Introduction: Navigating the Global Market for Suction Rubber Hose

In the ever-evolving landscape of industrial supplies, sourcing high-quality suction rubber hose presents a significant challenge for international B2B buyers. As demand for versatile and durable suction hoses grows across sectors such as agriculture, construction, and chemical processing, understanding the nuances of material types, sizes, and applications becomes crucial. This comprehensive guide aims to empower buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Vietnam and Saudi Arabia—by providing actionable insights into the global market for suction rubber hoses.

Navigating this complex market involves more than just selecting a product; it requires a strategic approach to supplier vetting, cost analysis, and compliance with local regulations. This guide covers a wide array of topics, including the different types of suction rubber hoses available, their specific applications, and critical factors to consider when assessing suppliers. Additionally, we delve into cost considerations and strategies for ensuring the best value for your investment. By arming yourself with this knowledge, you will be better equipped to make informed purchasing decisions that align with your operational needs and budget constraints. Whether you are looking for hoses for water, chemicals, or agricultural applications, this guide will serve as your essential resource for navigating the global market.

Оглавление

- Top 7 Suction Rubber Hose Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for Suction Rubber Hose

- Understanding Suction Rubber Hose Types and Variations

- Key Industrial Applications of Suction Rubber Hose

- 3 Common User Pain Points for ‘Suction Rubber Hose’ & Their Solutions

- Strategic Material Selection Guide for Suction Rubber Hose

- In-depth Look: Manufacturing Processes and Quality Assurance for Suction Rubber Hose

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘Suction Rubber Hose’

- Comprehensive Cost and Pricing Analysis for Suction Rubber Hose Sourcing

- Alternatives Analysis: Comparing Suction Rubber Hose With Other Solutions

- Essential Technical Properties and Trade Terminology for Suction Rubber Hose

- Navigating Market Dynamics and Sourcing Trends in the Suction Rubber Hose Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of Suction Rubber Hose

- Strategic Sourcing Conclusion and Outlook for Suction Rubber Hose

- Важный отказ от ответственности и условия использования

Understanding Suction Rubber Hose Types and Variations

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| General Purpose Rubber Hose | Durable, flexible, and resistant to abrasion | Agriculture, construction, and industrial | Плюсы: Versatile and durable; Конс: Can be heavy and may require additional fittings. |

| Всасывающий шланг для холодной погоды | Designed to remain flexible in low temperatures | Winter construction, snow removal | Плюсы: Maintains flexibility; Конс: Более высокая стоимость по сравнению со стандартными шлангами. |

| Прозрачный всасывающий шланг из ПВХ | Transparent for easy visibility of contents | Food processing, chemical handling | Плюсы: Allows monitoring of flow; Конс: Less durable than rubber options. |

| Heavy-Duty Rubber Suction Hose | Reinforced with additional layers for toughness | Mining, oil & gas industries | Плюсы: Extremely durable; Конс: More expensive and heavier. |

| Chemical-Resistant Rubber Hose | Specially formulated to withstand aggressive chemicals | Chemical processing, waste management | Плюсы: Protects against corrosion; Конс: Limited temperature range. |

What Are the Key Characteristics of General Purpose Rubber Hose?

General Purpose Rubber Hoses are designed for a wide range of applications, making them a staple in various industries. These hoses are typically constructed from a blend of synthetic rubber, providing excellent flexibility and resistance to abrasion. They are suitable for applications such as agriculture, construction, and industrial settings where durability is crucial. When purchasing, buyers should consider the hose’s compatibility with the fluids being transported, as well as the required fittings for seamless integration into existing systems.

Как работает всасывающий шланг для холодной погоды при низких температурах?

Cold Weather Suction Hoses are engineered to maintain their flexibility and performance in freezing temperatures, making them ideal for winter construction and snow removal operations. These hoses often feature specialized compounds that prevent them from becoming brittle, which is essential for reliable operation in harsh environments. B2B buyers should assess the temperature range of their applications and ensure that the hose can withstand the specific conditions it will face, as well as any additional costs associated with these specialized products.

Why Choose Clear PVC Suction Hose for Your Operations?

Clear PVC Suction Hoses are an excellent choice for applications where visibility of the transported material is essential, such as in food processing or chemical handling. The transparent material allows operators to monitor flow and detect any blockages or contamination quickly. While these hoses are generally lighter and easier to handle than rubber hoses, they may not offer the same level of durability. Buyers should weigh the need for visibility against the potential for wear and tear, particularly in more demanding environments.

What Makes Heavy-Duty Rubber Suction Hose Ideal for Industrial Use?

Heavy-Duty Rubber Suction Hoses are reinforced with additional layers, making them exceptionally tough and suitable for demanding applications in industries like mining and oil & gas. Their robust construction ensures they can withstand harsh conditions and abrasive materials. While they provide superior durability, the added strength comes at a higher price point and increased weight, which buyers should consider when evaluating their operational needs and logistics.

When Should You Consider Chemical-Resistant Rubber Hose?

Chemical-Resistant Rubber Hoses are formulated to handle aggressive chemicals, making them essential for applications in chemical processing and waste management. These hoses offer protection against corrosion and degradation, ensuring safety and longevity in harsh environments. However, buyers should be mindful of the specific chemicals the hose will encounter and the temperature ranges it can withstand, as these factors can significantly impact performance and safety.

