Introduction: Navigating the Global Market for high pressure rubber tubing

In the dynamic landscape of global commerce, sourcing high pressure rubber tubing presents a unique set of challenges for B2B buyers. With applications spanning hydraulic systems, gas and water supply, and various industrial processes, the demand for reliable tubing solutions is paramount. Buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate a complex market characterized by diverse product specifications, regulatory standards, and varying supplier capabilities. This guide serves as an essential resource, empowering decision-makers by providing comprehensive insights into the types of high pressure rubber tubing available, their specific applications, and critical considerations for supplier vetting.

Understanding the nuances of different hose constructions—such as steel wire reinforced, textile reinforced, and thermoplastic options—can significantly impact operational efficiency and safety. Additionally, we will delve into pricing structures, procurement strategies, and best practices for installation to ensure optimal performance. By equipping international buyers with the knowledge to make informed purchasing decisions, this guide aims to streamline the sourcing process, ultimately leading to enhanced productivity and reduced operational risks. Whether you are seeking to procure high pressure hoses for hydraulic systems or exploring innovative solutions for your industrial needs, this comprehensive guide will be your trusted companion in navigating the global market.

Índice

- Top 8 High Pressure Rubber Tubing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for high pressure rubber tubing

- Understanding high pressure rubber tubing Types and Variations

- Key Industrial Applications of high pressure rubber tubing

- 3 Common User Pain Points for ‘high pressure rubber tubing’ & Their Solutions

- Strategic Material Selection Guide for high pressure rubber tubing

- In-depth Look: Manufacturing Processes and Quality Assurance for high pressure rubber tubing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘high pressure rubber tubing’

- Comprehensive Cost and Pricing Analysis for high pressure rubber tubing Sourcing

- Alternatives Analysis: Comparing high pressure rubber tubing With Other Solutions

- Essential Technical Properties and Trade Terminology for high pressure rubber tubing

- Navigating Market Dynamics and Sourcing Trends in the high pressure rubber tubing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of high pressure rubber tubing

- Strategic Sourcing Conclusion and Outlook for high pressure rubber tubing

- Aviso importante e termos de utilização

Understanding high pressure rubber tubing Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Steel Wire Reinforced Hose | Composed of synthetic rubber with braided steel wire reinforcement | Hydraulic machinery, construction, and industrial use | Prós: High pressure resistance, durable; Contras: Less flexible compared to textile hoses. |

| Steel Wire Spiraled Hose | Features multiple layers of spiraled steel wire for extreme pressure | Oil and gas exploration, hydraulic systems | Prós: Excellent pressure tolerance; Contras: Heavier and bulkier than other types. |

| Textile Reinforced Hose | Lightweight with textile fabric reinforcement for flexibility | Agriculture, air compressors, and low-pressure systems | Prós: Highly flexible and lightweight; Contras: Lower pressure resistance than steel-reinforced hoses. |

| Thermoplastic Hydraulic Hose | Made from thermoplastic materials, providing flexibility and lightweight | Water-based hydraulic systems, general fluid transfer | Prós: Long service life, resistant to various fluids; Contras: May not withstand extreme temperatures. |

| Rotary Drilling Hose | Specialized for drilling applications, can handle high temperatures and pressures | Oil drilling, geological exploration | Prós: Designed for harsh environments; Contras: Typically more expensive due to specialized construction. |

What Are the Characteristics of Steel Wire Reinforced Hoses?

Steel wire reinforced hoses are designed for high-pressure applications, making them ideal for hydraulic machinery and industrial use. These hoses consist of a synthetic rubber inner tube, a steel wire braided reinforcement, and a durable outer cover. The robust construction offers excellent resistance to abrasion and environmental factors, ensuring longevity in demanding conditions. When purchasing, buyers should consider the specific pressure requirements and compatibility with the fluids being conveyed.

How Do Steel Wire Spiraled Hoses Differ?

Steel wire spiraled hoses are characterized by their multiple layers of spiraled steel wire, providing superior strength and resistance to extreme pressure. This type is commonly used in oil and gas exploration, where high-pressure environments are prevalent. The construction allows for flexibility while maintaining a high burst pressure rating. Buyers should assess the hose’s weight and bulkiness against their application needs, as these hoses can be heavier than other types.

Why Choose Textile Reinforced Hoses?

Textile reinforced hoses are favored for their lightweight and flexible nature, making them suitable for applications such as agriculture and air compressors. These hoses typically feature a synthetic rubber inner tube with textile fabric reinforcement, allowing for easy handling and installation. However, they have lower pressure resistance compared to steel-reinforced options. B2B buyers should weigh the need for flexibility against the pressure requirements of their specific applications.

What Are the Advantages of Thermoplastic Hydraulic Hoses?

Thermoplastic hydraulic hoses are known for their flexibility and lightweight properties, making them ideal for water-based hydraulic systems and general fluid transfer. Constructed from high-quality thermoplastic materials, they offer a long service life and resistance to various fluids. However, they may not perform well in extreme temperature environments. Buyers should consider the working temperature range and fluid compatibility when selecting thermoplastic hoses.

When to Use Rotary Drilling Hoses?

Rotary drilling hoses are specially designed for high-temperature and high-pressure applications in oil drilling and geological exploration. They feature a robust construction that can withstand harsh environments, including abrasion and corrosive fluids. While these hoses tend to be more expensive due to their specialized design, they are essential for safe and efficient drilling operations. B2B buyers should prioritize the specific requirements of their drilling applications when selecting these hoses.

Key Industrial Applications of high pressure rubber tubing

| Indústria/Setor | Specific Application of high pressure rubber tubing | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Petróleo e gás | Sistemas hidráulicos para perfuração e extração | Ensures reliable fluid transfer under extreme pressure | Compliance with international standards (ISO, SAE) |

| Construção e exploração mineira | Water and slurry transfer in heavy machinery | Enhances operational efficiency and reduces downtime | Durability against abrasion and environmental conditions |

| Agricultura | Irrigation and spraying systems | Improves crop yield and water conservation | Flexibility and resistance to weather conditions |

| Manufacturing & Automation | Power transmission in machinery | Increases productivity and equipment lifespan | Compatibility with hydraulic fluids and temperature ranges |

| Automotive & Transportation | Fuel and oil transfer in vehicle systems | Enhances safety and performance of vehicles | Resistance to oil, heat, and mechanical stress |

How is High Pressure Rubber Tubing Used in the Oil & Gas Industry?

