Article Contents

Engineering Insight: Hard Suction Hose Fire

Technical Importance of Hard Suction Hoses in Fire Response for Dredging Operations

In the demanding environment of modern dredging operations, the integrity and reliability of suction hose systems are critical—not only for material transport but also for emergency response, particularly in fire suppression scenarios. Hard suction hoses play a vital role in both Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD), where rapid access to large volumes of water is essential for firefighting systems. These hoses are engineered to maintain structural rigidity under full vacuum conditions, enabling efficient water intake from surrounding bodies even in turbulent or debris-laden environments.

Fire incidents on dredgers—often arising from engine overheating, hydraulic leaks, or electrical faults—require immediate and high-volume water delivery. Hard suction hoses, typically deployed as part of emergency fire pump systems, ensure uninterrupted water supply by resisting collapse, kinking, and abrasion. Unlike flexible hoses, hard suction hoses incorporate helical steel wire reinforcement and a rigid yet slightly flexible rubber compound, allowing them to sustain negative pressure during pump priming and operation. This structural resilience is particularly crucial during emergency fire response, where milliseconds count and system failure is not an option.

East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted name in marine rubber solutions since 2007, specializes in the design and manufacture of high-performance hard suction hoses tailored for the dredging industry. With over 150 skilled engineers and technical personnel, our R&D team leverages advanced material science and finite element analysis to optimize hose performance under extreme operational loads. Our engineering capabilities ensure that every hose meets stringent international standards, including ISO 9001 certification, and is compatible with WEDA and CEDA best practices.

Our hard suction hoses are designed for rapid deployment, featuring smooth internal bores to minimize friction loss and high-tensile textile reinforcement layers for burst resistance. Coupled with robust end fittings and anti-static properties, these hoses provide a safe, reliable conduit for firefighting systems aboard TSHDs and CSDs operating in coastal, offshore, and inland waterways.

With a 0.68 million square meter manufacturing facility in Jiangsu, China, East Marine maintains full control over the production lifecycle—from raw material selection to final pressure testing—ensuring consistent quality and on-time delivery for global maritime clients.

Technical Specifications – Hard Suction Hose for Fire Application

| Parameter | Specification |

|---|---|

| Inside Diameter Range | 100 mm – 600 mm |

| Working Pressure (Max) | 15 bar (217 psi) |

| Vacuum Resistance | Full vacuum (760 mmHg) at 65°C |

| Диапазон температур | -30°C to +85°C |

| Cover Material | Abrasion-resistant, flame-retardant synthetic rubber |

| Арматура | Helical steel wire + high-tensile textile layers |

| End Fittings | Flanged or threaded, stainless steel or carbon steel with anti-corrosion coating |

| Standards Compliance | ISO 1436, EN 12115, MSHA, and client-specific marine norms |

Advanced Manufacturing Process

Precision Manufacturing and Vulcanization Excellence for Hard Suction Fire Hoses

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted WEDA/CEDA member, the manufacturing of hard suction fire hoses represents the pinnacle of engineered resilience for demanding firefighting and industrial applications. Our process integrates advanced material science with rigorous industrial protocols within our 0.68M sqm purpose-built facility. Central to achieving the structural integrity and operational safety required in high-pressure suction scenarios is our controlled vulcanization process. This critical phase transforms compounded rubber blends—formulated for abrasion resistance, vacuum stability, and flame retardancy—into a monolithic, cross-linked matrix. Utilizing state-of-the-art computer-monitored autoclaves across our 18 dedicated production lines, we precisely manage time, temperature (typically 140°C–165°C), and pressure profiles. This ensures uniform curing depth, optimal adhesion between rubber layers and high-tensile textile reinforcements, and eliminates porosity that could compromise hose integrity under full vacuum or sudden pressure surges.

