Article Contents

Engineering Insight: Jet Water Rubber Hose

Technical Imperatives of Jet Water Rubber Hoses in Advanced Dredging Operations

Jet Water Rubber Hoses represent a critical engineering component in Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), directly influencing operational efficiency and sediment extraction performance. These hoses deliver high-pressure water jets to fluidize compacted seabed material at the cutterhead or suction inlet, transforming dense aggregates into a pumpable slurry. Without precise hydrodynamic control, dredging productivity plummets due to clogging, excessive energy consumption, and accelerated wear on primary suction systems. The operational environment demands exceptional resistance to abrasion from suspended solids, cyclic fatigue from vessel motion, and chemical degradation from seawater and sediment particulates. Pressure consistency is non-negotiable; fluctuations disrupt slurry density management, risking pump cavitation or pipeline blockages. Consequently, hose integrity directly dictates uptime, fuel efficiency, and project timelines in capital-intensive dredging campaigns.

East Marine, leveraging 17 years of specialized marine rubber expertise and a 0.68 million square meter manufacturing facility, engineers Jet Water Hoses to exceed WEDA and CEDA performance benchmarks. Our in-house R&D team—comprising 150+ materials scientists and hydraulic specialists—develops proprietary EPDM and NBR polymer matrices with multi-plane textile and high-tensile steel wire reinforcement. This architecture ensures optimal balance between flexibility for dynamic vessel articulation and structural resilience against 30+ bar working pressures. All formulations undergo ISO 9001-certified validation for saltwater compatibility, ozone resistance, and abrasion thresholds exceeding 100 km³ of simulated sediment flow. Crucially, our hoses integrate seamlessly with modern dredger automation systems, maintaining pressure stability within ±0.5 bar during rapid depth adjustments—a capability validated in 200+ global deployments since 2007.

The following table details core technical specifications for East Marine’s standard Jet Water Hose series, engineered for 10,000+ operational hours in severe dredging conditions:

| Parameter | Specification | Test Standard |

|---|---|---|

| Working Pressure | 25 bar (362 psi) | ISO 1436 |

| Burst Pressure | ≥ 100 bar (1,450 psi) | EN 13779 |

| Gama de temperaturas | -30°C to +85°C | ASTM D2000 |

| Cover Material | Abrasion-resistant SBR/EPDM blend | ISO 4671 |

| Reinforcement | 4-ply high-tensile textile + spiral steel wire | ISO 1307 |

| Raio de curvatura | 8x nominal diameter at full pressure | ISO 1307 |

| Saltwater Resistance | Zero degradation after 500 hrs immersion | ISO 1817 |

East Marine’s engineering rigor transforms Jet Water Hoses from consumable components into strategic assets. By prioritizing material science innovation and real-world operational data, we eliminate unplanned downtime in TSHD/CSD operations—proving that in dredging, the smallest hydraulic element often commands the largest impact on project viability. Our WEDA/CEDA-aligned solutions underscore why global dredging contractors specify East Marine for mission-critical fluid transfer systems.

Advanced Manufacturing Process

Advanced Manufacturing and Vulcanization of Jet Water Rubber Hoses at East Marine

