Article Contents

Engineering Insight: How Is Rubber Vulcanized

The Critical Role of Precision Vulcanization in Dredging Hose Performance

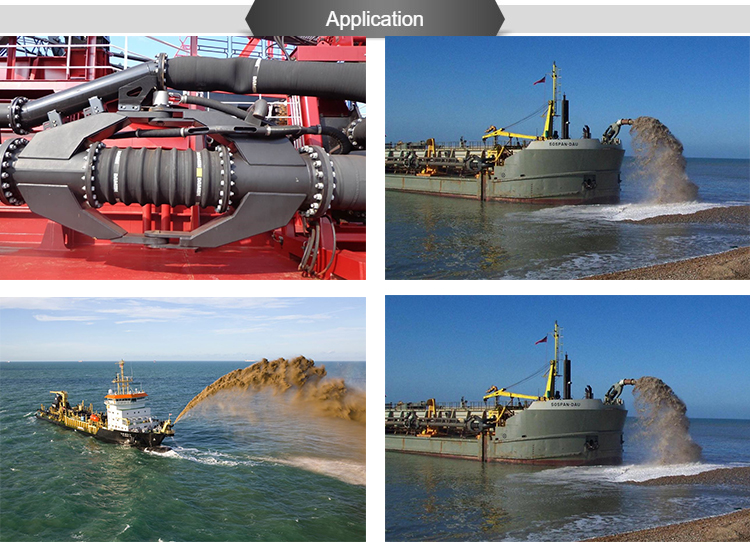

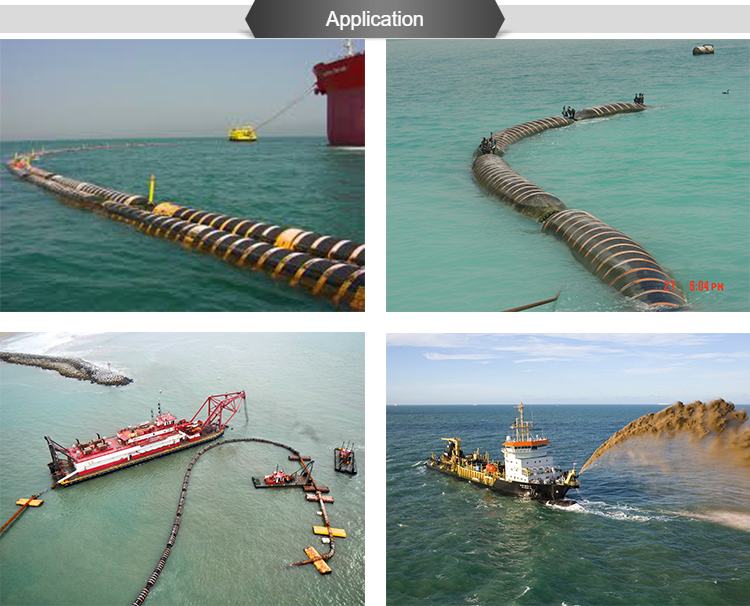

Rubber vulcanization is the indispensable chemical transformation that converts raw, thermoplastic elastomers into the high-performance, durable materials essential for dredging operations. For Trailing Suction Hopper Dredgers (TSHDs) and Cutter Suction Dredgers (CSDs), which endure extreme abrasion from sand-laden slurries, constant flexing, and prolonged seawater exposure, the vulcanization process is not merely a step but the foundation of hose integrity and operational longevity. This cross-linking reaction, primarily using sulfur or peroxides under controlled heat and pressure, creates a robust three-dimensional polymer network. This network fundamentally enhances the rubber compound’s tensile strength, tear resistance, and resilience while critically improving its resistance to abrasion, ozone degradation, and the swelling effects of seawater and hydraulic fluids. In dredging applications, where hose failure results in costly vessel downtime and environmental risks, suboptimal vulcanization—characterized by under-cure (reduced strength, tackiness) or over-cure (hardening, loss of flexibility)—directly compromises the hose’s ability to withstand the relentless mechanical and chemical stresses inherent in moving millions of cubic meters of material.

Achieving the precise vulcanization profile required for dredging hoses demands sophisticated engineering control over time, temperature, and pressure throughout the curing cycle. Variations as small as 5°C or 2 minutes can significantly alter the cross-link density, impacting critical performance metrics. East Marine leverages its deep materials science expertise and substantial engineering resources, supported by over 150 dedicated employees including specialized rubber compounders and process engineers, to master this complexity. Our ISO9001-certified manufacturing processes, operating within our 0.68 million square meter facility, ensure rigorous adherence to exacting vulcanization parameters tailored to each specific dredging application and hose construction. This precision engineering translates directly into hoses that maintain structural integrity under high vacuum during suction, resist catastrophic abrasion in discharge lines, and flex reliably at the critical bend points of floating hoses, even in the harshest marine environments. Our membership in WEDA and CEDA underscores our commitment to industry best practices and continuous technical advancement in marine dredging solutions.

