Introduction: Navigating the Global Market for Jet Water Rubber Hose

Navigating the global market for jet water rubber hose can be a daunting task for B2B buyers, especially in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality jet water rubber hoses that meet specific operational requirements while ensuring reliability and safety is a key challenge for industries ranging from construction to agriculture. This guide aims to provide a comprehensive overview of the various types of jet water rubber hoses available, their applications across different sectors, and critical factors to consider when vetting suppliers.

In addition to exploring the technical specifications of these hoses, such as pressure ratings, material durability, and compatibility with existing systems, we will delve into cost considerations, including budgeting for bulk purchases and understanding shipping logistics. With insights tailored for international B2B buyers, this resource equips decision-makers with the knowledge needed to make informed purchasing choices. By addressing common concerns and providing actionable strategies, this guide seeks to empower businesses in countries like Vietnam and Brazil to successfully navigate the complexities of sourcing jet water rubber hoses, ensuring they invest in products that enhance operational efficiency and safety.

Índice

- Top 4 Jet Water Rubber Hose Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for Jet Water Rubber Hose

- Understanding Jet Water Rubber Hose Types and Variations

- Key Industrial Applications of Jet Water Rubber Hose

- 3 Common User Pain Points for ‘Jet Water Rubber Hose’ & Their Solutions

- Strategic Material Selection Guide for Jet Water Rubber Hose

- In-depth Look: Manufacturing Processes and Quality Assurance for Jet Water Rubber Hose

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘Jet Water Rubber Hose’

- Comprehensive Cost and Pricing Analysis for Jet Water Rubber Hose Sourcing

- Alternatives Analysis: Comparing Jet Water Rubber Hose With Other Solutions

- Essential Technical Properties and Trade Terminology for Jet Water Rubber Hose

- Navigating Market Dynamics and Sourcing Trends in the Jet Water Rubber Hose Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of Jet Water Rubber Hose

- Strategic Sourcing Conclusion and Outlook for Jet Water Rubber Hose

- Aviso importante e termos de utilização

Understanding Jet Water Rubber Hose Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| High-Pressure Jet Hose | Reinforced with steel wire, withstands extreme pressure | Industrial cleaning, construction | Prós: High durability, suitable for tough tasks. Contras: Heavier and more expensive. |

| Dredging Jet Water Hose | Flexible, wear-resistant, designed for marine applications | Dredging, offshore projects | Prós: High reliability in harsh environments. Contras: Limited to specific applications. |

| Pressure Washer Jet Hose | Compatible with various pressure washers, multiple diameters | Residential and commercial cleaning | Prós: Versatile, easy to replace. Contras: May not withstand extreme conditions. |

| Chemical-Resistant Hose | Specially formulated rubber for chemical durability | Chemical processing, agriculture | Prós: Safeguards against chemical damage. Contras: Higher cost due to specialized materials. |

| Lightweight Garden Jet Hose | Made from flexible rubber, easy to handle | Gardening, light-duty cleaning | Prós: Easy to maneuver, affordable. Contras: Not suitable for high-pressure tasks. |

What Are the Key Characteristics of High-Pressure Jet Hoses?

High-pressure jet hoses are engineered to endure significant stress, typically reinforced with steel wire braids. These hoses are ideal for industrial cleaning and construction applications, where durability and reliability are paramount. When purchasing, consider the hose’s pressure rating, diameter, and compatibility with existing equipment. While they offer excellent performance, buyers should be aware that their weight can be a drawback for prolonged use.

How Do Dredging Jet Water Hoses Differ from Other Types?

Dredging jet water hoses are specifically designed for marine environments, featuring flexibility and wear-resistance to handle the rigors of dredging operations. These hoses excel in offshore projects where reliability under extreme conditions is essential. B2B buyers should focus on the hose’s working pressure and material composition. Although they are highly effective, their specialized nature may limit their use to particular applications.

Why Choose a Pressure Washer Jet Hose for Cleaning Tasks?

Pressure washer jet hoses are versatile, designed to connect seamlessly with various pressure washer models. They come in multiple diameters to cater to different cleaning needs, making them suitable for both residential and commercial applications. Buyers should assess the hose’s pressure rating and length for optimal performance. However, their limitations in extreme conditions should be considered, especially for industrial applications.

What Are the Benefits of Using Chemical-Resistant Hoses?

Chemical-resistant hoses are made from specially formulated rubber that can withstand exposure to harsh chemicals. These hoses are crucial in industries like chemical processing and agriculture, where safeguarding against chemical damage is essential. When selecting a chemical-resistant hose, buyers should evaluate compatibility with specific chemicals and the hose’s durability. While they provide excellent protection, the cost is typically higher than standard hoses.

How Do Lightweight Garden Jet Hoses Serve B2B Buyers?

Lightweight garden jet hoses are crafted for ease of use, making them ideal for gardening and light-duty cleaning tasks. They are flexible and easy to maneuver, appealing to buyers looking for affordability and convenience. However, their suitability for high-pressure applications is limited, which is an essential consideration for B2B buyers in more demanding sectors.

