Introduction: Navigating the Global Market for how is oil distributed

Navigating the complexities of oil distribution can be a daunting challenge for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Understanding how oil is distributed is crucial for sourcing reliable suppliers and optimizing procurement strategies. With global oil reserves concentrated primarily in the Middle East, North America, and select countries in South America and Africa, buyers must consider not only the geographical factors but also the intricate supply chain dynamics that influence availability and pricing.

This comprehensive guide delves into the various types of oil, the diverse applications across industries, and the critical aspects of supplier vetting. It also provides insights into pricing structures, market trends, and the geopolitical factors that can impact oil distribution. By equipping buyers with a thorough understanding of these elements, this guide empowers them to make informed purchasing decisions, ensuring they can navigate the global market with confidence and efficiency.

In a landscape marked by fluctuating prices and shifting supply chains, the ability to source oil effectively is paramount. Whether you are seeking to establish long-term partnerships or optimize your supply chain logistics, this guide serves as an essential resource for B2B buyers committed to achieving sustainable and cost-effective procurement solutions.

Índice

- Top 4 How Is Oil Distributed Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how is oil distributed

- Understanding how is oil distributed Types and Variations

- Key Industrial Applications of how is oil distributed

- 3 Common User Pain Points for ‘how is oil distributed’ & Their Solutions

- Strategic Material Selection Guide for how is oil distributed

- In-depth Look: Manufacturing Processes and Quality Assurance for how is oil distributed

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how is oil distributed’

- Comprehensive Cost and Pricing Analysis for how is oil distributed Sourcing

- Alternatives Analysis: Comparing how is oil distributed With Other Solutions

- Essential Technical Properties and Trade Terminology for how is oil distributed

- Navigating Market Dynamics and Sourcing Trends in the how is oil distributed Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how is oil distributed

- Strategic Sourcing Conclusion and Outlook for how is oil distributed

- Aviso importante e termos de utilização

Understanding how is oil distributed Types and Variations

| Tipo Nome | Principais caraterísticas distintivas | Aplicações B2B primárias | Breves prós e contras para os compradores |

|---|---|---|---|

| Crude Oil | Unrefined petroleum extracted from geological formations | Fuel production, petrochemicals, lubricants | Prós: Widely available, essential for various industries. Contras: Price volatility, requires refining. |

| Refined Oil Products | Processed derivatives of crude oil | Transportation fuels, heating oils | Prós: Ready for use, standardized quality. Contras: Limited supply chain flexibility. |

| Unconventional Oil | Oil extracted from non-traditional sources (e.g., shale, tar sands) | Energy production, specialty chemicals | Prós: Expanding supply sources, potential for lower costs. Contras: Environmental concerns, higher extraction costs. |

| Offshore Oil | Oil extracted from underwater reserves | Global energy supply, maritime logistics | Prós: Access to large reserves, potential for high yields. Contras: High operational costs, technical challenges. |

| Synthetic Oil | Man-made oil created from natural gas or coal | High-performance lubricants, specialty fuels | Prós: Tailored properties, less dependence on crude oil. Contras: Higher production costs, limited availability. |

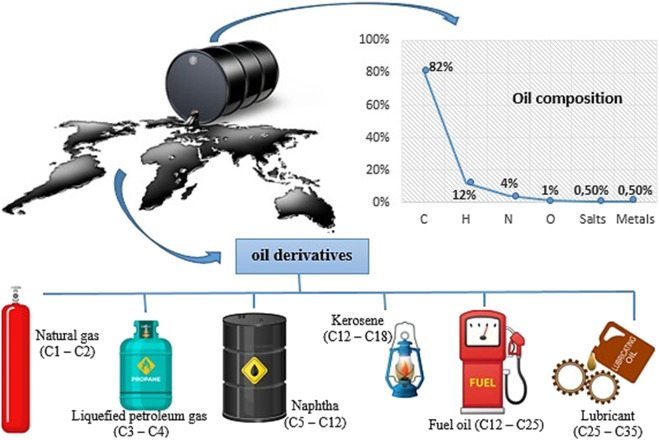

What Are the Characteristics of Crude Oil and Its B2B Suitability?

