Introduction: Navigating the Global Market for rubber vulcanization

Navigating the complexities of the global market for rubber vulcanization presents a significant challenge for international B2B buyers. With the increasing demand for high-performance rubber products across various industries, sourcing reliable suppliers of vulcanized rubber can be daunting. This guide aims to simplify the procurement process by providing insights into the different types of vulcanized rubber, their applications, and essential factors to consider when vetting suppliers. Whether you’re in the automotive, manufacturing, or consumer goods sector, understanding the nuances of vulcanization will empower you to make informed purchasing decisions.

Throughout this guide, we will delve into the mechanics of vulcanization, exploring its benefits such as enhanced durability, elasticity, and resistance to environmental factors. We will also address the critical aspects of cost considerations, regulatory compliance, and market trends that impact the sourcing of vulcanized rubber. For B2B buyers from Africa, South America, the Middle East, and Europe—especially in regions like Germany and Nigeria—this comprehensive resource will equip you with the knowledge to navigate the competitive landscape effectively. By leveraging this information, you can ensure that your procurement strategies align with industry standards and meet your operational needs, ultimately driving value and efficiency in your business operations.

Оглавление

- Top 4 Rubber Vulcanization Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for rubber vulcanization

- Understanding rubber vulcanization Types and Variations

- Key Industrial Applications of rubber vulcanization

- 3 Common User Pain Points for ‘rubber vulcanization’ & Their Solutions

- Strategic Material Selection Guide for rubber vulcanization

- In-depth Look: Manufacturing Processes and Quality Assurance for rubber vulcanization

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber vulcanization’

- Comprehensive Cost and Pricing Analysis for rubber vulcanization Sourcing

- Alternatives Analysis: Comparing rubber vulcanization With Other Solutions

- Essential Technical Properties and Trade Terminology for rubber vulcanization

- Navigating Market Dynamics and Sourcing Trends in the rubber vulcanization Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of rubber vulcanization

- Strategic Sourcing Conclusion and Outlook for rubber vulcanization

- Важный отказ от ответственности и условия использования

Understanding rubber vulcanization Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Traditional Vulcanization | Utilizes sulfur as the primary agent; forms cross-links in rubber. | Tires, gaskets, seals | Плюсы: High durability, excellent elasticity. Конс: Longer processing time, potential environmental concerns. |

| Inverse Vulcanization | Converts elemental sulfur into polymer; creates a 3D network. | Batteries, membranes, specialty applications | Плюсы: Cost-effective, environmentally friendly. Конс: Limited applications compared to traditional methods. |

| Accelerated Vulcanization | Uses accelerators to speed up the curing process significantly. | Automotive components, industrial products | Плюсы: Faster production times, consistent quality. Конс: Requires precise control of conditions. |

| Thermoplastic Vulcanizates (TPVs) | Combines properties of thermoplastics and vulcanized rubber. | Automotive seals, flexible hoses | Плюсы: Easily processed, recyclable. Конс: Generally higher material costs. |

| Microwave Vulcanization | Employs microwave energy for rapid curing of rubber. | Medical devices, specialty consumer goods | Плюсы: Reduced energy consumption, faster production. Конс: Equipment investment can be high. |

