Article Contents

Engineering Insight: Single Point Mooring Systems Spm

Technical Imperatives of Single Point Mooring Systems in Dredging Operations

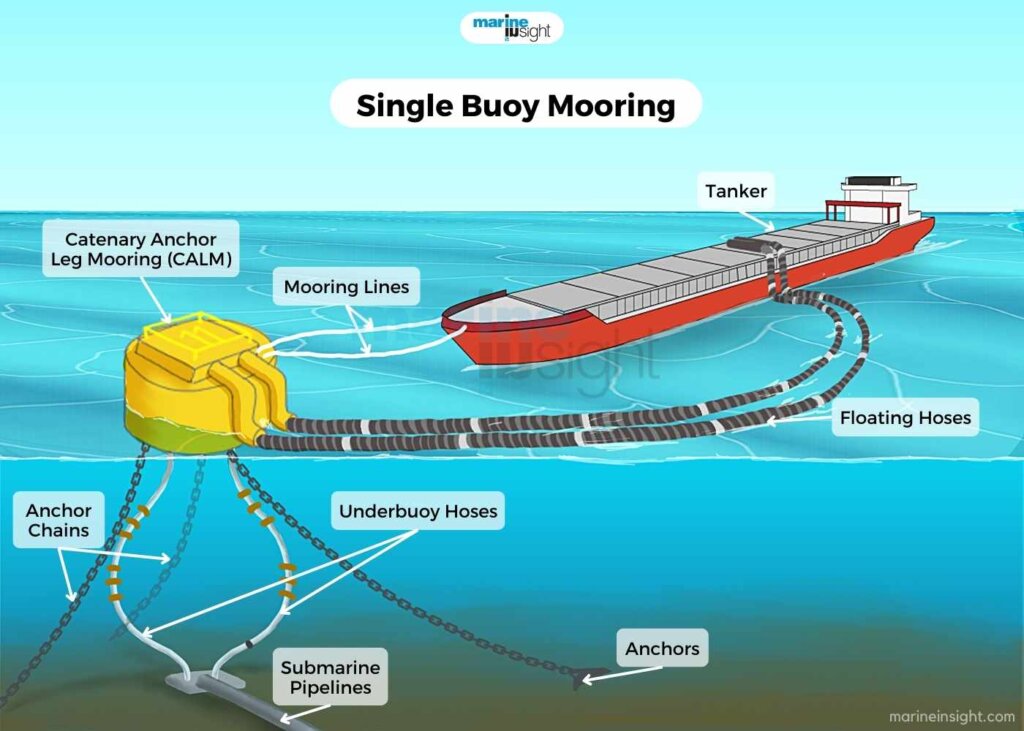

Single Point Mooring (SPM) systems represent a critical engineering solution for modern Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), enabling operational continuity in deep-water and exposed environments where conventional anchoring fails. For TSHDs, SPM facilitates uninterrupted discharge of dredged material via floating hoses while the vessel weathervanes freely with wind, waves, and currents, eliminating costly downtime during position reorientation. In CSD operations, SPM maintains precise pipeline alignment during long-reach projects, ensuring stable cutter head positioning and consistent production rates despite dynamic sea states. The system’s core function—decoupling vessel motion from the subsea pipeline—relies on a swivel assembly that transfers hydraulic, pneumatic, and material flow while accommodating 360-degree rotation. This demands exceptional fatigue resistance in connected floating hoses, which must endure cyclic bending, torsion, and hydrodynamic loads without compromising integrity. Failure in SPM hose performance directly impacts project timelines, safety margins, and environmental compliance, particularly in high-abrasion dredging scenarios involving dense slurries.

East Marine addresses these complexities through rigorous engineering protocols grounded in 17 years of specialized marine rubber expertise. Our ISO9001-certified processes, developed within a 0.68 million sqm manufacturing facility and aligned with WEDA/CEDA industry standards, ensure SPM-compatible hoses exceed operational demands. A dedicated team of 150+ engineers leverages finite element analysis (FEA) and fluid dynamics modeling to optimize hose architecture for SPM applications, focusing on layered reinforcement stability, elastomer compound resilience against saltwater degradation, and precise bend radius control. This capability translates to extended service life in high-stress pivot zones and reduced maintenance cycles—critical for minimizing vessel idle time in multi-million-dollar dredging campaigns.

