Introduction: Navigating the Global Market for offshore transfers hoses

In the dynamic and complex landscape of the offshore industry, sourcing reliable offshore transfer hoses is crucial for ensuring safe and efficient operations. With an increasing demand for energy and resource extraction, businesses face the challenge of selecting the right hoses that can withstand harsh marine environments while meeting regulatory standards. This guide serves as a comprehensive resource for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Brazil.

Within this guide, we delve into various types of offshore transfer hoses, including bulk transfer, bunkering, and chemical hoses, highlighting their specific applications and performance characteristics. We also provide insights on the importance of supplier vetting, ensuring that businesses partner with manufacturers who adhere to stringent quality and safety standards. Additionally, we address cost considerations, maintenance practices, and inspection protocols that are essential for the longevity and reliability of hose assemblies.

By equipping buyers with actionable knowledge, this guide empowers them to make informed purchasing decisions that enhance operational efficiency and compliance. Understanding the nuances of offshore transfer hoses not only mitigates risks but also drives competitive advantage in the global market, paving the way for successful business ventures in the offshore sector.

Table Of Contents

- Top 6 Offshore Transfers Hoses Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for offshore transfers hoses

- Understanding offshore transfers hoses Types and Variations

- Key Industrial Applications of offshore transfers hoses

- 3 Common User Pain Points for ‘offshore transfers hoses’ & Their Solutions

- Strategic Material Selection Guide for offshore transfers hoses

- In-depth Look: Manufacturing Processes and Quality Assurance for offshore transfers hoses

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore transfers hoses’

- Comprehensive Cost and Pricing Analysis for offshore transfers hoses Sourcing

- Alternatives Analysis: Comparing offshore transfers hoses With Other Solutions

- Essential Technical Properties and Trade Terminology for offshore transfers hoses

- Navigating Market Dynamics and Sourcing Trends in the offshore transfers hoses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of offshore transfers hoses

- Strategic Sourcing Conclusion and Outlook for offshore transfers hoses

- Important Disclaimer & Terms of Use

Understanding offshore transfers hoses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bulk Transfer Hose | Large diameter, high flow capacity | Oil and gas transfer, water transport | Pros: Efficient for large volumes; Cons: Higher cost, requires robust handling. |

| Bunkering Hose | Designed for fuel transfer, fire-resistant | Ship refueling operations | Pros: Safety features; Cons: Limited to specific applications. |

| Chemical Hose | Resistant to corrosive substances, flexible | Chemical transport and discharge | Pros: Versatile, durable; Cons: Requires careful selection based on chemicals. |

| Floating Hose | Buoyant design, minimizes environmental impact | Offshore oil transfer, ship-to-ship | Pros: Reduces risk of spills; Cons: More expensive, requires specific maintenance. |

| High-Pressure Hose | Designed to withstand extreme pressure | Hydraulic systems, drilling operations | Pros: High durability; Cons: Can be heavy and difficult to handle. |

What Are the Key Characteristics of Bulk Transfer Hoses?

Bulk transfer hoses are engineered to handle large volumes of liquids, typically featuring larger diameters to facilitate high flow rates. Their construction is robust, often made from materials that can withstand the rigors of offshore environments. These hoses are particularly suited for applications in oil and gas transfers, as well as for transporting water. When purchasing, buyers should consider factors such as the hose’s pressure rating and compatibility with the substances being transferred, as these elements can significantly affect operational efficiency.

How Do Bunkering Hoses Ensure Safe Fuel Transfer?

Bunkering hoses are specifically designed for the safe transfer of fuel, equipped with fire-resistant properties to mitigate risks during refueling operations. These hoses are commonly used in maritime settings where safety is paramount, especially in ship refueling. Buyers should prioritize hoses that meet international safety standards and consider the hose’s flexibility and durability to ensure optimal performance under various conditions. While they offer enhanced safety features, their specialized nature may limit their applications.

Why Choose Chemical Hoses for Transporting Hazardous Materials?

Chemical hoses are crafted to resist corrosive substances, making them essential for the transportation and discharge of various chemicals in offshore settings. Their flexibility allows for ease of handling in tight spaces, while their durability ensures long-lasting performance. B2B buyers must carefully select chemical hoses based on the specific chemicals they will transport, considering factors like temperature tolerance and chemical compatibility. While these hoses are versatile, improper selection can lead to safety hazards and operational downtime.