In the oil and gas sector, high pressure rubber tubing is critical for hydraulic systems used in drilling and extraction processes. These hoses are engineered to withstand extreme pressures and corrosive environments, ensuring safe and efficient fluid transfer. B2B buyers in this industry must prioritize sourcing hoses that comply with international standards, such as ISO and SAE, to guarantee performance and safety in challenging conditions typical of oil extraction sites.

What Role Does High Pressure Rubber Tubing Play in Construction & Mining?

In construction and mining, high pressure rubber tubing facilitates the transfer of water and slurries in heavy machinery, enabling efficient operation in rugged environments. These hoses are designed to resist abrasion and withstand various environmental factors, which is essential for maintaining productivity. Buyers in these sectors should consider the durability and flexibility of the tubing, ensuring it meets the specific demands of their operational conditions.

How is High Pressure Rubber Tubing Beneficial for Agriculture?

High pressure rubber tubing is widely used in irrigation and spraying systems within the agriculture industry. This tubing helps deliver water and fertilizers effectively, contributing to improved crop yield and efficient water use. When sourcing for agricultural applications, buyers should focus on the tubing’s flexibility and resistance to weather-related wear, ensuring long-term reliability in varying climatic conditions.

In What Ways Does High Pressure Rubber Tubing Enhance Manufacturing & Automation?

In manufacturing and automation, high pressure rubber tubing is essential for power transmission in hydraulic machinery. This application enhances productivity and extends the lifespan of equipment by ensuring reliable fluid flow under pressure. B2B buyers should look for hoses that are compatible with various hydraulic fluids and can operate within specified temperature ranges, ensuring optimal performance in industrial settings.

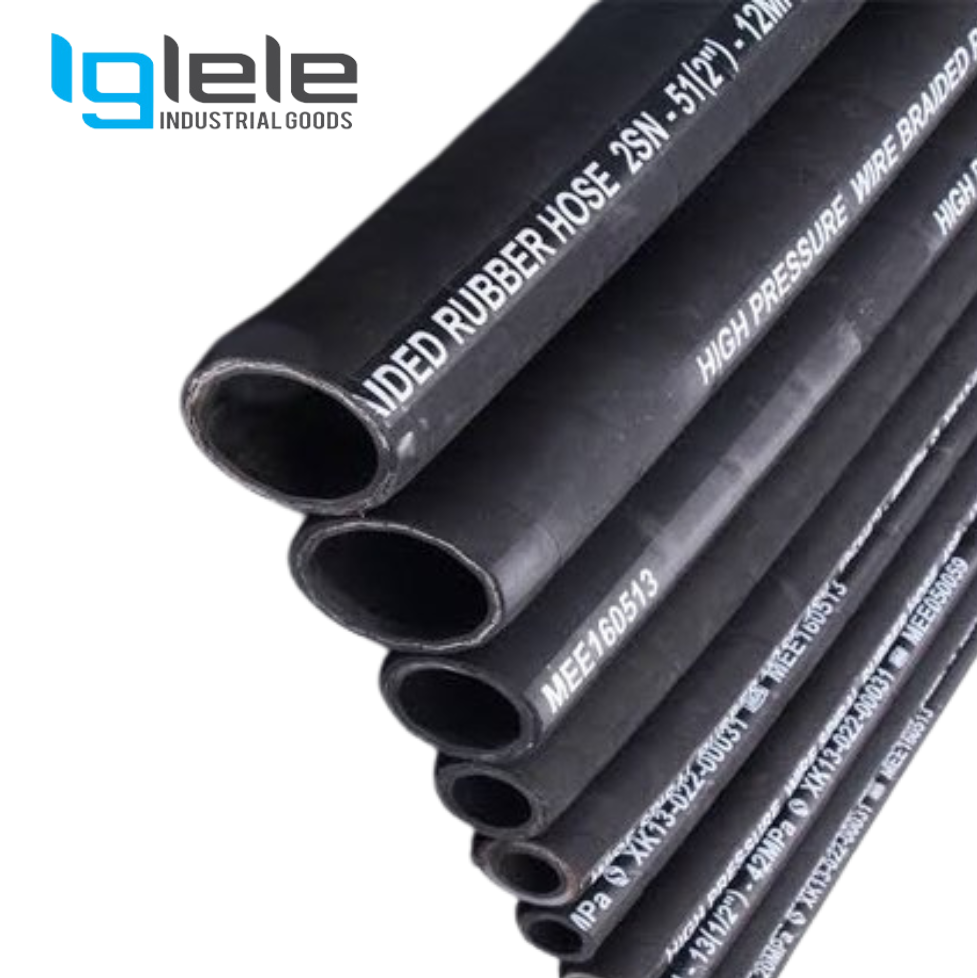

Illustrative image related to high pressure rubber tubing

How Does High Pressure Rubber Tubing Improve Safety in Automotive & Transportation?

In the automotive and transportation industries, high pressure rubber tubing is used for the transfer of fuel and oil in vehicle systems. This application is vital for enhancing vehicle safety and performance, as reliable fluid transfer is crucial for engine operation. Buyers should ensure that the tubing they source is resistant to oil, heat, and mechanical stress, thereby reducing the risk of leaks and ensuring the longevity of vehicle systems.

3 Common User Pain Points for ‘high pressure rubber tubing’ & Their Solutions

Scenario 1: Inconsistent Quality Leading to Equipment Downtime

O problema: B2B buyers frequently encounter issues with the inconsistent quality of high-pressure rubber tubing, which can lead to unexpected equipment failures and costly downtime. For instance, a manufacturer in Nigeria may source tubing that fails to meet the required pressure specifications or shows premature wear due to inadequate material quality. This not only disrupts production schedules but also raises safety concerns, particularly in industries dealing with hazardous materials.

A solução: To mitigate quality inconsistency, buyers should establish a robust supplier evaluation process. This involves sourcing tubing from reputable manufacturers who provide detailed product specifications and certifications, such as ISO standards. Buyers should also request samples for testing before making bulk purchases. Implementing a quality assurance protocol that includes regular inspections of incoming materials and establishing performance benchmarks can further ensure that the tubing meets operational demands. Additionally, having a contingency plan for alternative suppliers can minimize downtime in case of quality issues.

