High-performance applications, including motorsports | Extreme conditions such as high pressure and temperature |

What Are Composite Fuel Lines and Their Benefits?

Composite fuel lines are made from a blend of materials designed to provide superior chemical resistance and lower weight compared to traditional rubber hoses. They excel in high-performance environments, such as motorsports, where weight reduction is crucial. However, these lines typically come at a higher cost due to the advanced materials used in their construction. Installation can be more complex, requiring specialized fittings, which may increase labor costs.

How Do Metal Hose Solutions Compare?

Metal hoses, often constructed from stainless steel or other alloys, provide exceptional durability and resistance to high temperatures and pressures. They are ideal for extreme environments where traditional hoses may fail. While the initial investment is higher, metal hoses often have a longer lifespan and lower maintenance needs, making them a cost-effective choice in the long run. However, their installation can be more complex and may require skilled labor, which could add to upfront costs.

Conclusion: How to Choose the Right Fuel Transfer Solution

When evaluating fuel transfer solutions, B2B buyers should consider the specific requirements of their operations, including the nature of the fuel being handled, environmental conditions, and budget constraints. Fuel hoses are versatile and suitable for many applications, while composite lines may offer advantages in weight-sensitive scenarios. Metal hoses are best for extreme conditions requiring durability. A thorough assessment of performance, cost, and maintenance will guide buyers in selecting the most appropriate solution for their unique needs.

Essential Technical Properties and Trade Terminology for fuel hose manufacturers

What Are the Key Technical Properties of Fuel Hoses for Manufacturers?

Understanding the essential technical properties of fuel hoses is crucial for manufacturers and B2B buyers, as these specifications directly influence the performance, safety, and suitability of hoses for various applications. Here are several critical specifications to consider:

-

Grau do material

Fuel hoses are typically made from materials such as synthetic rubber, polyurethane, or thermoplastics. The material grade affects the hose’s resistance to chemicals, temperature, and abrasion. For instance, nitrile rubber is commonly used for its excellent oil and fuel resistance, making it suitable for automotive and industrial applications. Selecting the right material grade ensures durability and compliance with industry standards. -

Working Pressure

This specification refers to the maximum pressure a hose can handle during operation without failure. It is usually measured in psi (pounds per square inch). Understanding the working pressure is vital for ensuring that the hose can withstand the pressures encountered in fuel transfer systems. Selecting a hose with an appropriate working pressure minimizes the risk of leaks and ruptures, which can lead to hazardous situations. -

Temperature Tolerance

Fuel hoses must be able to operate effectively within specific temperature ranges. This tolerance is crucial because extreme temperatures can affect the integrity of the hose material, leading to degradation or failure. Buyers should consider the operating environment of their application to select hoses that maintain performance under expected temperature conditions. -

Raio de curvatura

The bend radius is the minimum radius a hose can be bent without compromising its structural integrity. A smaller bend radius allows for greater flexibility in installations, but it can also increase the risk of kinking or damage. Understanding this property is essential for manufacturers to ensure that hoses can be installed in tight spaces without affecting performance. -

Reinforcement Type

Many fuel hoses include reinforcements, such as wire braids or spirals, to enhance strength and pressure resistance. The type and configuration of reinforcement affect the hose’s flexibility, durability, and resistance to external forces. For B2B buyers, knowing the reinforcement type helps in selecting hoses that meet specific application requirements, especially in high-stress environments.

What Are Common Trade Terms in the Fuel Hose Industry?

Familiarity with trade terminology is essential for effective communication and negotiation in the fuel hose market. Here are some common terms that B2B buyers should know:

-

OEM (Fabricante de Equipamento Original)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for specific hose specifications that are compatible with existing systems. -

MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest order quantity that a supplier is willing to sell. This term is significant for buyers who need to manage inventory costs and ensure they are ordering a sufficient quantity to meet their operational needs without overcommitting financially. -

RFQ (Pedido de Cotação)

An RFQ is a standard business process where a buyer requests a price quote from suppliers. This process helps buyers compare prices and terms before making purchasing decisions, ensuring they receive competitive offers. -

Incoterms

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is crucial for buyers to clarify who is responsible for shipping costs, insurance, and risk during transportation. -

Prazo de execução

This term refers to the amount of time it takes from placing an order to receiving the product. Knowledge of lead times is essential for planning and ensures that buyers can manage their supply chain effectively, especially in industries where timely delivery is critical. -

Compliance Standards

Compliance standards refer to industry regulations that fuel hoses must meet, such as those set by organizations like ASTM or SAE. Understanding these standards helps buyers ensure that the products they purchase are safe, reliable, and suitable for their intended applications.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing fuel hoses, ultimately leading to better operational efficiency and safety in their applications.

Navigating Market Dynamics and Sourcing Trends in the fuel hose manufacturers Sector

What are the Current Market Dynamics and Key Trends in the Fuel Hose Manufacturers Sector?

