Описание

Armored Discharge Rubber Hose with Steel Flange

The armored discharge hose is widely used in dredging projects, port construction, and water conservancy works. It is mainly installed on dredger discharge pipelines or mounted on the ladder structure of cutter suction dredgers.

This armored hose is reinforced with internal wear-resistant steel rings and is specially engineered for harsh working conditions. It can handle sharp and abrasive materials—such as coral reef and weathered rock—that conventional dredging hoses cannot withstand over long periods. It is particularly suitable for conveying solid particles with angular shapes, high hardness, and large particle sizes.

Both ends are equipped with heavy-duty steel flanges, ensuring easy installation, quick replacement, and secure connection.

With excellent bending flexibility and strong pressure-bearing capacity, the armored discharge hose maintains reliable performance under complex conditions and continuous heavy loads, delivering stable conveying efficiency even in harsh environments.

Specifications:

| Descriptions | Details |

| Название продукта | Armored discharge Rubber Hose with Steel Flange |

| Origin | China |

| Inner Diameter(ID) | 100-1100mm |

| Length | 1000-11800mm |

| Working Pressure(WP) | 0.5-4.2Mpa |

| Burst Pressure(BP) | 1.5-12.6Mpa |

| Flange Type | Steel Flange |

| Application |

For CSD/TSHD dredger transport the hard and highly abrasivematerial. |

Key Benefits and Features:

- Equipped with internal wear-resistant steel rings, specially designed for harsh working conditions. Capable of long-term conveying of sharp and hard materials such as coral reef and weathered rock.

- High pressure-bearing capability, suitable for continuous heavy-load operations.

- Excellent bending flexibility, allowing the hose to adapt to complex pipeline layouts and deformation requirements.

- Steel flanges at both ends, ensuring easy installation and quick replacement.

- Widely used in dredging projects, port construction, and water conservancy works.

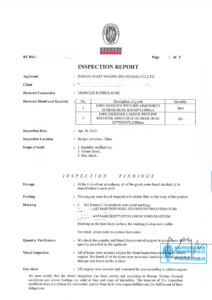

Discharge Rubber Hose Inspection:

To ensure each discharge rubber hose meets the required performance and safety standards, a series of strict inspections and tests are carried out throughout the production process:

-

Raw Material Test: Each batch of raw materials, including natural rubber, tensile textile, and rubber additives, is carefully inspected before entering the warehouse to ensure quality consistency and durability.

-

Hose Dimension Check: The hose’s inner and outer diameters, wall thickness, and flange alignment are measured to confirm they meet design specifications.

-

Weight Check: Each hose is weighed to verify it falls within the acceptable tolerance range, ensuring uniform product quality.

-

Working Pressure Test (if specified): The hose is subjected to pressure testing to confirm its ability to safely withstand the specified working pressure without leakage or deformation.

-

Bending Test (if specified): The hose is tested for flexibility and bending resistance to ensure reliable performance under working conditions.

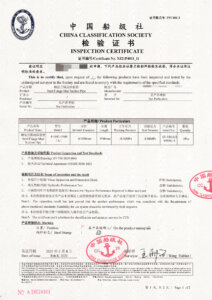

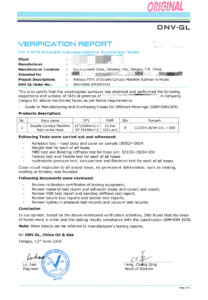

For additional assurance, we can invite third-party inspection agencies to conduct inspections according to customer requirements.

Discharge Rubber Hose Packaging Information:

To ensure the safety of transporting discharge rubber hoses and maximize loading efficiency, we adopt different packaging methods according to the order quantity:

-

Bulk cargo: Delivered in loose packing to the port and then consolidated into containers.

-

Small-volume cargo: Secured on wooden pallets before being loaded into containers to ensure stability and safety during transportation.

_1000x750-300x225.jpg)