Key Industrial Applications of Suction Rubber Hose

| Промышленность/сектор | Specific Application of Suction Rubber Hose | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Сельское хозяйство | Irrigation and Fertilizer Transfer | Efficient transport of water and nutrients to crops | Durability, flexibility, and resistance to chemicals |

| Строительство | Dewatering and Material Transfer | Rapid removal of water from sites, enhancing work efficiency | Size compatibility, pressure rating, and weather resistance |

| Mining and Quarrying | Slurry and Waste Material Handling | Effective management of waste and slurry in harsh conditions | Abrasion resistance, flexibility, and temperature tolerance |

| Еда и напитки | Liquid Transfer in Processing Plants | Safe transport of food-grade liquids, ensuring compliance | FDA compliance, material safety, and ease of cleaning |

| Химическая обработка | Transfer of Chemicals and Hazardous Materials | Secure handling of various chemicals, minimizing risks | Chemical compatibility, pressure ratings, and safety features |

How is Suction Rubber Hose Used in Agriculture?

In the agriculture sector, suction rubber hoses are vital for irrigation and fertilizer transfer. These hoses facilitate the efficient movement of water and nutrient solutions directly to crops, significantly improving yield and productivity. Buyers in this sector should prioritize hoses that are durable and flexible, capable of withstanding varying pressures and chemical exposure. Additionally, resistance to wear and tear is crucial, particularly in rough terrains common in many regions of Africa and South America.

What Role Does Suction Rubber Hose Play in Construction?

Suction rubber hoses are extensively used in construction for dewatering and material transfer applications. They allow for the rapid removal of water from excavation sites, which is critical for maintaining safety and work efficiency. When sourcing these hoses, construction companies should focus on size compatibility and pressure ratings to ensure they can handle the specific demands of their projects. Furthermore, hoses that are resistant to harsh weather conditions will prove beneficial, especially in the Middle East where extreme temperatures can affect equipment performance.

How is Suction Rubber Hose Essential in Mining and Quarrying?

In the mining and quarrying industries, suction rubber hoses are employed for handling slurries and waste materials. These hoses are designed to operate effectively under harsh conditions, providing a reliable solution for transporting abrasive materials. Buyers in this sector need to consider abrasion resistance and flexibility when sourcing hoses, as well as their ability to tolerate extreme temperatures. The rugged nature of mining operations in regions such as South America necessitates hoses that can withstand challenging environments.

Why is Suction Rubber Hose Important in Food and Beverage Processing?

In the food and beverage industry, suction rubber hoses are crucial for the safe transfer of liquids in processing plants. These hoses must comply with food safety regulations, ensuring that they do not contaminate the products being transported. Buyers should look for hoses that are FDA compliant, made from materials that are easy to clean, and resistant to wear over time. This is especially pertinent for international buyers in Europe, where strict regulations govern food safety and quality.

How Does Suction Rubber Hose Benefit Chemical Processing?

Suction rubber hoses are instrumental in the chemical processing sector for transferring various chemicals and hazardous materials. The secure handling of these substances is vital for minimizing risks associated with spills and leaks. When sourcing hoses for this application, businesses should ensure compatibility with specific chemicals, appropriate pressure ratings, and the inclusion of safety features. This is particularly important for buyers in the Middle East, where handling hazardous materials requires stringent safety measures.

3 Common User Pain Points for ‘Suction Rubber Hose’ & Their Solutions

Scenario 1: Issues with Hose Durability and Performance Under Pressure

Проблема: B2B buyers often encounter challenges with the durability of suction rubber hoses, especially in demanding industrial environments. For instance, a construction company may find that their hoses frequently rupture or degrade when subjected to high pressure or abrasive materials. This not only leads to operational downtime but also poses safety risks to workers handling faulty equipment. The cost of replacing hoses frequently can significantly impact project budgets, causing frustration and hesitation in making future purchasing decisions.

Illustrative image related to Suction Rubber Hose

Решение: To mitigate these issues, buyers should prioritize sourcing high-quality suction rubber hoses that are specifically designed for their intended applications. Look for hoses that are reinforced with materials such as textile or steel spirals, which enhance strength and resistance to wear and tear. Additionally, consider hoses rated for higher pressure applications; specifications should clearly state their maximum working pressure. Engaging with reputable suppliers who provide detailed product specifications and testing certifications can ensure that you select hoses that will withstand your operational demands. Regular maintenance checks and proper handling during use can also prolong the life of the hoses.

Scenario 2: Compatibility Issues with Existing Equipment

Проблема: A common pain point for B2B buyers is the compatibility of suction hoses with existing fittings and equipment. For example, a buyer might purchase a new suction rubber hose that does not fit properly with their established pumps or connectors. This mismatch can lead to leaks, inefficiencies, and ultimately the need for additional purchases to adapt the system, which can be both costly and time-consuming.

Решение: To avoid compatibility issues, buyers should take the time to document existing equipment specifications before making a purchase. This includes measuring the diameter of existing fittings and understanding the thread types used on connectors. When sourcing suction hoses, choose options with standardized fittings or those that come with adapters. Many suppliers offer pre-assembled hoses that include necessary fittings, which can save time and ensure a proper fit. Additionally, consulting with suppliers about the compatibility of the hoses with specific equipment can prevent future headaches.

Scenario 3: Limited Availability and Long Lead Times for Custom Lengths

Проблема: Many businesses require suction rubber hoses in specific lengths for their operations, yet they often face delays when sourcing these custom lengths from suppliers. A manufacturing plant might need hoses that exceed standard lengths to accommodate their layout, and if suppliers cannot meet these requirements promptly, it can halt production and lead to significant financial losses.

