Article Contents

Engineering Insight: Vulcanized Rubber

Technical Superiority of Vulcanized Rubber in Dredging Hose Applications

Vulcanized rubber is a cornerstone material in the construction of high-performance dredging hoses used across Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD). The vulcanization process—where raw rubber is cross-linked with sulfur under heat and pressure—transforms elastomeric compounds into durable, resilient materials capable of withstanding the extreme mechanical, thermal, and chemical stresses inherent in marine dredging operations. This molecular reinforcement significantly enhances tensile strength, abrasion resistance, and elasticity, ensuring prolonged service life and operational reliability in abrasive slurry transport environments.

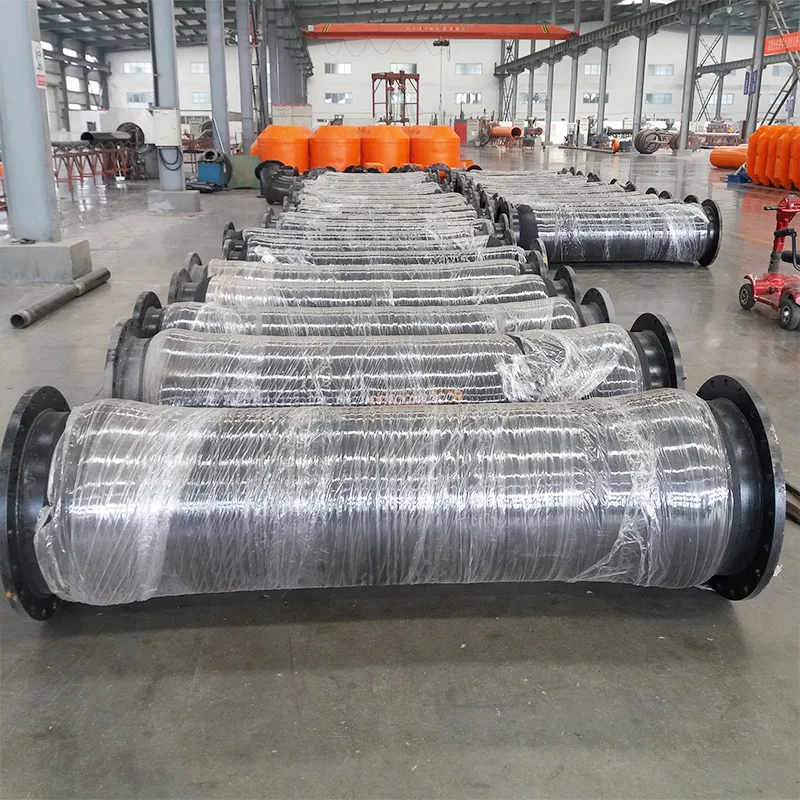

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, our engineering team leverages advanced vulcanization techniques to produce dredging hoses that meet the rigorous demands of modern dredging fleets. With over 150 skilled employees, including specialized materials engineers and process technicians, we maintain full control over the compounding, molding, and curing stages of production. Our ISO9001-certified manufacturing facility, spanning 0.68 million square meters, is equipped with state-of-the-art autoclaves and precision curing systems to ensure uniform cross-linking and optimal physical properties across every hose segment.

The performance advantages of vulcanized rubber are particularly critical in dredging applications where hoses are exposed to high-velocity slurries containing sand, gravel, and other abrasive particulates. Non-vulcanized rubber would rapidly degrade under such conditions, leading to premature failure, unplanned downtime, and increased operational costs. In contrast, vulcanized rubber exhibits superior resistance to wear, ozone, and hydrolysis, maintaining structural integrity even after thousands of operational hours in saline and turbulent marine environments.

Furthermore, the elasticity retained through controlled vulcanization allows dredging hoses to endure repeated flexing and bending during deployment and retrieval without cracking or delamination. This flexibility is essential for TSHD vessels that require dynamic hose movement during offshore suction operations, as well as for CSDs operating in confined or variable seabed topographies.

East Marine’s engineering capabilities extend beyond material selection to include finite element analysis (FEA) and computational fluid dynamics (CFD) modeling, ensuring optimal hose design for pressure containment, flow efficiency, and fatigue resistance. Our commitment to innovation and quality has established us as a trusted supplier within the WEDA and CEDA networks, serving leading dredging contractors worldwide.