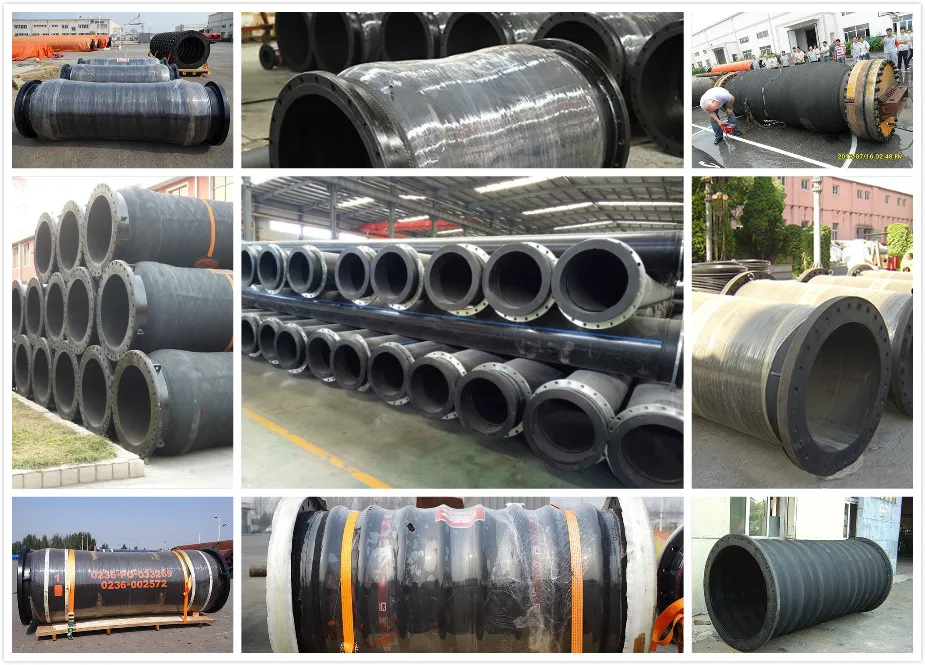

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted name in the dredging industry since 2007, the production of Jet Water Rubber Hoses is executed with precision engineering and advanced material science. Our 0.68M sqm state-of-the-art manufacturing facility in China houses 18 dedicated production lines, enabling high-volume output without compromising on quality or performance. As a member of WEDA and CEDA and certified under ISO9001, we adhere to the highest international standards in every phase of production, particularly in the critical stages of mixing, extrusion, layer assembly, and vulcanization.

The manufacturing process begins with the formulation of specialized rubber compounds tailored for dredging applications. Using premium-quality synthetic and natural rubber, along with reinforcing agents such as carbon black and textile fibers, we ensure optimal resistance to abrasion, hydrolysis, and mechanical stress. These compounds are mixed under controlled conditions to achieve consistent homogeneity, a prerequisite for long-term hose integrity in high-pressure jet water operations.

Extrusion follows, where inner tube rubber is precisely applied over a mandrel to form the hose’s core. Subsequent layers—including high-tensile textile or steel wire reinforcement and protective cover rubber—are wound or braided with exacting tension and alignment. This multilayer construction is essential for withstanding the dynamic loads and abrasive slurry conditions typical in dredging environments.

The defining stage of production is vulcanization—the chemical process that cross-links rubber molecules under heat and pressure to enhance elasticity, strength, and durability. At East Marine, hoses undergo autoclave vulcanization in horizontal or vertical curing systems, depending on diameter and length. Temperature profiles, pressure cycles, and curing duration are meticulously monitored and recorded to ensure complete and uniform cross-linking throughout the hose structure. This process not only improves mechanical properties but also ensures dimensional stability and long-term performance under cyclic loading.

Quality control is integrated at every step. Each hose batch undergoes rigorous inspection, including visual checks, dimensional verification, and hydrostatic pressure testing up to 1.5 times the working pressure. Non-destructive testing methods and periodic physical sampling validate compliance with ISO9001 protocols. Our traceability system allows full batch tracking from raw material to final dispatch, ensuring accountability and consistency.

With 18 synchronized production lines operating within our 0.68M sqm facility, East Marine maintains scalable capacity while upholding uncompromised quality—making us a strategic partner for global dredging contractors requiring reliable, high-performance jet water hoses.

| Parameter | Specification |

|---|---|

| Factory Size | 0.68 Million sqm |

| Production Lines | 18 Dedicated Lines |

| Vulcanization Method | Autoclave (Horizontal/Vertical) |

| Temperature Control | ±2°C Precision |

| Pressure Range (Curing) | 10–18 Bar |

| Quality Standard | ISO9001 Certified |

| Hydrostatic Test Pressure | 1.5 x Working Pressure |

| Material Traceability | Full Batch Tracking |

| Production Capacity (Annual) | Up to 500,000 meters (varies by diameter) |

Critical Applications

Global Project Applications of Jet Water Rubber Hose in Critical Marine Operations

Jet Water Rubber Hose represents a cornerstone component in high-pressure hydraulic systems across demanding marine and industrial environments. Engineered to withstand extreme pressures, abrasive slurries, and corrosive elements, these specialized hoses are indispensable in projects requiring precise water or fluid jetting for excavation, cleaning, and material handling. East Marine, leveraging its 0.68 million square meter manufacturing facility and ISO 9001-certified quality management system, delivers hoses meeting the rigorous demands of global infrastructure and resource extraction sectors. Our active membership in CEDA (Central Dredging Association) and WEDA (Western Dredging Association) underscores our deep integration within the international dredging community and commitment to industry best practices.