Key Industrial Applications of Jet Water Rubber Hose

| Indústria/Setor | Specific Application of Jet Water Rubber Hose | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

| Petróleo e gás | High-pressure water jetting for pipeline cleaning | Efficient removal of debris and buildup, reducing downtime | Ensure hoses are rated for high pressure and chemical resistance |

| Construction & Dredging | Dredging operations and sediment removal | Enhances productivity and safety in challenging environments | Look for wear-resistant materials and flexibility under pressure |

| Agricultura | Irrigation and soil compaction | Promotes efficient water distribution and soil management | Consider hose length, diameter, and compatibility with pumps |

| Manufacturing & Processing | Pressure washing of machinery and equipment | Maintains cleanliness and operational efficiency | Assess temperature tolerance and abrasion resistance |

| Environmental Services | Water jetting for waste management | Effective in cleaning and maintaining waste treatment facilities | Evaluate hose durability in harsh conditions and ease of handling |

How is Jet Water Rubber Hose Used in Oil & Gas Operations?

In the oil and gas sector, jet water rubber hoses are crucial for high-pressure water jetting applications, particularly in pipeline cleaning. They efficiently remove debris, sludge, and buildup, which can impede flow and lead to operational downtimes. Buyers in this industry should prioritize hoses that are rated for high pressures and possess chemical resistance, ensuring they can withstand harsh environments typically found in oil extraction and transportation.

What Role Does Jet Water Rubber Hose Play in Construction and Dredging?

In construction and dredging, jet water rubber hoses are employed for sediment removal and dredging operations. Their flexibility and wear-resistant properties allow them to perform effectively in challenging environments, such as underwater or muddy conditions. International buyers should seek hoses that can handle extreme working pressures and offer customization options to fit specific dredging equipment and requirements.

Why is Jet Water Rubber Hose Essential for Agricultural Applications?

In agriculture, jet water rubber hoses facilitate efficient irrigation and soil compaction management. They enable precise water distribution, which is essential for crop health and yield. Buyers should consider the hose’s length and diameter to ensure compatibility with their irrigation systems. Additionally, hoses must be durable enough to withstand various weather conditions prevalent in regions like Africa and South America.

How Does Jet Water Rubber Hose Improve Manufacturing and Processing Operations?

Manufacturing and processing industries utilize jet water rubber hoses for pressure washing machinery and equipment, ensuring cleanliness and operational efficiency. Regular maintenance using high-pressure water jets prevents equipment failure and prolongs lifespan. Buyers should focus on hoses that offer high-temperature tolerance and abrasion resistance to ensure reliability in demanding manufacturing environments.

What is the Importance of Jet Water Rubber Hose in Environmental Services?

In environmental services, jet water rubber hoses are vital for cleaning and maintaining waste treatment facilities. They provide effective water jetting solutions for waste management, helping in the removal of sludge and debris. Buyers should evaluate the hose’s durability in harsh conditions, as well as its ease of handling, to ensure optimal performance in waste management applications.

3 Common User Pain Points for ‘Jet Water Rubber Hose’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Hose Specifications for High-Pressure Applications

O problema: B2B buyers often struggle to select the appropriate jet water rubber hose for high-pressure applications, especially when the operational environment varies significantly. The challenge lies in understanding the specific pressure ratings, hose diameter, and material compatibility required for different tasks. Miscalculating these specifications can lead to hose failure, resulting in costly downtime and safety hazards. For example, a construction company in Brazil may need hoses that can withstand abrasive materials and high temperatures while delivering water at significant pressures.

A solução: To mitigate this issue, buyers should conduct a thorough needs assessment before sourcing hoses. Start by clearly defining the application requirements, including maximum pressure, temperature, and the type of fluid being transported. For high-pressure applications, look for hoses specifically rated for at least 20% more than the maximum expected pressure to ensure safety and longevity. Consult manufacturers or suppliers to access detailed product specifications, ensuring that the selected hose meets industry standards like ISO or SAE. It is also beneficial to request samples for testing under real-world conditions. By ensuring that the chosen hose aligns with your operational needs, you can significantly reduce the risk of failure and enhance overall efficiency.

Scenario 2: Problems with Hose Durability in Extreme Environments

O problema: In regions with harsh weather conditions, such as the extreme heat of the Middle East or the heavy rainfall of South America, buyers face the challenge of hose durability. Rubber hoses can degrade quickly due to UV exposure, ozone, and temperature extremes, leading to frequent replacements and interruptions in service. A company engaged in agricultural irrigation in Vietnam might find that their hoses are cracking and leaking after only a few months of use, resulting in wasted resources and increased maintenance costs.

A solução: Buyers should prioritize sourcing jet water rubber hoses designed for extreme environmental conditions. Look for hoses made from high-quality synthetic rubber compounds that offer UV and ozone resistance, along with robust reinforcement to withstand physical stress. When negotiating with suppliers, ask about the hose’s warranty and its expected lifespan in specific environmental conditions. Additionally, consider implementing a regular maintenance schedule to inspect hoses for early signs of wear, such as cracks or brittleness. Proper storage practices, such as keeping hoses coiled and out of direct sunlight when not in use, can also prolong their lifespan. By investing in durable products and proactive maintenance, businesses can minimize disruptions and reduce costs over time.

Scenario 3: Complications with Hose Compatibility and Fittings

O problema: Another common pain point for B2B buyers is ensuring compatibility between different hose types and the fittings or equipment they use. Many buyers may not realize that not all hoses are designed to work with standard fittings, leading to leaks and inefficiencies. For example, a mining operation in Africa might face challenges when trying to connect hoses to various machinery, resulting in operational delays and increased labor costs to find suitable adapters or replacements.