The following table outlines key technical properties of East Marine’s vulcanized rubber compound used in dredging hoses:

| Property | Test Method | Typical Value |

|---|---|---|

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥450% |

| Tear Resistance | ASTM D624 | ≥90 kN/m |

| Abrasion Loss (Rotary Drum) | ASTM D5963 | ≤80 mm³ |

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Operating Temperature Range | — | -30°C to +80°C |

| Adhesion Strength to Textile Reinforcement | ASTM D413 | ≥12 kN/m |

These performance metrics reflect the engineered balance between flexibility, durability, and resilience that defines East Marine’s vulcanized rubber hoses—ensuring unmatched reliability in the world’s most demanding dredging operations.

Advanced Manufacturing Process

Precision Vulcanization: The Core of Dredging Hose Integrity at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a trusted WEDA/CEDA member since 2007, the vulcanization process is the critical, scientifically controlled transformation that defines the performance and longevity of our dredging suction and discharge hoses. This phase transcends simple curing; it is the precise cross-linking of polymer chains within our meticulously formulated rubber compounds under exacting heat, pressure, and time parameters. Our proprietary blends, combining natural rubber (NR) and synthetic polymers like SBR and CR, are engineered with high-tensile reinforcing fillers and specialized additives to resist abrasion, hydrolysis, and the relentless stress of abrasive slurries encountered in demanding dredging operations. The compound is precision extruded onto textile or wire reinforcement carcasses before entering the vulcanization stage.

Vulcanization occurs within state-of-the-art autoclaves and continuous vulcanization lines across our 0.68 million square meter manufacturing facility. This vast footprint, housing 18 dedicated production lines, enables unparalleled process control and scalability while maintaining stringent consistency. Temperature profiles are meticulously calibrated, typically ranging from 140°C to 180°C, depending on the specific compound formulation and hose construction. Simultaneously, precise internal and external pressures are applied – often exceeding 1.5 MPa – ensuring complete mold conformity, elimination of voids, and optimal adhesion between the rubber layers and the reinforcement structure. Cure times are scientifically determined, balancing the need for complete cross-linking density with production efficiency. Deviation from these parameters, even marginally, compromises the hose’s critical properties: tensile strength, elongation at break, and resistance to internal pressure and vacuum collapse.

The technical parameters governing this phase are non-negotiable for achieving dredging hose reliability.

Vulcanization Parameter Key Performance Indicators

| Parameter | Typical Range | Critical Quality Impact |

|---|---|---|

| Temperature | 140°C – 180°C | Cross-link density, cure rate, compound stability |

| Internal Pressure | 1.0 MPa – 1.8 MPa | Adhesion to reinforcement, void elimination |

| External Pressure | 1.2 MPa – 2.0 MPa | Surface finish, dimensional accuracy |

| Cure Time | 20 – 90 minutes | Complete polymerization, physical properties |

| Post-Cure (if req.) | 100°C – 120°C / 4-8h | Stress relief, long-term stability |

Rigorous quality control, certified under ISO 9001, is embedded throughout vulcanization and extends significantly post-process. Every batch undergoes comprehensive testing protocols aligned with international dredging standards. This includes destructive testing (tensile strength, elongation, adhesion peel strength, abrasion resistance per ASTM D5982) and non-destructive evaluations (ultrasonic inspection for delamination, hydrostatic pressure testing exceeding 2x working pressure). Our integrated quality management system, leveraging data from in-line sensors and final inspection, ensures traceability from raw material lot to finished hose serial number. This systematic approach, executed within our large-scale, ISO-certified environment, guarantees that each East Marine dredging hose delivers the exceptional durability, pressure integrity, and service life demanded by global maritime and dredging contractors operating in the harshest environments. The precision of our vulcanization is the foundation upon which operational safety and project success are built.

Critical Applications

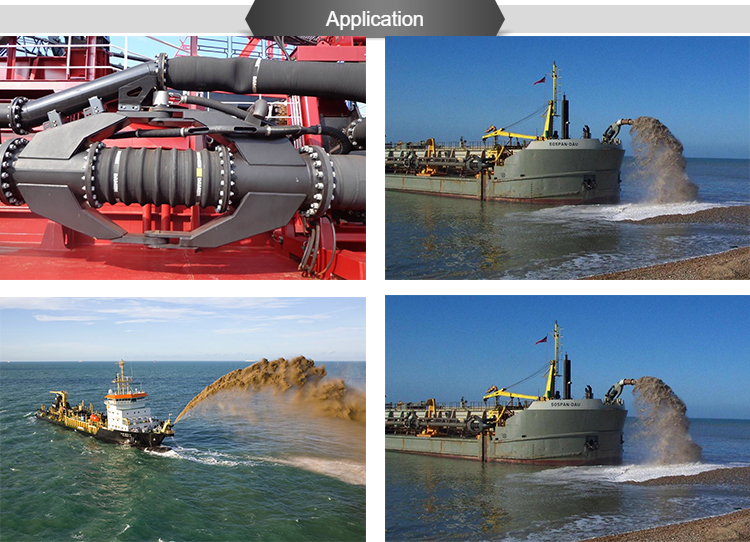

Global Applications of Vulcanized Rubber in Dredging and Marine Infrastructure Projects