Scenario 2: Difficulty in Finding Suitable Tubing for Specific Applications

O problema: Many buyers face challenges in identifying the right type of high-pressure rubber tubing for specialized applications, such as those requiring resistance to extreme temperatures or specific chemical exposures. For example, a company in Brazil may need tubing for a hydraulic system that operates at high temperatures and in corrosive environments, but standard offerings do not meet these specific requirements. This can lead to subpar performance and increased maintenance costs.

A solução: To overcome this challenge, buyers should engage with suppliers who specialize in custom solutions. Detailed discussions about the operational environment, including temperature ranges, chemical exposure, and pressure requirements, will help suppliers recommend the most suitable products. Buyers can also leverage industry-specific guidelines or standards, such as those provided by SAE or ISO, to narrow down their options. Additionally, investing in a thorough market research phase can uncover innovative tubing technologies, such as thermoplastic options that offer enhanced flexibility and durability under demanding conditions.

Scenario 3: Complications with Installation and Maintenance

O problema: Installation and maintenance of high-pressure rubber tubing can be daunting, particularly for businesses without dedicated technical staff. In regions like the Middle East, where temperatures can soar, improper installation may lead to premature failure of the hoses, resulting in operational disruptions. Buyers may find themselves grappling with installation errors or insufficient maintenance practices that jeopardize the longevity of the tubing.

A solução: To simplify installation and maintenance, buyers should prioritize suppliers that provide comprehensive installation guides and support. This may include instructional videos, detailed manuals, and on-site assistance. Additionally, implementing a routine maintenance schedule that includes regular inspections for wear and tear can significantly extend the lifespan of the tubing. Training sessions for existing staff on proper installation techniques and maintenance practices can also be beneficial. By investing in education and resources, businesses can ensure their high-pressure rubber tubing operates efficiently and safely, minimizing the risk of failures.

Strategic Material Selection Guide for high pressure rubber tubing

What Are the Key Materials Used in High Pressure Rubber Tubing?

When selecting high pressure rubber tubing, understanding the materials involved is crucial for ensuring optimal performance in various applications. Here, we analyze four common materials used in high pressure rubber tubing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Do Synthetic Rubber Materials Perform in High Pressure Applications?

Propriedades principais: Synthetic rubber, such as EPDM (Ethylene Propylene Diene Monomer) and NBR (Nitrile Butadiene Rubber), is known for its excellent temperature resistance, typically ranging from -40°C to +100°C. These materials also exhibit good resistance to oils, fuels, and weathering, making them suitable for various hydraulic applications.

Prós e contras: The durability of synthetic rubber is a significant advantage, as it can withstand harsh environmental conditions. However, the manufacturing process can be complex, leading to higher costs. While synthetic rubber is versatile, its compatibility with certain aggressive chemicals may be limited, requiring careful consideration.

Impacto na aplicação: Synthetic rubber tubing is widely used in hydraulic systems for vehicles and machinery, where it is essential to handle oils and hydraulic fluids. Buyers should ensure compatibility with the specific media being conveyed.

Considerações para compradores internacionais: Compliance with international standards such as ASTM and ISO is essential. Buyers from regions like Africa and South America should verify that the synthetic rubber meets local environmental regulations, particularly regarding oil and chemical resistance.

What Advantages Do Steel Wire Reinforced Hoses Offer?

Propriedades principais: Steel wire reinforced hoses are designed to withstand extremely high pressures, with ratings often exceeding 350 bar. The combination of synthetic rubber with steel reinforcement provides exceptional tensile strength and flexibility.

Prós e contras: The primary advantage of steel wire reinforced hoses is their ability to handle high-pressure applications without bursting. However, they can be heavier and less flexible than other options, which may complicate installation and handling. Additionally, the higher manufacturing complexity can lead to increased costs.

Impacto na aplicação: These hoses are ideal for applications in hydraulic systems, oil and gas extraction, and heavy machinery. Their robust design makes them suitable for transporting high-pressure fluids safely.

Illustrative image related to high pressure rubber tubing

Considerações para compradores internacionais: Buyers in the Middle East and Europe should pay attention to compliance with EN and SAE standards, ensuring that the hoses are certified for their intended use. Local regulations regarding safety and environmental impact should also be considered.

How Do Textile Reinforced Hoses Compare?

Propriedades principais: Textile reinforced hoses are lightweight and flexible, typically made from synthetic rubber and reinforced with textile fibers. They can handle pressures up to 20 bar and temperatures ranging from -40°C to +100°C.

Prós e contras: The flexibility and lightweight nature of textile reinforced hoses make them easy to install and maneuver, which is a significant advantage in tight spaces. However, they offer lower pressure ratings compared to steel reinforced hoses, limiting their use in high-pressure applications.

Impacto na aplicação: These hoses are commonly used in agricultural and irrigation systems, as well as in low-pressure hydraulic applications. Their compatibility with water and mild chemicals makes them suitable for various industries.

Considerações para compradores internacionais: Buyers should ensure that textile reinforced hoses comply with local standards, especially in regions with varying climatic conditions, such as Africa and South America. Understanding the specific application requirements is crucial for selecting the right hose.

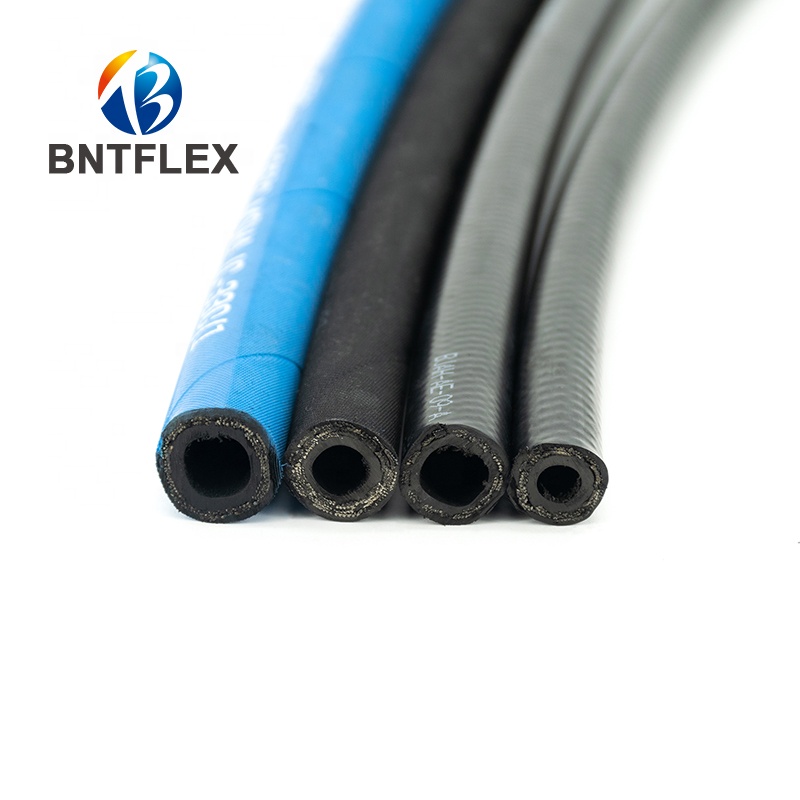

What Role Do Thermoplastic Hoses Play in High Pressure Systems?

