Article Contents

Engineering Insight: Discharge Hoses

Technical Imperatives of Discharge Hoses in Modern Dredging Operations

Discharge hoses represent a mission-critical component within the hydraulic transport systems of both Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs), directly influencing operational efficiency, vessel uptime, and project economics. Unlike static pipeline sections, discharge hoses must simultaneously withstand extreme internal pressures generated by powerful dredge pumps, the relentless abrasion of high-velocity slurries containing sand, gravel, and debris, and the complex dynamic stresses imposed by vessel motion, tidal changes, and connection/disconnection cycles. On TSHDs, the discharge hose operates under significant tension and bending as the vessel maneuvers while offloading, demanding exceptional flexibility and fatigue resistance to prevent kinking or structural failure. For CSDs, often deployed in fixed-position operations, discharge hoses face severe localized abrasion at swing points and constant high-pressure pulsation, requiring robust reinforcement and impact-resistant cover compounds. A single hose failure during critical discharge operations translates to immediate production stoppage, incurring substantial demurrage costs and jeopardizing project timelines. Consequently, the engineering integrity of the discharge hose – encompassing its pressure rating, abrasion resistance, flexibility, and overall durability – is non-negotiable for maintaining operational continuity in demanding marine environments.

East Marine leverages its 150+ strong engineering and manufacturing workforce, including specialized material scientists and finite element analysis (FEA) experts, to address these multifaceted challenges. Our dedicated R&D team, operating within our 0.68 million square meter ISO 9001 certified facility, focuses on optimizing rubber compound formulations for maximum wear life against abrasive media and developing advanced textile and wire reinforcement architectures to ensure pressure integrity under cyclic loading. As active WEDA and CEDA members, we maintain direct engagement with industry operational feedback, ensuring our hose designs evolve to meet the escalating performance demands of modern dredging fleets. This deep technical capability, coupled with rigorous in-house testing protocols exceeding ISO 14310 standards, allows us to deliver discharge hoses engineered for extended service life and predictable performance, directly contributing to reduced lifecycle costs for our clients.

The following table outlines key technical specifications characterizing East Marine’s premium dredging discharge hose series, engineered specifically for TSHD and CSD applications:

| Parameter | Typical Value Range | Significance |

|---|---|---|

| Working Pressure | 10 – 30 bar (145 – 435 psi) | Must exceed maximum system pump pressure with significant safety margin |

| Test Pressure | 1.5x Working Pressure | Validates structural integrity per ISO 14310 requirements |

| Gama de temperaturas | -30°C to +80°C (-22°F to +176°F) | Ensures flexibility in cold climates and resistance to heat buildup from slurry friction |

| Cover Compound | Specialized Abrasion-Resistant Synthetic Rubber | Critical defense against external wear, ozone, seawater, and UV degradation |

| Reinforcement | Multiple Plies of High-Tensile Textile + Helical Wire | Provides pressure containment, kink resistance, and tensile strength for TSHD |

| Bend Radius (Min) | 8x – 12x Nominal Diameter | Essential for safe operation during vessel movement on TSHDs |

| Resistência à abrasão | ASTM D5963: ≤ 80 mm³ loss | Quantifies wear life against abrasive slurries; lower value indicates superior performance |

This technical foundation, underpinned by East Marine’s substantial engineering resources and commitment to dredging industry standards, ensures our discharge hoses deliver the reliability and performance essential for maximizing dredge productivity in the world’s most challenging projects.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization of Dredging Discharge Hoses at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted name in marine industrial solutions, the production of high-performance dredging discharge hoses is rooted in precision engineering and advanced rubber processing. With a state-of-the-art 0.68M sqm manufacturing facility and 18 dedicated production lines, our operations are designed to deliver robust, durable, and reliable rubber hoses that meet the rigorous demands of global dredging projects.

The manufacturing process begins with the careful selection of premium-grade synthetic and natural rubber compounds, chosen for their abrasion resistance, flexibility, and resilience under high-pressure conditions. These raw materials are compounded in-house using advanced mixing technologies to ensure uniform consistency and optimal performance characteristics. The compounded rubber is then extruded into precise profiles that form the inner tube, reinforcement layers, and outer cover of the discharge hose.