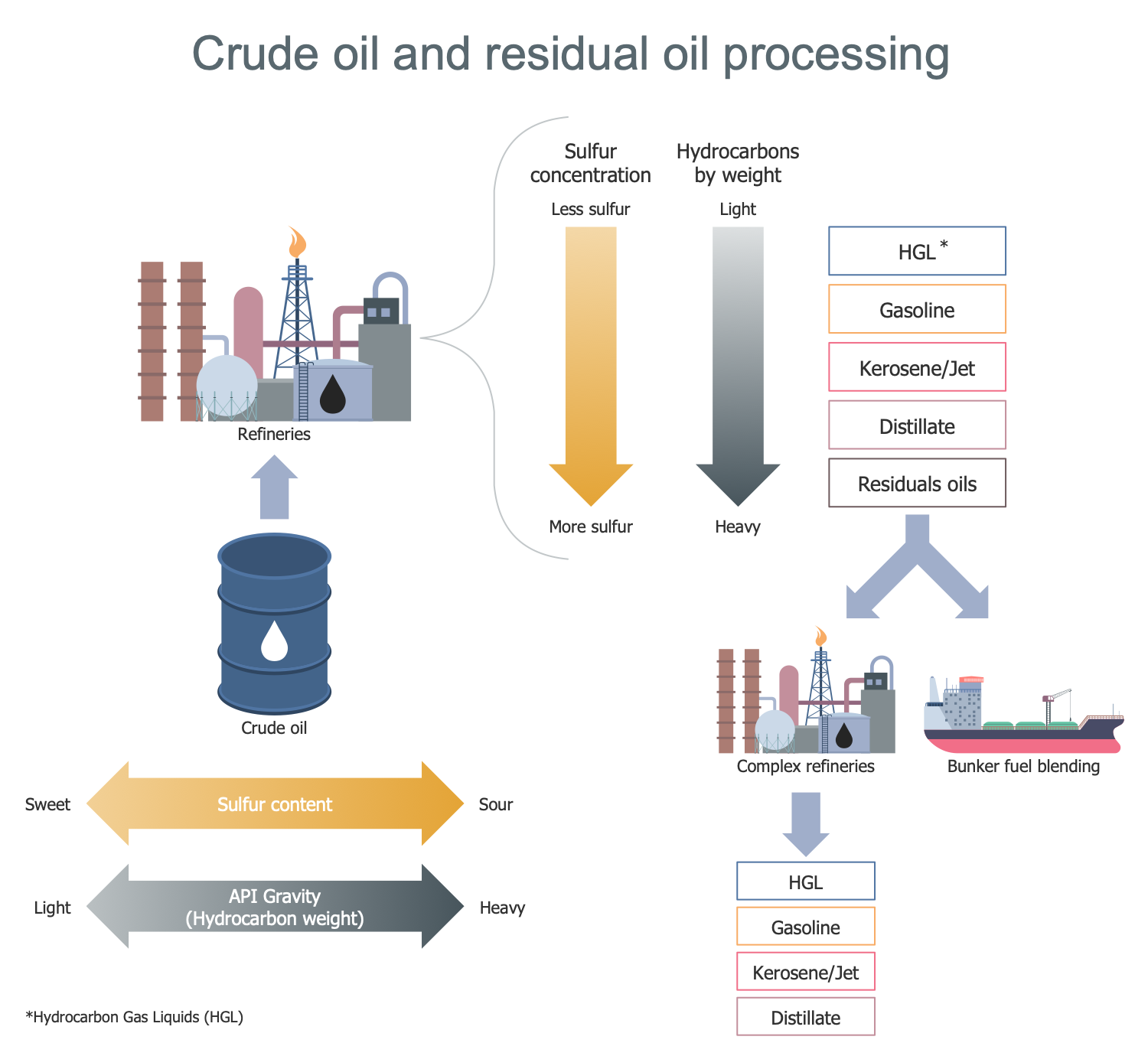

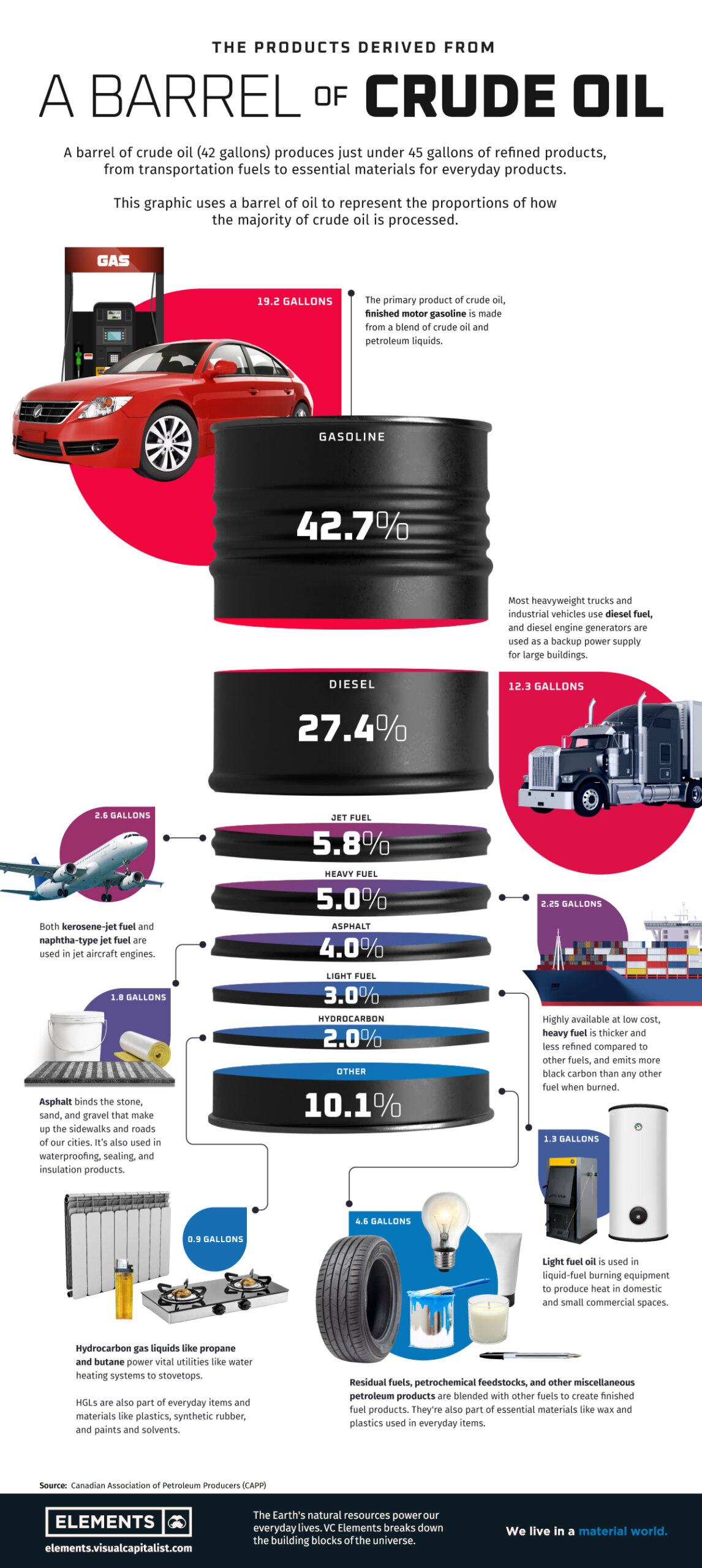

Crude oil is the fundamental raw material for the petroleum industry, extracted directly from geological formations. It is characterized by its varying viscosity, density, and sulfur content, which affect its refining process and end-use applications. For B2B buyers, crude oil serves as the primary feedstock for producing fuels, lubricants, and petrochemicals. Buyers should consider factors such as market prices, transportation logistics, and the specific refining capabilities of their facilities when sourcing crude oil.

How Do Refined Oil Products Differ in Application for Businesses?

Refined oil products are derivatives of crude oil that have undergone processing to meet specific quality standards. Common products include gasoline, diesel, and jet fuel. These products are essential for various sectors, including transportation, manufacturing, and energy generation. For B2B buyers, the advantages of refined oil products include their immediate usability and consistent quality. However, supply chain dynamics can limit flexibility in sourcing, making it crucial to establish reliable supplier relationships.

What Is Unconventional Oil and What Should Buyers Consider?

Unconventional oil refers to oil extracted from non-traditional sources, such as shale formations and tar sands. These sources have gained prominence due to technological advancements in extraction methods like hydraulic fracturing. B2B applications for unconventional oil include energy production and the creation of specialty chemicals. While it offers the potential for increased supply, buyers must weigh the environmental implications and often higher extraction costs against the benefits of diverse sourcing options.

Why Is Offshore Oil Important for Global Energy Supply?

Offshore oil is extracted from underwater reserves, often located in deep-sea environments. This type of oil is crucial for meeting global energy demands, particularly in regions with limited land-based resources. The primary B2B applications include energy supply and maritime logistics. Buyers should be aware of the high operational costs and technical challenges associated with offshore drilling, which can impact pricing and supply reliability.

How Does Synthetic Oil Compare to Traditional Oil Products?

Synthetic oil is engineered from natural gas or coal, designed to provide superior performance characteristics compared to traditional oils. Its tailored properties make it ideal for high-performance lubricants and specialty fuels used in demanding applications. For B2B buyers, the key advantages of synthetic oil include reduced dependency on crude oil and enhanced performance. However, higher production costs and limited availability may be significant considerations when evaluating synthetic oil options.

Illustrative image related to how is oil distributed

Key Industrial Applications of how is oil distributed

| Indústria/Setor | Specific Application of how is oil distributed | Valor/benefício para a empresa | Principais considerações de fornecimento para esta aplicação |

|---|---|---|---|

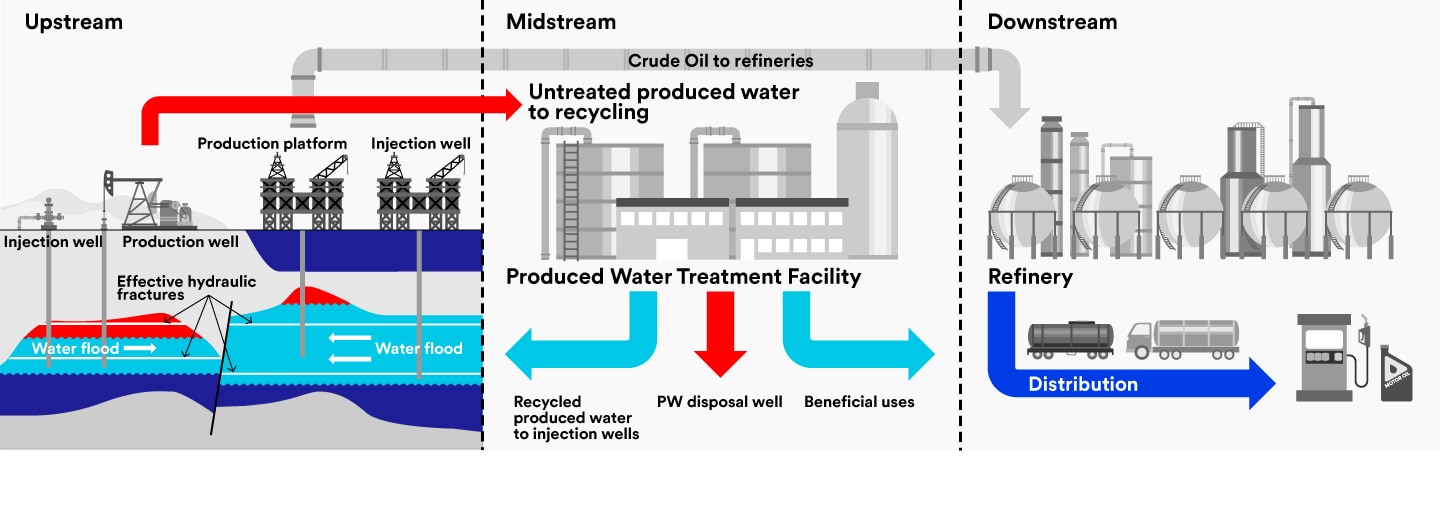

| Energy Production | Distribution of crude oil to refineries | Ensures a steady supply of raw materials for processing | Reliability of supply chains, logistics costs, geopolitical stability |

| Transportation | Fuel supply for shipping and aviation | Reduces operational costs and enhances efficiency | Quality of fuel, availability of storage facilities, compliance with regulations |

| Fabrico | Use of petroleum products in plastics and chemicals | Diversifies product offerings and enhances production efficiency | Consistency of supply, pricing volatility, sustainability practices |

| Agricultura | Distribution of fuel for agricultural machinery | Supports timely planting and harvesting activities | Availability of fuel types, pricing, and seasonal demand fluctuations |

| Automóvel | Supply of refined fuels for vehicles | Ensures operational reliability and customer satisfaction | Fuel quality standards, distribution network efficiency, regional regulations |

How is Oil Distributed in Energy Production?

In the energy sector, the distribution of crude oil to refineries is crucial for maintaining a consistent supply of raw materials necessary for fuel production. International B2B buyers, particularly from oil-rich regions like the Middle East and Africa, must consider the reliability of supply chains and logistics costs when sourcing oil. Geopolitical stability also plays a critical role, as disruptions can significantly impact supply.

What Role Does Oil Distribution Play in Transportation?

The transportation industry relies heavily on the distribution of fuel for shipping and aviation, which directly affects operational costs and efficiency. For B2B buyers in regions such as South America and Europe, ensuring a reliable fuel supply is paramount. Key considerations include the quality of fuel, the availability of storage facilities, and compliance with environmental regulations to avoid penalties and ensure smooth operations.

How Does Oil Distribution Impact Manufacturing?

Manufacturers utilize petroleum products in the creation of plastics and chemicals, making efficient oil distribution vital for production processes. This sector benefits from a diverse range of products that enhance manufacturing efficiency. Buyers must focus on the consistency of supply, as fluctuations can lead to production delays and increased costs. Additionally, pricing volatility is a significant concern that can impact overall profitability.

Why is Oil Distribution Important for Agriculture?

In agriculture, the distribution of fuel for machinery is essential for timely planting and harvesting. Farmers and agricultural businesses in regions like Africa require access to reliable fuel sources to maximize productivity. Key sourcing considerations include the availability of various fuel types, pricing structures, and the potential for seasonal demand fluctuations, which can affect overall operational efficiency.

How is Oil Distributed to the Automotive Sector?

The automotive industry depends on the supply of refined fuels to ensure vehicle reliability and customer satisfaction. B2B buyers in this sector must pay close attention to fuel quality standards, as poor-quality fuel can lead to mechanical failures and customer complaints. Additionally, the efficiency of distribution networks is crucial for maintaining a steady supply and minimizing costs, especially in regions with high vehicle density.

3 Common User Pain Points for ‘how is oil distributed’ & Their Solutions

Scenario 1: Navigating Complex International Regulations in Oil Distribution

O problema: B2B buyers often grapple with the complexities of international regulations governing oil distribution. Each country has its own set of rules regarding the import and export of petroleum products, which can lead to significant delays and unexpected costs. For instance, a buyer in Nigeria may face stringent local content regulations that require a certain percentage of the oil to be sourced from local suppliers. This not only complicates procurement but also risks non-compliance, resulting in fines or shipment delays.

A solução: To effectively navigate these regulations, B2B buyers should invest in thorough market research and engage local legal experts or consultants specializing in oil distribution laws. Establishing partnerships with local suppliers can also ease compliance issues and streamline the procurement process. Additionally, utilizing technology platforms that provide real-time updates on regulatory changes can help buyers stay ahead of compliance requirements. By proactively managing these factors, buyers can ensure smoother operations and minimize disruptions in their supply chain.

Scenario 2: Overcoming Supply Chain Disruptions in Oil Distribution

O problema: Supply chain disruptions are a common challenge for B2B buyers in the oil industry, particularly in regions with political instability or infrastructural weaknesses. For example, a buyer in Venezuela might experience interruptions in oil supply due to sanctions or logistical issues related to inadequate transportation infrastructure. These disruptions can result in stock shortages and impact operational efficiency, leading to lost revenue and customer dissatisfaction.