The global fuel hose manufacturers sector is currently experiencing significant transformations driven by technological advancements and changing market demands. Key factors propelling this growth include the rising energy needs in developing regions, especially in Africa and South America, and the increasing adoption of advanced materials and manufacturing techniques in Europe and the Middle East. International B2B buyers are particularly focused on sourcing fuel hoses that comply with stringent safety and regulatory standards, which are becoming more prevalent in the industry.

Emerging trends include the integration of smart technologies into manufacturing processes, such as IoT-enabled monitoring systems that enhance quality control and supply chain efficiency. Manufacturers are also leveraging automation to improve production speeds and reduce labor costs, which is particularly beneficial for large-scale operations in regions like Germany. Additionally, there is a notable shift towards customizable solutions, where buyers can specify requirements for flexibility, temperature resistance, and pressure tolerance, catering to specific applications in automotive, aerospace, and industrial sectors.

Illustrative image related to fuel hose manufacturers

The competitive landscape is intensifying as manufacturers expand their global reach, often partnering with local distributors to penetrate emerging markets effectively. This strategy not only helps in navigating complex regulatory environments but also ensures that products are tailored to local market needs. As such, international buyers must remain agile and informed about these dynamics to make strategic sourcing decisions that align with their operational requirements and market conditions.

How Does Sustainability and Ethical Sourcing Influence B2B Purchasing in the Fuel Hose Sector?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the fuel hose manufacturing sector. The environmental impact of production processes and the lifecycle of materials used in fuel hoses are under scrutiny as companies strive to enhance their corporate social responsibility (CSR) profiles. International buyers, especially those in regions with stringent environmental regulations, are increasingly favoring suppliers that demonstrate a commitment to sustainable practices.

This shift has led to a growing demand for ‘green’ certifications and materials. Manufacturers are exploring alternatives to traditional rubber and synthetic materials, opting instead for biodegradable or recyclable options that minimize ecological footprints. Additionally, the use of eco-friendly production methods is gaining traction, with companies adopting practices that reduce waste and energy consumption. Buyers are encouraged to inquire about a manufacturer’s sustainability practices, including their sourcing of raw materials, waste management strategies, and overall carbon footprint.

Moreover, ethical supply chains are crucial in building trust with consumers and stakeholders. Buyers are prioritizing manufacturers that can provide transparency regarding their sourcing practices, ensuring that materials are obtained without exploitation or harm to communities. By aligning procurement strategies with sustainability goals, B2B buyers can not only enhance their brand reputation but also contribute to a more sustainable future in the fuel hose sector.

Illustrative image related to fuel hose manufacturers

What is the Evolution of the Fuel Hose Manufacturing Sector and Its Relevance to Today’s Buyers?

The fuel hose manufacturing sector has evolved significantly over the past few decades, transitioning from basic rubber hoses to sophisticated products engineered for high performance and safety. Initially, the industry was characterized by limited technology and basic materials, focusing primarily on functionality. However, as global standards have tightened and the demand for specialized applications has increased, manufacturers have invested in research and development to enhance product offerings.

The introduction of advanced materials, such as synthetic rubbers and polymers, has enabled manufacturers to produce hoses that withstand extreme temperatures, pressures, and chemical exposures. This evolution is particularly relevant for today’s B2B buyers who require durable and reliable solutions for diverse applications ranging from automotive to industrial settings.

Furthermore, the rise of digital technologies has transformed the manufacturing landscape, allowing for more efficient production processes and better supply chain management. Buyers now benefit from enhanced product customization options and improved lead times, making it essential for them to stay informed about the latest advancements and trends within the sector. Understanding this evolution helps buyers make informed decisions that align with their operational needs and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of fuel hose manufacturers

1. How do I select the right fuel hose manufacturer for my business needs?

To select the right fuel hose manufacturer, start by assessing your specific requirements such as hose type, pressure ratings, temperature resistance, and material compatibility. Research potential manufacturers by checking their certifications, industry experience, and client testimonials. Additionally, request samples to evaluate the quality of their products. Consider their ability to customize hoses to fit your unique applications and their capacity for large orders. Engaging in direct communication can also help gauge their responsiveness and customer service.

2. What are the key factors to consider when sourcing fuel hoses internationally?

When sourcing fuel hoses internationally, consider factors such as compliance with local regulations and industry standards in your region. Evaluate the manufacturer’s reputation, production capabilities, and lead times. Logistics is crucial; assess shipping costs, customs duties, and delivery timelines. Payment terms should also be clearly defined to avoid any financial disputes. Lastly, ensure the manufacturer has robust quality assurance processes in place to deliver reliable products.

Illustrative image related to fuel hose manufacturers

3. What is the minimum order quantity (MOQ) for fuel hoses?

Minimum order quantities (MOQs) for fuel hoses can vary significantly between manufacturers and depend on the specific type of hose, materials used, and customization requirements. Typically, MOQs can range from as low as 100 meters to several thousand meters for standard products. It’s essential to discuss your needs directly with potential suppliers, as some may offer flexibility in MOQs for larger orders or long-term contracts. Always clarify any potential penalties for not meeting MOQ requirements.

