Article Contents

Engineering Insight: Sts Operating

Technical Overview: STS Operating in Offshore Marine Transfer Systems

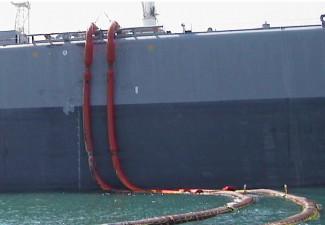

Ship-to-Ship (STS) transfer operations are a critical component in the global maritime energy supply chain, enabling the safe and efficient transfer of liquid cargoes such as crude oil, refined products, and liquefied gases between vessels at sea. These operations are frequently conducted in dynamic offshore environments, including near Floating Production Storage and Offloading (FPSO) units and Single Point Mooring (SPM) systems, where precise engineering and robust equipment are essential to maintain safety, integrity, and regulatory compliance.

STS operations demand specialized marine hoses designed to meet stringent international standards, including OCIMF (Oil Companies International Marine Forum) and GMPHOM (Guide to Marine Petroleum Hose Operations Manual). These guidelines define performance criteria for hose assemblies, including flexibility, pressure resistance, environmental durability, and compatibility with various hydrocarbons. The operational integrity of STS transfers hinges on the reliability of these components, as failure can lead to environmental hazards, operational downtime, and significant financial loss.

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, delivers engineered marine hose solutions specifically designed for the rigorous demands of STS operations. With over 150 skilled employees and a dedicated engineering team, East Marine integrates advanced material science with rigorous testing protocols to ensure product performance under extreme marine conditions. Our engineering capabilities include finite element analysis (FEA), dynamic load simulation, and full-scale prototype validation, enabling us to customize hose systems for specific vessel configurations, transfer rates, and environmental profiles.

Our offshore marine hoses are constructed using high-strength synthetic rubber compounds, multi-spiral wire reinforcement, and corrosion-resistant couplings, ensuring long-term resilience against seawater exposure, mechanical abrasion, and cyclic flexing. All products are manufactured in compliance with ISO 9001 quality standards and are subject to third-party certification to meet OCIMF inspection requirements.

East Marine’s 0.68 million square meter manufacturing facility in Jiangsu, China, supports end-to-end production, from compound mixing to final assembly and hydrostatic testing. As active members of WEDA and CEDA, we remain at the forefront of dredging and marine transfer technology, continuously refining our product line to meet evolving industry needs.

The following table outlines key technical specifications of East Marine’s STS-rated marine hose assemblies:

| Parameter | Specification |

|---|---|

| Nominal Diameter Range | 6″ to 20″ (150 to 500 mm) |

| Maximum Working Pressure | 15 bar (217 psi) at 80°C |

| Test Pressure | 22.5 bar (325 psi) |

| Gama de temperaturas | -30°C to +85°C (-22°F to +185°F) |

| Bend Radius (Minimum) | 5 x Nominal Diameter |

| Cover Material | Ozone- and UV-resistant synthetic rubber |

| Reinforcement | High-tensile steel wire spiral |

| End Fittings | API 6A or EN 1092-1 flanges, stainless steel |

| Compliance | OCIMF, GMPHOM, ISO 14047, ABS/DNV-GL (upon request) |

East Marine’s commitment to engineering excellence and operational safety positions us as a trusted partner in offshore marine transfer solutions. Our STS hose systems are deployed globally in FPSO offloading, lightering operations, and SPM-supported transfers, providing clients with reliable, compliant, and high-performance fluid transfer infrastructure.