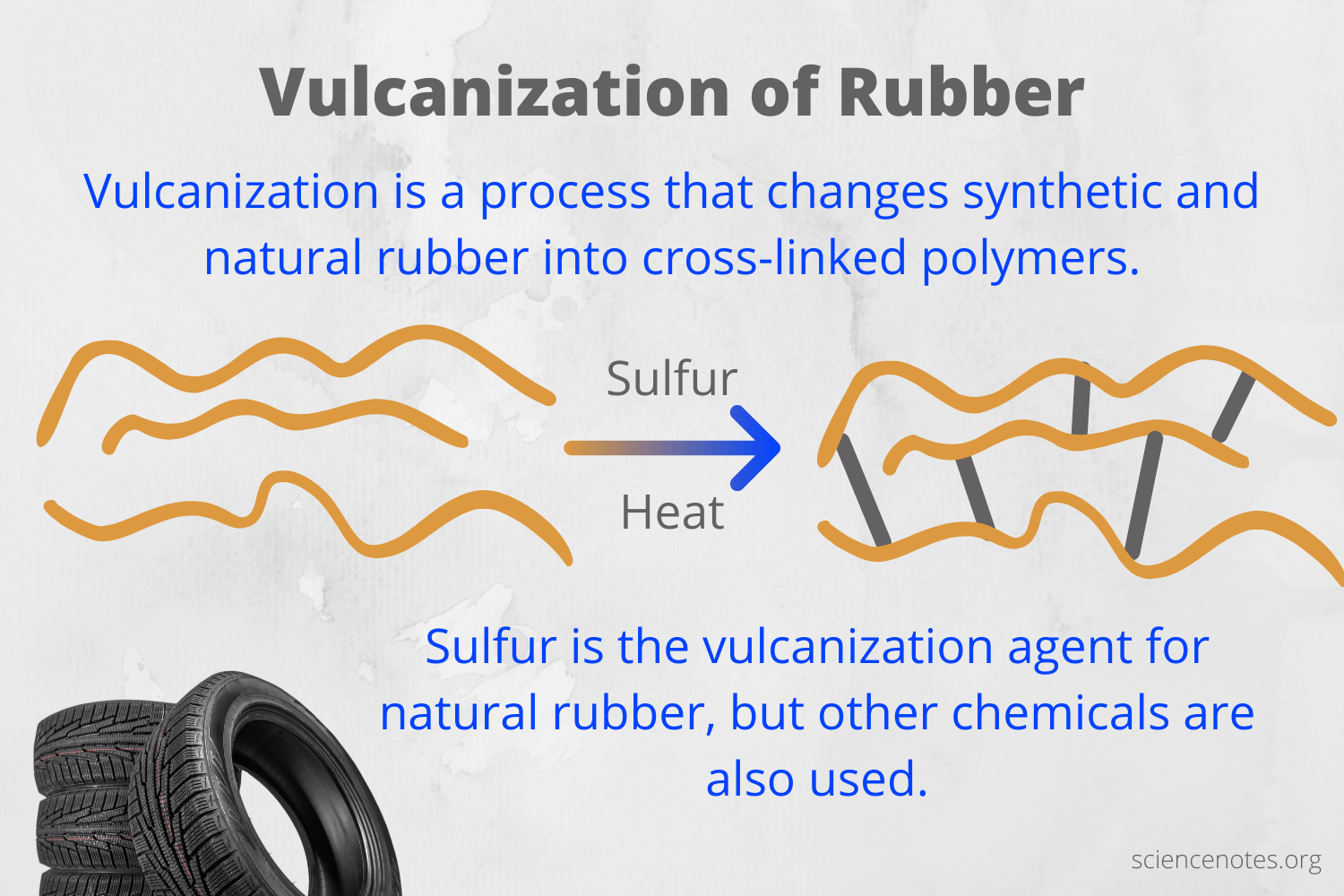

What Are the Characteristics of Traditional Vulcanization?

Traditional vulcanization is the most widely recognized method, primarily utilizing sulfur to create cross-links within the rubber matrix. This process enhances the rubber’s elasticity and strength, making it suitable for high-stress applications such as tires and gaskets. B2B buyers should consider the longevity and performance benefits of traditional vulcanized products, although they may face longer lead times and potential environmental regulations related to sulfur use.

How Does Inverse Vulcanization Differ from Other Methods?

Inverse vulcanization is a novel approach that transforms elemental sulfur into a stable polymer network. This method is particularly attractive for applications requiring chemical stability, such as batteries and membranes. For buyers, this method offers cost-effectiveness and environmental benefits, though its application range is narrower compared to traditional vulcanization techniques.

Illustrative image related to rubber vulcanization

What Advantages Does Accelerated Vulcanization Offer?

Accelerated vulcanization incorporates accelerators to expedite the curing process, resulting in faster production cycles without compromising the quality of the rubber. This method is especially beneficial for industries requiring high-volume output, such as automotive manufacturing. Buyers should weigh the advantages of speed and consistency against the need for precise control over curing conditions.

Why Consider Thermoplastic Vulcanizates (TPVs) for Your Applications?

Thermoplastic vulcanizates combine the elasticity of rubber with the processing advantages of thermoplastics, allowing for easier molding and recycling. TPVs are increasingly used in automotive and industrial applications where flexibility and durability are essential. While they offer significant processing benefits, the higher material costs may be a consideration for cost-sensitive buyers.

What Are the Benefits of Microwave Vulcanization?

Microwave vulcanization utilizes microwave energy to cure rubber rapidly, offering significant reductions in energy consumption and processing time. This method is particularly beneficial for medical devices and specialty consumer products where precision and speed are critical. However, the initial investment in microwave equipment can be substantial, making it a strategic consideration for B2B buyers focused on efficiency and innovation.

Key Industrial Applications of rubber vulcanization

| Промышленность/сектор | Specific Application of Rubber Vulcanization | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive | Tires | Enhanced durability and performance in various conditions | Compliance with safety standards, temperature resistance, and tread design specifications |

| Производство | Conveyor Belts | Increased resistance to wear and tear, improving operational efficiency | Customization options for size, load capacity, and environmental resistance |

| Consumer Goods | Footwear | Improved comfort and longevity, catering to consumer preferences | Availability of various designs, materials, and compliance with health regulations |

| Строительство | Seals and Gaskets | Enhanced sealing capabilities to prevent leaks and improve safety | Material compatibility with construction environments and certifications for durability |

| Electronics | Keypads and Switches | Increased tactile feedback and durability in devices | Specific requirements for flexibility, temperature tolerance, and chemical resistance |

How is Rubber Vulcanization Applied in the Automotive Industry?

In the automotive sector, rubber vulcanization is crucial for manufacturing tires. The vulcanization process enhances the strength and elasticity of rubber, allowing tires to withstand harsh driving conditions, heavy loads, and temperature fluctuations. This results in improved safety and performance, which are paramount for vehicle manufacturers. International buyers should consider compliance with local safety standards, tire tread specifications, and performance ratings when sourcing vulcanized rubber products.

What Role Does Rubber Vulcanization Play in Manufacturing Conveyor Belts?

Rubber vulcanization significantly benefits the manufacturing of conveyor belts used in various industries, including mining and logistics. The enhanced durability and resistance to wear and tear provided by vulcanization ensure that conveyor belts operate efficiently over extended periods, reducing downtime and maintenance costs. Buyers in this sector should seek suppliers who offer customizable options tailored to specific load capacities and environmental conditions, ensuring optimal performance.

Illustrative image related to rubber vulcanization

Why is Rubber Vulcanization Important for Consumer Goods like Footwear?

In the consumer goods industry, particularly in footwear production, vulcanized rubber provides improved comfort and longevity. The enhanced elasticity and strength of vulcanized rubber allow for the creation of flexible yet durable shoe soles that cater to consumer demands for both style and functionality. For international buyers, it is essential to consider design options, material sourcing, and adherence to health regulations to ensure product safety and marketability.

How Does Rubber Vulcanization Benefit the Construction Sector?

Rubber vulcanization is vital in producing seals and gaskets used in construction applications. The process ensures that these components can withstand environmental stressors, preventing leaks and enhancing safety in structures. Buyers should focus on material compatibility with specific construction environments, as well as certifications for durability and performance, to ensure that the products meet industry standards and project requirements.

In What Ways is Rubber Vulcanization Utilized in Electronics?

In the electronics industry, rubber vulcanization is employed in the production of keypads and switches, providing increased tactile feedback and durability in devices. The vulcanized rubber can maintain flexibility and withstand temperature variations, making it ideal for consumer electronics. Buyers should pay attention to specific performance requirements, such as chemical resistance and temperature tolerance, to ensure the reliability of electronic components in various applications.