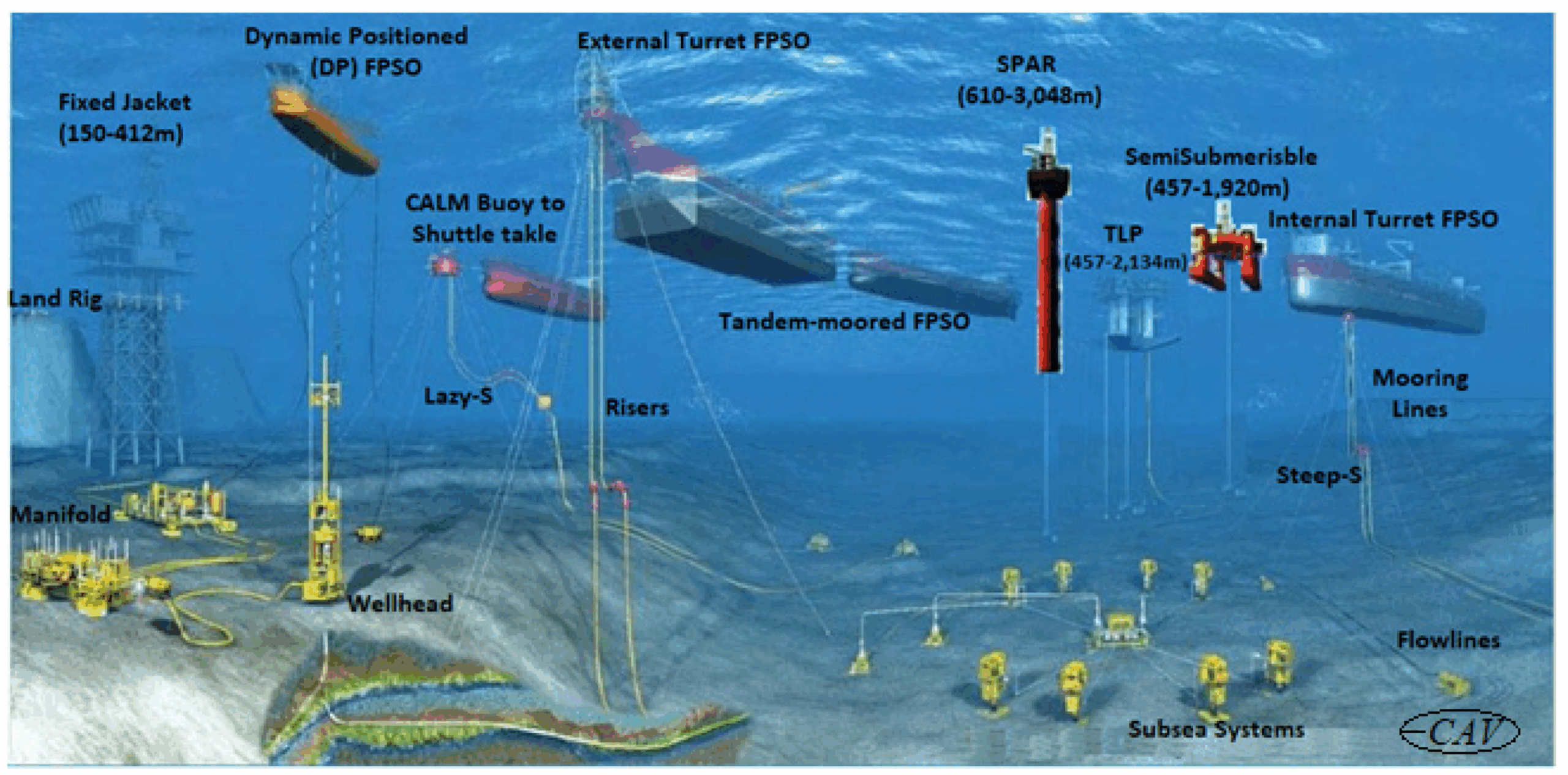

What Advantages Do Floating Hoses Offer in Offshore Operations?