Решение: To address this challenge, buyers should establish relationships with suppliers who offer flexible ordering options, including the ability to purchase hoses by the foot or in custom lengths. When placing orders, provide precise measurements and specifications to ensure that the hoses meet operational needs. Additionally, consider maintaining an inventory of commonly used hose lengths to reduce reliance on suppliers for urgent needs. Engaging suppliers who guarantee fast shipping and can accommodate custom requests quickly can help mitigate lead time issues and keep operations running smoothly.

Strategic Material Selection Guide for Suction Rubber Hose

What Are the Key Materials Used in Suction Rubber Hose?

When selecting suction rubber hoses, understanding the materials used is critical for ensuring optimal performance and longevity. Here, we analyze four common materials—PVC, rubber, polyurethane, and silicone—highlighting their properties, advantages, disadvantages, and suitability for various applications.

How Does PVC Compare for Suction Rubber Hose Applications?

Polyvinyl Chloride (PVC) is a widely used material for suction hoses due to its versatility and cost-effectiveness. PVC hoses are typically lightweight and flexible, allowing for easy handling and installation. They have a temperature rating of approximately -10°C to 60°C and can withstand moderate pressures, making them suitable for water and light chemical applications.

Плюсы: PVC is relatively inexpensive and widely available, making it an attractive option for budget-conscious buyers. Its resistance to corrosion and abrasion also enhances its durability in less demanding environments.

Конс: However, PVC hoses may not perform well in extreme temperatures or high-pressure applications. Additionally, they can become brittle over time, especially when exposed to UV light or harsh chemicals.

Влияние на применение: PVC hoses are ideal for transferring water, light chemicals, and agricultural sprays, but they may not be suitable for heavy-duty industrial applications.

What Advantages Does Rubber Offer for Suction Hose Construction?

Rubber is another common material for suction hoses, particularly in industrial settings. Known for its durability, rubber hoses can handle a wider temperature range, typically from -30°C to 80°C, and can withstand higher pressures compared to PVC.

Плюсы: The primary advantage of rubber is its superior flexibility and resilience, making it ideal for rugged environments. Rubber hoses are also resistant to wear and tear, which prolongs their lifespan.

Illustrative image related to Suction Rubber Hose

Конс: On the downside, rubber hoses are generally more expensive than PVC, and their manufacturing process can be more complex. Additionally, rubber may not be compatible with certain chemicals, limiting its use in specific applications.

Влияние на применение: Rubber hoses are well-suited for heavy-duty applications, including construction and mining, where durability and flexibility are paramount.

How Does Polyurethane Perform in Suction Hose Applications?

Polyurethane is a high-performance material that offers excellent abrasion resistance and flexibility. It can operate effectively in a temperature range of -40°C to 90°C and is known for its superior tensile strength.

Плюсы: One of the key advantages of polyurethane is its resistance to punctures and tears, making it ideal for harsh environments. It also maintains its flexibility even at low temperatures, which is crucial for applications in colder climates.

Конс: However, polyurethane hoses tend to be more expensive than both PVC and rubber. They may also be less resistant to certain chemicals, which could limit their application in specific industries.

Влияние на применение: Polyurethane hoses are particularly beneficial in industries where abrasion and flexibility are critical, such as in agricultural and construction applications.

What Role Does Silicone Play in Suction Hose Design?

Silicone is a specialized material often used in applications requiring high-temperature resistance, typically ranging from -60°C to 200°C. Silicone hoses are highly flexible and can maintain their properties under extreme conditions.

Плюсы: The main advantage of silicone is its ability to withstand extreme temperatures without degrading. It is also non-toxic and resistant to a wide range of chemicals, making it suitable for food and pharmaceutical applications.

Конс: The major drawback is the cost; silicone hoses are generally the most expensive option. Additionally, they may not be as durable as rubber or polyurethane in abrasive environments.

Illustrative image related to Suction Rubber Hose

Влияние на применение: Silicone hoses are ideal for applications in the food industry, pharmaceuticals, and any situation requiring high-temperature resistance.

Summary Table of Material Selection for Suction Rubber Hose

| Материал | Typical Use Case for Suction Rubber Hose | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| ПВХ | Water transfer, light chemicals | Экономичный и легкий | Brittle over time, limited pressure | Низкий |

| Резина | Сверхмощные промышленные приложения | Durable and flexible | Higher cost, complex manufacturing | Средний |

| Полиуретан | Agricultural and construction | Отличная стойкость к истиранию | Higher cost, limited chemical resistance | Высокий |

| Silicone | Food and pharmaceutical applications | High-temperature resistance | Most expensive, less durable in abrasion | Высокий |

This guide provides B2B buyers with essential insights into material selection for suction rubber hoses, ensuring informed decisions that align with their specific operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for Suction Rubber Hose

What Are the Main Stages of Manufacturing Suction Rubber Hose?

The manufacturing process of suction rubber hose involves several critical stages, each designed to ensure high-quality and durable products that meet the demands of various industries. These stages include material preparation, forming, assembly, and finishing.

-

Подготовка материалов

The first step in the manufacturing of suction rubber hose is the selection and preparation of raw materials. High-quality rubber compounds, often reinforced with synthetic fibers or steel wires, are chosen based on the intended application of the hose. The rubber must be resistant to abrasions, chemicals, and environmental conditions. Additives, such as plasticizers and stabilizers, are mixed with the rubber to enhance its properties. This mixture is then subjected to a rigorous quality check to ensure it meets the necessary specifications. -

Формирование

During the forming stage, the prepared rubber is extruded into the desired hose shape. Extrusion involves forcing the rubber mixture through a mold to create a continuous length of hose. The diameter and wall thickness can be adjusted according to customer specifications. In some cases, a reinforcing layer is added during this stage to provide additional strength and flexibility. This is particularly important for suction hoses, which must withstand vacuum pressure without collapsing. -

Сборка

After forming, the hose is cut to the required lengths. In this stage, fittings and connectors are attached to the hose. Common fittings include cam lock, threaded, and flanged connections, depending on the application. The assembly process is crucial, as improper fitting can lead to leaks and reduced performance. Each connection point is checked for compatibility and strength to ensure a reliable seal. -

Отделка

The final stage of manufacturing involves applying a protective coating or finishing treatment to enhance the hose’s durability. This could include surface treatments to improve resistance to UV light, ozone, and other environmental factors. The hoses may also undergo a curing process, where they are heated to set the rubber and improve its elasticity. This stage often includes additional quality checks to confirm that the hose meets the specified performance standards.