Our manufacturing ecosystem leverages vertical integration capabilities established since 2007, enabling strict oversight from raw material inspection through final testing. Each hose undergoes multi-stage dimensional verification and reinforcement layer alignment checks before vulcanization. Post-cure, hoses enter our ISO 9001-certified quality assurance sequence, which includes mandatory hydrostatic burst testing at 2x working pressure, vacuum retention validation per EN 1146 standards, and rigorous examination of couplings for leak-proof integrity. This systematic adherence to international benchmarks guarantees that every hard suction fire hose meets or exceeds NFPA 1962 and ISO 1402 requirements for safety-critical operations. The scale of our Jiangsu facility allows for consistent batch uniformity while accommodating large project volumes without compromising on the meticulous process controls demanded by emergency response sectors.

The following table outlines key technical specifications validated through our production and quality control framework:

| Parameter | Value | Standard Compliance |

|---|---|---|

| Max. Working Pressure | 15 bar (217 psi) | EN 1146, NFPA 1962 |

| Vacuum Resistance | Full vacuum (760 mmHg) | ISO 1402 |

| Диапазон температур | -40°C to +85°C | ASTM D2000 |

| Cover Material | Oil-Resistant SBR/NR Blend | ISO 188, ISO 37 |

| Арматура | High-Tensile Polyester | ISO 2393 |

| Радиус изгиба | ≤ 6x Hose ID | EN 13766 |

| Сертификаты | ISO 9001, CE, MSHA | WEDA Technical Guidelines |

This commitment to vulcanization precision and end-to-end quality management ensures East Marine hard suction fire hoses deliver uncompromised performance in municipal, marine, and industrial firefighting deployments where failure is not an option. Our process is engineered for reliability you can measure in operational longevity and safety compliance.

Critical Applications

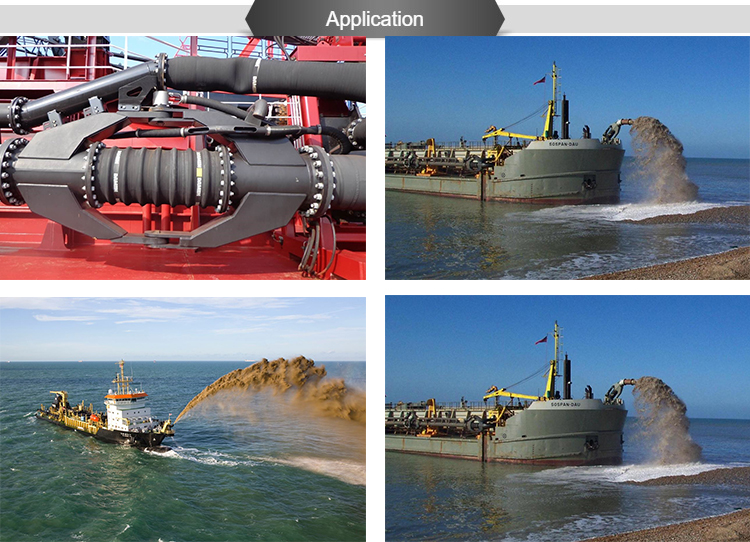

Global Applications of Hard Suction Hose in Fire and Dredging Operations

Hard suction hose, traditionally associated with firefighting, has evolved into a critical component in large-scale industrial and marine operations, particularly within the dredging, oil and gas, and land reclamation sectors. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a proud member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association), we engineer high-performance hard suction hoses designed to meet the rigorous demands of global infrastructure and emergency response projects.

In firefighting applications, hard suction hoses are essential for drafting water from open sources such as rivers, lakes, or reservoirs. These hoses are constructed to withstand full vacuum conditions without collapsing, ensuring a reliable water supply during emergency operations. However, their utility extends far beyond firefighting. In dredging projects, hard suction hoses serve as the primary conduit for transporting slurry—comprising sand, sediment, and water—from the seabed to disposal sites. Their robust construction, featuring helical steel wire reinforcement and abrasion-resistant rubber linings, allows for efficient and uninterrupted operation in high-wear environments.

Offshore and onshore oil fields also rely on hard suction hoses for fluid transfer during exploration and maintenance activities. These hoses are deployed in temporary pumping systems to manage drilling fluids, bilge water, and produced water. Their flexibility, combined with resistance to oil, UV exposure, and extreme temperatures, makes them ideal for remote and challenging environments. Additionally, in land reclamation projects—such as those seen in Southeast Asia and the Middle East—hard suction hoses are integral to the creation of new landmasses by transporting millions of cubic meters of dredged material from the ocean floor to designated reclamation zones.