3 Common User Pain Points for ‘rubber vulcanization’ & Their Solutions

Scenario 1: Challenges with Consistent Quality Control in Vulcanization Processes

Проблема: B2B buyers often face issues with maintaining consistent quality in rubber products due to variability in the vulcanization process. Factors such as temperature fluctuations, inconsistent sulfur content, and varying curing times can lead to defects like brittleness or insufficient elasticity. This inconsistency not only affects the durability and performance of rubber products but also impacts customer satisfaction and trust in the supplier. Buyers in regions with less stringent regulatory oversight may particularly struggle with these challenges, leading to further complications in ensuring product quality.

Illustrative image related to rubber vulcanization

Решение: To overcome quality control issues, buyers should implement a robust quality management system (QMS) that emphasizes real-time monitoring and control of the vulcanization process. Investing in advanced sensors and data analytics tools can help monitor temperature and sulfur levels during curing. Moreover, establishing a standardized operating procedure (SOP) for vulcanization can ensure consistency across batches. Regular training for personnel on the importance of each parameter in the vulcanization process will further enhance quality assurance. Buyers should also consider sourcing materials from suppliers who provide detailed specifications and batch certificates to verify the quality of the raw materials used.

Scenario 2: Difficulty in Meeting Specific Application Requirements

Проблема: Many B2B buyers encounter challenges when trying to meet specific application requirements for rubber products, such as temperature resistance, chemical compatibility, or tensile strength. Industries like automotive and aerospace have stringent standards that rubber components must meet. Failure to meet these specifications can result in product recalls, legal liabilities, and significant financial losses. Buyers may struggle to find suitable vulcanization methods that can tailor the rubber’s properties to meet these diverse needs, especially when sourcing from multiple suppliers.

Решение: To effectively meet specific application requirements, buyers should engage in detailed consultations with rubber suppliers who specialize in customized vulcanization solutions. It’s essential to communicate precise requirements, including the environmental conditions the rubber will face, such as exposure to chemicals or extreme temperatures. Suppliers can then recommend specific formulations, additives, and vulcanization techniques tailored to these needs. Additionally, conducting small-scale trials before mass production can help validate the performance of the rubber products under actual working conditions, ensuring that they meet the required specifications without compromising quality.

Scenario 3: High Costs Due to Inefficient Vulcanization Methods

Проблема: Cost efficiency is a critical concern for B2B buyers in the rubber industry. Many companies face high production costs attributed to inefficient vulcanization methods, which can lead to increased energy consumption and longer cycle times. This inefficiency not only eats into profit margins but also affects the competitiveness of the product in the market. Buyers in emerging markets may find this particularly challenging, as they often operate with tighter budgets and less access to advanced technology.

Illustrative image related to rubber vulcanization

Решение: To reduce costs associated with vulcanization, buyers should explore investing in modern, energy-efficient vulcanization equipment that optimizes both time and energy consumption. Technologies such as microwave or infrared curing can significantly reduce cycle times compared to traditional methods. Additionally, buyers should analyze their current production processes to identify bottlenecks and areas for improvement. Collaborating with suppliers who offer innovative vulcanization techniques can lead to better material utilization and reduced waste. Moreover, considering bulk purchasing of raw materials can lower costs, while negotiating long-term contracts with suppliers can provide price stability and better terms.

Strategic Material Selection Guide for rubber vulcanization

When selecting materials for rubber vulcanization, it’s crucial to understand the properties, advantages, and limitations of the most commonly used compounds. This guide analyzes four key materials that play a significant role in the vulcanization process: natural rubber, synthetic rubber (SBR), EPDM rubber, and silicone rubber. Each material offers unique properties that can affect product performance, durability, and suitability for various applications.

What Are the Key Properties of Natural Rubber in Vulcanization?

Natural rubber, derived from the sap of rubber trees, is known for its excellent elasticity and tensile strength. It performs well under a range of temperatures but has limitations regarding heat and ozone resistance. The vulcanization process enhances its durability, making it suitable for products like tires and seals. However, natural rubber can degrade when exposed to certain chemicals, which may limit its application in harsh environments.

Pros: High elasticity, good tensile strength, and cost-effective for mass production.

Cons: Poor resistance to heat, ozone, and certain chemicals, which may lead to premature failure in specific applications.

How Does Synthetic Rubber (SBR) Compare in Terms of Performance?

Styrene-Butadiene Rubber (SBR) is a widely used synthetic rubber that offers good abrasion resistance and aging stability. It is particularly effective in tire manufacturing due to its excellent wear characteristics. SBR can be vulcanized with sulfur to enhance its mechanical properties, making it suitable for various applications, including automotive and industrial products. However, it generally has lower elasticity compared to natural rubber.

Pros: Excellent wear resistance, good aging stability, and versatile application range.

Cons: Lower elasticity than natural rubber and higher susceptibility to temperature variations.

What Advantages Does EPDM Rubber Provide for Specific Applications?

Ethylene Propylene Diene Monomer (EPDM) rubber is known for its outstanding resistance to heat, ozone, and weathering. It is commonly used in automotive seals, roofing membranes, and electrical insulation. The vulcanization of EPDM enhances its durability and performance in outdoor applications. However, its compatibility with certain oils and solvents can be limited, which may restrict its use in specific environments.

Pros: Exceptional weather resistance, high durability, and excellent performance in outdoor applications.

Cons: Limited oil and solvent compatibility, which may restrict its use in some industrial applications.

Why Is Silicone Rubber a Preferred Choice for High-Temperature Applications?

Silicone rubber is renowned for its ability to withstand extreme temperatures, ranging from -60°C to +200°C (-76°F to +392°F). This makes it ideal for applications in automotive, aerospace, and medical industries. The vulcanization process enhances its properties, making it resistant to UV light and oxidation. However, silicone rubber can be more expensive than other types, which may be a consideration for cost-sensitive projects.