Illustrative image related to how is oil distributed

A solução: To mitigate supply chain risks, buyers should diversify their supplier base, avoiding reliance on a single source of oil. Establishing relationships with multiple suppliers across different regions can provide a safety net in times of crisis. Additionally, implementing robust inventory management practices, including safety stock levels and demand forecasting, can help cushion against sudden supply disruptions. Utilizing advanced analytics tools can also offer insights into potential risks and allow for more agile decision-making in response to changing market conditions.

Scenario 3: Understanding Pricing Fluctuations in Global Oil Markets

O problema: Price volatility in the global oil market poses a significant challenge for B2B buyers, impacting budgeting and forecasting. A buyer in the Middle East, for example, may struggle with sudden price hikes due to geopolitical tensions or changes in OPEC production levels. This unpredictability can complicate contract negotiations and financial planning, ultimately affecting the buyer’s bottom line.

A solução: To navigate pricing fluctuations effectively, buyers should adopt a hedging strategy to lock in prices or mitigate the risk of price increases. Engaging in long-term contracts with fixed pricing can also provide stability in budgeting. Additionally, buyers should stay informed about global market trends and utilize market intelligence tools that analyze price movements and forecasts. Collaborating with financial experts who specialize in commodity markets can further enhance a buyer’s strategy, enabling them to make informed decisions based on current and projected market conditions.

Strategic Material Selection Guide for how is oil distributed

What Materials Are Commonly Used in Oil Distribution and Their Key Properties?

When considering the distribution of oil, the choice of materials for pipelines, storage tanks, and other infrastructure is critical. Here, we analyze four common materials used in oil distribution: carbon steel, stainless steel, polyethylene, and fiberglass-reinforced plastic (FRP). Each material has unique properties, advantages, and limitations that can significantly impact performance and compliance with international standards.

How Does Carbon Steel Perform in Oil Distribution Applications?

Propriedades principais: Carbon steel is widely used for pipelines due to its high strength and ability to withstand high pressures and temperatures. It has good ductility, making it suitable for various applications in oil distribution.

Prós e contras: The primary advantage of carbon steel is its durability and cost-effectiveness, making it a popular choice for large-scale projects. However, it is prone to corrosion, especially in the presence of water or acidic environments, which can lead to costly maintenance and replacement.

Impacto na aplicação: Carbon steel is compatible with a variety of media, including crude oil and refined products. However, its susceptibility to corrosion necessitates protective coatings or cathodic protection systems to ensure longevity.

Considerações para compradores internacionais: Buyers from regions like Africa and the Middle East should ensure compliance with local standards and regulations, such as ASTM and API specifications. Understanding the local environmental conditions is crucial for selecting appropriate corrosion protection methods.

Illustrative image related to how is oil distributed

What Are the Benefits of Using Stainless Steel in Oil Distribution?

Propriedades principais: Stainless steel offers excellent corrosion resistance, high strength, and the ability to withstand extreme temperatures. It is particularly suitable for applications involving aggressive media.

Prós e contras: The main advantage of stainless steel is its longevity and reduced maintenance needs, making it ideal for harsh environments. However, it comes at a higher cost compared to carbon steel, which may be a limiting factor for some projects.

Impacto na aplicação: Stainless steel is compatible with a wide range of fluids, including corrosive substances. Its resistance to pitting and crevice corrosion makes it suitable for offshore and coastal applications.

Considerações para compradores internacionais: Buyers in Europe and South America should consider local standards for stainless steel grades (e.g., ASTM A312) and ensure that the selected material meets the specific requirements for their applications.

How Does Polyethylene Compare for Oil Distribution Systems?

Propriedades principais: Polyethylene is a lightweight, flexible material with good chemical resistance and low moisture absorption. It is often used in low-pressure applications.

Illustrative image related to how is oil distributed

Prós e contras: The primary advantage of polyethylene is its resistance to corrosion and low installation costs due to its lightweight nature. However, it has a lower temperature and pressure rating compared to metals, which may limit its use in high-demand scenarios.

Impacto na aplicação: Polyethylene is suitable for transporting refined products and is often used in rural areas where traditional materials may be cost-prohibitive. However, it is not recommended for high-temperature applications.

Considerações para compradores internacionais: Buyers should ensure that the polyethylene used complies with relevant standards (e.g., ASTM D3350) and is suitable for the specific types of oil being transported.

Illustrative image related to how is oil distributed

What Role Does Fiberglass-Reinforced Plastic (FRP) Play in Oil Distribution?

Propriedades principais: FRP offers excellent corrosion resistance, high strength-to-weight ratio, and thermal insulation properties. It is often used in environments where traditional materials may fail.

Prós e contras: The key advantage of FRP is its durability and resistance to a wide range of chemicals, making it suitable for various applications. However, the manufacturing process can be complex, leading to higher costs.

Impacto na aplicação: FRP is ideal for transporting corrosive fluids and can be used in both above-ground and underground applications. Its lightweight nature allows for easier installation and reduced transportation costs.

Considerações para compradores internacionais: Buyers in regions like the Middle East should verify compliance with international standards (e.g., ASTM D3299) and consider the specific environmental conditions that may affect the performance of FRP.

Summary Table of Material Selection for Oil Distribution

| Material | Typical Use Case for how is oil distributed | Vantagem chave | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Carbon Steel | High-pressure pipelines | Cost-effective and durable | Prone to corrosion | Médio |

| Aço inoxidável | Offshore pipelines and tanks | Excellent corrosion resistance | Higher cost | Elevado |

| Polietileno | Low-pressure transportation | Leve e resistente à corrosão | Limited temperature/pressure rating | Baixa |

| Fiberglass-Reinforced Plastic | Corrosive fluid transport | Durable and lightweight | Complex manufacturing process | Médio |

This analysis provides a comprehensive overview of the materials commonly used in oil distribution, their properties, and considerations for international B2B buyers. Understanding these factors can help buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how is oil distributed

What Are the Main Stages of the Oil Distribution Manufacturing Process?