Propriedades principais: Thermoplastic hoses are made from high-quality thermoplastics and can operate effectively at temperatures up to 100°C. They are lightweight and offer good chemical resistance.

Prós e contras: The main advantage of thermoplastic hoses is their flexibility and ease of installation. They are often less expensive than rubber hoses but may not provide the same durability under extreme conditions. Their lower pressure ratings can also limit their applications.

Impacto na aplicação: Thermoplastic hoses are suitable for a range of applications, including low-pressure hydraulic systems and air transfer. They are particularly useful in industries where weight and flexibility are critical.

Considerações para compradores internacionais: Buyers should verify compliance with relevant standards, such as ISO and ASTM, to ensure product reliability. Additionally, understanding local market preferences for materials can guide purchasing decisions.

Summary Table of Material Selection for High Pressure Rubber Tubing

| Material | Typical Use Case for high pressure rubber tubing | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha sintética | Hydraulic systems for vehicles and machinery | Excellent temperature and oil resistance | Limited chemical compatibility | Médio |

| Steel Wire Reinforced Hose | Oil and gas extraction, heavy machinery | High pressure tolerance | Heavier and less flexible | Elevado |

| Textile Reinforced Hose | Agricultural and irrigation systems | Lightweight and flexible | Lower pressure ratings | Baixa |

| Thermoplastic Hose | Low-pressure hydraulic systems, air transfer | Flexible and easy to install | Lower durability under extreme conditions | Médio |

This guide aims to assist B2B buyers in making informed decisions regarding material selection for high pressure rubber tubing, ensuring compliance with international standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for high pressure rubber tubing

What are the Key Stages in the Manufacturing Process of High Pressure Rubber Tubing?

The manufacturing of high pressure rubber tubing involves several critical stages, each designed to ensure the end product meets stringent performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to high pressure rubber tubing

-

Preparação do material

The foundation of high pressure rubber tubing lies in the selection of raw materials. High-quality synthetic rubber compounds are chosen based on the specific application requirements, such as resistance to abrasion, heat, and chemicals. During this stage, materials are mixed with various additives to enhance properties like flexibility, durability, and resistance to environmental factors. This process often employs advanced mixing techniques such as Banbury mixing or internal mixers to achieve a homogeneous blend. -

Formação

The forming stage involves shaping the prepared rubber into the desired hose configuration. This is typically achieved through extrusion, where the rubber compound is forced through a die to create a continuous tube. The process can be adjusted to meet varying diameters and wall thicknesses as required by specific applications. In some cases, additional components such as steel wire or textile reinforcements are integrated during extrusion to enhance the hose’s structural integrity and pressure resistance. -

Montagem

After forming, the hoses undergo an assembly process where reinforcement layers are added. These may consist of spiral or braided steel wire, which is crucial for maintaining the hose’s strength under high pressure. The assembly stage also includes the attachment of fittings, which are essential for connecting hoses to machinery or systems. This stage demands precision to ensure that all components fit securely, preventing leaks or failures during operation. -

Acabamento

The final stage in the manufacturing process is finishing, which involves curing the hoses through a vulcanization process. This step is critical for cross-linking the rubber molecules, which enhances the overall strength and elasticity of the tubing. After curing, hoses are inspected for surface defects and dimensional accuracy before being packaged for distribution.

What Quality Control Measures are Essential for High Pressure Rubber Tubing?

Quality control (QC) is vital in the manufacturing of high pressure rubber tubing to ensure that products meet international standards and customer expectations. Various quality assurance methods and international standards guide this process.

-

International Standards and Certifications

High pressure rubber tubing manufacturers often comply with international standards such as ISO 9001, which focuses on quality management systems. Other relevant certifications may include CE marking for compliance with EU regulations and API standards for products used in oil and gas applications. These certifications assure buyers that the products have undergone rigorous testing and meet safety and performance criteria. -

Key QC Checkpoints

A structured QC process typically includes several checkpoints:

– Controlo de qualidade de entrada (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified requirements before production begins.

– Controlo de qualidade durante o processo (IPQC): During the manufacturing process, random samples are taken to monitor quality at various stages, ensuring that production adheres to established standards.

– Controlo de qualidade final (FQC): Finished products undergo comprehensive testing to verify that they meet all specifications, including pressure tests, dimensional checks, and visual inspections for defects. -

Métodos de teste comuns

Various testing methods are employed to assess the performance of high pressure rubber tubing. These include:

– Hydraulic Pressure Testing: Determines the hose’s ability to withstand specified pressure levels.

– Abrasion Resistance Testing: Evaluates the outer layer’s durability against wear.

– Temperature Resistance Testing: Assesses how well the hose performs at elevated temperatures, ensuring it can operate within required thermal limits.

Como podem os compradores B2B verificar o controlo de qualidade dos fornecedores?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

-

Supplier Audits

Conducting on-site audits allows buyers to evaluate the manufacturing facilities and QC processes firsthand. During these audits, buyers can review documentation related to quality management systems, test results, and compliance with international standards. -

Pedido de relatórios de qualidade

Buyers should request detailed quality reports from suppliers, including certificates of compliance, test results, and any relevant audit findings. This documentation serves as proof of the supplier’s commitment to maintaining high standards. -

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. These agencies can conduct random inspections during production and at the final stage to ensure adherence to specified standards.

What are the Quality Control Nuances for International B2B Buyers?

When dealing with suppliers from different regions, it is important to be aware of specific nuances that may affect quality control.