Pros: Excellent temperature resistance, UV stability, and biocompatibility for medical applications.

Cons: Higher cost compared to other rubber types and lower tensile strength.

What Should International B2B Buyers Consider When Selecting Rubber Materials?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider compliance with regional standards such as ASTM, DIN, and JIS. Understanding local market preferences and regulations is vital for ensuring product acceptance. Additionally, factors such as sourcing capabilities, transportation logistics, and local manufacturing capabilities can influence material selection. Buyers should also evaluate the long-term performance and environmental impact of the materials chosen.

Illustrative image related to rubber vulcanization

| Материал | Typical Use Case for rubber vulcanization | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Natural Rubber | Tires, seals, gaskets | High elasticity and tensile strength | Poor resistance to heat and chemicals | Низкий |

| Synthetic Rubber (SBR) | Automotive tires, industrial products | Excellent wear resistance | Lower elasticity than natural rubber | Средний |

| EPDM Rubber | Automotive seals, roofing membranes | Exceptional weather resistance | Limited oil and solvent compatibility | Средний |

| Silicone Rubber | Aerospace, medical applications | Excellent temperature resistance | Higher cost and lower tensile strength | Высокий |

This strategic material selection guide provides a comprehensive overview for B2B buyers in the rubber vulcanization industry, enabling informed decisions that align with their specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber vulcanization

What are the Main Stages of the Rubber Vulcanization Manufacturing Process?

The manufacturing process of rubber vulcanization is intricate and involves several key stages that ensure the final product meets the necessary quality and performance standards. Understanding these stages will help B2B buyers assess potential suppliers and their capabilities effectively.

1. Material Preparation: What Is Involved in the Initial Stage?

The first step in the manufacturing process is the preparation of the raw materials. This typically involves selecting the appropriate type of rubber, whether natural or synthetic, and mixing it with sulfur and other additives. The additives may include accelerators, antioxidants, and fillers, which enhance specific properties of the rubber, such as strength, flexibility, and durability.

This phase also includes precise measurements and mixing to achieve a homogenous compound, often utilizing high-shear mixers. The quality of the raw materials used is crucial, as it directly impacts the performance of the vulcanized rubber. Buyers should inquire about the sourcing and quality control measures in place for these materials.

2. Forming: How Is the Rubber Shaped?

Once the rubber compound is ready, it is subjected to a forming process. This can involve molding or extrusion, depending on the final product requirements. In molding, the rubber is placed in a mold that defines its shape and dimensions. The mold is then subjected to heat, which initiates the vulcanization process.

Extrusion, on the other hand, involves forcing the rubber compound through a shaped die to create continuous profiles, such as seals or gaskets. This method is efficient for producing long lengths of product. Understanding the forming techniques used by suppliers can provide insight into their production capabilities and product variety.

3. Assembly: What Role Does it Play in the Process?

For products that require multiple components, the assembly stage is essential. This could involve attaching various rubber parts together or integrating metal or plastic components with the vulcanized rubber. During assembly, manufacturers must ensure that the components are aligned correctly and securely attached, as this affects the overall integrity of the final product.

B2B buyers should assess the assembly techniques employed by potential suppliers, as well as their capability to produce complex assemblies, which can be crucial for specific applications.

4. Finishing: What Are the Final Touches?

The finishing stage includes processes such as trimming, surface treatment, and inspection. After vulcanization, excess material is often removed to ensure that the product meets the specified tolerances. Surface treatments may be applied to enhance properties like adhesion or resistance to environmental factors.

Quality assurance checks are vital at this stage to verify that the final product meets industry standards and customer specifications. Buyers should inquire about the finishing processes and the measures taken to maintain product quality.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is critical in the rubber vulcanization process, ensuring that the final products are reliable and meet international standards. For B2B buyers, understanding these standards can help in selecting reputable suppliers.

What International Standards Are Relevant?

ISO 9001 is one of the most recognized quality management system standards globally. It outlines criteria for establishing an effective quality management system and focuses on continuous improvement and customer satisfaction. Suppliers adhering to ISO 9001 demonstrate a commitment to quality, which is crucial for B2B transactions.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in Europe or API certification for oil and gas applications are important. These certifications indicate compliance with specific regulatory and safety requirements.

Каковы ключевые контрольные точки контроля качества?

Quality control (QC) checkpoints are essential throughout the manufacturing process:

-

Входящий контроль качества (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality criteria before being used in production.

-

Внутрипроцессный контроль качества (IPQC): During manufacturing, ongoing checks are performed to monitor processes and ensure that they are within acceptable limits. This can include measuring temperature, pressure, and other critical parameters during vulcanization.

-

Окончательный контроль качества (ОКК): After the product is finished, a comprehensive inspection is conducted to verify that it meets all specifications and standards before shipment.

Как покупатели B2B могут проверять контроль качества поставщиков?

B2B buyers must ensure that their suppliers have robust quality control measures in place. Here are several ways to verify supplier QC:

What Should Buyers Look for in Audits and Reports?

Conducting supplier audits is an effective way to assess quality control practices. Buyers should request recent audit reports that outline the supplier’s compliance with quality standards and any corrective actions taken in response to non-conformities.

Understanding the audit frequency and the specific areas covered can provide insight into the supplier’s commitment to maintaining high quality. Additionally, buyers can consider third-party inspections, which offer an impartial assessment of the supplier’s quality processes.

What Testing Methods Are Commonly Used?

Common testing methods for rubber vulcanization include tensile strength testing, elongation testing, hardness testing, and abrasion resistance testing. These tests evaluate the physical properties of the vulcanized rubber and ensure that it meets the required specifications.

Buyers should inquire about the testing protocols used by suppliers, including the equipment and methods employed, to ensure that they are using industry-standard practices.

Каковы нюансы контроля качества для международных покупателей B2B?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Different regions may have varying standards and regulations, which can impact product compliance.