Floating hoses are designed to remain buoyant, minimizing environmental impact during offshore oil transfers and ship-to-ship operations. Their unique design helps reduce the risk of spills and allows for easier handling in turbulent waters. When selecting floating hoses, buyers should assess their cost-effectiveness and maintenance requirements, as these hoses can be more expensive than traditional options. However, their environmental benefits and operational safety make them a valuable investment for responsible offshore operations.

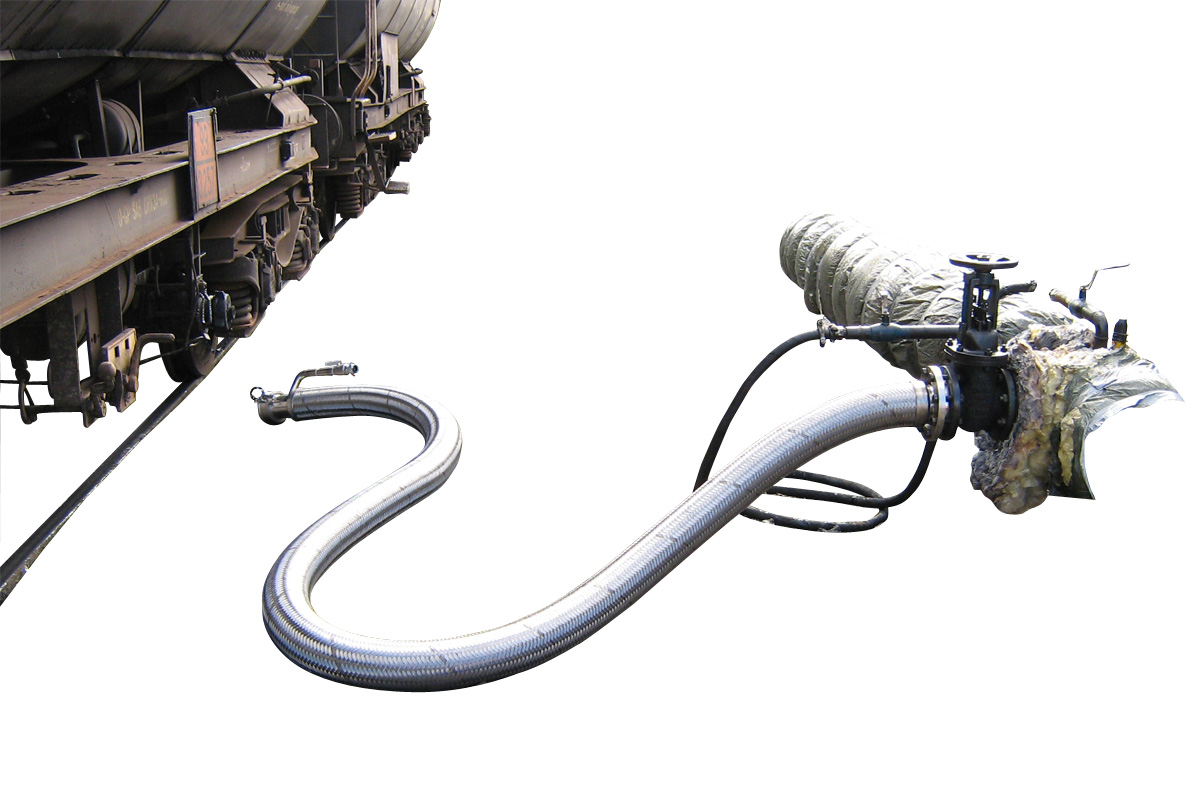

Illustrative image related to offshore transfers hoses

What Makes High-Pressure Hoses Essential for Drilling Operations?

High-pressure hoses are built to endure extreme pressure conditions, making them indispensable in hydraulic systems and drilling operations. These hoses provide the necessary strength and durability to handle demanding tasks, ensuring reliable performance in critical applications. Buyers should consider the specific pressure ratings and weight of these hoses, as they can be heavier and more challenging to manage. Despite their potential drawbacks, the safety and efficiency they provide in high-stress environments justify their use in offshore operations.