Reinforcement is a critical phase, where high-tensile textile or steel wire braids are applied to provide structural integrity and pressure resistance. The number of reinforcement layers is tailored to the intended working pressure, ensuring compliance with international standards such as ISO 1436 and CEDRA guidelines. Each layer is meticulously applied using computer-controlled machinery to maintain dimensional accuracy and uniform stress distribution.

The cornerstone of our manufacturing excellence lies in the vulcanization process. Vulcanization at East Marine is conducted in continuous sulfur-cure autoclaves under precisely controlled temperature and pressure conditions. This cross-linking process transforms the rubber from a plastic, malleable state into a durable elastomer with enhanced mechanical properties, including improved tensile strength, heat resistance, and long-term durability. Our vulcanization cycles are optimized based on hose specifications, ensuring consistent quality across every production batch.

Quality control is integrated at every stage of production. As an ISO 9001-certified manufacturer and active member of WEDA and CEDA, East Marine adheres to stringent quality assurance protocols. Each hose undergoes hydrostatic pressure testing, dimensional inspection, and visual examination post-vulcanization. Non-destructive testing methods are employed to verify reinforcement alignment and bond integrity between layers.

Our 18 synchronized production lines enable scalable output without compromising precision, supporting rapid delivery for large-scale dredging operations worldwide. The combination of advanced vulcanization technology, rigorous quality control, and vertically integrated manufacturing ensures that every discharge hose leaving our facility meets the highest standards of performance and reliability.

| Parameter | Specification |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 dedicated lines |

| Vulcanization Method | Continuous autoclave, sulfur-cure |

| Quality Standards | ISO 9001, ISO 1436, CEDRA compliance |

| Testing Procedures | Hydrostatic, dimensional, NDT |

| Reinforcement Materials | High-tensile textile, steel wire |

| Customization Capability | Diameter, length, pressure rating |

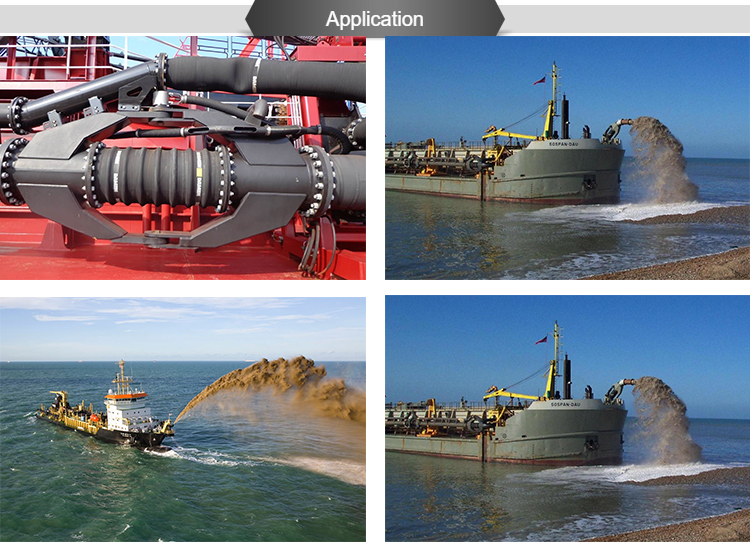

Critical Applications

Global Project Applications of Industrial Discharge Hoses in Critical Marine Operations

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a verified member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), delivers engineered discharge hose solutions essential for the most demanding global marine and offshore infrastructure projects. Our technical expertise, honed since 2007 within our 680,000 square meter ISO 9001 certified manufacturing facility, ensures hoses meet rigorous operational demands across diverse environments. Discharge hoses are not merely conduits; they are critical system components enabling project feasibility, efficiency, and longevity where abrasive slurries, challenging topographies, and harsh environmental conditions prevail.