Buyers should familiarize themselves with local regulations and certifications that may be required in their markets. Additionally, language barriers and cultural differences can affect communication regarding quality expectations, so establishing clear lines of communication with suppliers is essential.

Illustrative image related to rubber vulcanization

By comprehensively understanding the manufacturing processes and quality assurance practices involved in rubber vulcanization, B2B buyers can make informed decisions, ensuring that they partner with suppliers who meet their quality and performance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber vulcanization’

Введение

This practical sourcing guide provides a comprehensive checklist for B2B buyers seeking to procure rubber vulcanization services or products. The vulcanization process enhances the properties of rubber, making it suitable for various industrial applications. By following this step-by-step guide, buyers can ensure they select the right suppliers and materials that meet their specific needs.

Шаг 1: Определите технические характеристики

Before initiating the sourcing process, clearly outline your technical requirements for vulcanized rubber. This includes the desired physical properties, such as tensile strength, elasticity, and chemical resistance. Defining these specifications helps streamline the selection of suppliers and ensures that the final product meets your operational demands.

- Consider factors like temperature resistance, hardness, and intended application (e.g., automotive, industrial).

- Document any compliance standards relevant to your industry, such as ISO certifications.

Шаг 2: Исследование потенциальных поставщиков

Conduct thorough research to identify suppliers specializing in rubber vulcanization. Look for companies with a proven track record in your industry and geographical region. Supplier reliability and expertise can significantly impact the quality of the vulcanized products.

- Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers.

- Check for reviews and testimonials from existing clients to gauge their reputation.

Шаг 3: Оцените сертификаты поставщиков

Before moving forward, verify that potential suppliers hold relevant certifications. Certifications such as ISO 9001 and ISO 14001 indicate adherence to quality management and environmental standards. This step is crucial in ensuring that the supplier follows best practices in manufacturing and quality control.

Illustrative image related to rubber vulcanization

- Request documentation of certifications and any other quality assurance processes they follow.

- Ensure that the supplier’s certifications are current and applicable to your specific requirements.

Шаг 4: Запрос образцов для тестирования

Once you’ve shortlisted potential suppliers, request samples of their vulcanized rubber products. Testing samples allows you to evaluate the material’s physical properties and performance in real-world conditions. This step is essential for verifying that the supplier can meet your specifications.

- Conduct tests for durability, elasticity, and resistance to environmental factors relevant to your application.

- Compare samples from different suppliers to assess performance and quality.

Шаг 5: Discuss Production Capabilities

Engage in discussions with suppliers about their production capabilities and technology. Understanding their manufacturing processes, equipment, and capacity ensures that they can meet your volume and quality requirements. This step also helps identify any potential bottlenecks in production.

- Inquire about the timeframes for production and delivery, especially if you have tight schedules.

- Assess their ability to scale production as your needs grow.

Шаг 6: Переговоры об условиях и ценах

After selecting a preferred supplier, enter into negotiations regarding pricing, payment terms, and delivery schedules. It’s crucial to ensure that the terms align with your budget and operational timelines. Transparent negotiations can help build a strong partnership with the supplier.

- Consider long-term contracts for better pricing and stability, especially if you anticipate ongoing needs.

- Ensure clarity on any additional costs, such as shipping or customizations.

Шаг 7: Establish a Quality Control Process

Finally, implement a quality control process to monitor the performance of the vulcanized rubber products you receive. Establish clear criteria for quality assessment and communication channels for addressing any issues that arise. This step is vital for maintaining the integrity of your supply chain and ensuring product reliability.

- Set up regular reviews and feedback sessions with the supplier to discuss quality and performance.

- Monitor the products during initial orders to ensure they meet your established specifications consistently.

By following this checklist, B2B buyers can effectively navigate the sourcing process for rubber vulcanization, ensuring they select the right suppliers and products for their needs.

Comprehensive Cost and Pricing Analysis for rubber vulcanization Sourcing

What Are the Key Cost Components in Rubber Vulcanization Sourcing?

Understanding the cost structure of rubber vulcanization is crucial for B2B buyers aiming to optimize their sourcing strategies. The primary cost components include:

-

Материалы: The cost of raw materials such as natural or synthetic rubber, sulfur, and other additives significantly impacts the final price. Prices can fluctuate based on market conditions, availability, and quality, so buyers should consider sourcing from regions with stable supply chains.

-

Труд: Labor costs vary by region and can affect the overall cost structure. In markets like Africa and South America, labor may be less expensive compared to Europe, but this can also influence quality and consistency. Understanding local labor laws and wage standards is essential for budgeting.

-

Производственные накладные расходы: This includes costs associated with facility operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which in turn can lower pricing for buyers.

-

Инструментальная оснастка: The initial investment in molds and specialized equipment for vulcanization can be significant. Custom tooling for unique product specifications adds to the upfront costs but is necessary for achieving desired product characteristics.

-

Контроль качества (QC): Ensuring product quality through rigorous testing and compliance with industry standards incurs additional costs. Buyers should assess the QC measures in place to ensure they are receiving high-quality products.

-

Логистика: Transportation and shipping costs can vary widely depending on geographic location, shipping methods, and Incoterms. Buyers should factor in these costs when calculating total expenses.

-

Маржа: Suppliers typically add a margin to cover their costs and profit. Understanding the competitive landscape can provide leverage during negotiations.

How Do Price Influencers Affect Rubber Vulcanization Costs?

Several factors can influence the pricing of vulcanized rubber:

-

Объем и минимальное количество заказа (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs against supplier MOQs to maximize cost-efficiency.

-

Технические характеристики и персонализация: Custom formulations or specific performance characteristics can increase costs. Buyers should communicate clearly about their requirements to avoid unexpected price hikes.

-

Materials Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can lead to increased costs but may also ensure better performance and durability. Buyers should weigh the benefits of premium materials against their budget constraints.

-

Факторы поставщика: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge more, but their quality assurance and consistency can justify the cost.