Key Industrial Applications of offshore transfers hoses

| Industry/Sector | Specific Application of Offshore Transfers Hoses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Bunkering Operations | Ensures safe and efficient transfer of fuels | Compliance with international safety standards |

| Marine Transportation | Ship-to-Ship Transfers | Facilitates seamless fuel and cargo transfer at sea | Durability against harsh marine conditions |

| Chemical Processing | Chemical Transfer | Safe transportation of hazardous materials | Material compatibility and certification for chemicals |

| Water Management | Sea-Water Intake Systems | Reliable water sourcing for offshore applications | Resistance to corrosion and marine growth |

| Renewable Energy | Hydraulic Systems for Wind Turbines | Supports operational efficiency in energy generation | High-pressure ratings and flexibility requirements |

How Are Offshore Transfers Hoses Used in Oil and Gas Operations?

In the oil and gas industry, offshore transfers hoses are primarily used for bunkering operations, where fuel is transferred from shore to offshore platforms or between vessels. These hoses are designed to handle high-pressure and high-volume transfers safely, mitigating risks of spills and leaks. For international buyers, especially from regions like Africa and South America, it is critical to ensure that these hoses meet the stringent safety and environmental regulations applicable in their jurisdictions. Additionally, buyers should consider sourcing hoses that provide certifications for fire resistance and chemical compatibility, reflecting the harsh conditions often encountered in offshore environments.

What Role Do Offshore Transfers Hoses Play in Marine Transportation?

In marine transportation, offshore transfers hoses are essential for ship-to-ship (STS) transfers, allowing vessels to exchange fuel or cargo while at sea. This application is particularly beneficial in regions where port access may be limited, as it enables efficient logistics and operational flexibility. Buyers from regions such as the Middle East and Europe should prioritize hoses that are robust enough to withstand the corrosive marine environment and can be easily deployed and retracted. Ensuring compliance with international maritime safety regulations is also crucial for mitigating risks associated with fuel transfer operations.

Illustrative image related to offshore transfers hoses

How Are Offshore Transfers Hoses Used in Chemical Processing?

Offshore transfers hoses are vital in the chemical processing sector for the safe transportation of various hazardous materials. These hoses must be constructed from materials that are resistant to chemical degradation and can handle the specific pressures involved in transferring these substances. For international B2B buyers, particularly in emerging markets like Nigeria and Brazil, sourcing hoses that are certified for chemical compatibility and safety standards is imperative to prevent environmental hazards and ensure worker safety. Regular inspection and maintenance protocols should also be established to uphold operational integrity.

How Do Offshore Transfers Hoses Support Water Management?

In water management, offshore transfers hoses are utilized in sea-water intake systems, which are crucial for providing water for cooling and other operational needs on offshore platforms. These hoses must be capable of withstanding marine growth and corrosion while maintaining structural integrity under various environmental conditions. Buyers in regions with extensive offshore operations should consider hoses that offer superior resistance to biofouling and have a long service life to minimize replacement costs. Additionally, integrating sensors for monitoring flow rates and pressure can enhance operational efficiency.

What Is the Importance of Offshore Transfers Hoses in Renewable Energy?

In the renewable energy sector, particularly in offshore wind farms, offshore transfers hoses are used in hydraulic systems that operate turbines and other equipment. These hoses must exhibit high-pressure ratings and flexibility to accommodate the dynamic movements of offshore installations. For international buyers, especially in Europe where renewable energy investments are significant, sourcing hoses that comply with stringent European standards for pressure and durability is essential. Buyers should also evaluate the supply chain reliability to ensure timely delivery and support for maintenance needs.

3 Common User Pain Points for ‘offshore transfers hoses’ & Their Solutions

Scenario 1: Navigating Compliance and Safety Regulations in Offshore Operations

The Problem: B2B buyers often struggle with ensuring that their offshore transfer hoses meet stringent compliance and safety regulations. This issue is particularly critical in regions like Africa and South America, where regulatory frameworks can vary significantly. Buyers may find themselves overwhelmed by the need to meet specific standards—such as those outlined in the Dutch guideline NPR5527:2009 for hose inspections—which can lead to operational delays and financial penalties if overlooked.