How Is Quality Assurance Implemented in Suction Rubber Hose Manufacturing?

Quality assurance (QA) in the manufacturing of suction rubber hoses is critical for ensuring product reliability and safety. Various international and industry-specific standards guide the QA process, and several checkpoints are established throughout production.

-

What International Standards Guide the Quality Assurance Process?

Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems. This certification demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific standards like CE marking in Europe and API specifications in the oil and gas sector ensure that products meet safety and performance criteria relevant to their applications. -

Каковы ключевые контрольные точки контроля качества?

Quality control (QC) checkpoints are integral to the production process. Common checkpoints include:

– Входящий контроль качества (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

– Внутрипроцессный контроль качества (IPQC): Ongoing checks during manufacturing identify any deviations from quality standards, allowing for immediate corrective actions.

– Окончательный контроль качества (ОКК): Finished hoses undergo thorough testing to confirm they meet performance and safety standards before shipment. -

What Common Testing Methods Are Used for Suction Rubber Hoses?

Various testing methods are employed to assess the quality and durability of suction rubber hoses. These methods include:

– Pressure Testing: Hoses are subjected to high-pressure conditions to ensure they can withstand operational stresses without leaking or bursting.

– Vacuum Testing: This test verifies the hose’s ability to maintain its shape and integrity under suction conditions.

– Abrasion Resistance Testing: Hoses are tested against abrasive materials to evaluate their durability in harsh environments.

– Chemical Resistance Testing: This involves exposing hoses to different chemicals to ensure compatibility and longevity.

Как покупатели B2B могут проверять контроль качества поставщиков?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are actionable steps buyers can take:

-

Conduct Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality assurance measures. Buyers should assess the supplier’s facilities, equipment, and adherence to quality standards. -

Request Quality Reports and Certifications

Buyers should request documentation of quality certifications, such as ISO 9001 or CE marking. Regular quality reports can also provide transparency regarding the supplier’s production performance and quality metrics. -

Engage Third-party Inspection Services

Utilizing third-party inspection services can add an extra layer of assurance. These independent entities can evaluate the production process, conduct tests, and validate compliance with international standards before shipment.

Каковы нюансы контроля качества для международных покупателей B2B?

International buyers must navigate specific nuances in quality control that can vary by region and industry. Understanding these nuances is crucial for ensuring compliance and product reliability.

-

Regional Compliance Requirements

Different regions may have unique regulatory requirements for rubber products. Buyers should familiarize themselves with local standards and ensure that suppliers comply with these regulations to avoid potential legal issues. -

Cultural and Language Barriers

Communication can be a challenge when dealing with international suppliers. Buyers should ensure that quality specifications are clearly articulated and understood by all parties involved. Language barriers can lead to misunderstandings, so it may be beneficial to engage local representatives or translators. -

Прозрачность цепочки поставок

In today’s global marketplace, supply chain transparency is vital. Buyers should seek suppliers who are willing to share detailed information about their sourcing, manufacturing processes, and quality control measures, as this can enhance trust and collaboration.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing suction rubber hoses, ensuring they receive products that meet their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Suction Rubber Hose’

To assist international B2B buyers in successfully procuring suction rubber hoses, this practical sourcing guide provides a comprehensive checklist of essential steps. By following these steps, buyers can ensure they make informed decisions and secure high-quality products that meet their operational needs.

Шаг 1: Определите технические характеристики

Establishing clear technical specifications is the first step in sourcing suction rubber hoses. Consider the application requirements, such as pressure ratings, diameter, length, and material composition. This clarity helps in narrowing down options and ensures that the hoses will perform adequately in your intended environment, whether it’s for agricultural, industrial, or chemical transfer.

- Application Type: Identify if the hose is for water, chemicals, or other materials.

- Условия окружающей среды: Assess factors like temperature extremes or exposure to UV light.

Шаг 2: Research Market Trends and Pricing

Understanding market trends and pricing for suction rubber hoses is crucial. This knowledge allows you to gauge fair pricing and recognize quality indicators. Research different suppliers and compare prices based on specifications to avoid overpaying while ensuring you’re getting a reliable product.

- Industry Reports: Utilize resources like market analysis reports to understand pricing trends.

- Competitor Pricing: Check competitors’ offerings to benchmark your potential costs.

Шаг 3: Оцените потенциальных поставщиков

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record of reliability and quality, as this can significantly impact your operations.

- Certifications: Verify if suppliers have relevant certifications (ISO, CE, etc.) that reflect product quality.

- Customer Feedback: Seek testimonials and reviews from existing clients to gauge satisfaction levels.

Шаг 4: Request Samples and Quality Assurance

Once you have a shortlist of suppliers, request samples of the suction rubber hoses. Evaluating samples allows you to assess the quality, flexibility, and durability of the hoses firsthand. It’s vital to ensure that the samples meet your technical specifications and are suitable for your applications.