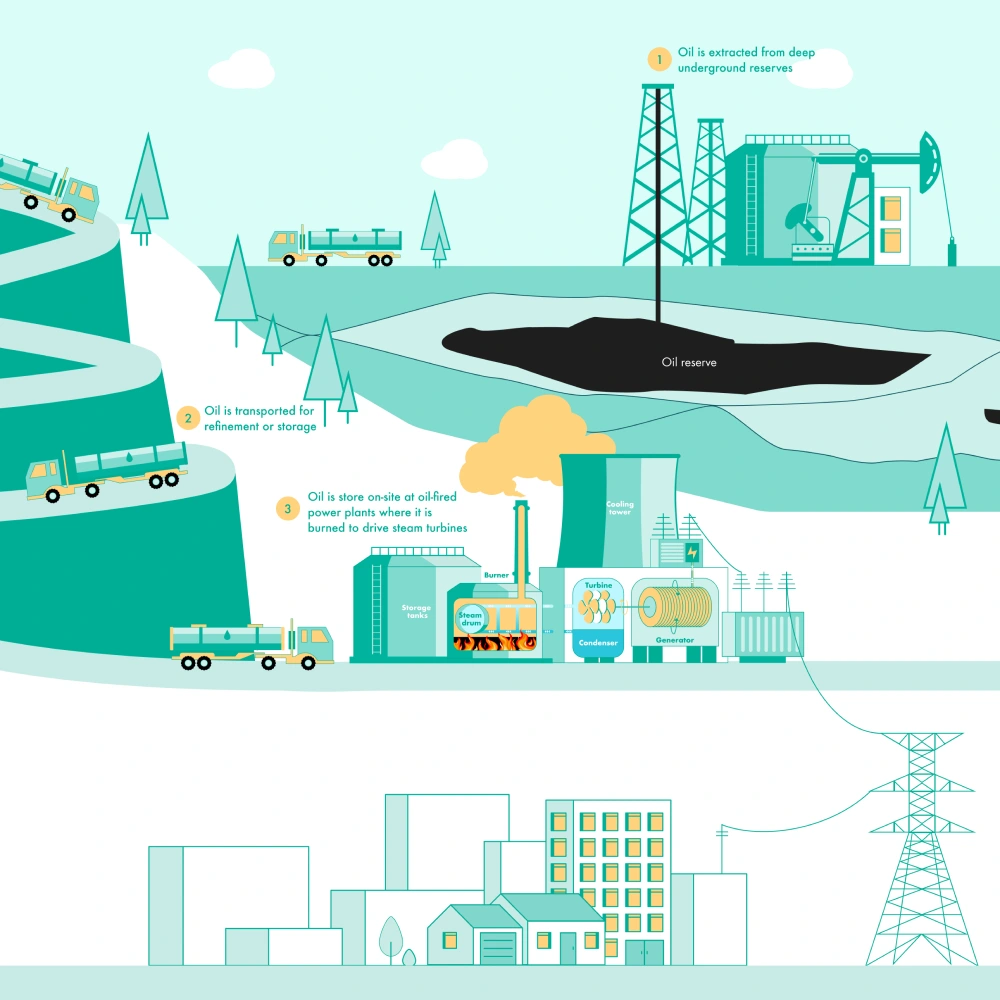

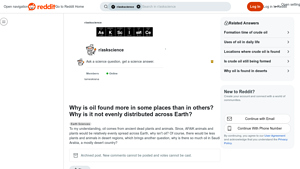

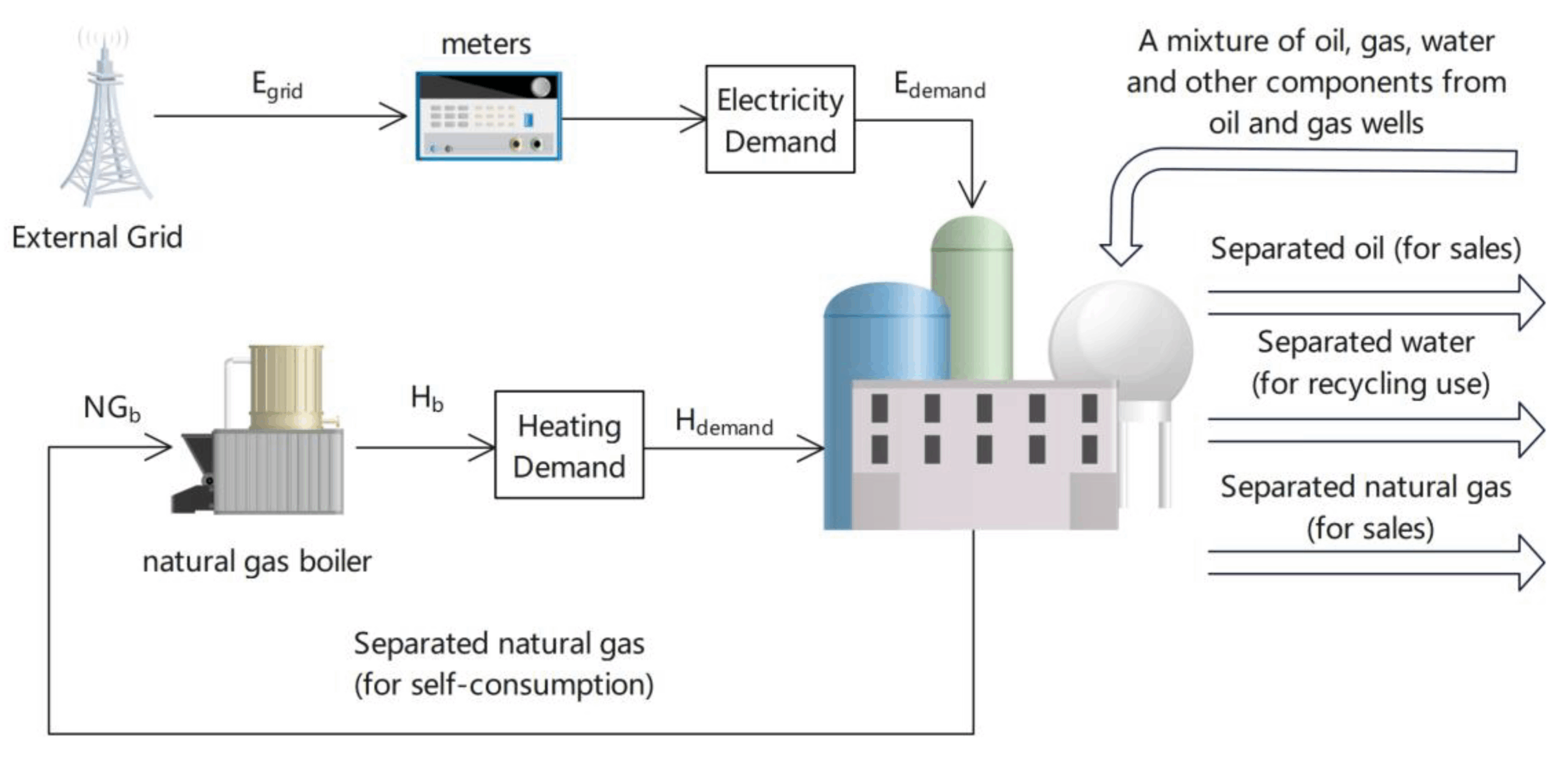

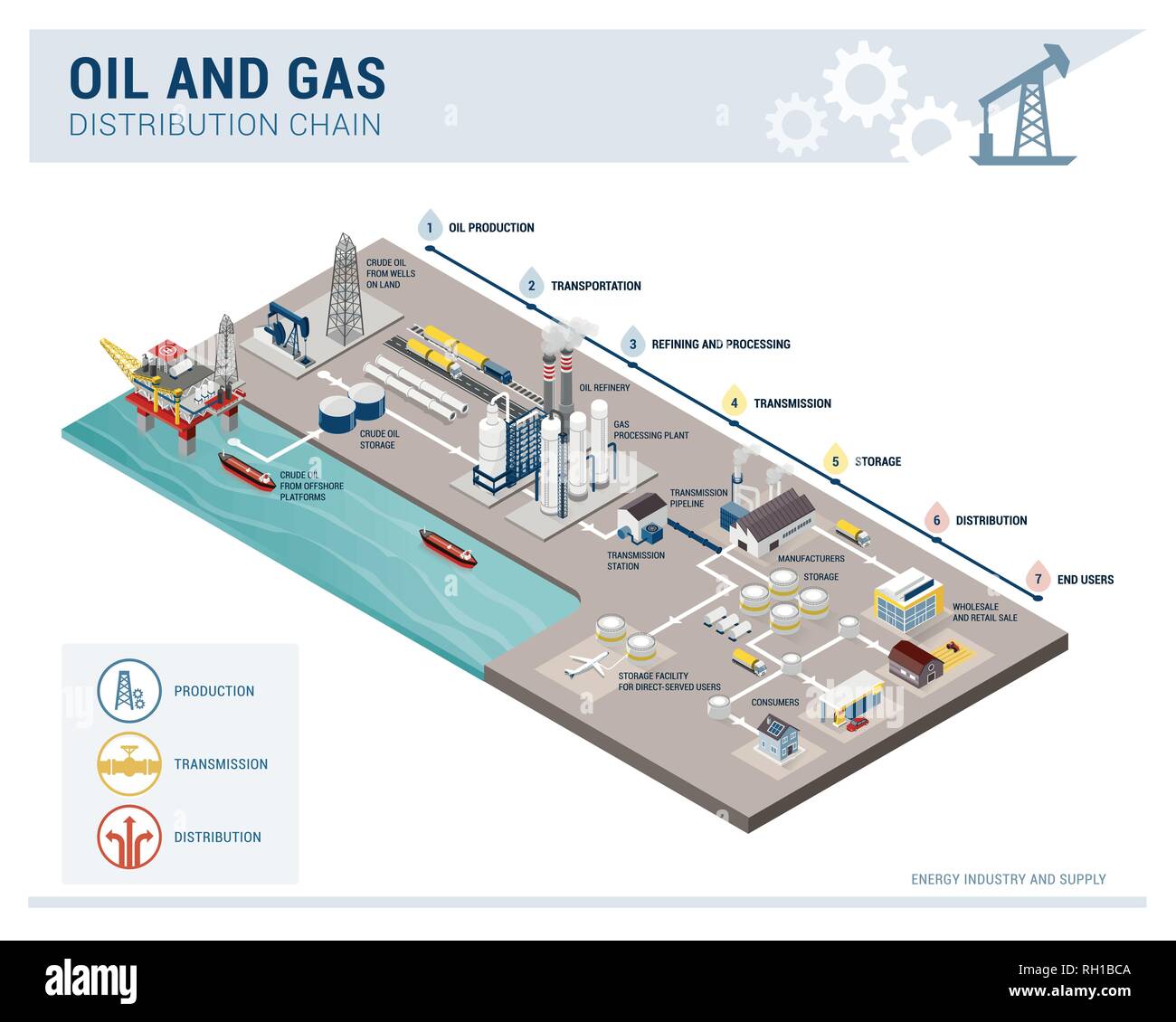

Oil distribution involves a complex manufacturing process designed to ensure that crude oil is efficiently transformed into marketable products and delivered to consumers. The main stages of this process include material preparation, forming, assembly, and finishing.

-

Preparação do material: The first step in oil distribution begins with the extraction of crude oil from oil fields. This process involves drilling wells and utilizing various techniques, such as hydraulic fracturing and horizontal drilling, to access underground reservoirs. Once extracted, crude oil is transported to refineries, where it undergoes initial processing.