-

Инкотермс: Understanding the agreed Incoterms (e.g., FOB, CIF) is vital, as they dictate who bears shipping costs and risks. Misunderstandings here can lead to unexpected expenses.

What Are Effective Buyer Tips for Negotiating Rubber Vulcanization Prices?

B2B buyers can adopt several strategies to enhance their sourcing efficiency:

-

Negotiate Terms: Engage suppliers in discussions about pricing and terms. Leverage your volume and long-term purchasing potential to negotiate better rates.

-

Ориентируйтесь на общую стоимость владения (TCO): Instead of just looking at the initial purchase price, consider factors like durability, maintenance, and lifecycle costs. This holistic view can lead to better long-term savings.

-

Stay Informed About Pricing Nuances: International buyers, particularly in regions like Africa and South America, should stay updated on local market trends and economic conditions, as these can affect material costs and availability.

-

Build Strong Supplier Relationships: Establishing long-term partnerships with suppliers can lead to better pricing, priority service, and improved collaboration on product development.

Заключение

Navigating the complexities of rubber vulcanization sourcing requires a thorough understanding of cost components, price influencers, and negotiation strategies. By considering these factors, B2B buyers can make informed decisions that enhance their procurement process and ultimately contribute to their bottom line. While indicative prices can provide a baseline, each sourcing scenario may differ significantly, emphasizing the importance of tailored negotiations and strategic supplier partnerships.

Alternatives Analysis: Comparing rubber vulcanization With Other Solutions

Understanding Alternatives to Rubber Vulcanization

In the quest for durable and reliable rubber products, rubber vulcanization has long been the industry standard due to its ability to enhance the mechanical properties of rubber. However, several alternative methods are available that may better suit specific applications or budget constraints. This section provides a comparative analysis of rubber vulcanization against two viable alternatives: thermoplastic elastomers (TPE) and silicone rubber molding.

Illustrative image related to rubber vulcanization

Сравнительная таблица

| Сравнительный аспект | Rubber Vulcanization | Thermoplastic Elastomers (TPE) | Silicone Rubber Molding |

|---|---|---|---|

| Производительность | High durability, excellent elasticity, resistant to wear and heat | Good flexibility and resilience, but lower heat resistance than vulcanized rubber | Excellent thermal stability, chemical resistance, and elasticity |

| Стоимость | Moderate to high due to processing and material costs | Generally lower initial costs, but may require more frequent replacement | Higher initial costs but can offer longer life in specific applications |

| Простота реализации | Requires specialized equipment and skilled labor | Easier to process and can be molded using standard injection molding techniques | Requires specific molds and curing processes, increasing complexity |

| Техническое обслуживание | Low maintenance once cured, long-lasting | Moderate maintenance; performance can degrade over time | Low maintenance, but may require periodic checks for wear |

| Лучший пример использования | Automotive parts, industrial components, consumer goods | Seals, gaskets, and flexible parts in various industries | Medical devices, automotive seals, and applications requiring high-temperature resistance |

Подробный анализ альтернатив

Thermoplastic Elastomers (TPE)

Thermoplastic elastomers are a versatile alternative to vulcanized rubber that combines the properties of rubber with the processability of plastics. TPEs are easier to mold and can be recycled, which may appeal to environmentally conscious businesses. However, while they offer good elasticity and flexibility, TPEs generally do not withstand high temperatures as well as vulcanized rubber, making them less suitable for applications where heat resistance is critical.

Silicone Rubber Molding

Silicone rubber molding is another alternative that provides excellent thermal stability and chemical resistance, making it ideal for applications in extreme environments, such as medical devices and automotive components. The initial costs for silicone rubber can be higher due to the specific molds and curing processes required. Nevertheless, silicone rubber often outperforms vulcanized rubber in terms of longevity and resilience to harsh conditions, making it a worthwhile investment for specific high-performance applications.

Conclusion: Making the Right Choice for Your Needs

When selecting the best solution for rubber products, B2B buyers must weigh the specific requirements of their applications against the characteristics of each method. Rubber vulcanization is optimal for durability and high-stress environments, while thermoplastic elastomers may be more cost-effective for less demanding applications. Silicone rubber molding, on the other hand, excels in extreme conditions but comes at a higher price point. By carefully evaluating performance needs, budget constraints, and application specifics, buyers can make informed decisions that align with their operational goals and enhance product reliability.

Essential Technical Properties and Trade Terminology for rubber vulcanization

What Are the Key Technical Properties of Rubber Vulcanization?

When selecting vulcanized rubber for industrial applications, understanding its essential technical properties is crucial. Here are several critical specifications that can impact the performance and suitability of rubber products:

Illustrative image related to rubber vulcanization

1. Material Grade

Material grade refers to the classification of rubber based on its composition and properties. Different grades indicate varying levels of durability, temperature resistance, and elasticity. For B2B buyers, selecting the correct material grade ensures that the rubber product meets specific application requirements, such as in automotive parts or industrial machinery.

2. Hardness (Shore Durometer)

Hardness is a measure of a material’s resistance to indentation, typically measured on the Shore durometer scale. The hardness level can significantly affect the rubber’s performance in specific applications. Softer rubbers provide better grip and flexibility, while harder rubbers offer increased durability and wear resistance. Understanding hardness helps buyers choose the right product for their operational needs.

3. Tensile Strength

Tensile strength is the maximum amount of tensile (stretching) stress that a rubber material can withstand before failure. This property is vital in applications where the rubber will be subjected to stretching or pulling forces. For B2B buyers, knowing the tensile strength helps ensure that the rubber can endure the mechanical stresses it will face in service.

4. Elongation at Break

Elongation at break measures how much a rubber material can stretch before it breaks. This property is crucial for products requiring flexibility and resilience, such as seals and gaskets. A higher elongation percentage indicates greater elasticity, which can be beneficial for applications that involve dynamic movements.