The Solution: To mitigate compliance risks, it is essential for buyers to partner with reputable suppliers who understand local regulations and international standards. Conduct thorough due diligence on potential vendors, asking for documentation of their compliance certifications and testing procedures. When sourcing hoses, prioritize those that come with a pressure test report and a clear maintenance protocol. Establish a routine inspection schedule for your hoses, leveraging the supplier’s inspection services if available. This proactive approach not only ensures compliance but also enhances safety and reliability during offshore operations.

Illustrative image related to offshore transfers hoses

Scenario 2: Addressing the Challenge of Hose Durability in Harsh Environments

The Problem: Offshore environments are notoriously harsh, characterized by extreme temperatures, saltwater exposure, and pressure variations. B2B buyers often face the challenge of sourcing hoses that can withstand these conditions without degrading. A failure in hose integrity can lead to leaks or bursts, resulting in costly downtime and potential environmental hazards.

The Solution: Invest in high-quality, specialized offshore transfer hoses designed for durability under extreme conditions. When selecting hoses, prioritize those made from advanced materials such as high-grade rubber, polyurethane, or specially formulated plastics that offer superior resistance to abrasion, chemicals, and temperature fluctuations. Work closely with suppliers to customize hoses that meet the specific requirements of your operational environment. Implement regular performance testing and condition monitoring to identify wear and tear early, thus preventing catastrophic failures.

Scenario 3: Streamlining Logistics and Inventory Management of Hose Supplies

The Problem: B2B buyers often encounter logistical headaches related to the procurement and storage of offshore transfer hoses. Delays in delivery can disrupt operations, while improper inventory management can lead to excess stock or shortages, both of which have financial implications. Buyers may also struggle with understanding the optimal quantities and types of hoses needed for different offshore projects.

Illustrative image related to offshore transfers hoses

The Solution: To streamline logistics, establish a robust inventory management system that tracks hose usage, performance, and replacement schedules. Collaborate with suppliers who offer just-in-time delivery services, ensuring that hoses arrive when needed without the burden of excess inventory. Utilize data analytics to forecast usage based on project timelines and historical data, allowing for more precise ordering. Consider developing a partnership with a logistics provider familiar with the offshore industry to enhance delivery efficiency and reduce lead times. This approach not only minimizes costs but also ensures that you have the right hoses available for any project at any time.

Strategic Material Selection Guide for offshore transfers hoses

What Are the Key Materials Used in Offshore Transfer Hoses?

When selecting materials for offshore transfer hoses, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and compatibility with specific media. Here, we analyze four common materials used in the manufacturing of offshore transfer hoses, providing insights that are particularly relevant to international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

How Does Rubber Perform in Offshore Transfer Hoses?

Rubber is a widely used material for offshore transfer hoses due to its excellent flexibility and resilience. It can withstand a range of temperatures, typically from -40°C to 100°C, making it suitable for various offshore applications. Additionally, rubber hoses exhibit good pressure ratings, often exceeding 10 bar, depending on the formulation.

Illustrative image related to offshore transfers hoses

Pros: Rubber hoses are durable and resistant to wear, making them ideal for high-abrasion environments. They are also relatively cost-effective, which is a significant consideration for large-scale projects.

Cons: However, rubber is susceptible to degradation from certain chemicals and UV exposure, which can limit its application in harsh offshore environments. Additionally, manufacturing rubber hoses can be complex, requiring specialized processes.

Impact on Application: Rubber is compatible with a wide range of media, including water, oil, and some chemicals, but users must verify compatibility to avoid failure.

What Are the Advantages of Using Polyurethane in Offshore Hoses?

Polyurethane is gaining popularity for offshore transfer hoses due to its superior abrasion resistance and flexibility. It can handle temperatures ranging from -30°C to 80°C and offers high pressure ratings, often exceeding 15 bar.

Pros: The primary advantage of polyurethane is its exceptional durability, which extends the lifespan of hoses in demanding conditions. It is also lighter than rubber, which can reduce shipping costs and ease installation.

Cons: The main drawback is its higher cost compared to rubber, which may deter some buyers. Additionally, polyurethane can be more challenging to manufacture, leading to longer lead times.

Impact on Application: Polyurethane hoses are compatible with various media, including fuels and chemicals, making them versatile for offshore operations. However, buyers should ensure compliance with international standards, such as ASTM or DIN, to meet safety regulations.

Why is PVC a Common Choice for Offshore Hoses?