-

Cultural and Regulatory Differences

Different countries may have varying regulatory requirements and cultural approaches to quality assurance. Buyers should familiarize themselves with these differences to ensure that they are adequately addressed in the supplier’s processes. -

Language Barriers

Communication can pose challenges, especially when discussing technical specifications or quality standards. It is advisable for buyers to engage translators or bilingual professionals to facilitate clear communication. -

Logistics and Supply Chain Considerations

Buyers should consider the logistics involved in sourcing high pressure rubber tubing from international suppliers. This includes understanding shipping regulations, import duties, and potential delays that may affect delivery timelines.

By understanding the manufacturing processes and quality assurance measures in place for high pressure rubber tubing, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive reliable and high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘high pressure rubber tubing’

Introdução

In the competitive landscape of B2B procurement, sourcing high pressure rubber tubing requires a strategic approach. This guide outlines a step-by-step checklist to help international buyers navigate the complexities of selecting the right products and suppliers. By following these actionable steps, you can ensure that your procurement process is efficient, effective, and aligned with your operational needs.

Passo 1: Definir as suas especificações técnicas

Clearly outline the requirements for your high pressure rubber tubing. This includes understanding the specific applications, pressure ratings, and environmental conditions the tubing will face. Consider factors such as:

- Fluid Compatibility: Ensure the tubing material is suitable for the fluids it will carry (e.g., oils, water, or chemicals).

- Temperature and Pressure Ratings: Specify the maximum operating temperatures and pressures to avoid failures.

Step 2: Research Industry Standards and Certifications

Familiarize yourself with relevant industry standards. Different regions and applications may adhere to various standards (e.g., SAE, ISO, EN). Understanding these standards is crucial for:

- Quality Assurance: Ensuring that the products meet safety and performance requirements.

- Regulatory Compliance: Avoiding potential legal issues related to non-compliance.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. Review their company profiles, product offerings, and customer reviews. Key points to consider include:

- Experience and Reputation: Look for suppliers with a proven track record in the high pressure rubber tubing market.

- Client References: Request references from similar industries or regions to gauge reliability and product performance.

Step 4: Request Samples and Conduct Testing

Prioritize obtaining samples before making a bulk purchase. Testing samples allows you to evaluate the quality and suitability of the tubing for your specific needs. Focus on:

- Durability Tests: Check for abrasion resistance, flexibility, and performance under pressure.

- Compatibility Tests: Ensure the tubing interacts well with the fluids it will carry without degradation.

Step 5: Verify Supplier Certifications

Confirm that suppliers hold relevant certifications. Certifications from recognized organizations (e.g., ISO 9001) indicate adherence to quality management standards. This step is vital for:

- Building Trust: Demonstrating that the supplier is committed to quality and customer satisfaction.

- Reducing Risk: Lowering the likelihood of receiving subpar products that could compromise operations.

Step 6: Assess After-Sales Support and Service

Evaluate the supplier’s after-sales support options. Reliable after-sales service can significantly impact your long-term satisfaction with the product. Consider:

- Installation Guidance: Does the supplier provide detailed installation instructions or support?

- Warranty and Returns: Understand the warranty policy and the process for returns or replacements in case of defects.

Step 7: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms. Effective negotiation can lead to better pricing, delivery schedules, and payment terms. Keep in mind:

- Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

- Delivery Timelines: Ensure the delivery schedule aligns with your operational needs to avoid disruptions.

By following this checklist, B2B buyers can make informed decisions when sourcing high pressure rubber tubing, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for high pressure rubber tubing Sourcing

What Are the Key Cost Components in High Pressure Rubber Tubing?

Understanding the cost structure of high pressure rubber tubing is essential for B2B buyers looking to optimize their sourcing strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materiais: The choice of materials significantly impacts the price. High-quality synthetic rubbers and reinforcements such as steel wire or textile braids increase both durability and cost. Buyers should evaluate the specific application requirements to determine the most suitable material, balancing performance and expense.

-

Labor and Manufacturing Overhead: Labor costs can vary by region, with countries having different wage standards affecting the overall pricing. Manufacturing overhead encompasses utilities, facility expenses, and equipment maintenance, all of which contribute to the final price.

-

Ferramentas: Custom tooling for specialized tubing can be a significant upfront cost. Buyers should consider whether the investment in custom tooling aligns with their long-term production needs.

-

Controlo de qualidade (CQ): Implementing stringent QC processes ensures product reliability and compliance with international standards. While this may add to the cost, it is crucial for minimizing risks associated with product failures.

-

Logística: Transportation costs can fluctuate based on distance, shipping methods, and Incoterms. Buyers should factor in these logistics costs when evaluating supplier quotes to understand the total expenditure.

-

Margem: Suppliers will include their profit margin in the pricing structure, which can vary based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect High Pressure Rubber Tubing Costs?

Several factors influence the pricing of high pressure rubber tubing, and understanding these can help buyers negotiate better deals.

-

Volume e quantidade mínima de encomenda (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production schedules to leverage volume discounts.

-

Especificações e personalização: Custom specifications can increase costs due to the need for specialized materials or manufacturing processes. Buyers should assess whether standard products can meet their needs to avoid unnecessary expenses.

-

Qualidade dos materiais e certificações: Tubing that meets specific quality standards or certifications (e.g., ISO, SAE) may come at a premium. Buyers should weigh the benefits of certification against the costs to ensure compliance with industry regulations.

-

Factores do fornecedor: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and service, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms will dictate who bears the risk and cost of transportation. Understanding these terms can help buyers optimize their shipping costs and responsibilities.

What Tips Can B2B Buyers Use for Effective Negotiation and Cost Efficiency?

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Pricing: Engage suppliers in discussions about pricing structures. Highlighting long-term partnership potential can sometimes yield better rates.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the potential costs associated with maintenance, downtime, and logistics. A lower upfront cost may not always lead to savings in the long run.

-

Compreender as nuances dos preços: Be aware of fluctuations in material costs and exchange rates, especially when dealing with international suppliers. This knowledge can aid in timing your purchases for better pricing.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication can help buyers stay informed about potential price changes or new product offerings.

-

Realizar estudos de mercado: Regularly analyze the market landscape and competitor pricing. This will empower buyers to make informed decisions and negotiate effectively.

In summary, navigating the complexities of sourcing high pressure rubber tubing requires a comprehensive understanding of cost structures, price influencers, and effective negotiation strategies. By employing these insights, B2B buyers can enhance their procurement processes, ensuring both quality and cost-effectiveness in their operations.