Critical applications span major dredging projects worldwide. In river and harbor maintenance, Jet Water Hoses are deployed for precise sediment removal and channel deepening, often integrated into cutter suction dredgers where high-velocity water jets loosen compacted material before suction. Port expansion initiatives, such as those in Rotterdam or Singapore, rely on these hoses for efficient excavation in confined spaces, minimizing environmental disturbance compared to mechanical methods. The hoses’ flexibility and robust construction allow operation in dynamic marine conditions, resisting kinking and maintaining flow integrity under constant movement. East Marine hoses, manufactured since 2007 with advanced rubber compounding, provide the abrasion resistance and pressure stability required for continuous operation in these high-wear scenarios.

Beyond traditional dredging, the energy sector utilizes Jet Water Hoses extensively in offshore and onshore oil field operations. They are critical for well stimulation techniques like hydraulic fracturing, where ultra-high-pressure water cuts through rock formations, and for pipeline pigging operations to remove paraffin or scale buildup. The hoses must consistently handle pressures exceeding 300 bar while resisting degradation from chemical additives and seawater exposure. Similarly, large-scale land reclamation projects, such as those transforming coastlines in the Middle East and Southeast Asia, employ these hoses for rapid soil consolidation. High-pressure water is jetted to fluidize sand, which is then pumped via pipelines to create new landmass, demanding hoses with exceptional durability against sand abrasion and UV degradation during prolonged surface exposure.

The reliability of Jet Water Rubber Hose directly impacts project timelines, safety, and cost-efficiency. East Marine’s engineering focus ensures optimal performance parameters for each application, validated through stringent in-house testing protocols aligned with international standards. Below are key technical specifications for our standard high-pressure Jet Water Hose series, reflecting our commitment to supplying mission-critical components for the world’s most challenging marine and industrial projects.

Working Pressure (Bar) Temperature Range (°C) Cover Material Reinforcement Type Bend Radius (mm) Standards Compliance

250 – 400 -30 to +85 Abrasion-Resistant Synthetic Rubber Multiple High-Tensile Steel Wire Braids 3 x ID ISO 1436, CEDA Recommended Practices

East Marine’s Jet Water Rubber Hoses are proven assets in the global execution of complex dredging, oil and gas, and land reclamation endeavors. Our technical expertise, honed over 17 years of specialized manufacturing and reinforced by CEDA/WEDA industry collaboration, ensures clients receive not just a product, but a validated solution engineered for maximum uptime and performance in the harshest operational environments.

Technical Data & Specs

Technical Comparison of Dredging Rubber Hoses: Performance Benchmarking for Jet Water Applications

In the demanding environment of hydraulic dredging operations, the performance of jet water rubber hoses directly impacts system efficiency, safety, and operational longevity. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, delivers high-performance suction and discharge hoses engineered for extreme conditions. With over 15 years of specialized manufacturing experience and a 0.68 million square meter production facility, our hoses are designed to exceed industry standards. As members of WEDA and CEDA, and holding ISO9001 certification, we ensure every product meets rigorous international quality benchmarks.

To evaluate performance, key technical parameters—inner diameter, working pressure, burst pressure, and bending radius—are critical. These factors determine flow capacity, structural integrity under pressure, safety margins, and flexibility during deployment. East Marine’s jet water rubber hoses are constructed using high-tensile synthetic rubber compounds and reinforced with spiral steel wire and high-modulus textile plies, ensuring optimal resistance to abrasion, vacuum collapse, and dynamic stress.

Below is a comparative analysis of East Marine’s standard dredging rubber hose against typical competitor offerings in the market. The data reflects standard configurations for 10-inch and 12-inch inner diameter hoses, commonly used in medium to large-scale dredging operations.

| Inner Diameter (in) | Parameter | Marinha do Leste | Industry Average (Competitors) |

|---|---|---|---|

| 10 | Working Pressure | 15 bar (217 psi) | 12 bar (174 psi) |

| Burst Pressure | 60 bar (870 psi) | 48 bar (696 psi) | |

| Bending Radius | 1,200 mm | 1,400 mm | |

| 12 | Working Pressure | 14 bar (203 psi) | 11 bar (159 psi) |

| Burst Pressure | 56 bar (812 psi) | 44 bar (638 psi) | |

| Bending Radius | 1,450 mm | 1,700 mm |

East Marine hoses demonstrate a 25% higher working pressure and a 25% improvement in burst pressure ratio (burst to working) compared to industry averages. This enhanced pressure performance is achieved through proprietary rubber formulation and precision layer lamination techniques. Additionally, the reduced bending radius—up to 15% tighter than competitors—allows for greater maneuverability in confined dredge sites and floating pipeline configurations, minimizing installation time and reducing stress on coupling joints.