In large-scale dredging operations, discharge hoses form the backbone of material transport systems. They efficiently convey dense, abrasive sand, silt, and gravel slurries over significant distances, often kilometers long, from cutter suction dredgers to reclamation sites or offshore disposal areas. Projects such as the expansion of the Port of Rotterdam, the Panama Canal widening, and maintenance dredging in the Mississippi River rely on hoses capable of sustaining high working pressures while resisting internal wear from solid particles and external damage from anchors or debris. East Marine hoses utilize specialized rubber compounds and multi-layer reinforcement to maintain structural integrity under continuous cyclic stress, minimizing downtime and operational costs for dredging contractors globally.

The offshore oil and gas sector represents another critical application domain. Discharge hoses are indispensable for fluid transfer during well testing, pipeline commissioning, and produced water management. They must exhibit exceptional resistance to hydrocarbons, varying temperatures, and dynamic motion induced by vessel movement or currents. East Marine hoses, designed with specific elastomers for chemical compatibility and robust textile or wire reinforcement for pressure and vacuum resistance, ensure safe and reliable hydrocarbon transfer in challenging deepwater and marginal field developments, directly supporting operational continuity and environmental safety protocols.

Land reclamation projects, fundamental to creating new urban or industrial zones, heavily depend on high-capacity discharge systems. Iconic projects like the Palm Jumeirah in Dubai or ongoing expansions in Singapore utilize vast networks of discharge hoses to transport millions of cubic meters of dredged material. These hoses must withstand prolonged exposure to sunlight, saltwater, and potential impact during installation on soft, unstable ground. East Marine’s solutions incorporate UV-stabilized covers and abrasion-resistant outer layers, ensuring consistent performance throughout the multi-year lifespan of major reclamation endeavors, directly contributing to the successful creation of new landmass.

The technical performance underpinning these global applications is defined by precise engineering specifications. Key parameters for standard East Marine dredging discharge hoses include:

Working Pressure (Bar) Temperature Range (°C) Cover Type Reinforcement Layers Standard Length (m)

10 – 30 -20 to +80 Weather/Abrasion Resistant Textile or Wire Braid 50 – 200

East Marine’s active CEDA and WEDA membership underscores our commitment to adhering to the highest international technical standards and best practices within the dredging and marine engineering community. This affiliation, combined with our extensive manufacturing capability and deep application knowledge, positions us as a strategic partner for operators executing complex discharge hose applications worldwide, ensuring project success through reliable, high-performance fluid transfer infrastructure.

Technical Data & Specs

Technical Specifications: Comparative Analysis of Dredging Rubber Discharge Hoses

In the demanding environment of dredging operations, the performance of discharge hoses is critical to operational efficiency, safety, and project timelines. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted member of WEDA and CEDA, delivers engineered rubber solutions designed for extreme conditions. With a manufacturing footprint spanning 0.68 million square meters and adherence to ISO9001 quality standards, East Marine’s dredging hoses are built to exceed industry benchmarks. This technical comparison evaluates key performance metrics—inner diameter, working pressure, burst pressure, and bending radius—between East Marine’s premium dredging hoses and typical competitor offerings.

Dredging discharge hoses must balance flexibility, pressure resistance, and durability. East Marine optimizes each parameter through advanced rubber compounding, high-tensile reinforcement layers, and precision manufacturing. The result is a product line that supports high-volume slurry transport while maintaining structural integrity under dynamic marine conditions. In contrast, many competitor hoses, particularly those from non-certified manufacturers, often compromise on material quality or design consistency, leading to premature failure and increased downtime.

A critical differentiator lies in pressure handling. East Marine hoses are engineered with multiple high-strength textile and steel reinforcement layers, enabling superior working and burst pressure ratings. This ensures safe operation even in high-head discharge applications, such as long-distance land reclamation or deep-sea dredging. Additionally, the optimized tube and cover rubber formulations provide exceptional resistance to abrasion, UV exposure, and seawater degradation.