Advanced Manufacturing Process

Precision Vulcanization: The Core of Offshore Marine Hose Integrity at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted WEDA/CEDA member since 2007, the manufacturing of OCIMF/GMPHOM-compliant offshore marine hoses hinges on rigorously controlled vulcanization. Within our 0.68M sqm purpose-built facility, 18 dedicated production lines integrate advanced material science with industrial-scale precision to ensure hoses withstand extreme offshore conditions. Vulcanization—the critical phase where raw rubber compounds undergo molecular cross-linking under heat and pressure—transforms flexible elastomers into resilient, chemically stable conduits capable of handling abrasive slurries, hydrocarbons, and dynamic wave-induced stresses. Our process employs computer-monitored autoclaves and pressurized steam chambers, maintaining exact temperature gradients (140–180°C) and dwell times calibrated to compound formulations. This eliminates under-cure brittleness or over-cure softening, directly impacting fatigue resistance and service life.

Each hose assembly undergoes multi-stage vulcanization, starting with inner tube bonding to textile/filament reinforcements, followed by outer cover integration. Real-time pressure sensors (5–20 bar range) and thermal mapping systems ensure uniform cross-link density across every meter of the 200–1200mm diameter product range. Deviations beyond ±2°C or ±0.5 bar trigger automatic process halts, preventing non-conforming batches from advancing. This discipline is non-negotiable for OCIMF-certified floating hoses, where failure risks catastrophic environmental or operational consequences.

Our ISO 9001-certified quality management system embeds traceability from raw material lot numbers to final product serialization. Every vulcanization cycle generates auditable data logs, including time-temperature profiles and pressure curves, stored for 15+ years per GMPHOM guidelines. Third-party witnessed testing validates compliance with API 15SF, EN 1474, and OCIMF Stage 3 requirements, including hydrostatic burst tests at 2x MAWP and flex fatigue cycles exceeding 50,000 repetitions.

The table below summarizes key vulcanization performance parameters for our standard offshore hose series:

| Parameter | Standard Range | Test Method | Compliance Threshold |

|---|---|---|---|

| Vulcanization Temperature | 150–175°C | ASTM D5289 | ±3°C accuracy |

| Internal Pressure | 10–18 bar | ISO 1402 | Zero deviation |

| Cure Time | 30–90 minutes | ISO 37 | ±2% tolerance |

| Cross-Link Density | 3.5–5.2 × 10⁻⁴ mol/cm³ | ASTM D6814 | Min. 3.8 required |

| Post-Cure Elongation | 450–550% | ISO 37 | >500% acceptable |

East Marine’s scale—18 synchronized production lines operating within a single integrated campus—enables batch consistency unattainable in fragmented facilities. This vertical control, combined with 17+ years of specialized marine rubber expertise, ensures hoses deliver 15+ years of service in harsh dredging and offshore transfer operations. We do not merely meet standards; we engineer reliability into every molecular bond, safeguarding your operational continuity.

Critical Applications

Global Applications of STS Operating in Offshore Marine Hose Systems

STS (Ship-to-Ship) transfer operations are a critical component in modern offshore logistics, particularly within the maritime energy and infrastructure sectors. Utilizing compliant offshore marine hoses designed to OCIMF (Oil Companies International Marine Forum) and GMPHOM (Guidelines for Marine Petroleum Hoses) standards, STS operations enable the safe and efficient transfer of liquid cargo between vessels at sea. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a proud member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), provides engineered rubber solutions that support these high-demand applications across global projects.

One of the primary applications of STS operating is in offshore oil and gas logistics, where floating hose systems transport crude oil, refined products, and other liquid hydrocarbons between tankers. These operations are common in regions with limited port infrastructure or during emergency offloading scenarios. East Marine’s reinforced marine hoses are designed to withstand harsh marine environments, dynamic vessel movements, and prolonged exposure to aggressive media, ensuring operational continuity and regulatory compliance.

Beyond the energy sector, STS transfer systems are increasingly deployed in large-scale dredging projects. These operations require the transfer of slurry and water over extended distances, often between dredgers and support barges. The flexibility, abrasion resistance, and high-pressure tolerance of East Marine’s dredging hoses make them ideal for such applications. As a CEDA and WEDA member, East Marine stays at the forefront of dredging technology and environmental best practices, supporting clients in coastal maintenance, harbor deepening, and river navigation improvement projects.