Illustrative image related to high pressure rubber tubing

Alternatives Analysis: Comparing high pressure rubber tubing With Other Solutions

In the realm of fluid conveyance, high pressure rubber tubing stands out for its versatility and durability. However, as international B2B buyers assess their options, it’s essential to consider alternative solutions that may better fit specific applications or operational environments. Below, we compare high pressure rubber tubing with two viable alternatives: thermoplastic hydraulic hoses and steel piping systems.

| Aspeto de comparação | High Pressure Rubber Tubing | Mangueiras hidráulicas termoplásticas | Steel Piping Systems |

|---|---|---|---|

| Desempenho | Excellent flexibility and resistance to abrasion; suitable for a wide range of fluids. | Good flexibility; lightweight; suitable for water and petroleum-based fluids. | High durability and strength; best for permanent installations under extreme conditions. |

| Custo | Moderate initial cost with potential for high long-term value due to durability. | Generally lower initial cost, but may require more frequent replacement. | Higher upfront costs; cost-effective over long-term use if installed correctly. |

| Facilidade de implementação | Requires careful installation and maintenance but is widely understood. | Easier to install and can be cut to length on-site, but may need special fittings. | Complex installation requiring welding or specialized fittings; not easily modified once installed. |

| Manutenção | Requires regular checks for wear and potential leaks; relatively easy to maintain. | Minimal maintenance but can be susceptible to UV damage if not protected. | Low maintenance once installed, but difficult to access for repairs. |

| Melhor caso de utilização | Ideal for dynamic applications with varying pressures and temperatures, such as construction and agriculture. | Suitable for light-duty applications where flexibility and weight are crucial, such as in mobile equipment. | Best for fixed installations in industrial settings, such as oil and gas, where high pressure and temperature resistance are needed. |

Understanding Thermoplastic Hydraulic Hoses as an Alternative

Thermoplastic hydraulic hoses are increasingly popular due to their lightweight nature and flexibility. They are made from high-quality thermoplastic materials that resist abrasion and offer a long service life. However, while they are less expensive initially, their susceptibility to UV damage can lead to more frequent replacements. They are particularly useful in applications where weight and ease of handling are critical, such as mobile machinery. Buyers should consider the environmental conditions when opting for this solution.

Evaluating Steel Piping Systems for High Pressure Applications

Steel piping systems are synonymous with durability and strength. They are ideal for high-pressure applications in fixed installations, such as in the oil and gas industry. While the initial costs are higher, their longevity can make them a cost-effective choice in the long run. Installation, however, requires specialized skills and can be complex, which may increase overall project timelines and costs. Steel piping is best for environments where extreme pressures and temperatures are consistently present.

Conclusão: Escolher a solução certa para as suas necessidades

When selecting between high pressure rubber tubing and its alternatives, B2B buyers must carefully assess their specific requirements, including the application environment, cost considerations, and installation capabilities. High pressure rubber tubing offers exceptional flexibility and durability, making it ideal for dynamic applications. In contrast, thermoplastic hoses provide a lightweight option for mobile applications, while steel piping is suited for permanent installations demanding maximum strength. By understanding the strengths and weaknesses of each alternative, buyers can make informed decisions that align with their operational needs and long-term goals.

Essential Technical Properties and Trade Terminology for high pressure rubber tubing

What Are the Key Technical Properties of High Pressure Rubber Tubing?

When sourcing high-pressure rubber tubing, understanding its technical properties is crucial for ensuring compatibility with your applications and maintaining system integrity. Here are several essential specifications:

-

Composição do material

High pressure rubber hoses are typically constructed from synthetic rubber materials, such as EPDM (Ethylene Propylene Diene Monomer) or NBR (Nitrile Butadiene Rubber). The choice of material affects resistance to abrasion, weathering, and chemical exposure. Selecting the right material is vital for operational efficiency and longevity, as it impacts the hose’s performance in various environments and fluid types. -

Pressão nominal

This specification indicates the maximum pressure the hose can safely withstand. Common pressure ratings range from 150 psi to over 5000 psi, depending on the hose design and application. Understanding pressure ratings helps buyers ensure that the tubing can handle the demands of their hydraulic systems without risk of failure, thus safeguarding equipment and personnel. -

Gama de temperaturas

High pressure rubber hoses operate efficiently within specific temperature limits, typically ranging from -40°C to +100°C, with some designed for higher peaks. The ability to withstand temperature fluctuations is critical in applications like hydraulic systems, where overheating can lead to hose failure. Buyers must consider this property to prevent operational disruptions in extreme conditions. -

Reinforcement Type

The structure of the hose often includes layers of reinforcement, such as steel wire braids or spirals. This reinforcement enhances durability and pressure resistance. For example, hoses with steel wire spirals can handle higher pressures and dynamic movements compared to those with textile braids. Identifying the appropriate reinforcement type is essential for ensuring the hose meets specific application requirements. -

Raio de curvatura

The minimum bend radius indicates how tightly a hose can be bent without risking damage. A smaller bend radius allows for greater flexibility in installation but may compromise durability. Buyers should assess the bend radius to ensure proper installation and operation, especially in compact or intricate systems. -

Resistência à abrasão

The outer layer of the hose is often tested for abrasion resistance, which is critical in applications where the hose may encounter rough surfaces. Enhanced abrasion resistance can prolong the hose’s lifespan and reduce maintenance costs. Understanding this property is crucial for industries with demanding environments, such as construction or mining.

What Are Common Trade Terminology and Their Importance in High Pressure Rubber Tubing Procurement?

Familiarity with industry-specific terms can streamline the procurement process and enhance communication with suppliers. Here are key terms to understand:

-

OEM (Fabricante de Equipamento Original)

This term refers to companies that produce components that are used in the manufacturing of another company’s product. Understanding OEM specifications is crucial for ensuring that the high-pressure rubber tubing meets the required standards for integration into existing systems. -

MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ helps businesses manage inventory costs and ensures that orders align with production needs without overcommitting resources. -

RFQ (Pedido de Cotação)

An RFQ is a formal process in which a buyer requests price quotes from multiple suppliers. This term is important for buyers seeking competitive pricing and terms, ensuring they receive the best value for high-pressure rubber tubing. -

Incoterms (Termos Comerciais Internacionais)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers clarify shipping costs, delivery responsibilities, and risk management, which is essential when sourcing products from different regions. -

Pressure Testing

This refers to the process of subjecting hoses to pressure levels beyond their normal operating conditions to ensure they can handle maximum stress. Recognizing the importance of pressure testing can aid buyers in selecting reliable and durable tubing for their applications. -

Compatibility

This term describes the ability of the rubber tubing to work effectively with various fluids and conditions. Assessing compatibility is vital for preventing chemical reactions that could lead to hose failure, ensuring operational safety and efficiency.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing high pressure rubber tubing, ultimately enhancing operational reliability and performance in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the high pressure rubber tubing Sector

What Are the Current Market Dynamics and Key Trends in the High Pressure Rubber Tubing Sector?