Polyvinyl chloride (PVC) is another material often used in offshore transfer hoses. It is known for its chemical resistance and can operate at temperatures from -10°C to 60°C.

Illustrative image related to offshore transfers hoses

Pros: PVC hoses are lightweight and cost-effective, making them an attractive option for many applications. They also offer good resistance to a variety of chemicals, enhancing their usability in offshore environments.

Cons: The pressure ratings for PVC hoses are generally lower than those of rubber or polyurethane, often around 6-8 bar. Additionally, PVC can become brittle over time, especially when exposed to UV light, which may limit its lifespan.

Impact on Application: PVC is suitable for transferring water and some chemicals but may not be ideal for high-pressure applications. International buyers should consider local regulations regarding material safety and environmental impact.

What Role Does Stainless Steel Play in Offshore Hose Assemblies?

Stainless steel is often used for fittings and couplings in offshore hose assemblies due to its outstanding corrosion resistance and strength. It can withstand extreme temperatures and pressures, making it suitable for high-stress applications.

Pros: The primary advantage of stainless steel is its durability and ability to resist corrosion, which is crucial in marine environments. It also has a long lifespan, reducing the need for frequent replacements.

Illustrative image related to offshore transfers hoses

Cons: However, stainless steel is more expensive than other materials, which can increase the overall cost of hose assemblies. Additionally, its weight may complicate installation and handling.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including corrosive chemicals and hydrocarbons. Buyers should ensure that their suppliers comply with international standards for material quality and safety.

Summary Table of Material Selection for Offshore Transfer Hoses

| Material | Typical Use Case for offshore transfers hoses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General fluid transfer, oil, and water | Durable and cost-effective | Susceptible to UV and chemical degradation | Medium |

| Polyurethane | High-abrasion applications, fuels | Exceptional durability and flexibility | Higher cost and complex manufacturing | High |

| PVC | Water and some chemical transfers | Lightweight and cost-effective | Lower pressure ratings and brittleness | Low |

| Stainless Steel | Hose fittings and couplings | Excellent corrosion resistance | Higher cost and heavier weight | High |

This analysis provides a comprehensive overview of the materials commonly used in offshore transfer hoses, equipping international B2B buyers with the information necessary to make informed purchasing decisions. Understanding these materials’ properties, advantages, and limitations is crucial for ensuring compliance with industry standards and optimizing operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for offshore transfers hoses

What Are the Key Stages in the Manufacturing Process of Offshore Transfer Hoses?

The production of offshore transfer hoses involves a systematic approach that emphasizes both material integrity and performance reliability. Understanding the main stages of manufacturing can help B2B buyers assess the quality and suitability of hoses for their specific applications.

Material Preparation: What Materials Are Used?

The manufacturing process begins with selecting high-quality materials tailored for specific operational requirements. Common materials include:

Illustrative image related to offshore transfers hoses

- Rubber Compounds: These are often used for flexibility and durability, suitable for various marine applications.

- Polyurethane: Known for its abrasion resistance and flexibility, polyurethane is commonly utilized in environments subject to wear and tear.

- Reinforcement Materials: Steel wires or synthetic fibers are incorporated to enhance strength and pressure resistance.

Before production, these materials undergo rigorous testing to ensure they meet international standards, which is essential for offshore operations.

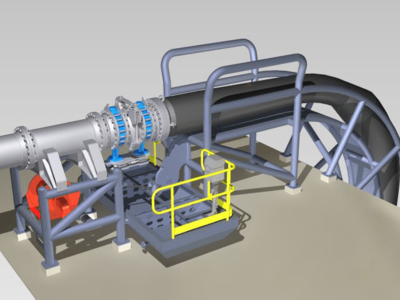

How Are Offshore Transfer Hoses Formed?

The forming stage involves shaping the prepared materials into hose components. This typically includes:

- Extrusion: This method shapes rubber or polyurethane into long hoses through a die, allowing for continuous lengths that can be cut to required specifications.

- Molding: For components such as couplings and end fittings, materials are often molded to achieve precise shapes and dimensions.