4. How can I ensure the quality of fuel hoses from a manufacturer?

To ensure the quality of fuel hoses, inquire about the manufacturer’s quality assurance protocols, such as ISO certifications and testing methods. Request documentation of test results for specific batches, including pressure tests and material certifications. A reputable manufacturer will be transparent about their quality processes and may offer warranties on their products. Additionally, consider conducting factory visits or third-party inspections to assess production practices and quality control measures.

5. What customization options are typically available for fuel hoses?

Most fuel hose manufacturers offer a variety of customization options, including different sizes, lengths, and materials tailored to specific applications. Customization may also encompass features such as varying pressure ratings, bend radii, and resistance to specific chemicals or temperatures. Some manufacturers can also provide branded or color-coded hoses. Discuss your unique needs with potential suppliers to determine the extent of customization they can accommodate.

6. What payment terms should I expect when dealing with international fuel hose manufacturers?

Payment terms can vary by manufacturer, but common practices include upfront deposits (typically 30-50%) with the balance due upon shipment or delivery. Some manufacturers may offer letters of credit or payment through escrow services for larger orders, which can provide additional security. It’s crucial to negotiate and agree on payment terms before finalizing any contracts to avoid misunderstandings. Always ensure that the terms are documented in the purchase agreement.

7. How do logistics and shipping affect my fuel hose procurement?

Logistics and shipping play a significant role in fuel hose procurement, impacting delivery times and overall costs. Consider factors such as the manufacturer’s location, shipping methods, and associated freight costs. Understand the customs regulations in your country, as they may affect the delivery timeline and additional fees. Engaging a logistics partner familiar with international trade can help streamline the process, ensuring timely delivery and compliance with all regulations.

8. What steps should I take if I encounter issues with my fuel hose order?

If you encounter issues with your fuel hose order, first review your purchase agreement and any communication with the manufacturer to ensure that you have complied with all terms. Document the specific issues, including photographs or samples of defective products. Contact the manufacturer directly to discuss the problem and seek resolution, whether it’s a replacement, refund, or another form of compensation. Maintaining clear, professional communication can facilitate a smoother resolution process.

Top 5 Fuel Hose Manufacturers Manufacturers & Suppliers List

1. Gates – Fuel Line Hose

Domínio: gates.com

Registered: 1994 (31 years)

Introdução: Fuel Line Hose designed for fuel-efficient and environmentally-safe performance. Available in various inside diameters ranging from 3.2 mm to 101.6 mm (0.125 in to 4.00 in) and outside diameters ranging from 0.36 in to 0.92 in. Suitable for enhancing engine performance.

2. Continental – Fuel Lines for Engines

Domínio: continental-industry.com

Registered: 2018 (7 years)

Introdução: Continental Fuel Lines for Engines, including Cooling Water Lines, Fuel Supply Lines, and Oil Lines. Designed for various applications in Passenger Cars, Commercial Vehicles, Industrial Vehicles, and Two-Wheelers. Features include high durability and resistance to extreme temperatures, suitable for both standard and special applications.

3. McGill Hose – Tigerdrop™ Clear Drop Hose TDH Series

Domínio: mcgillhose.com

Registada: 2000 (25 anos)

Introdução: McGill Hose offers a variety of Fuel Drop/Delivery Hoses from manufacturers like Continental ContiTech, Kuriyama, and Novaflex. Key products include: 1. Tigerdrop™ Clear Drop Hose TDH Series – Biofuel compatible, handles gasoline, ethanol, diesel, and biodiesel. Features non-permeable, phthalate-free polyurethane construction, grounding wire for static electricity dissipation, and an easy slide he…

4. Fisheries Supply – Marine Fuel Hoses

Domínio: fisheriessupply.com

Registada: 1998 (27 anos)

Introdução: This company, Fisheries Supply – Marine Fuel Hoses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. TIPCO Technologies – Fluid Solutions

Domínio: shop.tipcotech.com

Registada: 2001 (24 anos)

Introdução: This company, TIPCO Technologies – Fluid Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for fuel hose manufacturers

In the evolving landscape of fuel hose manufacturing, strategic sourcing emerges as a critical component for international B2B buyers. By prioritizing suppliers with a strong track record in quality, customization, and compliance, businesses can ensure a reliable supply chain that meets specific operational needs. Key takeaways from our guide highlight the importance of selecting manufacturers that offer robust product features, such as temperature resistance, flexibility, and durability, which are essential for various applications across industries.

Moreover, leveraging relationships with manufacturers from diverse regions—particularly those in Africa, South America, the Middle East, and Europe—can provide competitive advantages, including cost efficiency and access to innovative technologies. As global demand for fuel hoses continues to rise, buyers should remain proactive in evaluating their sourcing strategies, focusing on suppliers that can adapt to changing market dynamics.

Looking ahead, the future of fuel hose manufacturing holds promise with advancements in materials and production techniques. We encourage B2B buyers to take action now by engaging with reliable suppliers and exploring new opportunities that align with their business objectives. By doing so, you will not only enhance your operational efficiency but also position your company for long-term success in an increasingly competitive marketplace.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, pedir amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.