-

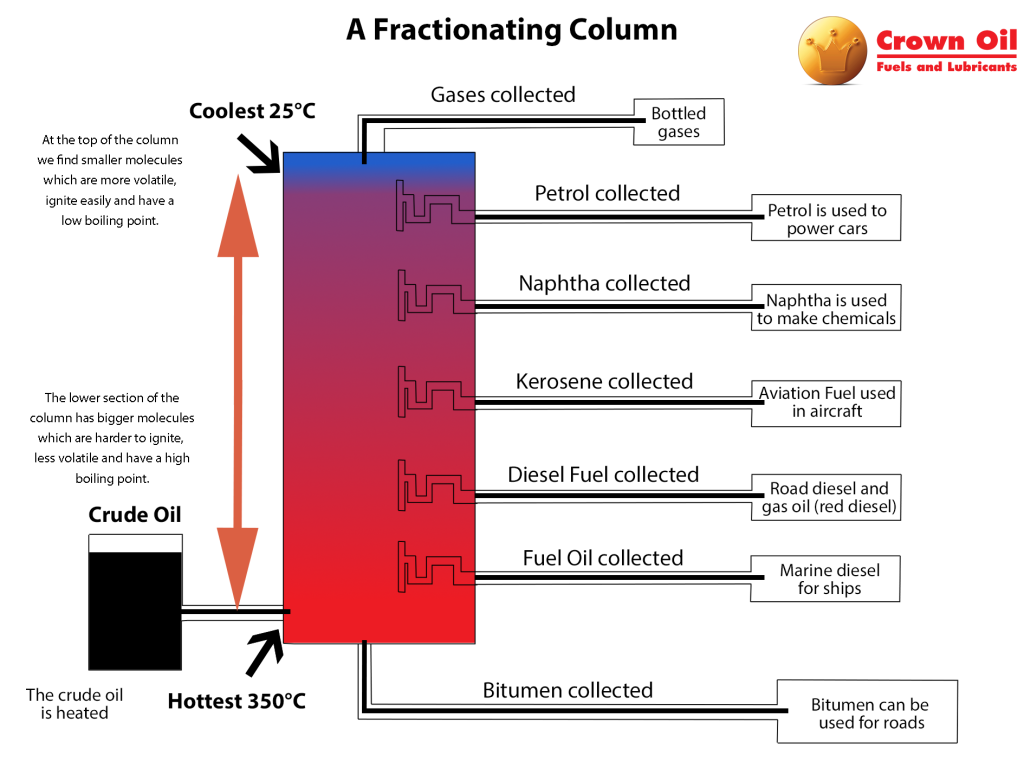

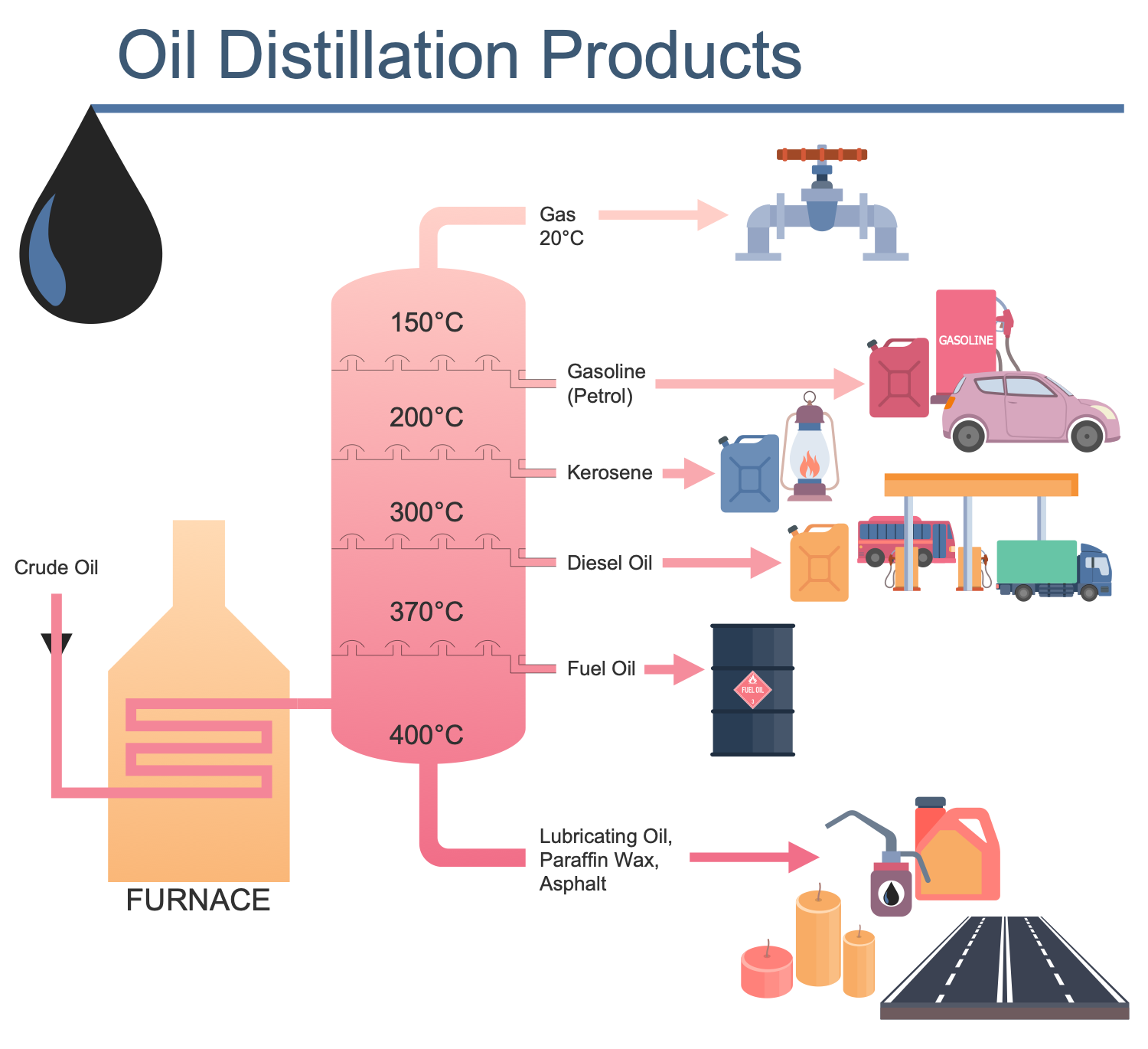

Formação: In the refining process, crude oil is subjected to distillation, where it is heated and separated into various components based on boiling points. This stage is crucial as it allows for the separation of lighter products (like gasoline) from heavier ones (like diesel and lubricating oils). Advanced techniques such as hydrocracking and catalytic reforming are also employed to enhance the quality and yield of the products.

-

Montagem: After distillation, the refined products are blended according to specific formulations to meet market demands and regulatory standards. This blending process is critical for ensuring product quality and consistency. Each product may require different additives to enhance performance characteristics, such as anti-knock agents in gasoline or detergents in diesel.

-

Acabamento: The final stage involves quality checks and packaging of the refined products. Finished products are stored in tanks or transported via pipelines, trucks, or ships to distribution centers. Each of these methods has unique logistics challenges, which require careful planning and execution to ensure timely delivery.

What Quality Assurance Standards Are Important for Oil Distribution?

Quality assurance is vital in the oil distribution process to ensure compliance with international standards and industry-specific regulations. For B2B buyers, understanding these standards is crucial for assessing supplier reliability and product quality.

-

International Standards: ISO 9001 is the most recognized international standard for quality management systems. It focuses on meeting customer expectations and delivering satisfaction. Compliance with ISO 9001 ensures that suppliers maintain consistent quality in their processes, which is particularly important in oil distribution where product integrity is paramount.

-

Industry-Specific Standards: In addition to ISO standards, oil distribution must comply with specific industry standards such as those set by the American Petroleum Institute (API) and the European Conformity (CE) marking. API standards cover various aspects of oil production, refining, and distribution, ensuring safety and quality throughout the supply chain.

What Are the Key Quality Control Checkpoints in Oil Distribution?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the oil distribution process. For B2B buyers, understanding these checkpoints can help in evaluating the robustness of a supplier’s QC procedures.

-

Controlo de qualidade de entrada (IQC): This checkpoint occurs upon receipt of raw materials and components. Suppliers must verify that incoming shipments meet predefined specifications and standards. This includes checking for proper labeling, documentation, and physical inspections.

-

Controlo de qualidade durante o processo (IPQC): During the manufacturing and refining process, IPQC involves monitoring production parameters, conducting regular inspections, and performing tests to ensure that the process remains within specified limits. This stage is crucial for identifying and addressing any issues before they escalate.

-

Controlo de qualidade final (FQC): Once products are finished, FQC involves comprehensive testing and validation to ensure that the end products meet quality standards. This can include chemical composition analysis, performance testing, and packaging inspections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some strategies to effectively assess a supplier’s QC practices:

-

Realização de auditorias: Regular audits of suppliers can provide insight into their QC processes. These audits should evaluate compliance with international and industry-specific standards, as well as assess the effectiveness of their quality management systems.

-

Reviewing Quality Reports: Suppliers should provide documentation of their quality control activities, including inspection reports, testing results, and compliance certificates. Reviewing these documents can help buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. These independent reviews can help identify potential issues and validate the supplier’s adherence to established standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control and certification when sourcing oil products from different regions. Understanding these nuances can aid in making informed purchasing decisions.

-

Regional Standards Variations: Different countries may have varying regulatory requirements and standards for oil products. Buyers need to familiarize themselves with these local standards to ensure compliance and avoid potential legal issues. For instance, certain additives may be permitted in one country but banned in another.

-

Cultural Considerations: Cultural differences can influence quality control practices. Buyers should be aware of how local customs and business practices may affect supplier reliability and communication. Building relationships with local suppliers can enhance trust and improve quality outcomes.

-

Documentation and Traceability: For international transactions, maintaining thorough documentation is crucial. This includes ensuring that all quality certifications, test results, and compliance documents are readily available and in the correct language. Traceability of products back to their origin can also be a significant factor in quality assurance.

Conclusão

In the oil distribution industry, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers. By focusing on the main stages of production, adhering to relevant standards, implementing robust QC checkpoints, and verifying supplier practices, businesses can ensure they source high-quality products that meet their operational needs. This proactive approach not only mitigates risks but also enhances supply chain efficiency, ultimately leading to better service delivery in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how is oil distributed’

Introdução

This practical sourcing guide is designed to help B2B buyers navigate the complexities of oil distribution. Understanding how oil is sourced, transported, and delivered is crucial for making informed procurement decisions. By following this checklist, you will gain insights into the critical aspects of oil distribution, ensuring that you partner with the right suppliers and optimize your supply chain.

Passo 1: Identify Your Oil Requirements

Before initiating procurement, clearly define your specific oil needs, including type, quantity, and quality specifications. Different regions produce various types of crude oil, and understanding your requirements will help you target suppliers who can meet those needs. Additionally, consider the geographical location of your operations to facilitate logistics.

Illustrative image related to how is oil distributed

Passo 2: Research Global Oil Distribution Networks

Investigate the global oil distribution landscape, focusing on major oil-producing regions such as the Middle East, Africa, and South America. Understanding the flow of oil from production to consumption will enable you to identify potential suppliers and distribution channels. Pay attention to the logistics involved, including pipeline networks, shipping routes, and storage facilities.

Passo 3: Avaliar potenciais fornecedores

Before committing to a supplier, conduct thorough evaluations. Request company profiles, certifications, and case studies from previous clients. Look for suppliers with experience in your specific region and industry to ensure they understand local regulations and market dynamics.

- Key Considerations:

- Verify the supplier’s production capacity and reliability.

- Assess their compliance with international quality standards.

Passo 4: Understand Pricing Structures and Terms

Familiarize yourself with the pricing models used in the oil industry, which can vary based on factors like market conditions, transportation costs, and contract terms. Understanding these elements will help you negotiate effectively and secure favorable terms. Be sure to clarify payment terms, delivery schedules, and any potential penalties for non-compliance.

Passo 5: Assess Logistics and Transportation Capabilities

Evaluate the logistics capabilities of your chosen suppliers, including their transportation networks and storage facilities. Efficient logistics are vital for timely delivery and can significantly impact your supply chain operations. Consider factors such as:

- Proximity to major transportation hubs.

- Availability of secure storage options.

- Flexibility in shipping methods (e.g., pipeline, tanker).