East Marine’s hard suction hoses are engineered to international standards, supporting ISO9001-certified quality management systems. With a manufacturing footprint spanning 0.68 million square meters, we deliver hoses that meet stringent performance criteria for pressure, vacuum, and abrasion resistance. Our participation in CEDA and WEDA ensures alignment with global best practices and continuous innovation in dredging technology.

The versatility and durability of hard suction hoses make them indispensable across multiple sectors. As global demand for coastal protection, port expansion, and offshore energy grows, so does the need for reliable, high-capacity fluid transfer solutions. East Marine remains at the forefront of this evolution, providing engineered rubber products that support sustainable and efficient project execution worldwide.

| Technical Specification | Value |

|---|---|

| Internal Diameter Range | 100–600 mm |

| Working Pressure | Up to 15 bar |

| Vacuum Resistance | Full vacuum (0.098 MPa) |

| Диапазон температур | -30°C to +80°C |

| Cover Material | Abrasion-resistant, ozone- and UV-resistant synthetic rubber |

| Арматура | High-tensile textile plies with embedded helical steel wire |

| Standards Compliance | ISO 1307, ISO 4671, ISO 6134, MSHA, and CEDA guidelines |

Technical Data & Specs

Technical Specifications: Critical Parameters for Dredging Suction and Discharge Hose Performance

Within the demanding environment of hydraulic dredging operations, the selection of suction and discharge hoses transcends basic fluid transfer; it is a fundamental safety and operational efficiency decision. Misconceptions sometimes arise regarding “hard suction hose fire” applications; it is imperative to clarify that dredging hoses are engineered specifically for abrasive slurry transport under high vacuum and pressure conditions, distinct from firefighting equipment standards. East Marine, leveraging 17 years of specialized marine rubber expertise and adherence to WEDA/CEDA best practices, designs hoses rigorously tested for the unique challenges of dredging – including resistance to abrasion, vacuum collapse, and dynamic stress during deployment. Key technical parameters defining hose capability and longevity are Inner Diameter (ID), Working Pressure, Burst Pressure, and Bending Radius. These factors directly impact slurry flow velocity, system safety margins, resistance to kinking during articulation, and overall project uptime. Superior engineering in these areas minimizes catastrophic failure risks, reduces maintenance downtime, and ensures consistent productivity in critical dredging cycles.

Understanding the interplay of these specifications is vital. A larger ID increases flow capacity but demands higher pump power and affects maneuverability. Working Pressure must reliably exceed maximum operational system pressure, including surge spikes from slurry blockages or pump cycling. Crucially, the Burst Pressure ratio (Burst Pressure divided by Working Pressure) is a non-negotiable safety indicator; industry best practice mandates a minimum 4:1 ratio, though leading engineered solutions target 6:1 or higher for critical subsea applications. An excessively tight Bending Radius risks kinking and flow restriction, while an overly large radius hinders deployment in confined spaces or around vessel structures. East Marine’s engineering philosophy centers on optimizing all four parameters synergistically, utilizing advanced rubber compounding, high-tensile textile reinforcement, and precision vulcanization within our ISO9001-certified 0.68 million sqm facility. This integrated approach delivers hoses that maintain structural integrity under extreme vacuum during suction lift and withstand high-pressure discharge cycles without compromising flexibility.

The following table provides a comparative analysis of typical technical specifications for heavy-duty dredging suction and discharge hoses in the 8-inch to 24-inch ID range, reflecting East Marine’s engineered standards against common market offerings. Data represents standard configurations for dredging-specific hoses handling abrasive slurries.