The high pressure rubber tubing market is increasingly influenced by global economic shifts, technological advancements, and evolving customer needs. A significant driver is the rise in industrial automation across sectors such as oil and gas, construction, and agriculture, particularly in emerging markets in Africa, South America, and the Middle East. This automation trend necessitates reliable, high-performance hydraulic systems, increasing demand for durable and efficient rubber hoses.

Technological innovations are shaping the sourcing landscape, with digital platforms enabling buyers to access a broader range of suppliers and products. E-commerce has streamlined the procurement process, allowing businesses to compare specifications, prices, and lead times more effectively. Additionally, there’s a growing emphasis on customization, as companies seek hoses tailored to their specific operational requirements, including varying pressure ratings, lengths, and materials that can withstand harsh environments.

Illustrative image related to high pressure rubber tubing

As international buyers from regions like Brazil and Nigeria navigate these dynamics, they must stay attuned to regional regulations and standards, which can impact sourcing decisions. For instance, compliance with ISO and EN standards is critical to ensure product safety and performance. Furthermore, the ongoing shift towards localized sourcing strategies can mitigate supply chain risks, particularly in a post-pandemic landscape, where reliability and agility are paramount.

How Is Sustainability and Ethical Sourcing Reshaping the High Pressure Rubber Tubing Market?

Sustainability has emerged as a core concern for B2B buyers in the high pressure rubber tubing sector. The environmental impact of rubber production—ranging from deforestation to pollution—has prompted companies to seek out ethical sourcing options. Buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices, such as using recycled materials or adopting eco-friendly manufacturing processes.

The importance of ethical supply chains cannot be overstated. Businesses that align with sustainability goals often benefit from enhanced brand reputation, customer loyalty, and potential cost savings in the long run. As a result, many manufacturers are obtaining certifications such as ISO 14001 for environmental management systems, which assures buyers of their commitment to reducing ecological footprints.

Furthermore, the development of ‘green’ materials, including bio-based synthetic rubbers and eco-friendly alternatives to traditional compounds, is gaining traction. These innovations not only reduce environmental harm but also provide opportunities for manufacturers to differentiate themselves in a competitive marketplace. Buyers focused on sustainability will find that these materials can meet high-performance standards while aligning with their corporate responsibility objectives.

What Is the Historical Context of High Pressure Rubber Tubing Development?

The evolution of high pressure rubber tubing can be traced back to the industrial revolution, where the need for flexible yet durable materials became apparent. Early rubber hoses were primarily used in steam applications, but advancements in material science led to the development of synthetic rubbers, which offered enhanced durability and resistance to various environmental factors.

By the mid-20th century, the introduction of reinforced hoses significantly transformed the industry, enabling them to withstand higher pressures and harsher operational conditions. This period marked a shift towards specialized applications, as industries such as construction and automotive began to rely heavily on high pressure tubing for hydraulic systems.

In recent decades, the focus has shifted towards innovation and sustainability, with manufacturers investing in research and development to create hoses that meet the demands of modern applications while minimizing environmental impact. This ongoing evolution underscores the importance of staying informed about both historical context and future trends, allowing buyers to make strategic sourcing decisions that align with industry advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of high pressure rubber tubing

1. How do I choose the right high pressure rubber tubing for my application?

Selecting the appropriate high pressure rubber tubing involves assessing several factors, including the type of fluid being transported, operating pressure, temperature range, and environmental conditions. Consider the hose’s construction, such as whether it features textile braid, steel wire braids, or spiraled reinforcements, which can impact flexibility and durability. Additionally, ensure compliance with relevant international standards (e.g., ISO, EN, SAE) to guarantee safety and performance. Consulting with suppliers about specific applications can also provide valuable insights into the best choices for your needs.

2. What is the best material for high pressure rubber tubing?

The best material for high pressure rubber tubing typically includes synthetic rubber compounds that offer excellent resistance to abrasion, corrosion, and extreme temperatures. Common materials include EPDM, nitrile, and neoprene, which provide durability and longevity under high pressure. For specialized applications, such as those involving petroleum-based fluids, hoses reinforced with steel wire may be necessary to handle extreme pressures. It’s crucial to match the material properties with your specific operational requirements to ensure optimal performance and safety.

Illustrative image related to high pressure rubber tubing

3. What factors should I consider when vetting suppliers of high pressure rubber tubing?

When vetting suppliers, prioritize their experience in manufacturing high pressure rubber tubing and their compliance with international quality standards. Review their certifications, such as ISO 9001, and assess their production capabilities, including technology and materials used. Additionally, consider their reputation in the market, customer reviews, and the availability of customization options. Engaging in discussions about their logistics capabilities and after-sales support can also help gauge their reliability as a long-term partner.

4. What are typical minimum order quantities (MOQs) for high pressure rubber tubing?

Minimum order quantities for high pressure rubber tubing can vary significantly based on the supplier and specific product specifications. Generally, MOQs can range from a few hundred meters to several thousand, depending on the type of tubing and customization requirements. It’s advisable to discuss your needs with potential suppliers to understand their flexibility in MOQs, especially if you are looking for smaller quantities for testing or initial projects.

5. What payment terms are typically offered by suppliers of high pressure rubber tubing?

Payment terms can vary widely among suppliers, but common practices include options like 30% upfront payment with the balance due upon delivery, or net 30/60 terms after invoicing. Some suppliers may also accept letters of credit, especially for international transactions. It’s essential to clarify payment terms upfront and ensure they align with your cash flow and budgetary requirements. Discussing potential discounts for early payment can also be beneficial.

6. How can I ensure the quality of high pressure rubber tubing before purchase?

To ensure quality, request samples of the tubing for testing before committing to a larger order. Inquire about the supplier’s quality assurance processes, including testing for pressure resistance, temperature tolerance, and abrasion resistance. Additionally, checking for third-party certifications and conducting factory audits can help verify the supplier’s adherence to quality standards. Establishing a clear communication channel for quality expectations and potential issues will also facilitate a smoother procurement process.