A solução: To address compatibility issues, buyers should focus on standardizing hose fittings across their operations. Before purchasing hoses, evaluate the existing equipment to determine the most common fitting sizes and types used. When placing orders, specify the fittings required or choose hoses that come with compatible fittings. It’s also wise to maintain a small inventory of commonly used adapters and connectors to minimize downtime during operations. Collaborating with suppliers who offer customization options can further streamline this process, allowing businesses to receive hoses that are ready to connect seamlessly with their existing systems. By taking these proactive steps, organizations can enhance operational efficiency and reduce the risks associated with equipment incompatibility.

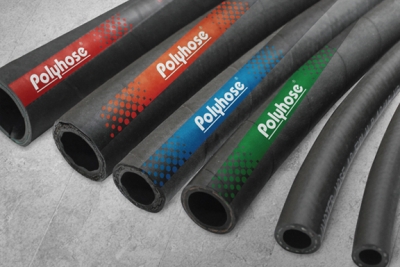

Illustrative image related to Jet Water Rubber Hose

Strategic Material Selection Guide for Jet Water Rubber Hose

What Are the Key Materials Used in Jet Water Rubber Hose Production?

When selecting materials for jet water rubber hoses, it is crucial to consider their properties, advantages, and limitations. This analysis will focus on four common materials: EPDM (Ethylene Propylene Diene Monomer), NBR (Nitrile Butadiene Rubber), CR (Chloroprene Rubber), and TPU (Thermoplastic Polyurethane). Each material has unique characteristics that can significantly impact performance and application suitability.

How Does EPDM Rubber Perform in Jet Water Hoses?

EPDM is a synthetic rubber known for its excellent weather resistance and durability. It can withstand a temperature range of -40°C to +150°C and offers good resistance to ozone, UV radiation, and aging. This makes EPDM suitable for outdoor applications and environments with fluctuating temperatures.

Prós: EPDM hoses are highly flexible, lightweight, and resistant to water and steam, making them ideal for various jetting applications. They also have a lower cost compared to other materials.

Contras: While EPDM is resistant to many environmental factors, it has limited oil resistance, which can be a drawback in applications involving petroleum-based fluids.

Impacto na aplicação: EPDM is well-suited for water jetting and cleaning applications but may not be suitable for industries that involve oil or chemical exposure.

Considerações para compradores internacionais: Compliance with ASTM and ISO standards is essential. EPDM hoses are widely accepted in various regions, including Europe and South America, where environmental resistance is crucial.

Illustrative image related to Jet Water Rubber Hose

What Are the Benefits of NBR Rubber for Jet Water Hoses?

NBR, or Nitrile Butadiene Rubber, is renowned for its excellent oil and fuel resistance, making it a preferred choice in applications where exposure to hydrocarbons is a concern. NBR hoses can typically handle temperatures ranging from -30°C to +100°C.

Prós: NBR hoses offer superior durability and are resistant to abrasion and wear, making them suitable for high-pressure applications. They are also relatively affordable.

Contras: NBR has limited resistance to ozone and UV light, which can lead to degradation when exposed to outdoor environments.

Illustrative image related to Jet Water Rubber Hose

Impacto na aplicação: NBR is ideal for industries such as automotive and oil drilling, where oil compatibility is critical. However, its outdoor usability is limited compared to EPDM.

Considerações para compradores internacionais: Buyers in oil-rich regions, such as the Middle East, should prioritize NBR for applications involving oil transport. Compliance with local standards is crucial, especially in industries with strict regulations.

How Does Chloroprene Rubber (CR) Compare for Jet Water Hoses?

Chloroprene Rubber, commonly known as CR, offers a good balance of properties, including weather resistance, flexibility, and chemical stability. CR can typically withstand temperatures from -40°C to +120°C.

Prós: CR hoses are resistant to oil, ozone, and UV light, making them versatile for both indoor and outdoor applications. They are also flame retardant, adding an extra layer of safety.

Illustrative image related to Jet Water Rubber Hose

Contras: The cost of CR can be higher than EPDM and NBR, which may deter budget-conscious buyers.

Impacto na aplicação: CR is suitable for a wide range of applications, including chemical processing and general industrial use, where both oil and weather resistance are required.

Considerações para compradores internacionais: CR hoses are compliant with various international standards, making them suitable for buyers across Europe and Africa, where chemical exposure is a concern.

What Advantages Does Thermoplastic Polyurethane (TPU) Offer?

TPU is a versatile material known for its outstanding abrasion resistance and flexibility. It can operate effectively in temperatures ranging from -30°C to +90°C.

Prós: TPU hoses are lightweight, flexible, and resistant to oils, chemicals, and abrasion, making them ideal for high-performance applications. They also have a longer lifespan compared to traditional rubber materials.

Contras: The manufacturing complexity and higher cost of TPU can be a barrier for some buyers, particularly in cost-sensitive markets.

Impacto na aplicação: TPU is well-suited for high-pressure applications and environments where durability and flexibility are paramount.

Considerações para compradores internacionais: As TPU is gaining popularity in various industries, compliance with international standards is essential, especially for buyers in Europe and South America, where high-performance materials are preferred.

Summary Table of Material Selection for Jet Water Rubber Hose

| Material | Typical Use Case for Jet Water Rubber Hose | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| EPDM | Water jetting, outdoor applications | Excellent weather resistance | Limited oil resistance | Baixa |

| NBR | Oil transport, automotive applications | Superior oil resistance | Poor ozone resistance | Med |

| CR | Chemical processing, industrial use | Good all-around resistance | Higher cost | Elevado |

| TPU | High-pressure applications, durability-focused | Outstanding abrasion resistance | Manufacturing complexity | Elevado |

This guide provides a comprehensive overview of material options for jet water rubber hoses, helping international B2B buyers make informed decisions based on their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for Jet Water Rubber Hose

What Are the Main Stages in the Manufacturing Process of Jet Water Rubber Hose?