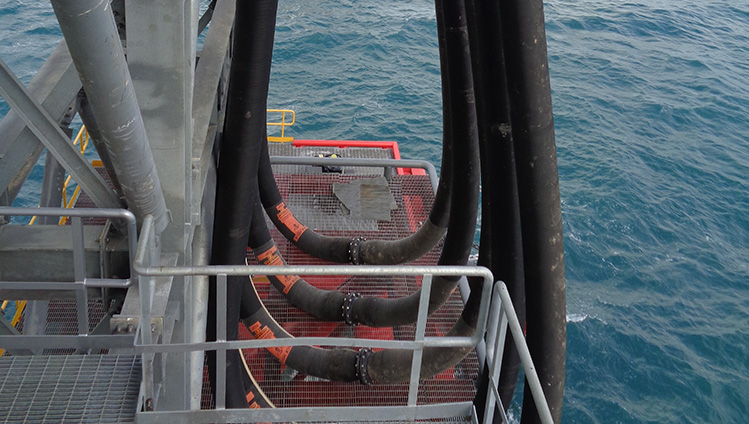

- Braiding: Reinforcement layers are braided around the hose core to enhance strength and flexibility. This is critical for high-pressure applications, ensuring that the hoses can withstand significant forces during operation.

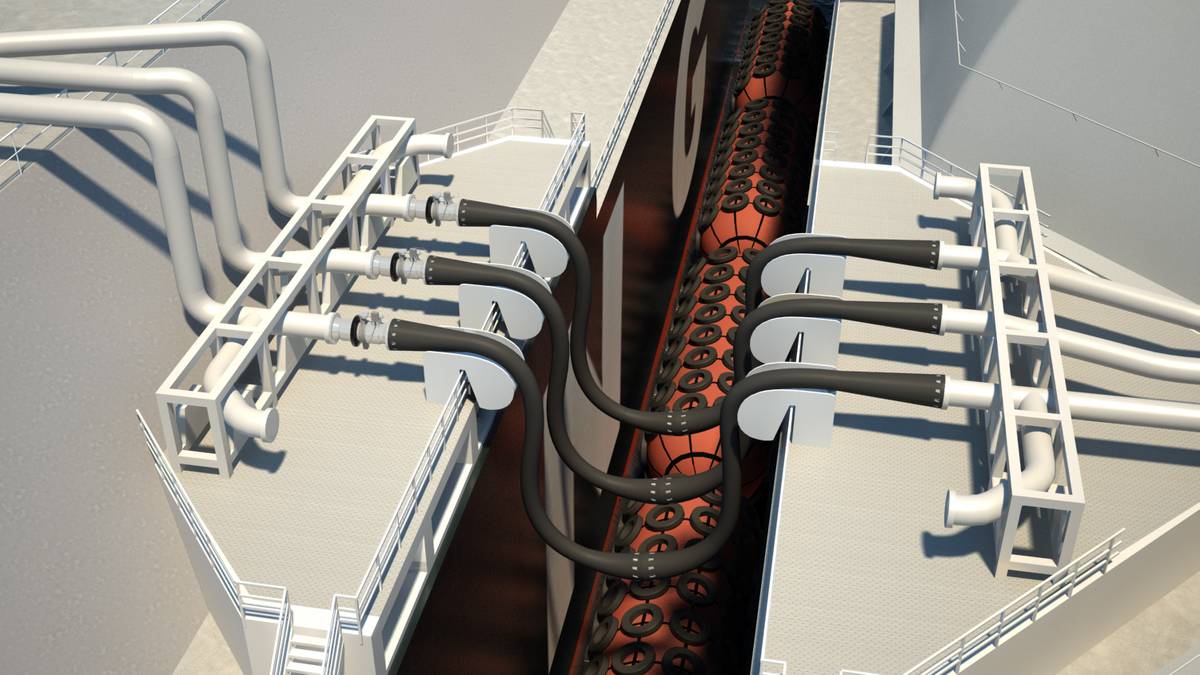

What Does the Assembly Process Entail?

Once the individual components are formed, they are assembled into complete hose systems. This stage may involve:

- Coupling Attachment: End fittings are attached using specialized techniques to ensure a secure connection that can handle high pressures.

- Tagging and Identification: Hoses can be tagged with colored labels for easy identification, which is beneficial for inventory management and operational efficiency.