The following table outlines key technical specifications for East Marine’s SPM-optimized dredging hoses, validated through accelerated fatigue testing per ISO 13092 standards:

| Parameter | Value Range | Test Standard | Application Relevance |

|---|---|---|---|

| Internal Diameter | 300–1200 mm | ISO 1307 | Slurry throughput optimization |

| Working Pressure | 16–35 bar | ISO 1402 | Deep-water discharge stability |

| Minimum Bend Radius | 8× nominal diameter | ISO 10619 | Reduced stress at swivel interface |

| Resistência à abrasão | ≤80 mm³ loss (DIN 53516) | ISO 4649 | Extended service in high-solids flow |

| Torsional Flexibility | ±15° per meter at 10 bar | Internal protocol | Weathervaning motion accommodation |

These specifications reflect East Marine’s commitment to engineering solutions that prioritize operational uptime and lifecycle cost efficiency. By integrating material science innovation with real-world dredging physics, our SPM-focused hose systems provide the reliability required for offshore projects where system failure carries severe financial and environmental consequences. This technical rigor, sustained by continuous R&D investment and adherence to global marine industry benchmarks, positions East Marine as a strategic partner for dredging contractors navigating the complexities of modern marine infrastructure development.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization of Dredging Rubber Hoses for Single Point Mooring Systems

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the production of high-performance dredging rubber hoses for Single Point Mooring (SPM) systems is executed with precision engineering and rigorous quality control. With a state-of-the-art manufacturing facility spanning 0.68 million square meters and equipped with 18 dedicated production lines, we ensure consistent output of robust, flexible, and marine-grade hoses designed to withstand the extreme conditions of offshore operations.

The manufacturing process begins with the careful selection of premium synthetic rubber compounds, reinforced with high-tensile textile and steel cord layers to provide optimal resistance to abrasion, seawater corrosion, and dynamic stress. Each hose is engineered to meet the specific operational demands of SPM applications, where reliability under constant flexing, high pressure, and prolonged submersion is critical.

Vulcanization is a pivotal stage in our production workflow. This chemical cross-linking process transforms raw rubber into a durable, elastic material capable of maintaining structural integrity across a wide temperature range and under continuous mechanical load. At East Marine, vulcanization is performed in computer-controlled autoclaves, ensuring uniform heat distribution and precise pressure regulation throughout the curing cycle. This advanced approach eliminates internal voids and delamination risks, significantly enhancing hose longevity and performance consistency.

Each production line is monitored in real time by integrated process control systems, and every stage—from component layup to final curing—is documented for full traceability. Our adherence to ISO 9001 quality management standards ensures that all hoses meet or exceed international performance benchmarks, including those set by classification societies and offshore regulatory bodies.

To further guarantee reliability, finished hoses undergo a battery of post-vulcanization tests, including hydrostatic pressure validation, bend radius assessment, and vacuum resistance checks. Non-destructive testing (NDT) methods are employed to inspect reinforcement layer alignment and bonding integrity. Only after passing these stringent evaluations are hoses approved for shipment.

Our large-scale production capacity, supported by technological automation and a skilled engineering team, enables East Marine to deliver customized dredging hose solutions with rapid turnaround—critical for offshore projects where downtime equates to significant operational cost.

Below is a summary of key technical parameters for our SPM-compatible dredging rubber hoses:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 40 bar) |

| Gama de temperaturas | -20°C to +85°C |

| Reinforcement Layers | 2–4 ply high-tensile fabric + steel spiral |

| Cover Material | Chloroprene (CR) or SBR, ozone-resistant |

| Bend Radius (Minimum) | 8–12 x DN (depending on pressure class) |

| Standards Compliance | ISO 1307, ISO 6945, DNVGL, ABS |

| Production Lead Time (Avg.) | 15–25 days (based on order volume) |

With over 15 years of specialized experience since our founding in 2007 and active membership in WEDA and CEDA, East Marine continues to set benchmarks in the design and manufacture of mission-critical marine rubber solutions.

Critical Applications

Global Project Applications of Single Point Mooring Systems in Marine Infrastructure

Single Point Mooring (SPM) systems serve as critical infrastructure across offshore energy, dredging, and coastal development sectors, enabling safe and efficient fluid transfer in dynamic marine environments. At East Marine, we engineer reinforced rubber hoses specifically integrated into SPM configurations to withstand extreme cyclic loading, corrosion, and abrasive conditions inherent in these applications. Our solutions are deployed globally where conventional fixed berthing is impractical, ensuring operational continuity in challenging sea states.