Manufacturing jet water rubber hoses involves a series of intricate stages designed to ensure durability, performance, and safety. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to Jet Water Rubber Hose

-

Preparação do material: The process begins with the selection of high-quality materials, typically synthetic rubber compounds like EPDM or NR (natural rubber), which provide flexibility and resistance to abrasion. These materials are mixed with various additives, including antioxidants, accelerators, and fillers, to enhance performance characteristics such as temperature resistance and longevity. The mixing process is closely monitored to ensure uniformity and adherence to specifications.

-

Formação: Once the materials are prepared, they undergo shaping into hose forms. This involves extrusion, where the rubber compound is forced through a die to create the desired hose profile. In cases where reinforcement is needed, layers of textile or steel wire are added during this phase to provide strength and pressure resistance. The forming process is crucial, as it directly affects the hose’s ability to withstand high-pressure applications.

-

Montagem: After forming, the hoses are cut to the required lengths, and fittings or couplings are attached. This step may involve crimping or bonding the ends of the hose to the fittings to ensure a secure connection. Quality control measures are implemented at this stage to verify that all components are correctly assembled and meet design specifications.

-

Acabamento: The final stage involves curing the hoses in a controlled environment, where heat is applied to set the rubber. This vulcanization process enhances the material’s strength and elasticity. Once cured, the hoses are tested for flexibility, pressure resistance, and overall quality. Finally, they are cleaned, packaged, and prepared for shipment.

How Is Quality Assurance Implemented in Jet Water Rubber Hose Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each hose meets international and industry-specific standards. Several key checkpoints and practices are involved in maintaining high-quality production.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001:2015 standards, which outline requirements for a quality management system. Compliance with these standards helps ensure consistency in product quality and enhances customer satisfaction. Additionally, industry-specific certifications, such as CE and API, may also be relevant, depending on the intended application of the hoses.

-

Pontos de controlo de qualidade:

– Controlo de qualidade de entrada (IQC): Raw materials are inspected upon arrival to confirm they meet specified quality standards. This includes checking for material integrity and compliance with technical data sheets.

– Controlo de qualidade durante o processo (IPQC): Throughout the manufacturing process, random samples are taken at various stages (e.g., during extrusion and assembly) to assess quality. This helps identify any defects early in the production cycle.

– Controlo de qualidade final (FQC): Before packaging, finished hoses undergo rigorous testing to verify performance specifications, such as burst pressure, flexibility, and overall durability. Common testing methods include hydrostatic testing, abrasion resistance tests, and temperature cycling tests. -

Common Testing Methods for Quality Assurance:

– Teste hidrostático: This test evaluates the hose’s ability to withstand high pressure by filling it with water and applying pressure until a predetermined threshold is reached.

– Abrasion Resistance Testing: This assesses the hose’s durability under conditions that simulate real-world wear and tear.

– Temperature Cycling Tests: These tests check the hose’s performance under varying temperature conditions, ensuring it can operate effectively in diverse environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those operating in international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and performance.

-

Realização de auditorias: Prospective buyers should conduct on-site audits of suppliers to assess their manufacturing capabilities and quality control practices. This can provide insights into the production environment, equipment used, and adherence to quality standards.

-

Pedido de documentação de garantia de qualidade: Buyers should ask for documentation that outlines the supplier’s quality management system, including certifications (like ISO 9001) and testing protocols. This information can help buyers gauge the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the manufacturing process can provide an unbiased assessment of the supplier’s quality control practices. These inspections often include detailed reports on compliance with industry standards and testing outcomes.

-

Reviewing Quality Control Reports: Suppliers should provide regular quality control reports detailing the results of tests conducted on finished products. This information helps buyers understand the consistency of product quality and any potential issues that may arise during production.

-

Understanding Certification Nuances: International buyers should be aware of the specific certifications required in their regions. For instance, compliance with CE marking is crucial for the European market, while API standards may be necessary for the oil and gas sector. Understanding these requirements helps ensure that the products meet local regulations and standards.

What Are the Challenges and Considerations for International B2B Buyers?

International B2B buyers should be cognizant of various challenges and considerations when sourcing jet water rubber hoses. These may include:

-

Logistical Challenges: Shipping and customs regulations can vary significantly between countries, affecting delivery times and costs. Buyers should work closely with suppliers to understand these logistics and ensure smooth transportation.

-

Cultural Differences: Different regions may have varying expectations regarding quality standards and customer service. Buyers should communicate clearly with suppliers about their specific needs and expectations to foster a successful partnership.

-

Currency Fluctuations: Price volatility can impact budgeting and costs. Buyers should consider negotiating fixed pricing contracts or exploring currency hedging options to mitigate risks associated with exchange rate fluctuations.

By understanding the manufacturing processes and quality assurance measures in place for jet water rubber hoses, international B2B buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Jet Water Rubber Hose’

In the competitive landscape of industrial procurement, sourcing the right jet water rubber hose is crucial for operational efficiency and safety. This guide provides a systematic approach to help B2B buyers make informed decisions when procuring these essential components.