- Quality Standards: Confirm that samples adhere to international quality standards.

- Testing Conditions: Consider testing the hoses under actual working conditions if possible.

Шаг 5: Переговоры о сроках и условиях

Negotiating favorable terms and conditions with your chosen supplier is essential for a successful partnership. This includes discussing pricing, payment terms, delivery schedules, and warranty policies. Clear agreements can prevent misunderstandings and ensure a smooth procurement process.

- Скидки за объем: Inquire about discounts for bulk purchases to optimize costs.

- Lead Times: Clarify expected lead times to align with your project timelines.

Шаг 6: Establish a Communication Plan

Effective communication with your supplier is key to a successful sourcing process. Establish regular check-ins and updates regarding your order status, potential delays, and quality assurance. This proactive approach helps to build a strong relationship and facilitates easier problem resolution.

- Point of Contact: Designate a specific contact person for streamlined communication.

- Feedback Mechanism: Implement a system for providing feedback on product quality and service.

Шаг 7: Review and Finalize the Purchase Order

Before finalizing the purchase, review all details meticulously. Ensure that all specifications, terms, and conditions are accurately documented in the purchase order. This final check can help to avoid costly mistakes and ensure that the supplier delivers exactly what you need.

- Documentation: Keep a record of all communications and agreements for future reference.

- Order Confirmation: Request a formal order confirmation from the supplier to verify details.

By following this checklist, B2B buyers can navigate the complexities of sourcing suction rubber hoses effectively, ensuring they procure the right products for their specific needs.

Comprehensive Cost and Pricing Analysis for Suction Rubber Hose Sourcing

What Are the Key Cost Components in Suction Rubber Hose Production?

Understanding the cost structure of suction rubber hoses is essential for B2B buyers seeking to optimize their sourcing strategies. The main cost components include:

-

Материалы: The choice of materials significantly impacts the cost. High-quality rubber, PVC, or specialty materials designed for specific applications (e.g., cold weather resistance) will incur higher costs but provide better durability and performance.

-

Труд: Labor costs vary based on geographical location and the complexity of the manufacturing process. In regions with higher labor costs, such as Europe, the overall price of the hoses may be elevated compared to lower-cost labor regions like parts of Asia.

-

Производственные накладные расходы: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, thereby affecting final pricing.

-

Инструментальная оснастка: Custom tooling for specialized hose designs or fittings can add to initial costs. Buyers should consider whether the investment in tooling is justified based on their volume needs.

-

Контроль качества (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While this adds to manufacturing costs, it can prevent costly failures or recalls in the long run.

-

Логистика: Transportation costs can vary significantly based on the supplier’s location and the chosen shipping method. Understanding the logistics involved is crucial for calculating total costs.

-

Маржа: Supplier margins can fluctuate based on market demand, competition, and brand reputation. It’s vital to assess whether the margin aligns with the quality and service provided.

How Do Price Influencers Affect Suction Rubber Hose Sourcing?

Several factors influence the pricing of suction rubber hoses, impacting the overall purchasing strategy:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Understanding your requirements and negotiating for volume discounts can lead to substantial savings.

-

Технические характеристики и персонализация: Customized hoses designed for specific applications (e.g., differing diameters or lengths) can incur additional costs. Buyers should balance the need for customization with budget constraints.

-

Materials Quality and Certifications: Premium materials and certifications (such as ISO or CE) can increase costs but also enhance product reliability. Buyers should evaluate if the added quality justifies the price difference.

-

Факторы поставщика: The reputation, reliability, and service level of the supplier can influence pricing. Established suppliers may charge more due to their proven track record.

-

Инкотермс: Understanding Incoterms is critical for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can all impact total costs.

What Tips Can Enhance Cost-Efficiency in Suction Rubber Hose Procurement?

B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should consider the following strategies for effective sourcing:

-

Negotiate Terms: Always engage in negotiations with suppliers. Leverage your purchasing volume or long-term partnership potential to secure better pricing or favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial price, consider maintenance, durability, and replacement costs. A higher-quality hose may cost more upfront but result in lower TCO due to reduced failures and downtime.

-

Understand Pricing Nuances: Pricing can vary significantly based on regional market dynamics. For instance, buyers in Africa may face different logistical challenges compared to those in Europe, affecting the final price.

-

Build Strong Supplier Relationships: Establishing long-term relationships with suppliers can lead to better service, priority during high-demand periods, and potentially lower prices through loyalty.

-

Проведите исследование рынка: Stay informed about market trends and competitor pricing. This knowledge can empower you during negotiations and help identify the most suitable suppliers.

By understanding these cost components, price influencers, and actionable tips, B2B buyers can enhance their sourcing strategies for suction rubber hoses, ensuring they make informed decisions that align with their operational needs and budgetary constraints.

Alternatives Analysis: Comparing Suction Rubber Hose With Other Solutions

Exploring Alternatives to Suction Rubber Hose

In the quest for effective fluid transfer solutions, suction rubber hoses stand as a reliable choice. However, various alternatives exist that may cater to specific needs or preferences of international B2B buyers. Understanding these alternatives, their strengths, and weaknesses allows businesses to make informed decisions about their fluid transfer solutions.