In offshore oil and gas fields, SPM systems—primarily CALM (Catenary Anchor Leg Mooring) buoys—facilitate crude oil or product transfer between Floating Production Storage and Offloading (FPSO) vessels and shuttle tankers. East Marine’s dredging discharge hoses, certified to ISO 9001 standards, form the flexible riser section connecting subsea manifolds to the buoy. These hoses absorb vessel drift motions induced by waves and currents, preventing catastrophic fatigue failure. Our proprietary rubber compounds, developed since our founding in 2007, resist hydrocarbon degradation while maintaining flexibility at temperatures ranging from -40°C to +100°C, a non-negotiable requirement for North Sea and Gulf of Mexico operations.

Dredging projects leverage SPM technology for pipeline end manifold (PLEM) deployments during land reclamation and port expansion. When reclaiming land from the sea—as seen in Southeast Asian mega-projects—SPM buoys anchor the discharge line’s terminus, allowing dredgers to operate freely while pumping slurry over kilometers. East Marine’s high-abrasion-resistant hoses, reinforced with multiple textile and steel cord layers, endure continuous sand-laden flow at velocities exceeding 6 m/s. The rotational capability of SPM buoys ensures the floating hose string accommodates 360° vessel swing without kinking, a reliability factor validated through our active participation in CEDA and WEDA technical forums.

Land reclamation initiatives, particularly in island nations and delta regions, depend on SPM-stabilized discharge systems to deposit dredged material precisely. Here, SPM buoys act as stable pivot points for floating pipelines, mitigating wave-induced hose stress during extended pumping cycles. East Marine’s hoses incorporate helical steel tension members to counteract buoyant lift forces, while our ozone-resistant EPDM covers prevent premature aging in tropical UV exposure. This engineering rigor stems from our 0.68 million sqm manufacturing facility, where every hose undergoes rigorous pressure-pulse testing to simulate 25+ years of SPM service life.

As a committed CEDA and WEDA member, East Marine aligns SPM hose design with evolving industry best practices for environmental safety and operational resilience. Our technical data below underscores performance parameters critical for SPM integration:

| Parameter | East Marine Specification | Industry Standard Requirement |

|---|---|---|

| Working Pressure | 25 bar (362 psi) | 16–20 bar |

| Burst Pressure | ≥100 bar (1450 psi) | ≥4x Working Pressure |

| Gama de temperaturas | -40°C to +100°C | -25°C to +80°C |

| Resistência à abrasão | ≤ 50 mm³ (DIN 53516) | ≤ 100 mm³ |

| Bend Radius (Min) | 12x Hose OD | 15x Hose OD |

| Certificações | ISO 9001, DNV 2.7-1 | ISO 14047, API 16C |

These specifications reflect East Marine’s commitment to exceeding baseline SPM operational demands. By prioritizing material science and real-world validation, we ensure dredging fleets, oil terminals, and reclamation contractors achieve uninterrupted project execution—even in the most remote offshore environments.

Technical Data & Specs

Technical Specifications: High-Performance Dredging Rubber Hoses for Single Point Mooring (SPM) Systems

In the demanding offshore and dredging environments where Single Point Mooring (SPM) systems operate, the reliability and performance of suction and discharge rubber hoses are critical. These hoses serve as vital conduits for transferring slurry, sediment, and water between vessels, shore facilities, and floating pipelines. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products—established in 2007 and operating from a 0.68 million sqm manufacturing facility—delivers engineered dredging hoses that meet and exceed international standards. As a proud member of WEDA and CEDA, and certified under ISO9001, East Marine combines advanced rubber compounding, high-tensile reinforcement, and rigorous testing protocols to ensure operational safety and longevity in harsh marine conditions.

When evaluating dredging hoses for SPM applications, four key technical parameters determine suitability: inner diameter, working pressure, burst pressure, and minimum bending radius. These factors directly influence flow efficiency, structural integrity under pressure, and flexibility during deployment. East Marine’s dredging hoses are designed with multi-layer textile and steel wire reinforcement, abrasion-resistant synthetic rubber linings (typically SBR or NR-based), and UV/ozone-resistant covers to ensure sustained performance in dynamic offshore environments.