Passo 1: Definir as suas especificações técnicas

Establishing clear technical specifications is the first step in sourcing a jet water rubber hose. This includes determining the hose diameter, pressure ratings, and temperature tolerance based on your application requirements. Consider the working environment, as hoses used in high-pressure or abrasive conditions will need to meet stringent durability standards.

- Key Specifications to Consider:

- Diameter: Ensure compatibility with existing equipment.

- Classificações de pressão: Match the hose to your system’s operational pressure.

- Material: Choose hoses made from high-quality rubber for flexibility and resistance to wear.

Passo 2: Pesquisa de potenciais fornecedores

Conduct thorough research to identify potential suppliers specializing in jet water rubber hoses. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors. Investigating multiple suppliers allows you to compare products, prices, and services.

- What to Look For:

- Industry Reputation: Look for reviews and testimonials from other buyers.

- Product Range: Ensure the supplier offers a variety of hoses to meet different specifications.

Passo 3: Avaliar potenciais fornecedores

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. A reliable supplier will have a proven track record and the ability to meet your specific needs.

- Key Evaluation Criteria:

- Certifications: Verify if the supplier complies with relevant industry standards (e.g., ISO).

- Manufacturing Capabilities: Assess their production capacity and quality control measures.

Passo 4: Pedido de amostras e realização de testes

Once you have shortlisted suppliers, request samples of the jet water rubber hoses. Testing these samples in your operational environment is essential to ensure they perform as expected under actual working conditions.

- Testing Considerations:

- Durability Tests: Evaluate resistance to abrasion and pressure.

- Flexibility Tests: Ensure the hose maintains performance in various temperatures.

Passo 5: Negotiate Pricing and Terms

Once you are satisfied with the samples, engage in negotiations regarding pricing, delivery schedules, and payment terms. Clear communication during this stage can lead to favorable terms that benefit both parties.

Illustrative image related to Jet Water Rubber Hose

- Negotiation Tips:

- Descontos por volume: Inquire about pricing reductions for bulk orders.

- Payment Terms: Discuss flexible payment options to support cash flow management.

Passo 6: Confirm After-Sales Support and Warranty

Before finalizing the purchase, confirm the supplier’s after-sales support and warranty policies. Reliable customer service and warranty options can save costs and time should any issues arise post-purchase.

- Essential Support Elements:

- Technical Support: Ensure the supplier offers assistance for installation and maintenance.

- Warranty Coverage: Understand what is covered under warranty to avoid unexpected costs.

Passo 7: Finalize Purchase and Monitor Performance

Once all terms are agreed upon, finalize your purchase. After receiving the hoses, monitor their performance closely during initial operations to ensure they meet your specifications and expectations.

- Performance Monitoring:

- Regular Inspections: Conduct routine checks for wear and tear.

- Feedback Loop: Maintain communication with the supplier to address any concerns promptly.

By following this checklist, B2B buyers can streamline the procurement process for jet water rubber hoses, ensuring they acquire high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for Jet Water Rubber Hose Sourcing

What are the Key Cost Components in Jet Water Rubber Hose Manufacturing?

When sourcing jet water rubber hoses, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materiais: The quality of rubber, reinforcements (such as steel wire), and additional components like couplings significantly affect the price. Higher-quality materials often lead to better durability and performance, which can justify higher costs.

-

Trabalho: Labor costs can vary based on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can also impact the quality of the final product.

-

Despesas gerais de fabrico: This includes costs associated with utilities, equipment maintenance, and facility operation. Efficient manufacturing processes can help reduce overhead, contributing to lower overall costs.

-

Ferramentas: Customization often requires specialized tooling, which can be a significant upfront investment. For large orders, these costs can be amortized over many units, but smaller orders may face higher per-unit tooling costs.

-

Controlo de qualidade (CQ): Ensuring consistent quality through rigorous testing is vital, particularly for high-pressure applications. Comprehensive QC processes can add to the cost but help prevent costly failures in the field.

-

Logística: Shipping costs are influenced by the distance from the manufacturer to the buyer, as well as the mode of transportation. Incoterms also play a role in determining who bears these costs.

-

Margem: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can vary based on market conditions, competition, and supplier reputation.

How Do Price Influencers Affect the Cost of Jet Water Rubber Hoses?

Several factors can influence the pricing of jet water rubber hoses:

-

Volume/MOQ: Bulk orders often lead to lower prices per unit. Negotiating minimum order quantities (MOQs) can be beneficial for cost savings.

-

Especificações e personalização: Custom hoses designed for specific applications may incur higher costs due to the need for specialized materials and tooling.

-

Qualidade dos materiais e certificações: Hoses that meet international standards and certifications typically command higher prices. Buyers should consider the long-term benefits of investing in certified products.

-

Factores do fornecedor: Supplier reputation, reliability, and customer service can influence pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: The choice of Incoterms affects the total cost by defining responsibilities for shipping, insurance, and tariffs. Understanding these terms is essential for accurate cost projections.

What Tips Can Buyers Use for Effective Negotiation and Cost-Efficiency?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negociar as condições: Always negotiate on price and payment terms. Building a relationship with suppliers can lead to better deals over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and performance. A higher upfront cost may be justified by lower long-term operational costs.

-

Leverage Local Knowledge: Engage local intermediaries who understand regional market dynamics and can assist in navigating the complexities of international trade.

-

Compreender as nuances dos preços: Be aware of seasonal price fluctuations and market demand variations. Timing your purchase can lead to significant savings.

-

Realizar estudos de mercado: Benchmark prices from multiple suppliers to ensure you are getting competitive rates. Utilize industry reports to stay informed about market trends.