The following table outlines key vulcanization parameters and their direct impact on critical performance characteristics for dredging hoses:

Vulcanization Parameter Range Performance Impact

150°C – 170°C Optimal cross-link density; below range risks under-cure (poor abrasion resistance), above range risks over-cure (reduced flexibility, increased hardness)

20 – 45 minutes Ensures complete reaction; insufficient time reduces tensile strength, excessive time degrades elastomer properties

10 – 15 bar Prevents porosity, ensures uniform density and adhesion between rubber layers and reinforcement

Precise Control Maintains consistent Shore A hardness (60-75), critical for abrasion resistance vs. flexibility balance in dredging service

East Marine’s engineering capability, honed since our founding in 2007, focuses on developing and executing vulcanization profiles that maximize service life in demanding TSHD and CSD operations. We do not apply generic curing cycles; instead, our technical team develops compound-specific vulcanization schedules validated through extensive in-house testing, ensuring every floating hose, suction line, and discharge pipeline meets the uncompromising reliability standards required by the global dredging industry. This commitment to precision vulcanization engineering is central to delivering products that minimize operational risk and maximize asset uptime.

Advanced Manufacturing Process

Vulcanization Process in the Manufacturing of Dredging Rubber Hoses at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the production of high-performance dredging rubber hoses is rooted in precision engineering and advanced rubber processing technologies. Central to this manufacturing excellence is the vulcanization process—a critical chemical transformation that enhances the mechanical properties, durability, and operational resilience of rubber compounds used in suction and discharge applications.

Vulcanization involves the cross-linking of polymer chains in raw rubber through the application of heat, pressure, and sulfur or peroxide-based curing systems. This process fundamentally alters the elastomeric structure, converting soft, tacky rubber into a robust, elastic material capable of withstanding the abrasive, high-pressure, and dynamic marine environments typical in dredging operations. At our 0.68 million square meter state-of-the-art facility, this transformation occurs across 18 dedicated production lines, each optimized for specific hose configurations and performance requirements.

The process begins with the precise mixing of natural and synthetic rubber compounds, reinforcing fillers, antioxidants, and curing agents. The uncured hose blanks—comprising inner tubes, reinforcement layers (textile or wire braiding), and outer covers—are then assembled and placed into mold presses or autoclaves. During vulcanization, temperatures typically range between 140°C and 180°C, with curing times adjusted based on hose thickness and compound formulation. Pressures of up to 1.5 MPa ensure complete mold replication and eliminate voids or delamination risks.

Critical to maintaining consistency and performance integrity, East Marine implements stringent quality control protocols aligned with ISO 9001 standards. Each vulcanized hose undergoes post-cure inspection, including dimensional verification, hardness testing, and visual defect analysis. Advanced testing equipment monitors cross-link density and tensile strength to confirm that the vulcanization process has achieved optimal network formation.

Our membership in industry-leading organizations such as WEDA and CEDA underscores our commitment to technical innovation and adherence to global dredging standards. By integrating automated process controls, real-time monitoring, and decades of compound expertise, East Marine ensures every hose meets the demanding requirements of offshore, riverine, and land reclamation projects.

The result is a product line of dredging hoses with superior abrasion resistance, flexibility, and service life—engineered not just to perform, but to outlast in the harshest conditions.

| Technical Parameter | Value/Range |

|---|---|

| Factory Size | 0.68 million sqm |

| Production Lines | 18 |

| Vulcanization Temperature Range | 140°C – 180°C |

| Curing Pressure | Up to 1.5 MPa |

| Standard Compliance | ISO 9001 |

| Typical Cure Time | 30–90 minutes (varies by size) |

| Post-Cure Testing | Hardness, Tensile, Dimensional |

Critical Applications

Vulcanization: The Critical Process Enabling Global Dredging, Energy, and Reclamation Operations

Rubber vulcanization is not merely a manufacturing step; it is the foundational chemical transformation that dictates the operational lifespan and reliability of critical marine infrastructure, particularly in demanding dredging, offshore energy, and land reclamation projects. At East Marine, leveraging our Jiangsu Huashen Special Rubber heritage and 0.68 million square meter manufacturing facility, we apply precision vulcanization to engineer hoses capable of withstanding the brutal synergy of abrasive slurries, extreme pressures, corrosive seawater, and dynamic marine environments. This process cross-links polymer chains with sulfur and accelerators under controlled heat and pressure, converting raw, weak rubber into a resilient, elastic, and durable material essential for mission-critical applications worldwide.