| Inner Diameter (Inches) | Working Pressure (psi) | Burst Pressure (psi) | Minimum Bending Radius (x ID) |

|---|---|---|---|

| East Marine Standard Dredging Hose | |||

| 8 | 150 | 1200 | 8 |

| 12 | 120 | 960 | 8 |

| 16 | 100 | 800 | 8 |

| 20 | 80 | 640 | 8 |

| 24 | 70 | 560 | 8 |

| Typical Market Range (Competitors) | |||

| 8 | 120-150 | 480-750 | 10-12 |

| 12 | 100-120 | 400-600 | 10-12 |

| 16 | 80-100 | 320-500 | 10-12 |

| 20 | 60-80 | 240-400 | 10-12 |

| 24 | 50-70 | 200-350 | 10-12 |

East Marine consistently achieves an industry-leading 8:1 Burst Pressure to Working Pressure ratio across its standard dredging hose range, significantly exceeding the common market ratio of 4:1 to 6:1. This engineering margin provides critical safety against pressure surges inherent in slurry pumping, directly mitigating rupture risks. Furthermore, our hoses maintain a superior minimum bending radius of 8 times the ID, compared to the typical 10-12 times observed in competitor products. This enhanced flexibility facilitates easier handling, reduces stress during installation on dredgers or trailing suction hopper dredger (TSHD) ladder systems, and minimizes kink-induced flow disruption in complex operational layouts. These specifications are not theoretical; they are validated through rigorous in-house testing per ISO 1436 and project-proven in global dredging operations since our founding in 2007. Partnering with East Marine ensures access to technically superior hose solutions engineered for maximum safety, durability, and operational efficiency in the world’s most challenging marine environments.

Partner with East Marine

Conclusion: Trusted Performance in Demanding Fire and Dredging Applications

When it comes to hard suction hose systems used in fire suppression, emergency dewatering, or industrial dredging operations, reliability under extreme conditions is non-negotiable. At East Marine, a trusted subsidiary of Jiangsu Huashen Special Rubber Products, we engineer high-performance rubber hoses designed to meet the rigorous demands of fire response teams, marine contractors, and industrial operators worldwide. With over 15 years of specialized manufacturing experience since our founding in 2007, we have built a reputation for delivering robust, abrasion-resistant, and vacuum-rated suction hoses that perform consistently in the harshest environments.

Our hard suction hoses are constructed using premium synthetic rubber compounds and high-tensile reinforcement layers, ensuring resistance to kinking, collapse under full vacuum, and degradation from exposure to UV, ozone, and a wide range of fluids. Whether deployed in firefighting operations requiring rapid water intake from natural sources or in dredging projects demanding continuous slurry transfer, our hoses maintain structural integrity and flow efficiency. Every product is manufactured in our 0.68 million square meter facility in China—an ISO9001-certified production environment—and undergoes stringent quality control protocols to meet international standards, including those recognized by WEDA and CEDA members.

Beyond product excellence, East Marine is committed to providing comprehensive technical support and responsive customer service. We understand that downtime can be costly, which is why our engineering team works closely with clients to ensure optimal hose selection, configuration, and lifecycle performance. Our global footprint, including a dedicated branch in Singapore, enables faster logistics, localized support, and real-time communication for clients across Asia, the Middle East, Africa, and beyond.

For urgent inquiries, technical consultations, or custom hose solutions, our team is readily accessible. Connect with us via WhatsApp at +86-13806109365 for immediate assistance, or email us at hsdredging@eastmarine.tech to request product specifications, pricing, or engineering drawings. Our Singapore office ensures bilingual and time-zone-aligned support for regional clients, reinforcing our commitment to seamless international collaboration.

Partner with East Marine for hard suction hose solutions engineered for durability, backed by data-driven design, and supported by a global team that understands the urgency and precision your operations demand.

| Technical Specification | Value |

|---|---|

| Inner Diameter Range | 4″ to 16″ (100mm to 400mm) |

| Working Vacuum | Full vacuum (29.9 inHg / 101.3 kPa) |

| Диапазон температур | -30°C to +80°C |

| Cover Resistance | Abrasion, UV, Ozone, Weathering |

| Reinforcement Layer | High-tensile synthetic fabric + helix steel wire |

| Standards Compliance | Meets or exceeds NFPA 1962, EN 1768 |

| Color Options | Black, Red, Orange (custom on request) |

| Minimum Bend Radius (10″ hose) | 24″ (610mm) |

| Certification | ISO9001, WEDA/CEDA Industry Member |

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.