Disclaimer on Indicative Prices

It is essential to note that prices for jet water rubber hoses can vary significantly based on the factors discussed above. The information provided is indicative and may not reflect current market conditions or specific supplier pricing. Always seek detailed quotes tailored to your particular requirements and circumstances.

Alternatives Analysis: Comparing Jet Water Rubber Hose With Other Solutions

Exploring Alternatives to Jet Water Rubber Hose: Key Comparisons

In the industrial landscape, selecting the right hose solution is crucial for operational efficiency and cost-effectiveness. While the Jet Water Rubber Hose is a popular choice for various applications, there are several alternatives that may better suit specific needs. This analysis compares the Jet Water Rubber Hose with two viable alternatives: PVC Water Hose and Pressure Washer Hose, focusing on critical aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

| Aspeto de comparação | Mangueira de borracha para água a jato | PVC Water Hose | Pressure Washer Hose |

|---|---|---|---|

| Desempenho | High pressure resistance, flexible, and durable | Moderate pressure tolerance, less flexible | Excellent for high-pressure applications, abrasion-resistant |

| Custo | Higher initial investment | Generally low cost | Mid-range pricing, varies by specifications |

| Facilidade de implementação | Requires specific fittings for high pressure | Easy to connect and use | Requires specific connectors; user-friendly |

| Manutenção | Low maintenance, resistant to wear | Moderate maintenance; can degrade over time | Low maintenance, but requires inspection for wear |

| Melhor caso de utilização | Dredging, industrial cleaning | General water delivery, gardening | Pressure washing, heavy-duty cleaning tasks |

Análise pormenorizada das alternativas

PVC Water Hose

PVC hoses are a cost-effective alternative for many applications. They are lightweight and easy to handle, making them ideal for general water delivery tasks, gardening, and light-duty cleaning. However, they have a lower pressure tolerance compared to Jet Water Rubber Hoses, which may limit their use in high-pressure applications. Over time, PVC hoses can degrade under harsh environmental conditions, requiring more frequent replacements.

Pressure Washer Hose

Designed specifically for high-pressure applications, pressure washer hoses excel in delivering water at significant force. They are often reinforced with steel braiding to withstand extreme pressures, making them suitable for heavy-duty cleaning tasks in commercial and industrial settings. The cost of pressure washer hoses can vary based on specifications, but they typically fall into a mid-range price category. While they require specific connectors, they are user-friendly and generally require low maintenance; however, regular inspections for wear and tear are advisable to ensure safety and performance.

Making the Right Choice for Your Business Needs

When evaluating hose solutions for your business, consider the specific demands of your operations. The Jet Water Rubber Hose is unparalleled for high-pressure environments, especially in dredging and industrial cleaning applications. In contrast, if your needs are more general, a PVC water hose may suffice at a lower cost. For those engaged in pressure washing or heavy-duty cleaning, a pressure washer hose could provide the best performance.

Ultimately, the right choice will depend on factors such as application requirements, budget constraints, and maintenance capabilities. Understanding the strengths and weaknesses of each option will empower B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for Jet Water Rubber Hose

What Are the Key Technical Properties of Jet Water Rubber Hose?

Jet water rubber hoses are essential components in various industrial applications, particularly in high-pressure water jetting systems. Understanding their technical properties is crucial for B2B buyers to ensure they select the right hose for their specific needs.

-

Composição do material

The primary material used in jet water rubber hoses is synthetic rubber, often EPDM (Ethylene Propylene Diene Monomer) or NR (Natural Rubber). These materials are chosen for their excellent resistance to abrasion, weathering, and extreme temperatures. For B2B buyers, selecting the right material grade can mean the difference between a durable hose that performs well under pressure and one that fails prematurely. -

Working Pressure and Burst Pressure

Working pressure is the maximum pressure a hose can safely withstand during regular operation, while burst pressure indicates the maximum pressure the hose can handle before failure. For example, a hose rated for 3000 PSI working pressure and 9000 PSI burst pressure provides a safety margin that is vital in high-stress applications. Understanding these ratings helps buyers select hoses that can handle their operational demands without risk of failure. -

Diameter and Weight Specifications

Jet water hoses come in various inner diameters (ID) and outer diameters (OD), typically ranging from 1/4 inch to 2 inches. The diameter affects the flow rate and pressure drop in the system. Additionally, the weight of the hose impacts handling and installation. Buyers should consider the application requirements—larger diameters may be necessary for high flow rates, while lighter hoses are easier to maneuver. -

Gama de temperaturas

The operational temperature range of a hose indicates the extremes it can handle without degrading. For jet water hoses, this can often be between -40°C to 155°C. Understanding the temperature limits is crucial for applications involving hot water or steam, ensuring that the hose maintains its integrity under varying conditions. -

Raio de curvatura

The bend radius is the minimum radius a hose can be bent without risking damage. A smaller bend radius allows for more flexible installations, particularly in tight spaces. For B2B buyers, knowing the bend radius helps in planning hose layouts and ensuring that the hose will function effectively in the intended application.

What Are Common Trade Terms Related to Jet Water Rubber Hose?

Familiarity with industry jargon is essential for B2B buyers to facilitate effective communication and negotiations.