7. What logistics considerations should I keep in mind when sourcing high pressure rubber tubing internationally?

Logistics considerations include shipping methods, lead times, and customs regulations that could affect delivery times and costs. Evaluate the supplier’s ability to handle international shipping and their experience with customs clearance in your country. Consideration should also be given to the packaging of the tubing to prevent damage during transit. Establishing a clear timeline and communication regarding shipment tracking will help manage expectations and ensure timely delivery.

8. How can I customize high pressure rubber tubing to meet my specific needs?

Customization options for high pressure rubber tubing may include varying lengths, diameters, and materials tailored to specific applications. Many suppliers offer the ability to adjust specifications based on pressure ratings, temperature resistance, and fluid compatibility. Engage with your supplier early in the process to discuss your requirements and explore available customization options. Providing detailed specifications and potential application scenarios will help the supplier deliver a product that meets your exact needs.

Top 8 High Pressure Rubber Tubing Manufacturers & Suppliers List

1. McMaster – High-Pressure Tubing Solutions

Domínio: mcmaster.com

Registered: 1994 (31 years)

Introdução: This company, McMaster – High-Pressure Tubing Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. High Pressure Hose – Rubber Hydraulic Hoses

Domínio: highpressure-hose.com

Registada: 2012 (13 anos)

Introdução: High Pressure Rubber Hose for Air, Oils and Water; Applications: hydraulic systems, gas and water supply; Materials: synthetic rubber, steel wire, textile; Types: Steel wire reinforced hydraulic hoses (SAE 100 R1/R2/R5, EN 853 1SN/2SN), Steel wire spiraled hydraulic hoses (EN 856 4SH/4SP, SAE 100 R12/R13/R15), Textile reinforced hydraulic hoses (EN 854 1TE/2TE/3TE, SAE 100 R3/R4/R6), Thermoplastic…

3. Tubes International – Rubber Hydraulic Hoses

Domínio: tubes-international.com

Registada: 2007 (18 anos)

Introdução: Rubber hydraulic hoses are used in high pressure hydraulic systems for control and power supply. They are designed to transfer hydraulic oil compliant with ISO 6743-4, excluding HFD R, HFD S, and HFD T fire-resistant fluids. For water, water-based fluids, and air, the maximum working temperature is +70°C. For air over 17 bar, the external layer of the hose should be pinpricked and have additional …

4. Hose and Fitting Supply – Hydraulic Hoses

Domínio: hoseandfittingsupply.com

Registada: 2008 (17 anos)

Introdução: Hydraulic Hoses & Attachments – Multipurpose Industrial Rubber Hoses. Designed for high pressure applications. Compatible with petroleum and some water-based products. Interchangeable with Weatherhead, Aeroquip, and Parker hoses. Reinforced with high tensile steel wire for strength. Outer layer of synthetic rubber for resistance to oils, abrasion, and weather. Commonly used in hydraulic systems fo…

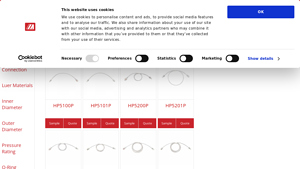

5. Meritoem – High Pressure Tubing

Domínio: meritoem.com

Registada: 2008 (17 anos)

Introdução: High Pressure Tubing available in 1200, 900, and 500 psi. Materials include clear PVC, co-extruded nylon/polyurethane, or flexible braided polyurethane. Connection options are male rotator or fixed male luer connector. Custom configurations are available. Specific products include: HP5100P (500 psi, 10″, Rotator/Female luer, PVC), HP5101P (500 psi, 10″, Male/Female luer, PVC), HP5200P (500 psi, 20…

6. Hosecraft USA – RM1 Multipurpose Rubber Nitrile Hose

Domínio: hosecraftusa.com

Registada: 2005 (20 anos)

Introdução: Hosecraft USA offers a variety of rubber hoses suitable for different applications. Key products include:

1. RM1 MULTIPURPOSE RUBBER NITRILE HOSE: Premium quality, oil resistant, suitable for compressed air, water, and many chemicals, with a temperature range of -20F to 180F.

2. RM2 MULTIPURPOSE RUBBER EPDM HOSE: Economical, suitable for water and compressed air, with excellent weather and abras…

7. Fire Hose Direct – Red 1 x 50′ High Pressure Rubber Hose

Domínio: firehosedirect.com

Registado: 2011 (14 anos)

Introdução: Red 1″ x 50′ Non-Collapsible High Pressure Rubber Hose (Alum 1″ NH Couplings)

8. NewAge Industries – Tubing and Hose Products

Domínio: newageindustries.com

Registada: 1998 (27 anos)

Introdução: NewAge Industries offers a variety of tubing and hose products made from materials such as silicone, polyurethane, PVC, fluoropolymer, nylon, Viton™, Hytrel®, polyethylene, thermoplastic rubber (TPR), latex, and polypropylene. The products include unreinforced tubing, corrugated or convoluted tubing, and braid-reinforced hose for enhanced strength and pressure capabilities. The company emphasizes …

Strategic Sourcing Conclusion and Outlook for high pressure rubber tubing

As the demand for high pressure rubber tubing continues to escalate across diverse industries, strategic sourcing emerges as a critical factor for international B2B buyers. Understanding the intricacies of material selection, manufacturing standards, and performance specifications is essential for making informed purchasing decisions. By collaborating with reputable manufacturers and suppliers, businesses can ensure the reliability and longevity of their hydraulic systems, minimizing downtime and enhancing operational efficiency.

Furthermore, buyers in Africa, South America, the Middle East, and Europe should prioritize sourcing partners who demonstrate a commitment to quality and compliance with international standards, such as ISO and SAE. This not only ensures product integrity but also fosters trust and long-term partnerships that can adapt to evolving market needs.

Looking ahead, the landscape for high pressure rubber tubing is poised for innovation, with advancements in materials and production technologies enhancing performance capabilities. By embracing these changes and focusing on strategic sourcing, businesses can position themselves for success in a competitive global market. Now is the time to engage with trusted suppliers and explore opportunities that will drive operational excellence and sustainability in your hydraulic applications.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Illustrative image related to high pressure rubber tubing

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, pedir amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.