Flexibility is another area where East Marine excels. A smaller bending radius allows for tighter maneuverability during deployment, especially in congested port areas or complex pipeline configurations. This reduces the need for additional couplings or support floats, lowering both installation time and overall project cost.

The following table presents a representative comparison across standard dredging hose sizes, highlighting East Marine’s technical leadership in the sector.

| Inner Diameter (mm) | Working Pressure (bar) – East Marine | Working Pressure (bar) – Competitors | Burst Pressure (bar) – East Marine | Burst Pressure (bar) – Competitors | Bending Radius (mm) – East Marine | Bending Radius (mm) – Competitors |

|---|---|---|---|---|---|---|

| 200 | 16 | 10–12 | 64 | 30–40 | 900 | 1,100–1,300 |

| 300 | 16 | 10–12 | 64 | 30–40 | 1,200 | 1,500–1,700 |

| 400 | 15 | 10 | 60 | 30 | 1,600 | 2,000–2,200 |

| 500 | 14 | 9 | 56 | 27 | 2,000 | 2,500–2,800 |

| 600 | 12 | 8 | 48 | 24 | 2,400 | 3,000–3,300 |

East Marine’s consistent engineering standards ensure minimal variance across production batches, a key advantage in large-scale dredging projects requiring uniform hose performance. Backed by over 15 years of specialized manufacturing experience since 2007, East Marine continues to set the benchmark for reliability and innovation in dredging hose technology.

Partner with East Marine

Conclusion and Technical Partnership Commitment

East Marine delivers engineered discharge hose solutions that directly address the operational rigidity and environmental challenges inherent in modern dredging projects. Our hoses transcend basic fluid transfer by integrating advanced rubber compounding, multi-spiral wire reinforcement, and abrasion-resistant cover formulations proven in high-sediment, high-pressure applications. This technical precision ensures extended service life under cyclic bending, vacuum conditions, and abrasive slurries—critical factors impacting project timelines and total cost of ownership. With over 17 years of specialization since our 2007 founding, and operating from our 680,000 sqm ISO 9001-certified facility in Jiangsu, we maintain rigorous control over raw material sourcing, vulcanization processes, and hydraulic validation testing. As active WEDA and CEDA members, our engineering team continuously aligns with evolving industry standards, including EN 14706 and API 17K, to future-proof your dredging infrastructure.

The following table summarizes core technical capabilities for our standard dredging discharge hose series, reflecting our commitment to performance transparency:

| Parameter | Specification Range | Test Standard |

|---|---|---|

| Nominal Diameter (DN) | 200 mm – 1200 mm | ISO 1307 |

| Working Pressure | 10 bar – 25 bar | ISO 1402 |

| Vacuum Resistance | Full vacuum (760 mmHg) | ISO 10360 |

| Bend Radius (Min) | 8x DN | EN 14706 |

| Cover Abrasion Loss | ≤ 50 mm³ (DIN 53516) | ISO 4649 |

| Gama de temperaturas | -30°C to +80°C | ASTM D573 |

| Flange Standards | PN16, ANSI B16.5, JIS 10K | Customizable |

Operational continuity in dredging hinges on hose reliability. East Marine’s Singapore branch provides localized technical support for Southeast Asian and Oceania projects, ensuring rapid response to site-specific engineering queries, pressure surge analysis, and lifecycle optimization. Our team collaborates directly with your engineers to validate hose configuration against project sediment profiles, pump curves, and marine growth factors—transforming specifications into field-proven performance.

Initiate a technical consultation to eliminate downtime risks in your next capital dredging or reclamation project. Contact our global engineering desk via WhatsApp at +86-13806109365 for immediate structural analysis support, or email detailed project requirements to hsdredging@eastmarine.tech. Include pipeline length, maximum head pressure, and slurry density for a customized performance validation report within 48 hours. For clients in the Asia-Pacific region, leverage our Singapore technical hub for on-site joint inspection services and accelerated prototyping. East Marine does not supply generic hoses—we deliver audited hydraulic solutions backed by 17 years of marine infrastructure expertise. Partner with us to convert dredging efficiency targets into operational reality.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.