-

OEM (Fabricante de Equipamento Original)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of jet water hoses, an OEM may supply hoses for integration into larger systems or machinery. Understanding OEM relationships can help buyers identify reliable suppliers and quality assurance processes. -

MOQ (Quantidade mínima de encomenda)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For jet water hoses, MOQs can vary significantly among manufacturers. Buyers must be aware of MOQs to effectively manage inventory and ensure they meet their operational needs without overcommitting financially. -

RFQ (Pedido de Cotação)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products. In the jet water hose market, an RFQ allows buyers to compare costs, specifications, and delivery terms, facilitating informed purchasing decisions. -

Incoterms (Termos Comerciais Internacionais)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is critical for buyers involved in cross-border purchasing, as they determine who is responsible for shipping costs, insurance, and risks. -

Prazo de execução

Lead time refers to the time it takes from placing an order to receiving the product. In the context of jet water hoses, understanding lead times is vital for project planning and ensuring timely availability of materials for operations.

By comprehensively grasping the essential technical properties and trade terminology associated with jet water rubber hoses, B2B buyers can make informed decisions that enhance operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the Jet Water Rubber Hose Sector

What Are the Current Market Dynamics and Key Trends in the Jet Water Rubber Hose Sector?

The global jet water rubber hose market is witnessing a significant transformation driven by several key factors. Rapid industrialization and the increasing demand for high-pressure water jetting applications across various sectors such as construction, mining, and marine are propelling growth. Additionally, technological advancements in hose manufacturing, including improved material compositions and production techniques, are enhancing the performance and durability of jet hoses. For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding these trends is crucial for informed purchasing decisions.

Emerging technologies such as IoT-enabled monitoring systems are becoming prevalent, allowing for real-time tracking of hose performance and maintenance needs. These innovations not only improve operational efficiency but also help in minimizing downtime, a critical aspect for industries reliant on water jetting. Furthermore, there is a growing emphasis on customization, with suppliers offering tailored solutions to meet specific application requirements, thereby enhancing user satisfaction.

Market dynamics are also influenced by regional factors. In emerging markets like Vietnam and Brazil, infrastructure development projects are on the rise, leading to an increased demand for robust jet water hoses. Conversely, in Europe and the Middle East, strict regulatory frameworks around safety and environmental standards are shaping sourcing strategies, urging buyers to prioritize compliance alongside performance.

How Is Sustainability Impacting the Sourcing of Jet Water Rubber Hose?

Sustainability is increasingly becoming a focal point in the sourcing of jet water rubber hoses. With growing awareness about environmental issues, B2B buyers are seeking suppliers who can demonstrate a commitment to eco-friendly practices. The production of jet water hoses often involves materials that can be harmful to the environment, prompting the need for sustainable alternatives.

Buyers should prioritize suppliers that utilize recycled materials or those that have obtained ‘green’ certifications, such as ISO 14001, which indicates adherence to environmental management standards. Additionally, the development of biodegradable hose options is emerging as a viable solution, aligning with global sustainability goals.

Illustrative image related to Jet Water Rubber Hose

Ethical sourcing practices are also gaining traction. Companies are increasingly evaluating their supply chains for transparency and social responsibility, ensuring that their suppliers adhere to fair labor practices and environmental stewardship. This shift not only enhances brand reputation but also attracts environmentally conscious customers, thereby driving market competitiveness.

What Is the Brief Evolution of Jet Water Rubber Hose Technology?

The evolution of jet water rubber hose technology can be traced back to the early 20th century, with the introduction of rubber as a primary material for hose manufacturing. Initially, these hoses were designed for basic water delivery applications. Over the decades, advancements in rubber formulations, including the incorporation of synthetic materials, significantly improved the hoses’ resistance to wear, heat, and pressure.

The introduction of high-tensile steel wire braiding in the 1980s marked a pivotal moment, allowing hoses to withstand much higher pressures and making them suitable for industrial applications such as hydro blasting and dredging. Today, manufacturers are focused on integrating smart technology into hose design, enhancing functionality and monitoring capabilities. This evolution reflects the sector’s responsiveness to the changing demands of global industries, ensuring that jet water rubber hoses meet the rigorous standards of performance, safety, and sustainability expected by modern B2B buyers.

Illustrative image related to Jet Water Rubber Hose

Frequently Asked Questions (FAQs) for B2B Buyers of Jet Water Rubber Hose

-

1. How do I choose the right jet water rubber hose for my application?

Choosing the right jet water rubber hose involves assessing the specific requirements of your application, such as the pressure rating, diameter, and temperature range. Consider the working conditions, including the type of fluids being transported and environmental factors like temperature extremes. It’s also important to check the hose’s flexibility and durability to ensure it can withstand regular use. Consult with suppliers for recommendations based on your operational needs and any industry standards that may apply. -

2. What is the best material for a jet water rubber hose?

The best material for a jet water rubber hose is typically EPDM (Ethylene Propylene Diene Monomer) synthetic rubber, which offers excellent resistance to heat, ozone, and weathering. This material is ideal for high-pressure applications and provides flexibility, allowing for easier maneuverability during use. Other materials, such as nitrile rubber, can also be suitable depending on the specific chemical resistance required. Always verify that the chosen material meets the specifications for your intended application. -

3. What are the key specifications to consider when sourcing jet water rubber hoses?

When sourcing jet water rubber hoses, key specifications to consider include the inner diameter (ID) and outer diameter (OD), working pressure, burst pressure, temperature range, and the hose’s flexibility. Additionally, review the hose’s construction, including reinforcement layers, to ensure it can handle the required pressure and environmental conditions. It’s also important to check for certifications that indicate compliance with industry standards, which can assure quality and reliability. -