| Сравнительный аспект | Всасывающий резиновый шланг | Всасывающий шланг из ПВХ | Stainless Steel Hose |

|---|---|---|---|

| Производительность | High flexibility and durability; excellent for rugged environments. | Good for general-purpose applications but less flexible than rubber. | Exceptional pressure resistance; ideal for high-temperature applications. |

| Стоимость | Generally higher due to material quality ($6.61/ft). | More affordable ($1.97/ft), especially for bulk purchases. | Higher initial investment due to material ($15+/ft). |

| Простота реализации | Flexible and easy to install; often comes pre-assembled. | Lightweight and easy to handle; may require additional fittings. | Heavier and requires specialized tools for installation. |

| Техническое обслуживание | Low maintenance; resistant to abrasion and weather. | Moderate maintenance; can be prone to cracking over time. | Low maintenance; resistant to corrosion but can be dented. |

| Лучший пример использования | Industrial applications requiring high durability and flexibility. | Agricultural or light-duty applications where cost is a factor. | Applications involving high pressure or temperature, such as chemical processing. |

Understanding PVC Suction Hose: Pros and Cons

PVC suction hoses are a popular alternative, particularly in cost-sensitive applications. They offer good performance for light to moderate duties, making them suitable for agricultural and general-purpose uses. The lightweight nature of PVC hoses allows for easier handling and installation. However, they are less durable than rubber hoses, particularly under harsh conditions, and may crack or degrade over time when exposed to extreme temperatures or UV light.

Evaluating Stainless Steel Hose: Pros and Cons

Stainless steel hoses provide unparalleled performance in high-pressure and high-temperature environments. They are ideal for chemical processing and applications where corrosion resistance is crucial. However, the initial investment for stainless steel hoses is significantly higher than that of rubber or PVC hoses. Their weight and rigidity can complicate installation, requiring specialized tools and fittings. Despite these challenges, their longevity and durability can make them a cost-effective solution in the long run for demanding applications.

Making the Right Choice for Your Fluid Transfer Needs

Selecting the appropriate fluid transfer solution hinges on understanding your specific requirements, including the type of material being transferred, environmental conditions, and budget constraints. Suction rubber hoses excel in durability and flexibility, making them suitable for rugged industrial applications. PVC hoses offer a cost-effective solution for lighter duties, while stainless steel hoses are best reserved for high-pressure scenarios. By carefully assessing these factors, international B2B buyers can align their choices with operational needs and ensure efficient fluid transfer in their respective industries.

Essential Technical Properties and Trade Terminology for Suction Rubber Hose

What Are the Key Technical Properties of Suction Rubber Hose?

Understanding the technical properties of suction rubber hoses is essential for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade of suction rubber hoses typically refers to the type of rubber or PVC used in manufacturing. Common grades include EPDM, SBR, and PVC, each offering different levels of chemical resistance, flexibility, and durability. For example, EPDM is excellent for weather resistance, making it suitable for outdoor applications. Selecting the right material grade is crucial for ensuring the hose can withstand the specific environmental conditions and the nature of the fluids being transported.

2. Diameter and Length

The diameter of suction hoses can range from 1 inch to 12 inches, while lengths are available in standard increments, such as 25, 50, and 100 feet. The size selected directly impacts flow rates and pressure capabilities. Choosing the appropriate diameter ensures optimal fluid transfer and minimizes potential blockages, which is vital for maintaining efficiency in industrial operations.

3. Working Pressure and Vacuum Rating

The working pressure indicates the maximum pressure the hose can handle without failure, while the vacuum rating refers to the amount of suction the hose can withstand. These ratings are expressed in PSI (pounds per square inch) and inches of mercury (Hg), respectively. For B2B buyers, understanding these ratings is critical to ensure that the hose will perform safely and effectively in high-demand applications, such as construction or agricultural settings.

4. Temperature Range

Suction rubber hoses come with specified temperature ranges, often from -20°F to 150°F or more, depending on the material. This specification is vital for applications involving hot or cold fluids, as exceeding the recommended temperature can lead to hose failure. Buyers should ensure that the temperature range aligns with their operational requirements to avoid costly downtimes and replacements.

5. Flexibility and Bend Radius

Flexibility refers to how easily a hose can be maneuvered without kinking, while bend radius indicates the minimum curvature that a hose can handle without damage. A more flexible hose can reduce installation time and improve performance in tight spaces. Understanding these properties helps buyers choose hoses that fit their operational layout and requirements.

What Are Common Trade Terms Related to Suction Rubber Hose?

In addition to technical properties, familiarity with industry terminology is essential for effective communication and negotiation. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. For suction rubber hoses, OEMs provide hoses that meet specific engineering standards and can be customized for unique applications, ensuring compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects purchasing decisions and inventory management. Understanding the MOQ helps businesses plan their orders effectively and negotiate better terms.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For buyers of suction rubber hoses, submitting an RFQ allows them to gather pricing information, compare suppliers, and make informed purchasing decisions based on cost and quality.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding the transportation of goods. For example, terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify who bears the cost and risk during shipping. Familiarity with Incoterms is crucial for international buyers to ensure smooth logistics and reduce potential disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead time is essential for B2B buyers, as it affects project timelines and inventory levels. Buyers should inquire about lead times when negotiating terms to ensure they meet operational deadlines.

By comprehensively understanding these technical specifications and trade terminologies, B2B buyers can enhance their decision-making process when sourcing suction rubber hoses, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the Suction Rubber Hose Sector

What Are the Current Market Dynamics and Key Trends in the Suction Rubber Hose Sector?

The suction rubber hose market is experiencing significant growth driven by various global factors. Key drivers include the increasing demand from industries such as agriculture, construction, and waste management, particularly in emerging markets across Africa, South America, and the Middle East. These regions are witnessing rapid industrialization and infrastructure development, leading to a heightened need for durable and efficient suction hoses for fluid transfer.