The superior flexibility without compromising structural integrity is a result of optimized reinforcement layer design and advanced curing processes. All hoses undergo 100% hydrostatic testing and vacuum resistance checks up to 0.9 bar, ensuring reliability under full operational loads.

East Marine’s commitment to engineering excellence ensures that our dredging hoses deliver unmatched durability, flow efficiency, and safety margins. For operators seeking to minimize downtime and maximize uptime in abrasive, high-pressure environments, our technical specifications set a new benchmark in the global dredging industry.

Partner with East Marine

Conclusion: Engineered Reliability for Demanding Dredging Operations

The Jet Water Rubber Hose detailed throughout this specification represents the culmination of East Marine’s two decades of specialized expertise in high-performance marine fluid transfer systems. Engineered to withstand the relentless abrasion, extreme pressure fluctuations, and corrosive environments inherent in modern dredging, this hose is not merely a component but a critical operational asset. Its reinforced construction, utilizing premium synthetic rubber compounds and high-tensile textile/cord reinforcements, delivers exceptional flexibility without compromising structural integrity, ensuring consistent flow efficiency and minimizing downtime during critical project phases. The proven resistance to wear, kinking, and vacuum collapse directly translates to extended service life and reduced total cost of ownership – a paramount consideration for fleet managers and project engineers operating within stringent budgetary and schedule constraints. In the high-stakes arena of capital and maintenance dredging, where pipeline failure equates to significant financial loss and project delays, the reliability engineered into every meter of East Marine hose is non-negotiable.

Technical Specifications Summary: Jet Water Rubber Hose

| Parameter | Value | Standard Compliance |

|---|---|---|

| Working Pressure | 1.0 – 1.5 MPa (10 – 15 bar) | ISO 1436 / EN 853 Type 1SN |

| Burst Pressure | ≥ 4.0 MPa (40 bar) | Minimum 4x Working Press. |

| Gama de temperaturas | -30°C to +80°C | Continuous Operation |

| Cover Material | SBR/NR Blend, Abrasion Resistant | Customizable for Oil Resist. |

| Reinforcement | High-Tensile Polyester Cord | Multiple Plies |

| Bend Radius (Min.) | 6 x Nominal Diameter | Ensures Flow Efficiency |

| Color | Standard Black (Custom Options) | High Visibility Options |

East Marine, operating as a dedicated subsidiary of Jiangsu Huashen Special Rubber Products Co. Ltd., leverages our 0.68 million square meter manufacturing facility – one of the largest specialized rubber product complexes in the Asia-Pacific region – to deliver uncompromising quality and scalability. Our ISO 9001-certified quality management system, coupled with active membership in WEDA (Western Dredging Association) and CEDA (Central Dredging Association), ensures our solutions are developed and validated against the most rigorous international industry standards and real-world operational feedback. Founded in 2007, our singular focus on marine and dredging applications means we understand the unique challenges you face, from the North Sea to the Mekong Delta.

Global project demands require responsive, localized support. East Marine provides comprehensive technical and supply chain management through our strategically located Singapore branch, ensuring rapid coordination, regional inventory availability, and dedicated engineering assistance for projects across Southeast Asia, the Indian subcontinent, and the broader Indo-Pacific region. Our commitment extends beyond the point of sale; we partner with clients to optimize hose selection, installation, and lifecycle management, maximizing uptime and operational efficiency.

Initiate Your Project with Confidence

Do not compromise on the integrity of your dredging fluid transfer system. Contact East Marine’s engineering team today to discuss your specific Jet Water Rubber Hose requirements and receive a tailored technical proposal. Our experts are prepared to analyze your operational parameters, provide detailed performance validation data, and ensure seamless integration into your existing pipeline infrastructure. For immediate technical consultation or quotation requests, connect directly via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Mention your project location and operational specifications to expedite the process. Leverage the manufacturing depth, technical authority, and global support network of a partner trusted by leading dredging contractors worldwide since 2007. Secure the reliability your project demands – contact East Marine now.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.