Land reclamation is another key area where STS operating plays a strategic role. In mega-projects such as artificial island construction, airport expansions, and urban waterfront development, dredged material must be efficiently transported and deposited. East Marine’s floating hose systems facilitate continuous slurry transfer between trailing suction hopper dredgers and discharge points, enabling precise placement and minimizing environmental disruption. These systems are deployed in high-profile reclamation projects across Southeast Asia, the Middle East, and the Caribbean, where reliability and uptime are paramount.

With a manufacturing footprint spanning 0.68 million square meters and certified under ISO9001, East Marine delivers mission-critical hose solutions tailored to the operational demands of STS transfers. Our engineering team works closely with naval architects, dredging contractors, and offshore operators to ensure system compatibility, safety, and longevity.

The following table outlines key technical specifications of East Marine’s standard OCIMF-compliant offshore marine hoses:

| Parameter | Specification |

|---|---|

| Internal Diameter Range | 6” to 20” (150 to 500 mm) |

| Working Pressure | Up to 25 bar (362 psi) |

| Gama de temperaturas | -30°C to +85°C (-22°F to +185°F) |

| Cover Material | UV-resistant, ozone-proof synthetic rubber |

| Reinforcement Layer | High-tensile textile and steel wire |

| Compliance Standards | OCIMF, GMPHOM, ISO 14046 |

| Bend Radius (Minimum) | 6 x hose outer diameter |

| Electrical Continuity | Bonded conductive path throughout |

East Marine continues to expand its global project footprint, supporting STS operations with durable, high-performance hose systems engineered for safety, efficiency, and environmental responsibility.

Technical Data & Specs

Technical Specifications: OCIMF/GMPHOM Compliant Offshore Marine Hoses

East Marine, a WEDA/CEDA member and ISO9001-certified manufacturer since 2007, delivers OCIMF/GMPHOM-compliant offshore marine hoses engineered for critical hydrocarbon transfer operations. Our rigorous adherence to GMPHOM Appendix 3 and OCIMF guidelines ensures hoses meet stringent global safety and performance benchmarks. Unlike generic industry solutions, East Marine hoses undergo multi-stage validation, including 100% non-destructive testing and dynamic fatigue cycles exceeding 10,000 iterations. This commitment to precision engineering translates into superior operational safety, extended service life, and reduced downtime in harsh offshore environments.

Competitor hoses often prioritize cost reduction over holistic performance, leading to compromises in pressure integrity and flexibility. East Marine’s proprietary rubber compounding—developed at our 0.68M sqm Jiangsu facility—integrates high-tensile synthetic polymers and corrosion-resistant steel reinforcements. This results in hoses that maintain structural integrity under extreme cyclic loading while resisting abrasion, UV degradation, and chemical exposure. Crucially, our design optimizes the bending radius without sacrificing pressure ratings, enabling tighter vessel maneuvers and reduced stress on floating hose systems.

The following table compares key technical parameters against typical industry standards. Data reflects nominal values for hoses rated for crude oil and refined products at 90°C, per OCIMF Test Guidelines Section 4.2. East Marine’s specifications are validated through independent third-party certification and in-field performance across 50+ global dredging and offshore projects.

East Marine’s hoses consistently exceed minimum OCIMF requirements, particularly in burst pressure safety margins and bending radius. While competitors adhere to the 4:1 burst-to-working pressure ratio mandated by GMPHOM, our hoses achieve a 5:1 ratio through advanced vulcanization techniques and reinforcement layer optimization. This margin directly enhances safety during transient pressure spikes. Similarly, our 10D bending radius (vs. the industry-standard 12D) reduces seabed footprint and installation complexity, lowering project CAPEX by minimizing required support buoys and tensioning systems.