5. Compression Set

Compression set refers to the rubber’s ability to return to its original thickness after being compressed. A lower compression set indicates better resilience and longevity in applications where the rubber is subjected to continuous pressure. Understanding this property is essential for B2B buyers looking for durable components in machinery or automotive applications.

What Are Common Trade Terms in Rubber Vulcanization?

Navigating the rubber vulcanization industry requires familiarity with specific jargon and trade terms. Here are several commonly used terms that are essential for B2B transactions:

Illustrative image related to rubber vulcanization

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are used as components in another company’s end product. Understanding OEM relationships is vital for buyers looking to source rubber components that fit into larger assemblies or machines.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it directly impacts inventory management and cost efficiency. Knowing the MOQ helps businesses assess whether they can meet their production needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting price quotes for specific products or services. This term is essential for B2B buyers who want to compare pricing and terms from different suppliers, allowing for informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers involved in cross-border transactions, as they clarify shipping responsibilities, risk management, and cost allocation.

5. Curing Agents

Curing agents, often sulfur-based, are additives that facilitate the vulcanization process by promoting cross-linking in rubber. Knowledge of curing agents is important for buyers to ensure that the vulcanization process meets their specific performance requirements.

6. Accelerators

Accelerators are substances added to the rubber mixture to speed up the vulcanization process. Familiarity with different types of accelerators allows buyers to optimize production efficiency and product performance.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed decisions in the rubber vulcanization market, ultimately leading to better product selection and supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the rubber vulcanization Sector

What Are the Current Market Dynamics and Key Trends in Rubber Vulcanization?

The rubber vulcanization market is experiencing significant transformation driven by globalization, technological advancement, and evolving consumer preferences. Key global drivers include the rising demand for high-performance rubber products, particularly in the automotive, aerospace, and industrial sectors. As countries in Africa, South America, the Middle East, and Europe continue to invest in infrastructure and manufacturing, the need for durable, high-quality rubber components is increasing. For instance, Germany’s automotive industry heavily relies on vulcanized rubber for tires and seals, while Nigeria’s growing manufacturing sector presents new opportunities for suppliers.

Emerging B2B technology trends are reshaping sourcing strategies. Digital platforms for procurement are becoming essential, enabling buyers to access a wider range of suppliers and streamline their supply chains. Technologies such as artificial intelligence and machine learning are being integrated into quality control processes, enhancing product consistency and reducing waste. Additionally, the adoption of Industry 4.0 practices, which emphasize automation and data exchange in manufacturing, is driving innovation in the vulcanization process, leading to improved efficiency and lower costs.

International buyers must also navigate fluctuating raw material prices and trade policies that can impact sourcing decisions. The volatility of sulfur prices, a key component in vulcanization, necessitates strategic partnerships and diversified sourcing channels to mitigate risks. As markets evolve, buyers who stay informed and agile in their sourcing strategies will be better positioned to capitalize on growth opportunities.

How Are Sustainability and Ethical Sourcing Impacting the Rubber Vulcanization Sector?

Sustainability is increasingly at the forefront of the rubber vulcanization sector, driven by environmental concerns and consumer demand for greener products. The vulcanization process traditionally involves the use of sulfur and various chemicals, which can have significant environmental impacts if not managed properly. As such, there is a growing emphasis on adopting sustainable practices throughout the supply chain.

Ethical sourcing is becoming essential for B2B buyers looking to align their procurement strategies with corporate social responsibility goals. Buyers are prioritizing suppliers who demonstrate commitment to sustainable practices, such as sourcing natural rubber from certified plantations that follow environmentally friendly practices. Certifications like Forest Stewardship Council (FSC) and Global Organic Latex Standard (GOLS) are gaining traction, allowing buyers to ensure the materials used in vulcanized rubber products meet stringent environmental and ethical standards.

Moreover, innovations in bio-based and recycled materials are emerging as viable alternatives to traditional rubber. Suppliers are increasingly offering products that incorporate these materials, appealing to businesses looking to reduce their carbon footprint. By prioritizing sustainability and ethical sourcing, B2B buyers can not only fulfill regulatory requirements but also enhance their brand reputation in a market that increasingly values environmental stewardship.

What Is the Historical Context of Rubber Vulcanization and Its Relevance to Today’s B2B Buyers?

The process of rubber vulcanization was first developed in the 19th century by Charles Goodyear, revolutionizing the rubber industry. This innovation transformed raw rubber into a durable, elastic material suitable for a wide range of applications, from tires to industrial seals. As manufacturing processes evolved, so did the vulcanization techniques, incorporating advanced materials and technologies to improve efficiency and product performance.

Understanding the historical context of vulcanization is crucial for today’s B2B buyers. It highlights the ongoing importance of innovation in manufacturing processes and the need for suppliers to adapt to changing market demands. This historical perspective also underscores the significance of established relationships in the supply chain, as many companies rely on long-standing partnerships with suppliers who have a deep understanding of the materials and processes involved in rubber vulcanization. By recognizing this evolution, buyers can make more informed sourcing decisions, ensuring they partner with suppliers that not only deliver quality products but also contribute to ongoing advancements in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber vulcanization

-

How do I select the right vulcanized rubber supplier?

Choosing the right supplier for vulcanized rubber requires thorough research and vetting. Start by assessing their industry experience and reputation. Request samples to evaluate the quality of their products. Additionally, consider suppliers with certifications such as ISO 9001, which indicates a commitment to quality management. Engaging in direct communication can also help gauge their customer service and responsiveness. Lastly, check reviews and testimonials from other B2B clients to ensure reliability and consistency in delivery. -

What are the key benefits of vulcanized rubber over traditional rubber?

Vulcanized rubber offers enhanced strength, elasticity, and durability compared to traditional rubber. The vulcanization process creates cross-links between polymer chains, resulting in a material that can withstand greater mechanical stress and resist deformation. It is also more resistant to abrasion and environmental factors such as heat and chemicals, making it suitable for a variety of applications, from automotive to industrial uses. This increased performance often translates into lower long-term costs due to reduced wear and maintenance needs. -

What factors influence the cost of vulcanized rubber products?