Passo 6: Verify Regulatory Compliance and Certifications

Ensure that your suppliers adhere to all relevant regulations and possess necessary certifications. This includes environmental regulations, safety standards, and quality assurance certifications. Compliance not only mitigates risk but also enhances your company’s reputation and sustainability efforts.

Passo 7: Establish Strong Communication Channels

Effective communication is key to successful procurement and distribution. Establish clear lines of communication with your suppliers to facilitate real-time updates on production, shipment status, and any potential issues. Regular check-ins will help build a strong partnership and ensure that any challenges are addressed promptly.

By following this checklist, B2B buyers can make informed decisions about oil distribution, ultimately leading to more effective procurement strategies and stronger supplier relationships.

Comprehensive Cost and Pricing Analysis for how is oil distributed Sourcing

What Are the Key Cost Components in Oil Distribution?

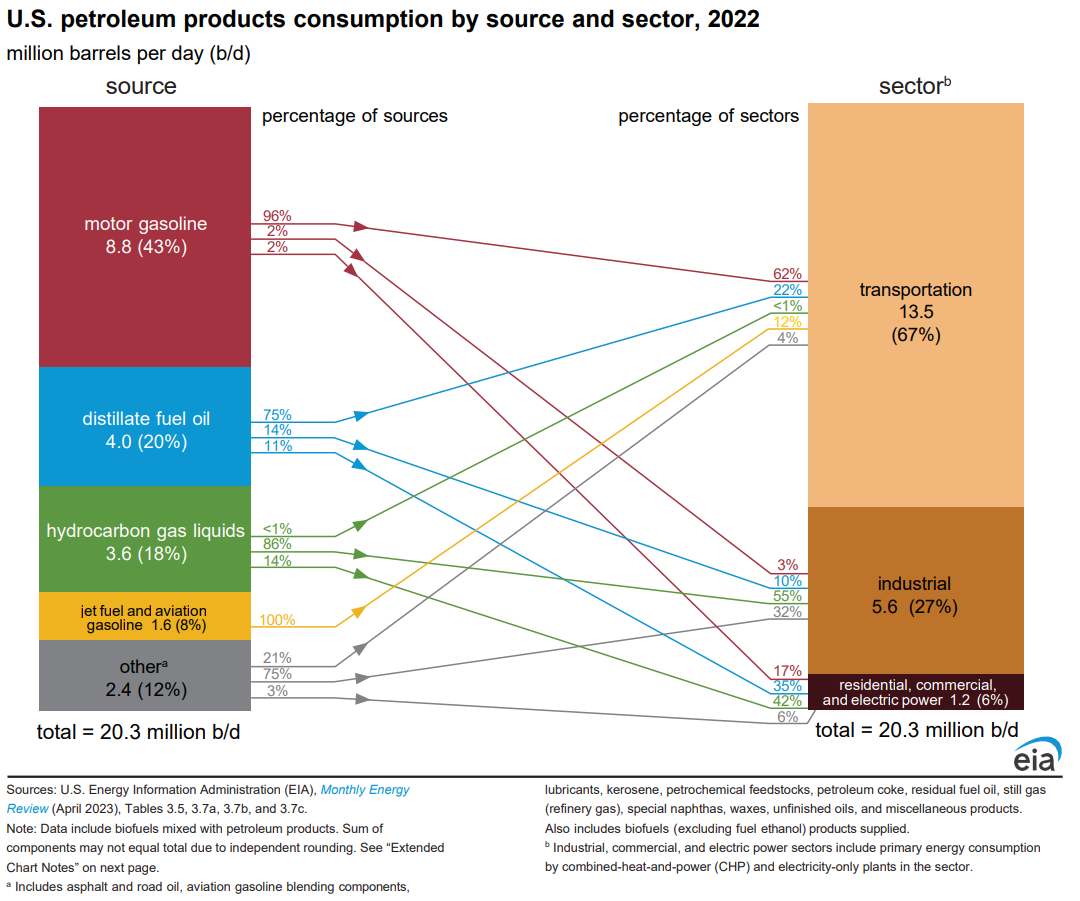

The cost structure in oil distribution encompasses several critical components that international B2B buyers must understand. Firstly, materials form the largest part of the cost, primarily influenced by crude oil prices, which are volatile and subject to global market fluctuations. Labor costs include wages for skilled workers involved in extraction, refining, and logistics.

Illustrative image related to how is oil distributed

Manufacturing overhead is another essential factor, covering operational expenses like facility maintenance, utilities, and administrative costs. Tooling costs pertain to the specialized equipment needed for extraction and transportation, which can vary significantly based on technology and scale of operations. Quality control (QC) processes are necessary to ensure compliance with international standards, adding further costs. Finally, logistics encompass transportation, warehousing, and distribution, which are critical for timely delivery and can be affected by geographic challenges, especially in regions like Africa and South America.

How Do Price Influencers Affect Oil Distribution Costs?

Several factors influence pricing in the oil distribution sector. Volume and Minimum Order Quantities (MOQs) play a significant role; larger orders typically reduce per-unit costs due to economies of scale. Buyers need to assess their consumption patterns to negotiate favorable terms. Additionally, specifications and customization of oil products can lead to price variations. Higher quality or specialized oils often command premium prices due to the additional processing and certification required.

Supplier factors such as reputation, reliability, and historical performance also influence pricing. A well-established supplier may offer higher prices, justified by their reliability and service quality. Furthermore, Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact total costs. International buyers must be aware of these terms to avoid unexpected expenses.

Illustrative image related to how is oil distributed

What Are Essential Buyer Tips for Cost-Efficiency in Oil Distribution?

For B2B buyers, particularly in Africa, South America, the Middle East, and Europe, negotiation strategies are crucial. Engaging in long-term contracts with suppliers can yield better pricing and stability in supply. Buyers should also conduct a Custo total de propriedade (TCO) analysis, considering not just the purchase price but all associated costs, including logistics, storage, and potential tariffs.

Understanding pricing nuances is vital, especially for international transactions. Currency fluctuations, geopolitical risks, and local market conditions can alter costs dramatically. Buyers in regions like Saudi Arabia and Nigeria should remain aware of their local market dynamics and how they interact with global oil prices.

Lastly, it’s essential to recognize that prices can vary significantly based on the region and market conditions. Therefore, while indicative prices can be provided, they should be viewed as a baseline rather than fixed quotes. Continuous market research and supplier relationship management are key to maintaining cost efficiency in oil distribution.

Illustrative image related to how is oil distributed

Conclusão

Navigating the complexities of oil distribution requires a deep understanding of cost components, pricing influencers, and strategic negotiation. By leveraging these insights, international B2B buyers can make informed decisions that enhance their supply chain efficiency and profitability.

Alternatives Analysis: Comparing how is oil distributed With Other Solutions

Exploring Alternatives for Oil Distribution: A Comparative Analysis

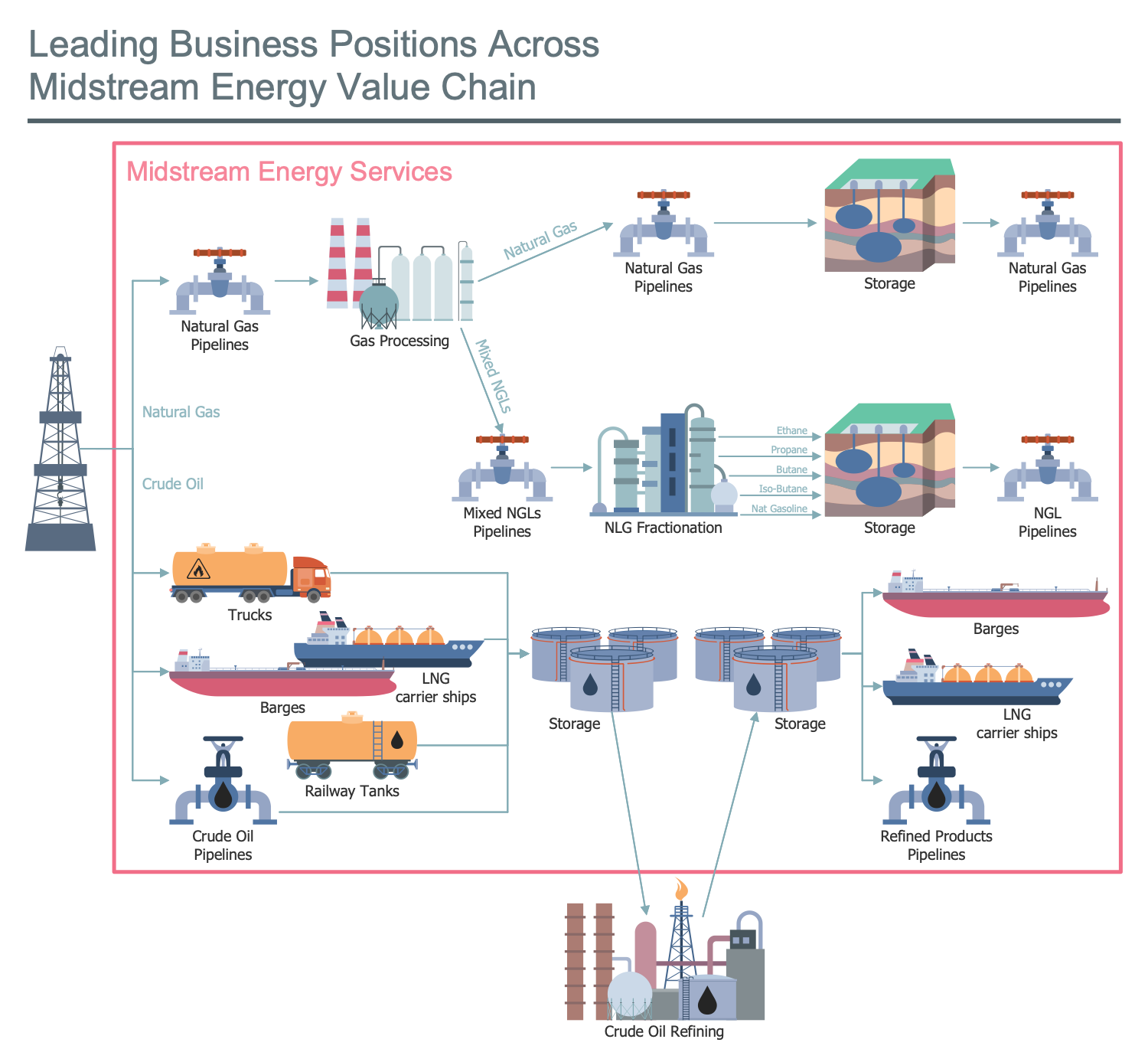

In the realm of energy resources, oil distribution remains a pivotal method for meeting global energy demands. However, as environmental concerns and technological advancements evolve, various alternative solutions are emerging. This section delves into how oil distribution compares to other viable methods, such as pipeline transportation and renewable energy distribution systems.