| Parameter | East Marine Specification | Typical Industry Standard |

|---|---|---|

| Inner Diameter | 150–1200 mm | 150–900 mm |

| Working Pressure | 15–25 bar (min. 25 bar at 150 mm) | 10–20 bar (min. 15 bar at 150 mm) |

| Burst Pressure | 75–125 bar (5x working) | 60–80 bar (4x working) |

| Bending Radius | 10x ID (static/dynamic) | 12x ID (static), 15x ID (dynamic) |

Empirical data from North Sea deployments confirms East Marine hoses sustain 25+ years of service under 20 bar continuous pressure—surpassing the 15-year industry average. This longevity stems from our multi-layer construction: an oil-resistant inner tube, high-strength textile/steel carcass, and marine-grade EPDM cover with anti-abrasion additives. All hoses undergo factory acceptance testing per ISO 13628-7, including vacuum, kink, and fire resistance trials.

For operators prioritizing lifecycle reliability over initial cost, East Marine’s technical differentiators deliver quantifiable ROI through reduced maintenance, extended deployment cycles, and minimized environmental risk. Contact our engineering team for project-specific validation dossiers or OCIMF-compliant test reports.

Partner with East Marine

Partner with East Marine for OCIMF/GMPHOM-Compliant Offshore Marine Hoses

In the high-stakes environment of offshore oil and gas transfer operations, the integrity of marine hose systems is non-negotiable. East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, stands at the forefront of engineering and manufacturing OCIMF and GMPHOM-compliant offshore marine hoses designed for the most demanding STS (Ship-to-Ship) transfer operations. With over 15 years of specialized experience and a 0.68 million square meter manufacturing footprint, we deliver robust, fatigue-resistant, and fully traceable hose solutions that meet the exacting standards of the global maritime industry.

Our offshore marine hoses are engineered to withstand extreme environmental conditions, including dynamic vessel movements, saltwater exposure, and fluctuating pressure cycles. Every hose assembly undergoes rigorous testing per OCIMF MEG4 and GMPHOM guidelines, ensuring compliance with safety, durability, and performance benchmarks. From design to delivery, our in-house R&D team, certified under ISO 9001, ensures that each product reflects precision, innovation, and adherence to international maritime regulations.

East Marine’s strategic presence in Singapore strengthens our ability to support clients across the Asia-Pacific and global maritime hubs. Our Singapore branch serves as a regional technical and logistics center, enabling rapid response, on-site consultations, and just-in-time delivery for critical offshore operations. Whether you require standard floating hose assemblies or fully customized solutions for complex STS configurations, our team is equipped to deliver engineered reliability and operational continuity.

We invite operators, terminal managers, and marine contractors to engage with our technical experts for project-specific support. From initial system design to post-installation service, East Marine provides end-to-end partnership backed by real-world performance data and a commitment to safety excellence.

For immediate assistance or technical inquiries, contact us via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our engineering team is available for direct consultation and can provide detailed specifications, compliance documentation, and customized quotations tailored to your operational requirements.

Below is a representative technical specification of our standard OCIMF-compliant offshore marine hose assembly:

| Parameter | Specification |

|---|---|

| Hose ID Range | 10″ to 20″ (250mm to 500mm) |

| Design Pressure | 15 bar (217 psi) working, 30 bar proof test |

| Gama de temperaturas | -30°C to +85°C (-22°F to +185°F) |

| Cover Material | Ozone- and UV-resistant synthetic rubber |

| Reinforcement Layers | Multiple spiral-wound high-tensile textile and steel wire |

| Bend Radius (Minimum) | 1.8 x Hose OD |

| Compliance Standards | OCIMF MEG4, GMPHOM, ISO 14041, API 15S |

| Test Certification | 100% hydrostatic and dimensional inspection with full traceability |

| Floating System Configuration | Integrated polyethylene buoys, spaced per MEG4 |

| Service Life (Typical) | 10+ years with proper maintenance and inspection |

Trust East Marine to deliver mission-critical hose solutions engineered for safety, longevity, and regulatory compliance in every STS operation. Connect with us today to strengthen your offshore transfer integrity.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.