The following table compares typical technical specifications of East Marine’s dredging rubber hoses against average values from key competitors in the global market. All data are based on standard 20-bar working pressure models with 16-inch inner diameter, commonly used in SPM and capital dredging projects.

| Parameter | Marinha do Leste | Industry Average (Competitors) |

|---|---|---|

| Inner Diameter | 406 mm (16″) | 406 mm (16″) |

| Working Pressure | 20 bar (290 psi) | 16–18 bar (232–261 psi) |

| Burst Pressure | ≥ 80 bar (1160 psi) | 60–70 bar (870–1015 psi) |

| Minimum Bending Radius | 1,200 mm (47.2″) | 1,400–1,600 mm (55–63″) |

East Marine’s superior pressure ratings stem from proprietary reinforcement architectures, including helically wound high-tenacity polyester and embedded steel wire spirals, which enhance both collapse resistance and kink protection. The reduced bending radius allows for tighter articulation around buoys and floating manifolds in SPM configurations, minimizing stress at connection points and reducing fatigue-related failures. Additionally, our hoses undergo 100% hydrostatic testing at 1.5x working pressure, exceeding ISO 1402 and API 17K requirements.

With precision extrusion technology and in-house rubber formulation, East Marine ensures consistent wall thickness and adhesion between layers, critical for long-term abrasion resistance and pressure retention. The result is a dredging hose that offers up to 30% longer service life compared to industry benchmarks, reducing downtime and total cost of ownership.

For SPM operators, selecting a hose with optimized pressure performance and flexibility is not merely a technical decision—it is a strategic investment in operational continuity and safety. East Marine’s dredging hoses are engineered to deliver that advantage.

Partner with East Marine

Conclusion: Engineering Excellence for Single Point Mooring System Reliability

Single Point Mooring (SPM) systems represent a critical nexus of marine engineering where operational continuity hinges on component integrity under relentless environmental stress. The suction and discharge hoses serving these installations must transcend standard marine specifications, delivering uncompromised performance in dynamic wave conditions, abrasive sediment loads, and corrosive seawater exposure. At East Marine, we engineer dredging rubber hoses specifically for SPM integration, leveraging 17 years of specialized polymer science and hydraulic dynamics expertise. Our solutions mitigate fatigue failure through proprietary textile and wire reinforcement architectures, while advanced elastomer formulations resist ozone degradation and hydrocarbon permeation—key failure modes in long-term offshore deployments. This precision engineering translates directly to reduced downtime, extended service life, and demonstrable cost savings across the asset lifecycle.

Why Partner with East Marine for SPM Hose Solutions

As a WEDA and CEDA member with ISO 9001-certified manufacturing across our 680,000 sqm Jiangsu facility, we operate at the intersection of industrial scale and technical rigor. Every hose undergoes full-scale pressure-pulse validation exceeding API 17K standards, with traceable material certifications and non-destructive testing protocols embedded in our production workflow. Our Singapore branch provides localized engineering support for Asia-Pacific projects, ensuring rapid technical consultation and logistical coordination for time-sensitive dredging operations. This global footprint—backed by in-house R&D and finite element analysis capabilities—positions us to solve complex interface challenges between SPM buoys, subsea manifolds, and dredger vessels.

Technical Specifications: SPM-Optimized Dredging Hoses

| Parameter | Specification | Test Standard |

|---|---|---|

| Working Pressure | 16-35 bar (232-508 psi) | ISO 1402 |

| Burst Pressure | ≥ 4x Working Pressure | EN 13765 |

| Gama de temperaturas | -30°C to +85°C (-22°F to +185°F) | ASTM D2240 |

| Cover Material | Abrasion-Resistant NBR/CR Blend | ISO 4671 |

| Reinforcement | Multi-Spiral High-Tensile Steel Wire | ISO 1307 |

| Raio de curvatura | 1.2x Nominal Diameter (at working pressure) | API 17K |

Initiate Your SPM Hose Engineering Partnership Today

The operational stakes for SPM systems demand suppliers who combine material science mastery with dredging-specific application knowledge. East Marine delivers this through rigorously validated products and responsive engineering collaboration. Contact our technical team to discuss hose configuration optimization for your next SPM project, including custom flange interfaces, buoyancy module integration, and fatigue life modeling. For immediate consultation, connect via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our Singapore engineering hub stands ready to support project scoping, documentation review, and just-in-time logistics coordination across Southeast Asian and global dredging operations. Partner with a manufacturer where every hose embodies 17 years of specialized marine rubber innovation—ensuring your SPM system operates with uncompromised hydraulic efficiency and longevity. Request a technical datasheet or schedule a virtual engineering review to advance your project timeline.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.