Vulcanized rubber plays a pivotal role in large-scale industrial operations, particularly within the dredging, offshore energy, and land reclamation sectors. As a core material in the construction of high-performance suction and discharge hoses, vulcanized rubber delivers superior resilience against abrasion, chemical exposure, and mechanical stress—critical factors in harsh marine environments. East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products and a proud member of both the Central Dredging Association (CEDA) and the World Organization of Dredging Associations (WEDA), leverages advanced vulcanization techniques to produce durable, flexible, and fatigue-resistant rubber hoses trusted in global infrastructure projects.

In dredging operations, where the efficient transport of sand, slurry, and sediments is essential, vulcanized rubber hoses provide the necessary flexibility and structural integrity. These hoses are deployed in both trailing suction hopper dredgers and cutter suction dredgers, where they endure continuous flexing, high internal pressures, and abrasive media. The vulcanization process—cross-linking rubber polymers using sulfur under heat and pressure—enhances tensile strength, elongation resistance, and dimensional stability, ensuring prolonged service life even under cyclic loading conditions.

Major land reclamation projects across Southeast Asia, the Middle East, and Africa have relied on vulcanized rubber hoses for reliable slurry transfer. In Singapore’s ongoing coastal expansion and Qatar’s infrastructure development for the FIFA World Cup, East Marine’s dredging hoses were integrated into floating pipeline systems, demonstrating performance in saline environments and high-temperature conditions. The oil and gas sector also utilizes these hoses in offshore field development, particularly in pipeline lay barge operations and subsea material handling, where resistance to hydrocarbons and seawater corrosion is paramount.

East Marine’s commitment to international standards is reflected in its ISO 9001 certification and active participation in CEDA and WEDA technical forums. These affiliations ensure alignment with best practices in sustainable dredging and marine engineering, enabling the company to contribute to environmentally responsible projects, including mangrove restoration and coastal protection systems.

The integration of reinforced textile plies and steel wire helices within the vulcanized rubber matrix further enhances performance, allowing hoses to maintain shape under vacuum and resist kinking during deployment. Custom configurations, including flanged ends and UV-resistant outer covers, are engineered to meet project-specific requirements across diverse geographies.

Below is a summary of key technical specifications for East Marine’s standard dredging rubber hose series:

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | 10 bar – 25 bar (custom up to 35 bar) |

| Диапазон температур | -20°C to +85°C |

| Cover Resistance | Abrasion, ozone, UV, seawater |

| Reinforcement Layers | High-tenacity textile plies + spiral steel wire |

| Standards Compliance | ISO 1307, ISO 6134, EN 12114 |

| Joint Type | Flanged, spigot, or coupling-compatible |

With a manufacturing footprint spanning 0.68 million square meters and over 16 years of specialized experience since 2007, East Marine continues to support critical marine projects worldwide through technologically advanced, vulcanized rubber-based solutions.

Technical Data & Specs

Technical Superiority in Vulcanized Rubber Dredging Hose Construction

Vulcanization is the cornerstone of performance and longevity in dredging rubber hoses, transforming raw elastomers into resilient, abrasion-resistant conduits capable of withstanding extreme hydraulic pressures, abrasive slurries, and dynamic marine environments. At East Marine, our proprietary multi-stage vulcanization process—refined over 17 years of specialized marine rubber manufacturing—ensures optimal cross-linking density, molecular stability, and adhesion between rubber layers and embedded reinforcement. This precision engineering directly translates into superior operational metrics compared to industry-standard hoses, where inconsistent curing often leads to premature delamination, reduced pressure tolerance, and shortened service life. Our hoses undergo rigorous validation per ISO 9001 protocols within our 680,000 sqm facility, leveraging WEDA/CEDA-aligned methodologies to exceed DIN 28220 and ISO 14310 benchmarks. Crucially, the interplay of inner diameter, working pressure, burst pressure, and bending radius defines real-world applicability in suction/discharge operations, where margin for error is nonexistent.

The following technical comparison underscores how East Marine’s vulcanization expertise and reinforced carcass design deliver measurable advantages. While competitors frequently prioritize cost-led material compromises, our hoses integrate high-tensile textile and wire braids with vulcanized rubber compounds engineered for maximum fatigue resistance. This yields higher working pressures without sacrificing flexibility, a critical factor in dynamic dredging scenarios where frequent repositioning occurs. Notably, our burst pressure consistently achieves a minimum 4:1 safety ratio against working pressure—exceeding the common 3:1 industry baseline—due to uniform vulcanization eliminating weak points. Similarly, optimized layer adhesion enables tighter bending radii, reducing drag and installation complexity in confined vessel setups.