Comparison Table

| Aspeto de comparação | How Is Oil Distributed | Pipeline Transportation | Renewable Energy Distribution |

|---|---|---|---|

| Desempenho | High efficiency for bulk transport; reliant on infrastructure | Very high efficiency over long distances; subject to geographical limitations | Variable performance; dependent on weather and time of day |

| Custo | High initial investment in infrastructure; fluctuating operational costs | Moderate to high initial investment; lower ongoing costs | Initial setup costs can be high; long-term savings on fuel and maintenance |

| Facilidade de implementação | Complex due to regulatory and environmental considerations | Complex; requires extensive planning and permits | Increasingly streamlined with advancements in technology |

| Manutenção | High maintenance for pipelines and storage facilities | Regular inspections and repairs required | Low maintenance once established; requires monitoring of energy sources |

| Melhor caso de utilização | Ideal for high-demand markets needing consistent supply | Best for regions with existing infrastructure; large-scale transportation | Optimal for sustainable initiatives; suitable for decentralized energy needs |

Análise aprofundada das alternativas

Pipeline Transportation

Pipelines are a traditional method for transporting oil and gas over long distances with high efficiency. They are designed for bulk transport and can deliver large volumes of product continuously. However, the initial investment is significant, and the regulatory hurdles can be daunting. Additionally, pipelines are vulnerable to leaks and environmental concerns, making maintenance a critical aspect. This method is best suited for regions with established infrastructure and a high demand for fossil fuels.

Renewable Energy Distribution

With the global shift towards sustainability, renewable energy distribution is gaining traction. This method encompasses the distribution of energy from sources like solar, wind, and hydropower. While the performance can be variable depending on environmental conditions, advancements in battery storage and smart grid technology are enhancing reliability. The initial setup costs may be high, but the long-term savings and lower environmental impact make it an attractive option for businesses aiming for sustainability. This method is ideal for decentralized energy needs, especially in regions looking to reduce their carbon footprint.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between oil distribution and its alternatives, B2B buyers must consider several factors, including performance, cost, and environmental impact. The choice ultimately hinges on the specific needs of the business, regional infrastructure, and long-term sustainability goals. For companies operating in high-demand markets with existing oil infrastructure, traditional oil distribution may be the best option. Conversely, businesses looking to innovate and reduce their environmental impact should explore renewable energy distribution solutions. By carefully evaluating these aspects, buyers can make informed decisions that align with their operational goals and sustainability commitments.

Essential Technical Properties and Trade Terminology for how is oil distributed

What Are the Key Technical Properties of Oil Distribution?

Understanding the technical properties of oil is crucial for B2B buyers in the global market. Here are some critical specifications that impact oil distribution:

-

API Gravity

– Definition: API gravity is a measure of how heavy or light a petroleum liquid is compared to water. It is expressed in degrees on the American Petroleum Institute (API) scale.

– Importance: A higher API gravity indicates a lighter oil, which is generally more valuable due to its higher yield of gasoline and other refined products. Buyers should consider API gravity when sourcing oil to meet specific refining requirements. -

Sulfur Content

– Definition: This refers to the amount of sulfur present in crude oil, typically measured in parts per million (ppm).

– Importance: Oil with low sulfur content, known as “sweet” crude, is preferred for refining as it produces fewer pollutants. In contrast, “sour” crude, which has higher sulfur content, often requires additional processing, impacting production costs and environmental compliance. -

Viscosity

– Definition: Viscosity measures a fluid’s resistance to flow, typically at a specific temperature.

– Importance: The viscosity of crude oil influences its ease of transportation through pipelines and its suitability for various refining processes. Buyers must ensure that the viscosity aligns with transportation and processing capabilities to minimize costs and delays. -

Pour Point

– Definition: The pour point is the lowest temperature at which oil can flow.

– Importance: Understanding the pour point is vital for logistics, especially in colder climates. Oil that solidifies at higher temperatures may require heating during transport, increasing operational costs. -

Composition

– Definition: This encompasses the various hydrocarbons and non-hydrocarbon compounds present in crude oil, affecting its chemical behavior during refining.

– Importance: The composition impacts refining efficiency and the types of products that can be derived from crude oil. Buyers should analyze the composition to ensure it meets their end-product specifications.

What Are Common Trade Terms in Oil Distribution?

Familiarity with industry terminology is essential for effective communication and negotiation in oil distribution. Here are some key terms:

-

OEM (Fabricante de Equipamento Original)

– Explanation: This term refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: In oil distribution, OEMs may provide equipment or technology critical for extraction and refining processes, ensuring compatibility and quality in operations. -

MOQ (Quantidade mínima de encomenda)

– Explanation: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is crucial for buyers to manage inventory levels and cash flow. It helps in negotiating bulk orders, which can lead to cost savings. -

RFQ (Pedido de Cotação)

– Explanation: An RFQ is a formal request from a buyer to suppliers to provide pricing for specific products or services.

– Relevance: Utilizing RFQs allows buyers to compare prices and terms from different suppliers, enabling informed decision-making and better procurement strategies. -

Incoterms (Termos Comerciais Internacionais)

– Explanation: Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is essential for understanding the logistics and cost implications in oil distribution, particularly in cross-border transactions. -

FCA (Free Carrier)

– Explanation: Under this Incoterm, the seller delivers the goods, cleared for export, to a carrier nominated by the buyer at a specified place.

– Relevance: This term is crucial for buyers to understand their responsibilities regarding shipping and insurance, impacting overall procurement costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that optimize their supply chain and enhance their competitive advantage in the oil market.

Navigating Market Dynamics and Sourcing Trends in the how is oil distributed Sector

What Are the Current Market Dynamics and Key Trends in Oil Distribution?

The global oil distribution market is shaped by several key drivers, including geopolitical factors, technological advancements, and evolving consumer demands. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are experiencing a paradigm shift in sourcing strategies. The emergence of digital supply chain solutions is streamlining logistics and enhancing transparency, allowing buyers to track oil shipments in real-time. Furthermore, the rise of unconventional oil production methods, such as shale extraction in the U.S. and offshore drilling in Brazil, is diversifying supply sources and influencing pricing dynamics.

Illustrative image related to how is oil distributed

In addition to technological advancements, sustainability is becoming a critical factor in sourcing decisions. Buyers are increasingly prioritizing suppliers that adhere to ethical practices and environmental standards. The integration of blockchain technology is also gaining traction, enabling secure and transparent transactions that bolster trust among stakeholders. As oil reserves in traditional regions become depleted, international buyers are expanding their search to less-explored basins in Africa and South America, where untapped resources may offer competitive advantages.

How Is Sustainability and Ethical Sourcing Reshaping Oil Distribution?

The environmental impact of oil distribution is under heightened scrutiny, prompting a shift toward sustainable practices. B2B buyers are increasingly aware of the implications of their sourcing decisions, leading to a demand for ethical supply chains. This involves selecting suppliers who prioritize reduced carbon footprints, responsible drilling practices, and community engagement. The importance of sustainability is reflected in the growing trend of ‘green’ certifications, which provide assurance that products meet environmental standards.

Moreover, buyers are encouraged to seek out suppliers who invest in renewable energy and innovative technologies aimed at minimizing environmental harm. As the global market evolves, those who embrace sustainable practices are likely to gain a competitive edge. Ethical sourcing not only enhances brand reputation but also mitigates risks associated with regulatory compliance and potential backlash from environmentally-conscious consumers.

What Is the Evolution of Oil Distribution in the B2B Sector?

The history of oil distribution can be traced back to the mid-19th century when the first commercial oil well was drilled in Pennsylvania. Since then, the industry has undergone significant transformations, driven by technological advancements and geopolitical shifts. The establishment of major oil fields in the Middle East during the 20th century marked a turning point, positioning this region as a dominant player in global oil supply.

Illustrative image related to how is oil distributed

In recent decades, the rise of emerging markets has altered the landscape of oil distribution. Countries such as Nigeria and Brazil have developed their oil sectors, contributing to a more diversified supply chain. This evolution reflects not only the growing demand for energy but also the need for international buyers to adapt their sourcing strategies in response to fluctuating market dynamics and environmental concerns. The future of oil distribution will likely be characterized by a balance between traditional practices and innovative, sustainable approaches that cater to an increasingly conscientious global market.