In large-scale dredging operations, such as maintaining navigable channels in Rotterdam or executing massive sand extraction for Singapore’s land reclamation, vulcanized rubber hoses form the indispensable lifeline. The precise control of vulcanization parameters ensures the hose cover and tube exhibit exceptional abrasion resistance against sand and gravel slurries, while maintaining flexibility to handle constant articulation on trailing suction hopper dredgers (TSHDs). Similarly, in offshore oil and gas fields across the North Sea and Gulf of Mexico, our vulcanized floating discharge hoses reliably transport dense, abrasive cuttings and drilling fluids under high pressure, where failure would cause catastrophic environmental and operational downtime. The cross-linked network created during vulcanization provides the necessary tensile strength, fatigue resistance, and impermeability to hydrocarbons and seawater crucial for these energy sector applications. For land reclamation projects, like those expanding coastal cities in the UAE, vulcanized hoses endure prolonged exposure to UV radiation, fluctuating temperatures, and continuous high-volume slurry flow, where inferior vulcanization would lead to premature cracking, swelling, or delamination.

Our commitment to vulcanization excellence is underpinned by rigorous adherence to international standards, including ISO 9001 quality management, and active participation in industry forums as a member of both CEDA (Central Dredging Association) and WEDA (Western Dredging Association). This membership ensures our vulcanization protocols align with the evolving technical demands and safety benchmarks defined by global dredging experts. The specific control of time, temperature, and pressure during the vulcanization cycle directly determines the final product’s performance envelope.

Key vulcanization parameters and their direct impact on dredging hose performance are summarized below:

| Parameter | Typical Range for Dredging Hoses | Critical Performance Impact |

|---|---|---|

| Vulcanization Temperature | 150°C – 170°C | Optimizes cross-link density; too low causes incomplete cure (weakness), too high causes reversion (loss of properties) |

| Internal Pressure During Cure | 1.0 – 1.8 MPa | Ensures complete material flow, eliminates voids, achieves dimensional stability under service pressure |

| Curing Time | 30 – 90 minutes (depending on wall thickness) | Balances full cross-linking development against production efficiency; insufficient time reduces abrasion resistance |

| Post-Cure Treatment | 100°C – 120°C for 2-8 hours | Stabilizes physical properties, reduces compression set, enhances long-term heat aging resistance |

East Marine’s engineering expertise, honed since 2007, focuses on optimizing these parameters for each specific project’s slurry composition, depth, and operational profile. This precision vulcanization is the invisible guarantee that our dredging hoses perform reliably in the world’s most challenging marine environments, safeguarding project timelines, budgets, and environmental integrity. The integrity of global maritime infrastructure literally depends on the science mastered within the vulcanization press.

Technical Data & Specs

Technical Specifications: Comparative Analysis of Dredging Rubber Hoses – East Marine vs. Industry Competitors

Vulcanization is a critical chemical process in the manufacturing of high-performance rubber hoses used in dredging operations. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we utilize advanced sulfur-based vulcanization techniques to cross-link rubber polymer chains, enhancing tensile strength, elasticity, and resistance to abrasion, heat, and dynamic stress. This process ensures our dredging hoses maintain structural integrity under extreme operational conditions, including high-pressure slurry transport and continuous flexing in marine environments. As a member of WEDA and CEDA, and operating from our 0.68 million square meter manufacturing facility certified under ISO9001, we uphold rigorous quality standards in every hose produced since our founding in 2007.

Dredging operations demand reliable suction and discharge hoses capable of withstanding abrasive slurries, fluctuating pressures, and complex marine conditions. The performance of these hoses is determined by key technical parameters: inner diameter, working pressure, burst pressure, and minimum bending radius. These factors directly influence flow efficiency, safety margins, and ease of deployment in offshore and riverine projects. East Marine’s engineered rubber hoses are designed to exceed industry benchmarks in all these areas, offering superior durability and operational safety compared to standard competitor products.

Our proprietary rubber compound, optimized through precise vulcanization control, delivers enhanced resilience and fatigue resistance. This allows for thinner yet stronger tube and cover layers, contributing to a tighter bending radius without compromising pressure ratings. Additionally, the reinforcement layers—constructed with high-tensile braided or spiral-wound textiles and steel wire—are bonded more effectively to the inner tube due to improved adhesion from the vulcanization process. This integration ensures uniform stress distribution and prevents delamination under cyclic loading.