Illustrative image related to Suction Rubber Hose

In addition, technological advancements in manufacturing processes are enhancing the quality and versatility of suction hoses. Innovations such as improved materials and construction techniques are yielding hoses that can withstand extreme conditions, including high pressures and varying temperatures. For international B2B buyers, this represents an opportunity to source products that not only meet industry standards but also offer enhanced performance characteristics.

Emerging trends in sourcing practices are also notable. Buyers are increasingly looking for suppliers who can provide customization options, allowing them to tailor hose specifications to their specific applications. This trend is amplified by the rise of digital marketplaces and e-commerce platforms, facilitating easier access to a wider range of suppliers and products. Furthermore, the ability to purchase hoses by the foot or roll is becoming a preferred option, allowing businesses to minimize waste and manage inventory more effectively.

How Is Sustainability and Ethical Sourcing Influencing the Suction Rubber Hose Market?

Sustainability is becoming a cornerstone of sourcing strategies in the suction rubber hose sector. As global awareness of environmental issues rises, buyers are increasingly prioritizing suppliers that adhere to ethical sourcing practices and offer sustainable products. The environmental impact of rubber production, including deforestation and carbon emissions, is prompting companies to seek out hoses made from recycled or eco-friendly materials.

Ethical supply chains are crucial for B2B buyers not only from a compliance perspective but also for enhancing brand reputation. Buyers should look for suppliers that possess green certifications, such as ISO 14001, which signify adherence to environmental management standards. Additionally, the use of sustainable materials, such as bio-based rubbers or recycled plastics, is gaining traction in the industry. This shift not only reduces the carbon footprint but also appeals to environmentally conscious consumers and businesses.

By focusing on sustainability and ethical sourcing, companies can differentiate themselves in a competitive market, attract new customers, and foster loyalty among existing clients. Furthermore, incorporating sustainable practices can lead to cost savings in the long term through reduced waste and improved operational efficiencies.

Illustrative image related to Suction Rubber Hose

What Is the Historical Context of the Suction Rubber Hose Industry?

The suction rubber hose industry has evolved significantly over the past century. Initially, hoses were primarily made from natural rubber, which, while effective, had limitations in durability and resistance to chemicals. The introduction of synthetic rubber in the mid-20th century revolutionized the industry, providing hoses that could withstand a broader range of temperatures and chemicals.

Over the decades, advancements in manufacturing technologies have further enhanced the performance of suction hoses. The development of reinforced structures and flexible materials has allowed hoses to be used in more demanding applications, from industrial fluid transfer to agricultural irrigation. Today, the market is characterized by a diverse range of products, catering to various industries and applications, reflecting the ongoing evolution and adaptation of the suction rubber hose sector to meet modern demands.

This historical perspective underscores the importance of innovation and adaptability in sourcing strategies, providing international B2B buyers with insights into the factors that have shaped the current landscape of the suction rubber hose market.

Frequently Asked Questions (FAQs) for B2B Buyers of Suction Rubber Hose

-

How do I choose the right suction rubber hose for my application?

Selecting the appropriate suction rubber hose involves considering several factors, including the type of material (rubber, PVC, etc.), diameter, length, and application-specific requirements such as temperature and pressure ratings. Assess the media being transported (water, chemicals, or slurry) to ensure compatibility. It’s also essential to evaluate environmental conditions, such as exposure to UV light or extreme temperatures, which may affect hose performance. Consulting with suppliers can provide insights into the best options for your specific needs. -

What is the best material for suction hoses in industrial applications?

Rubber and PVC are the most common materials used for suction hoses in industrial settings. Rubber hoses are preferred for rugged applications due to their flexibility and durability, making them suitable for heavy-duty tasks. In contrast, PVC hoses are lightweight and resistant to various chemicals, making them ideal for applications where weight is a concern. Ultimately, the choice depends on the intended use, environmental conditions, and the type of substances being transported. -

What are the typical minimum order quantities (MOQ) for suction rubber hoses?

Minimum order quantities for suction rubber hoses vary by supplier and can range from as low as 10 meters to several hundred meters. For international buyers, MOQs may be influenced by shipping costs, production capacity, and customization requirements. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms and potentially lower the MOQ based on your order size and frequency. -

How can I verify the quality of suction rubber hoses from suppliers?

To ensure the quality of suction rubber hoses, request certifications and compliance documents, such as ISO or ASTM standards, which indicate adherence to industry norms. Additionally, inquire about the supplier’s quality assurance processes, including material sourcing and testing procedures. Requesting samples before placing large orders can also help verify product quality and performance under your specific conditions. -

What payment terms should I expect when sourcing suction rubber hoses internationally?

Payment terms for international orders typically include options such as a Letter of Credit, advance payment, or net 30/60 days after delivery. The specific terms will depend on the supplier’s policies, your negotiation leverage, and the level of trust established. It’s crucial to clarify payment terms in advance to avoid misunderstandings and ensure a smooth transaction process. -

What shipping options are available for importing suction rubber hoses?

Shipping options for suction rubber hoses include air freight, sea freight, and express courier services. Air freight is faster but typically more expensive, making it suitable for urgent orders. Sea freight, while slower, is often more cost-effective for larger shipments. Ensure to discuss shipping timelines and costs with your supplier, and consider customs clearance processes in your destination country to avoid delays. -

Can suction rubber hoses be customized to meet specific requirements?

Yes, many suppliers offer customization options for suction rubber hoses, including modifications in length, diameter, and material. Additional features such as specific fittings or reinforcements for high-pressure applications can also be requested. When discussing customization with suppliers, provide detailed specifications and usage conditions to ensure the final product meets your operational needs. -

What should I know about logistics and supply chain management when sourcing suction rubber hoses?