The cost of vulcanized rubber products can be influenced by several factors, including the type of rubber used (natural vs. synthetic), the complexity of the manufacturing process, and the specific additives employed. Additionally, the scale of production plays a significant role; larger orders can reduce per-unit costs due to economies of scale. Freight and logistics costs, particularly for international shipments, also contribute to the overall price. Be sure to discuss all these factors with your supplier to obtain a transparent quotation. -

What minimum order quantities (MOQ) should I expect when sourcing vulcanized rubber?

Minimum order quantities (MOQ) for vulcanized rubber can vary significantly depending on the supplier and the specific product. Typically, MOQs can range from a few hundred kilograms to several tons. It’s essential to communicate your requirements clearly with potential suppliers and explore options for lower MOQs, especially if you are testing new products. Some suppliers may offer flexibility for first-time orders or prototype runs, allowing you to assess product suitability without committing to large quantities. -

How can I ensure the quality of vulcanized rubber products?

To ensure the quality of vulcanized rubber products, request detailed product specifications, including material composition and performance characteristics. Implement a quality assurance plan that includes regular testing and inspections of incoming materials. Collaborate with suppliers who provide certifications and test results to validate the quality of their products. Establishing a strong communication line with your supplier can also facilitate quick resolutions to any quality concerns, ensuring that you receive materials that meet your standards. -

What payment terms are typically offered by vulcanized rubber suppliers?

Payment terms can vary widely among vulcanized rubber suppliers, depending on their policies and your business relationship. Common arrangements include payment in advance, net 30 or net 60 terms, and partial payments upon order confirmation. For international transactions, consider discussing the use of letters of credit or escrow services to mitigate risks. Always clarify payment terms before finalizing any agreements to avoid misunderstandings and ensure smooth transactions. -

How do logistics and shipping impact the sourcing of vulcanized rubber?

Logistics and shipping are critical factors when sourcing vulcanized rubber, especially for international buyers. Consider the lead time for production and delivery, which can vary based on the supplier’s location and shipping methods. Evaluate shipping costs, which can significantly affect overall expenses, particularly for large orders. Collaborate with suppliers who have experience with international shipping regulations and customs to streamline the process and minimize delays. -

What customization options are available for vulcanized rubber products?

Customization options for vulcanized rubber products are extensive and can include variations in size, shape, hardness, and color. Suppliers often offer tailored formulations to meet specific performance requirements, such as increased heat resistance or enhanced flexibility. Discuss your project needs in detail with potential suppliers, as they may also provide prototyping services to test custom designs before full-scale production. This flexibility can help ensure that the final product aligns perfectly with your operational needs.

Top 4 Rubber Vulcanization Manufacturers & Suppliers List

1. ScienceDirect – Vulcanization Process

Домен: sciencedirect.com

Зарегистрирован: 1997 (28 лет)

Введение: Vulcanization is a chemical process that enhances the elasticity and retractile force of rubbery or elastomeric materials by forming a crosslinked molecular network, reducing permanent deformation after the removal of applied forces. It typically involves the insertion of crosslinks between polymer chains using sulfur or other vulcanizing agents. The process enhances mechanical properties, durabil…

2. Britannica – Vulcanization Process

Домен: britannica.com

Registered: 1995 (30 years)

Введение: Vulcanization is a chemical process that improves the physical properties of natural or synthetic rubber, resulting in higher tensile strength, resistance to swelling and abrasion, and enhanced elasticity over a wider temperature range. The process involves heating rubber with sulfur, discovered by Charles Goodyear in 1839. Accelerators can be added to speed up vulcanization or lower the required …

3. WARE – Industrial & Commercial Boiler Solutions

Домен: wareinc.com

Зарегистрирован: 2000 (25 лет)

Введение: WARE is an industrial & commercial boiler rental and service company that specializes in sales, service, valve repair, rentals, parts, turn key and boiler training. Key offerings include:

– Boiler Rentals: Serving a wide range of purposes across applications and industries.

– Boiler Sales: Providing new, used, and remanufactured boiler equipment for over 70 years.

– Aux Equipment: Offering industr…

4. Walker Rubber – Custom Rubber Extrusions

Домен: walker-rubber.co.uk

Registered: 1999 (26 years)

Введение: Rubber Extrusions, Custom Rubber Extrusions, Angle Extrusion, Rubber Boat Window Seals, Brick Grabs, Cab Tyres, Rubber Cable Protection, Coloured Extrusions, Container Door Seal Extrusion, Conveyor Side Skirting, Rubber Door Seals, EPDM Extrusions, Rubber Expansion Seals, Rubber Façade Seal Extrusions, Flame Retardant Extrusions, Food Grade Extrusions, Rubber Gate Seals, Rubber Glazing Seals, H Pr…

Strategic Sourcing Conclusion and Outlook for rubber vulcanization

As the global rubber industry continues to evolve, the importance of strategic sourcing in rubber vulcanization cannot be overstated. B2B buyers must prioritize partnerships with suppliers who not only understand the nuances of vulcanization but also offer tailored solutions that enhance product performance. The ability to procure high-quality vulcanized rubber is essential for industries ranging from automotive to consumer goods, where durability and elasticity are paramount.

Investing in strategic sourcing enables companies to secure competitive pricing, ensure consistent quality, and leverage innovations in vulcanization processes. By aligning with suppliers who utilize advanced technologies and sustainable practices, businesses can enhance their product offerings while minimizing their environmental footprint.

Looking ahead, international buyers—particularly from Africa, South America, the Middle East, and Europe—should actively seek out suppliers that demonstrate flexibility and responsiveness to market demands. Engaging in strategic sourcing not only fosters long-term partnerships but also positions companies to capitalize on emerging trends in rubber applications. Take the next step in your sourcing strategy today—explore partnerships that drive innovation and sustainability in rubber vulcanization.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.

Illustrative image related to rubber vulcanization