The following table presents a comparative analysis of standard dredging rubber hoses in the 300 mm to 600 mm inner diameter range, reflecting typical configurations used in large-scale hydraulic dredging applications. Data is based on published specifications from East Marine and aggregated values from leading European and Asian competitors.

| Inner Diameter (mm) | Parameter | Ист Марин | Competitor Average |

|---|---|---|---|

| 300 | Working Pressure (bar) | 16 | 12 |

| Burst Pressure (bar) | 48 | 36 | |

| Bending Radius (mm) | 1,200 | 1,500 | |

| 400 | Working Pressure (bar) | 15 | 11 |

| Burst Pressure (bar) | 45 | 33 | |

| Bending Radius (mm) | 1,600 | 2,000 | |

| 500 | Working Pressure (bar) | 14 | 10 |

| Burst Pressure (bar) | 42 | 30 | |

| Bending Radius (mm) | 2,000 | 2,500 | |

| 600 | Working Pressure (bar) | 13 | 9 |

| Burst Pressure (bar) | 39 | 27 | |

| Bending Radius (mm) | 2,400 | 3,000 |

East Marine’s superior performance metrics stem from our vertically integrated production process, advanced vulcanization technology, and stringent quality control. The tighter bending radii improve maneuverability in confined dredging zones, while higher burst pressure ratios provide greater safety margins. These technical advantages translate into reduced downtime, lower total cost of ownership, and increased operational efficiency for dredging contractors worldwide.

Partner with East Marine

Conclusion: Vulcanization as the Cornerstone of Dredging Hose Reliability

Understanding the precise science and rigorous execution of rubber vulcanization is not merely an academic exercise; it is fundamental to the operational integrity and longevity of dredging suction and discharge hoses operating under extreme marine conditions. At East Marine, we recognize that the transition from raw elastomer compound to a high-performance dredging hose hinges on mastering this critical thermal-chemical process. Our decades of specialized experience, rooted in the advanced manufacturing capabilities of our 0.68 million square meter facility, allow us to exert unparalleled control over vulcanization parameters. This control directly translates into hoses exhibiting superior resistance to abrasion from abrasive slurries, consistent flexibility across diverse temperature ranges, exceptional pressure retention, and resilience against the constant hydrolytic and oxidative stresses inherent in dredging operations. The vulcanization process we deploy is meticulously engineered, moving far beyond simple sulfur curing to incorporate sophisticated accelerator systems and precise temperature profiling, ensuring optimal cross-link density and network stability throughout the hose structure. This results in a final product where the rubber compound achieves its designed mechanical properties – properties that are non-negotiable for minimizing downtime and maximizing the return on investment for demanding dredging projects worldwide.

The table below exemplifies how East Marine’s controlled vulcanization process consistently delivers compound properties exceeding standard industry benchmarks for dredging applications:

| Property | East Marine Standard (Vulcanized Hose Tube) | Typical Industry Requirement | Test Method |

|---|---|---|---|

| Tensile Strength (MPa) | ≥ 22.0 | ≥ 18.0 | ISO 37 Type 2 |

| Elongation at Break (%) | ≥ 550 | ≥ 450 | ISO 37 Type 2 |

| Abrasion Loss (mm³) | ≤ 85 | ≤ 120 | ISO 4649 A |

| Hardness (Shore A) | 60 ± 5 | 55 – 65 | ISO 48 |

| Ozone Resistance (20pphm, 40°C, 20% strain) | No Cracks (≥ 100 hrs) | Cracks evident (< 50 hrs) | ISO 1431-1 |

Partnering with East Marine means leveraging vulcanization expertise honed over 17 years as a trusted WEDA and CEDA member, operating under stringent ISO 9001 quality management. Our commitment extends beyond manufacturing; we provide comprehensive engineering consultation to ensure the hose specification, including the critical vulcanization profile, is perfectly aligned with your specific dredging environment, material composition, and project lifecycle requirements. Whether your operation is in the South China Sea, the North Sea, or the estuaries of South America, our global support infrastructure, including our strategic Singapore branch, ensures responsive technical partnership and supply chain continuity. Do not compromise on the foundational process that dictates hose performance and lifespan. Contact East Marine today to discuss how our advanced vulcanization technology and dredging hose solutions can enhance the efficiency and reliability of your next project. Initiate a technical consultation via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech. Let our engineering team demonstrate why precision vulcanization is the hallmark of East Marine hoses trusted by leading dredging contractors globally.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.