Effective logistics and supply chain management are crucial when sourcing suction rubber hoses internationally. Consider factors such as lead times, shipping methods, and potential tariffs or duties that may apply upon importation. Establish clear communication with suppliers regarding delivery schedules and inventory levels to prevent disruptions. Additionally, developing relationships with reliable freight forwarders can enhance the efficiency of your logistics operations.

Top 7 Suction Rubber Hose Manufacturers & Suppliers List

1. Factory Direct Hose – Suction Hose Solutions

Домен: factorydirecthose.com

Зарегистрирован: 2004 (21 год)

Введение: {“product_types”: [“1 Inch Suction Hose”, “1.25 Inch Suction Hose”, “1.5 Inch Suction Hose”, “2 Inch Suction Hose”, “2.5 Inch Suction Hose”, “3 Inch Suction Hose”, “4 Inch Suction Hose”, “5 Inch Suction Hose”, “6 Inch Suction Hose”, “8 Inch Suction Hose”, “10 Inch Suction Hose”, “12 Inch Suction Hose”], “materials”: [“Clear PVC”, “Green PVC”, “Rubber”], “features”: [“Durable”, “High quality”, “Mad…

2. Hosecraft USA – Suction Hoses Overview

Домен: hosecraftusa.com

Зарегистрирован: 2005 (20 лет)

Введение: Hosecraft USA offers a variety of suction hoses suitable for different applications. Key product details include: 1. RN1 Rubber Suction Hose: Reinforced with textile plies and a helical wire, available in diameters from 1-1/2″ to 8″, operating temperature range -25F to 185F. 2. RN2 Lightweight Rubber Suction Hose: Made from EPDM rubber with a polyethylene helix, available in diameters from 1″ to 6…

3. Texcel – Water Suction & Discharge Hose

Домен: texcelrubber.com

Registered: 1996 (29 years)

Введение: Product Name: Water Suction & Discharge Hose

Available Sizes: 1 in, 1-1/4 in, 1-1/2 in, 2 in, 2-1/2 in, 3 in, 4 in, 5 in, 6 in, 8 in, 10 in, 12 in

Max Working Pressure: 50 psi, 150 psi

Standard Lengths: 20 ft, 25 ft, 100 ft, 200 ft

Vacuum Ratings: 20 in/Hg, 25 in/Hg, 29 in/Hg

Units of Measure: FT, PIECE

4. Midwest Hose – Black Rubber Suction Hose

Домен: midwesthose.com

Зарегистрирован: 2000 (25 лет)

Введение: {“name”: “Black Rubber Suction Hose”, “applications”: [“water”, “salt water”, “mild acids such as water based agriculture fertilizers”], “specifications”: {“tube”: “EPDM”, “cover”: “EPDM”, “reinforcement”: “Multiple textile plies, dual helix wire”, “safety_factor”: “4:1”, “temperature_range”: “-40°F to 180°F”}, “sizes”: [{“part_number”: “MWHBRS150-24”, “id”: “1-1/2”, “od”: “1.86”, “max_wp”: “150”,…

5. Amazon Hose – Suction and Discharge Hoses

Домен: shop.amazonhose.com

Зарегистрирован: 1998 (27 лет)

Введение: This company, Amazon Hose – Suction and Discharge Hoses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Kuriyama – Water Suction Industrial Rubber Hoses

Домен: products.kuriyama.com

Зарегистрирован: 1997 (28 лет)

Введение: Water Suction Industrial Rubber Hoses include the following products: T202AA – 150 PSI EPDM General Purpose Water S&D Hose, T204AA – SBR Water S&D Hose, T223AA – 300 PSI EPDM Heavy Duty S&D Hose.

7. Hose Shop – Water Suction & Discharge Hose

Домен: hoseshop.com

Зарегистрирован: 2003 (22 года)

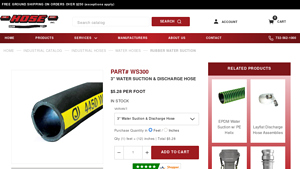

Введение: {“part_number”:”WS300″,”description”:”3″ Water Suction & Discharge Hose”,”price_per_inch”:”$0.84″,”available_variants”:[“1-1/4″ Water Suction & Discharge Hose”,”1-1/2″ Water Suction & Discharge Hose”,”2″ Water Suction & Discharge Hose”,”2-1/2″ Water Suction & Discharge Hose”,”3″ Water Suction & Discharge Hose”,”4″ Water Suction & Discharge Hose”,”5″ Water Suction & Discharge Hose”,”6″ Water Suctio…

Strategic Sourcing Conclusion and Outlook for Suction Rubber Hose

In conclusion, strategic sourcing for suction rubber hoses presents significant opportunities for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By prioritizing quality, durability, and customization options, businesses can enhance operational efficiency and safeguard their investments in critical infrastructure. Sourcing from reliable suppliers ensures access to a diverse range of products, from lightweight PVC options to heavy-duty rubber hoses, tailored to specific applications across various industries.

As the demand for effective fluid transfer solutions continues to grow, adopting a strategic sourcing approach can yield substantial cost savings and enhance supply chain resilience. Buyers should leverage global supplier networks to identify innovative products that meet industry standards while considering factors such as lead times and shipping logistics to optimize their procurement processes.

Looking ahead, engaging with reputable manufacturers and suppliers will not only streamline operations but also foster long-term partnerships that drive mutual growth. Now is the time to evaluate your sourcing strategies and explore the vast potential of suction rubber hoses to elevate your business’s capabilities in a competitive market.

Важный отказ от ответственности и условия использования

⚠️ Важное заявление об отказе от ответственности

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу. перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.