Описание

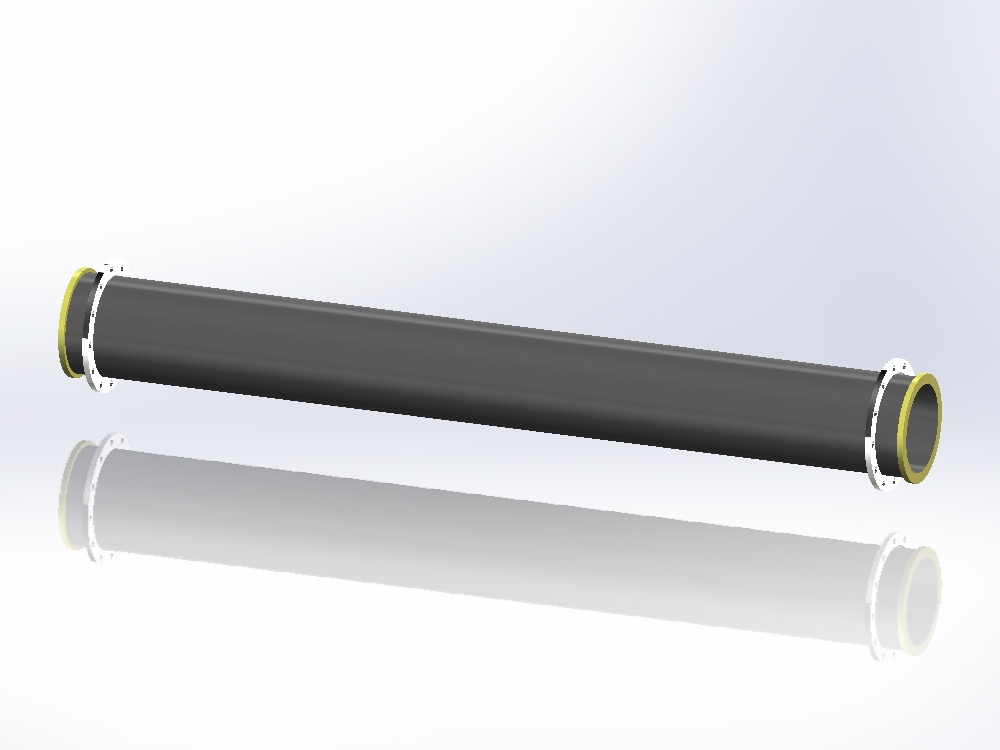

HDPE Pipe with Steel Flange

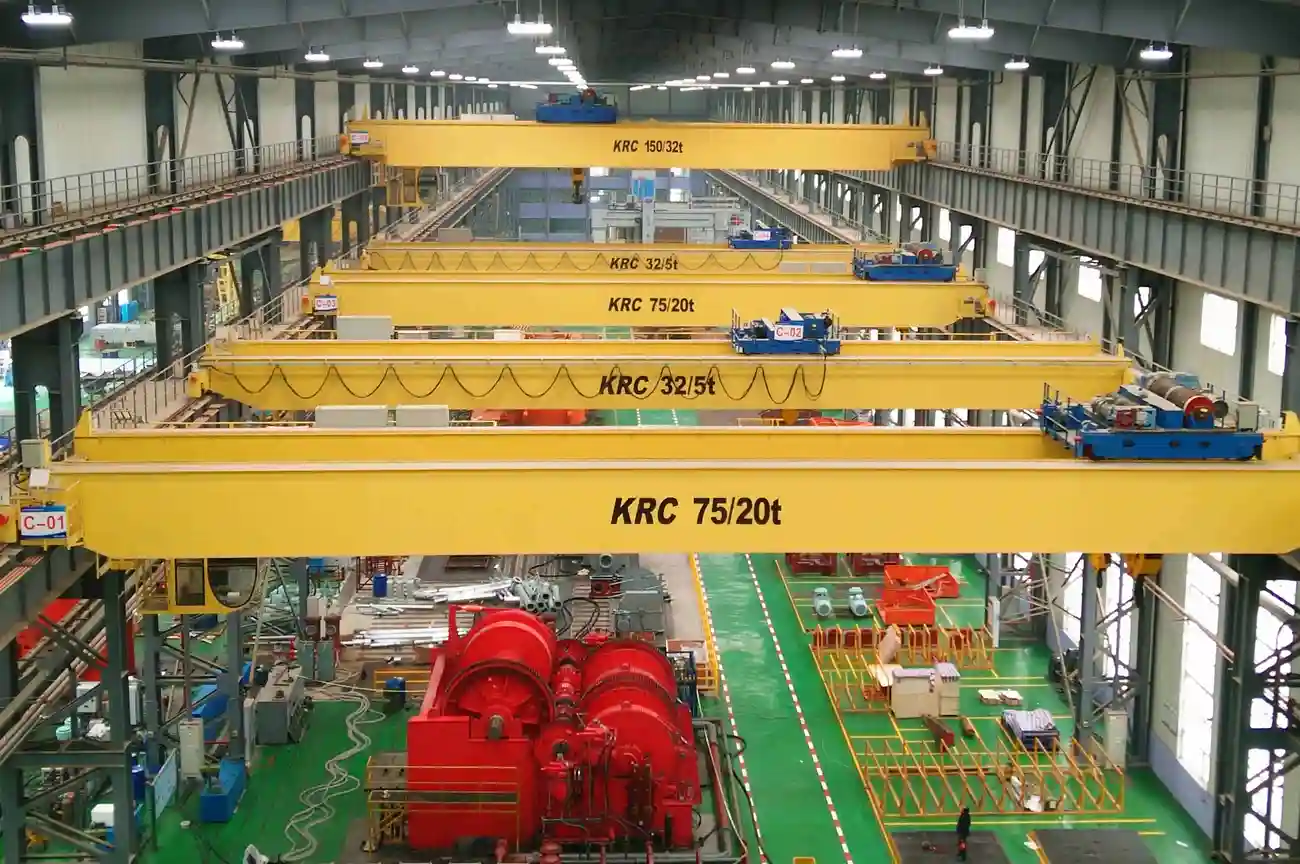

HDPE dredging pipes are high-performance pipeline systems specifically designed for harsh dredging environments and are made from high-density polyethylene (HDPE).

They address common issues found in traditional pipes used in dredging—such as abrasion, corrosion, weight, and efficiency—and are mainly used for transporting slurry, mud, and sand sediments removed from oceans, lakes, and rivers.

Thanks to their high mechanical strength and chemical resistance, HDPE pipes have become the preferred choice for fluid transportation systems in dredging projects.

Specifications:

| Descriptions | Details |

| Название продукта | HDPE Pipe with Steel Flange |

| Origin | China |

| Outside Diameter(OD) | 200-800mm |

| Length | 5800 or 11800mm |

| Working Pressure(WP) | 0.6-1.5Mpa |

| Burst Pressure(BP) | 1.8-4.5Mpa |

| Flange Type | Steel Flange |

| Application |

Clearing Waterways and Transporting Sediments to Keep Channels Unobstructed. |

Key Benefits and Features:

- HDPE is a highly tough material with an extremely high elongation at break, allowing it to withstand strong impacts, compression, and bending without brittle failure.

- It offers excellent corrosion resistance and chemical stability, making it suitable for various complex water conditions and media. Maintenance costs are very low, and unlike steel pipes, no anti-corrosion treatment is required.

- Transportation and installation costs are low: no heavy lifting equipment is needed; manual handling and connection are sufficient.

- With the use of backing rings/flange adapters, installation, disassembly, and transport are convenient, shortening project lead time and improving operational efficiency.

- It has strong environmental adaptability—its flexibility allows it to accommodate complex terrains, such as crossing gullies or adapting to changes in riverbeds.

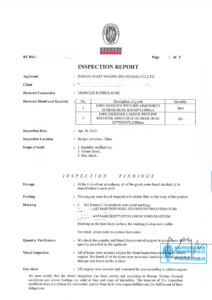

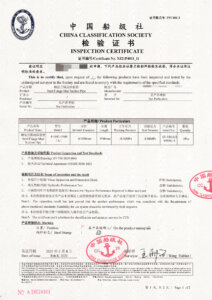

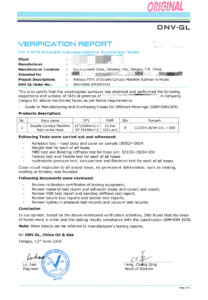

For additional assurance, we can invite third-party inspection agencies to conduct inspections according to customer requirements.