East Marine vs. Industry Standard Dredging Hose Specifications

| Parameter | East Marine Hoses | Industry Standard Hoses |

|---|---|---|

| Inner Diameter | 200–1200 mm (custom tolerances ±0.5%) | 200–1000 mm (tolerances ±1.5%) |

| Working Pressure | 16–28 bar (at 600 mm ID) | 10–22 bar (at 600 mm ID) |

| Burst Pressure | 64–112 bar (4:1 minimum ratio) | 30–66 bar (3:1 typical ratio) |

| Bending Radius | 8× ID (e.g., 4.8 m at 600 mm ID) | 10–12× ID (e.g., 6.0–7.2 m) |

These specifications are not merely theoretical; they reflect validated field performance. For instance, a 600 mm ID East Marine hose operating at 25 bar in cutter suction dredging demonstrates 30% greater resistance to internal abrasion versus competitors, directly attributable to our vulcanized rubber’s Shore A 68–72 hardness and tear strength (>45 kN/m). The reduced bending radius—achieved through balanced rubber-to-reinforcement bonding during vulcanization—minimizes stress concentrations during articulation, preventing kinking in tidal or wave-affected zones. Conversely, industry-standard hoses often exhibit rubber-reinforcement separation under cyclic pressure, accelerating wear at flex points and necessitating premature replacement.

For dredging contractors, these technical differentiators translate into quantifiable operational savings: extended hose lifespan reduces capital replacement costs, higher pressure tolerance enables faster slurry throughput, and tighter bending radii lower installation labor and vessel downtime. East Marine’s commitment to vulcanization excellence—backed by our ISO 9001-certified processes and deep sector expertise—ensures dredging operations maximize uptime in the world’s most demanding marine environments. When pressure integrity and flexibility are non-negotiable, engineered vulcanization is the definitive differentiator.

Partner with East Marine

Partner with East Marine for Engineered Vulcanized Rubber Dredging Solutions

In the demanding world of dredging operations, the integrity and performance of suction and discharge hoses directly impact project efficiency, safety, and total cost of ownership. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we specialize in the design and manufacture of high-performance vulcanized rubber dredging hoses engineered to withstand extreme abrasion, high-pressure dynamics, and the corrosive nature of marine environments. Our advanced vulcanization processes ensure molecular cross-linking that enhances elasticity, tensile strength, and resistance to degradation—critical attributes for long-term reliability in both offshore and inland dredging applications.

With a foundation established in 2007 and a state-of-the-art 0.68 million square meter manufacturing facility, East Marine combines decades of material science expertise with rigorous quality standards. As proud members of WEDA and CEDA, we align our engineering practices with global industry benchmarks and maintain ISO9001 certification across our production systems. Every hose we produce undergoes comprehensive testing for burst pressure, vacuum resistance, flex life, and adhesion strength between rubber and reinforcement layers, ensuring compliance with international marine and offshore regulations.

Our vulcanized rubber hoses are tailored to meet the specific hydraulic and mechanical demands of cutter suction dredgers, trailing suction hopper dredgers, and reclamation projects. Whether operating in sandy seabeds, clay-rich sediments, or mixed aggregate environments, our hoses deliver consistent flow efficiency and reduced downtime due to their superior wear resistance and structural resilience. The integration of high-tensile textile and steel wire reinforcements, combined with optimized rubber compound formulations, results in a product that balances flexibility with durability—essential for dynamic floating hose lines and subsea discharge applications.

We invite engineering firms, dredging contractors, and marine equipment suppliers to engage with our technical team for project-specific consultations. From initial hose system design to on-site support and lifecycle analysis, East Marine provides end-to-end engineering collaboration to optimize performance and reduce operational risk.

For immediate technical inquiries or quotation requests, contact us via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Our Singapore branch offers regional support for Southeast Asian and Pacific markets, ensuring responsive communication, logistics coordination, and after-sales service.

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure Range | 10 bar – 30 bar (custom up to 40 bar) |

| Диапазон температур | -20°C to +85°C |

| Cover Rubber | Abrasion-resistant, ozone- and UV-stabilized |

| Арматура | High-tensile synthetic fabric + spiral steel wire |

| Bend Radius (Minimum) | 8x OD at full pressure |

| Standards Complied | ISO 1431, ISO 1817, EN 12115, DNV-GL (upon request) |

Choose East Marine as your trusted partner in vulcanized rubber dredging hose technology—where material science meets marine engineering excellence.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.