Frequently Asked Questions (FAQs) for B2B Buyers of how is oil distributed

-

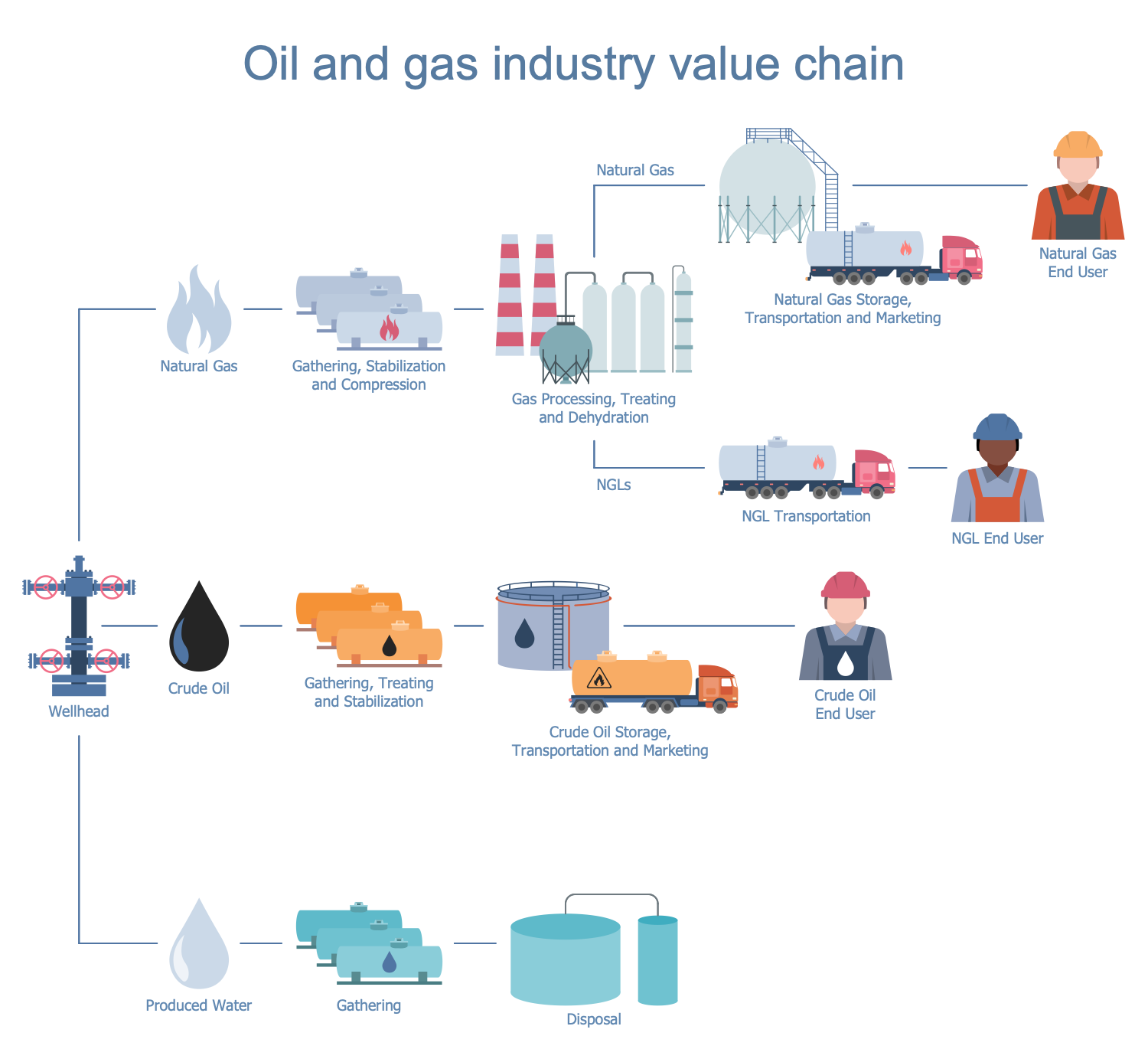

How is oil distributed globally?

Oil distribution involves multiple stages: extraction, transportation, and refining. After extraction, crude oil is transported via pipelines, tankers, or rail to refineries, where it is processed into various petroleum products. The distribution networks are often influenced by geopolitical factors, infrastructure capabilities, and market demand. Regions with significant oil reserves, such as the Middle East and North America, play crucial roles in global supply chains. Understanding these dynamics is essential for B2B buyers to navigate sourcing and logistics effectively. -

What are the main logistics considerations for oil distribution?

Logistics in oil distribution encompass transportation modes, storage facilities, and regulatory compliance. Buyers must consider the efficiency of pipelines versus tankers, the availability of storage options near refineries, and adherence to local and international regulations. Additionally, the geopolitical stability of transit routes can impact delivery times and costs. Partnering with logistics experts familiar with the oil industry can help mitigate risks and optimize supply chain operations. -

What are the key factors to vet suppliers in the oil industry?

When vetting suppliers, B2B buyers should assess several critical factors: supplier reputation, reliability, compliance with international standards, and financial stability. Evaluating past performance through references and case studies can provide insights into their operational capabilities. Additionally, understanding a supplier’s commitment to sustainability and ethical practices is increasingly important in today’s market. Conducting thorough due diligence ensures that you partner with trustworthy suppliers who can meet your needs. -

How can I customize my oil order based on specific requirements?

Customization of oil orders often involves specifying the type of crude oil, volume, and delivery schedule. Buyers should communicate their requirements clearly to suppliers, including any quality specifications or certifications needed. Many suppliers offer flexibility in packaging and blending options to meet unique needs. Engaging in direct discussions with potential suppliers can facilitate tailored solutions that align with your operational demands and quality standards. -

What are the minimum order quantities (MOQ) for oil purchases?

Minimum order quantities (MOQ) for oil can vary significantly based on the supplier and the type of oil being sourced. Some suppliers may have stringent MOQs due to transportation and storage costs, while others may accommodate smaller orders. It’s essential to clarify MOQ during negotiations to ensure that your purchasing needs align with the supplier’s capabilities. Understanding these parameters helps buyers manage inventory effectively and optimize cash flow. -

What payment terms should I expect when sourcing oil internationally?

Payment terms in international oil trade can range from advance payments to letters of credit, depending on the supplier’s policies and the buyer’s creditworthiness. It’s common to negotiate terms that balance risk for both parties, such as partial upfront payments followed by balance payments upon delivery. Buyers should also consider currency fluctuations and their impact on pricing. Establishing clear payment terms upfront can prevent misunderstandings and build trust in the business relationship. -

How do quality assurance (QA) processes work in oil distribution?

Quality assurance (QA) in oil distribution involves rigorous testing and monitoring throughout the supply chain. Suppliers typically conduct tests to ensure the oil meets specified standards for purity, viscosity, and other characteristics. Buyers should request documentation of these QA processes, including certifications from relevant authorities. Establishing clear quality expectations and incorporating QA checks into contracts ensures that the product delivered meets operational requirements and regulatory standards. -

What are the challenges in sourcing oil from Africa, South America, and the Middle East?

Sourcing oil from regions like Africa, South America, and the Middle East presents unique challenges, including political instability, fluctuating market conditions, and varying regulatory environments. Buyers must navigate these complexities by conducting thorough market research and risk assessments. Engaging local experts and establishing strong relationships with suppliers can help mitigate risks. Additionally, staying informed about geopolitical developments and market trends is essential for making informed sourcing decisions.

Top 4 How Is Oil Distributed Manufacturers & Suppliers List

1. Britannica – Global Petroleum Distribution

Domínio: britannica.com

Registered: 1995 (30 years)

Introdução: Petroleum is not evenly distributed globally, with slightly less than half of the world’s proven reserves located in the Middle East. Other significant regions include Canada, the United States, Latin America, Africa, and the former Soviet Union countries. The Middle East holds about 50% of proven reserves but only accounts for 30% of global oil production, while the United States produces roughly…

2. Reddit – Oil Formation Factors

Domínio: reddit.com

Registada: 2005 (20 anos)

Introdução: Oil is found more in some places than others due to the geological processes involved in its formation. Key factors include: 1. Source Rock: Oil originates from kerogen, formed from the accumulation of dead organisms on the ocean floor. 2. Reservoir Rock: Oil and gas, being less dense than kerogen, migrate upwards and can accumulate in reservoir rocks if there is a trap rock to contain them. 3. Tr…

3. Datex Corp – Footprint WMS Solutions

Domínio: datexcorp.com

Registada: 2000 (25 anos)

Introdução: Footprint WMS, Track and Trace, Billing, Data Management, Labor Optimization, Cartonization, Inventory Management, Quality Control, Customer Visibility, Platform Overview, App Studio, API Integrations & EDI, Reporting & Analytics, Security & Compliance, Cloud Native Architecture, Artificial Intelligence.

4. EBSCO – Oil and Gas Distribution

Domínio: ebsco.com

Registada: 1990 (35 anos)

Introdução: Oil and gas distribution is a critical component of the petroleum industry, focusing on the extraction, processing, and transportation of nonrenewable resources. Key details include:

– Crude oil production is concentrated in countries like Russia, Saudi Arabia, the United States, and Venezuela, while natural gas production is mainly in the U.S., Canada, and Iran.

– Petroleum formation occurs thr…

Strategic Sourcing Conclusion and Outlook for how is oil distributed

What Are the Key Insights for Strategic Sourcing in Oil Distribution?

In summary, understanding the distribution of oil is crucial for international B2B buyers as it directly influences sourcing strategies and market dynamics. With nearly half of the world’s proven reserves concentrated in the Middle East, and significant production capabilities in North America and Latin America, strategic sourcing requires a nuanced approach that considers geopolitical factors, production capabilities, and regional demand. Buyers must prioritize partnerships with reliable suppliers from regions with proven reserves while remaining agile to adapt to fluctuating market conditions.

The importance of strategic sourcing cannot be overstated; it empowers businesses to mitigate risks associated with supply chain disruptions and price volatility. By leveraging data analytics and market insights, companies can make informed decisions that enhance their competitive edge.

Looking ahead, it is essential for B2B buyers, especially from Africa, South America, the Middle East, and Europe, to foster collaborations that not only ensure a stable supply of oil but also promote sustainable practices. As the energy landscape evolves, embracing innovative sourcing strategies will position businesses favorably in a competitive market. Engage with industry experts and consider the long-term implications of your sourcing decisions to thrive in this ever-changing environment.

Aviso importante e termos de utilização

⚠️ Declaração de exoneração de responsabilidade importante

As informações fornecidas neste guia, incluindo o conteúdo relativo a fabricantes, especificações técnicas e análises de mercado, destinam-se apenas a fins informativos e educativos. Não constitui aconselhamento profissional em matéria de aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Illustrative image related to how is oil distributed

Embora tenhamos feito todos os esforços para garantir a exatidão e a atualidade das informações, não somos responsáveis por quaisquer erros, omissões ou informações desactualizadas. As condições de mercado, os detalhes da empresa e as normas técnicas estão sujeitos a alterações.

Os compradores B2B devem efetuar a sua própria diligência prévia independente e exaustiva antes de tomar qualquer decisão de compra. Isto inclui contactar diretamente os fornecedores, verificar as certificações, pedir amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é suportado exclusivamente pelo leitor.