4. How can I verify the credibility of a jet water rubber hose supplier?

To verify the credibility of a supplier, conduct thorough research by checking their industry reputation, customer reviews, and certifications. Request references from previous clients and evaluate their experience with similar products. Additionally, inquire about their manufacturing processes, quality control measures, and any warranties offered. Engaging in direct communication can also provide insight into their customer service and responsiveness, which are crucial for a successful partnership. -

5. What is the minimum order quantity (MOQ) for jet water rubber hoses?

The minimum order quantity (MOQ) for jet water rubber hoses varies by supplier and can depend on factors like the hose specifications and customization options. Generally, MOQs can range from a few hundred to several thousand meters. When negotiating with suppliers, discuss your specific needs and see if they offer flexibility on MOQs, especially for first-time orders or for buyers establishing a long-term relationship. -

6. What payment terms should I expect when purchasing jet water rubber hoses internationally?

Payment terms for international purchases of jet water rubber hoses can vary significantly among suppliers. Common options include upfront payments, partial payments with balance upon delivery, or net 30/60/90-day terms. It’s essential to clarify these terms before placing an order and to ensure they align with your cash flow needs. Additionally, consider using secure payment methods such as letters of credit or escrow services to mitigate risks associated with international transactions. -

7. How do I ensure quality assurance for jet water rubber hoses?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. It’s advisable to conduct factory audits or request third-party inspections before shipment to verify compliance with agreed standards. Additionally, consider ordering samples for testing prior to bulk purchases. Establishing clear quality control protocols in your contract can also help ensure that the products meet your expectations upon delivery. -

8. What logistics considerations should I keep in mind for importing jet water rubber hoses?

When importing jet water rubber hoses, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Evaluate the total landed cost, including shipping fees, tariffs, and taxes, to avoid unexpected expenses. Partnering with an experienced freight forwarder can streamline the process and help navigate complex import regulations. Additionally, plan for potential delays and communicate with your supplier to stay informed about shipment status.

Top 4 Jet Water Rubber Hose Manufacturers & Suppliers List

1. Texcel – Water Jetting Hose

Domínio: texcelrubber.com

Registada: 1996 (29 anos)

Introdução: {“products”:[{“id”:”WJETT-2.5-100″,”description”:”2.5″ WATER JETTING HOSE”,”unit_of_measure”:”FT PIECE (100 FT)”,”in_stock”:true},{“id”:”WJETT-4.0-100″,”description”:”4″ WATER JETTING HOSE”,”unit_of_measure”:”FT PIECE (100 FT)”,”in_stock”:true}]}

2. Tubes International – WATERBLAST Hoses

Domínio: tubes-international.com

Registada: 2007 (18 anos)

Introdução: WATERBLAST hoses are designed for ultra high pressure water applications, specifically for water jet cutting and cleaning. Key specifications include:

– Hose design: Multi-braid (multispiral) rubber hydraulic hose

– Pressure range: 700 to 1450 bar

– Diameter range: 6 to 25 mm

– Maximum length: 100 m

– Working temperature range: -10°C to +70°C (up to +100°C for short periods)

– Fittings: Spec…

3. EMSTEC – Custom Rubber Dredging Hoses

Domínio: emstec.net

Registada: 2004 (21 anos)

Introdução: EMSTEC Rubber Dredging Hoses are custom-built to meet client specifications, available in sizes from 100 mm ID to 2200 mm ID. They feature an adjustable inner lining for specific medium requirements, wear indicator layers for abrasive mediums, and high tensile strength textile reinforcement for pressure and tensile strength control. The outer cover is made from a rubber compound resistant to weath…

4. Gates – Waterjet Hose

Domínio: gates.com

Registered: 1994 (31 years)

Introdução: {“Product Name”: “Waterjet Hose”, “Recommended Use”: “Ultra high pressure water blasting applications, not for hydraulic applications”, “Impulse Tested”: “More than 25,000 cycles at 15,000 psi”, “Temperature Range”: “-20°C to +70°C (-4°F to +158°F)”, “Size”: “1/2 inch”, “Inside Diameter”: {“mm”: 12.70, “in”: 0.50}, “Outside Diameter”: {“mm”: 24.6, “in”: “N/A”}, “Maximum Working Pressure”: {“psi”: …

Strategic Sourcing Conclusion and Outlook for Jet Water Rubber Hose

As the demand for efficient and durable jet water rubber hoses continues to rise, strategic sourcing becomes essential for international B2B buyers. Key takeaways include the importance of selecting suppliers with proven reliability and flexibility to meet diverse industry needs, especially in challenging environments across Africa, South America, the Middle East, and Europe. Emphasizing quality, performance, and customization capabilities in your sourcing strategy will not only enhance operational efficiency but also ensure long-term partnerships that drive business success.

Investing in high-quality jet water rubber hoses can lead to significant cost savings and improved productivity. Buyers should prioritize suppliers that adhere to strict quality management systems and offer comprehensive support services. Additionally, understanding the specific applications and technical requirements of these hoses is crucial for making informed purchasing decisions.

Looking ahead, the market for jet water rubber hoses is poised for growth, driven by advancements in manufacturing and increasing infrastructure development worldwide. B2B buyers are encouraged to engage proactively with suppliers to explore innovative solutions that can elevate their operations. Now is the time to leverage strategic sourcing to secure a competitive edge in your industry.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Illustrative image related to Jet Water Rubber Hose

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, pedir amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.