Quality control measures are crucial during assembly to prevent defects that could compromise performance.

How Is the Finishing Stage Conducted?

The finishing stage focuses on preparing the hoses for delivery and ensuring they meet all specifications. This includes:

Illustrative image related to offshore transfers hoses

- Surface Treatment: Hoses may undergo treatments to enhance resistance to environmental factors such as UV exposure and chemical degradation.

- Pressure Testing: Each hose assembly is subjected to pressure testing to verify its integrity and performance under operational conditions.

This final inspection is vital, as it confirms that the hoses meet the stringent demands of offshore applications.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance in the manufacturing of offshore transfer hoses is critical for ensuring safety and compliance with international standards. B2B buyers should be familiar with several key certifications and quality control checkpoints.

What Are the Relevant International Standards for Offshore Hoses?

- ISO 9001: This standard outlines criteria for a quality management system and is crucial for ensuring consistent product quality.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health and safety standards.

- API Standards: The American Petroleum Institute (API) provides specifications for hoses used in the oil and gas industry, ensuring they meet rigorous operational requirements.

Understanding these certifications helps B2B buyers gauge the reliability and safety of the products they are purchasing.

What Are the Key QC Checkpoints in Hose Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure product integrity. These checkpoints include:

- Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards.

- Final Quality Control (FQC): The final inspection includes pressure testing and surface assessments to ensure that the finished product is free from defects.

These checkpoints are essential for minimizing risks associated with defective products.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are practical steps to ensure compliance and quality:

What Should Buyers Look for in Supplier Audits?

- Supplier Audits: Conducting audits or requesting audit reports can provide insights into a supplier’s quality management practices. Buyers should inquire about the frequency and scope of these audits.

- Documentation: Suppliers should provide documentation of quality control processes, including inspection and testing protocols.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s adherence to quality standards.

What Are the QC and Certification Nuances for International Buyers?

International buyers may encounter unique challenges related to quality assurance. Key considerations include:

- Understanding Regional Standards: Different regions may have varying standards and regulations, so it’s essential for buyers to be aware of these differences.

- Logistical Considerations: The transport of hoses across borders may require additional certifications or inspections, which can affect delivery timelines and costs.

- Cultural Factors: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and compliance.

By understanding these nuances, buyers can make informed decisions when selecting suppliers for offshore transfer hoses.

Conclusion: Why Is Quality Assurance Essential for Offshore Transfer Hoses?

The manufacturing processes and quality assurance protocols for offshore transfer hoses are critical to ensuring safety, reliability, and compliance in demanding environments. B2B buyers must remain vigilant in assessing suppliers, understanding manufacturing techniques, and verifying quality control measures to safeguard their investments and operational efficiency. By prioritizing these aspects, companies can secure high-performance hoses that meet the rigorous demands of offshore applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘offshore transfers hoses’

To effectively procure offshore transfer hoses, it’s essential to follow a structured approach that ensures you select the right products and suppliers for your specific needs. This guide provides a comprehensive checklist to assist international B2B buyers in navigating the complexities of sourcing offshore transfer hoses.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes specifications such as hose type (e.g., chemical, marine, or bunkering hoses), diameter, length, and pressure ratings.

– Why It Matters: Defining these parameters helps in identifying the correct hoses for your operations, ensuring safety and compliance with industry standards.

Step 2: Research Regulatory Compliance Requirements

Understand the regulatory frameworks governing offshore operations in your region. Different countries may have specific standards, such as the Dutch guideline NPR5527:2009 for hose inspections.

– What to Look For: Check if the hoses meet local and international certifications. This ensures that your procurement aligns with safety and environmental regulations, mitigating risks of non-compliance.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to assess their credibility and reliability. Request company profiles, product catalogs, and customer testimonials.

– Why It Matters: A reputable supplier can provide quality products and responsive service. Look for suppliers with experience in the offshore industry and positive feedback from clients in similar regions.

Illustrative image related to offshore transfers hoses

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers possess relevant certifications such as ISO 9001 or other industry-specific qualifications. This step is critical for guaranteeing product quality and safety.

– What to Look For: Certifications indicate a supplier’s commitment to quality management and operational excellence, which are vital in the offshore sector.

Step 5: Request Samples and Conduct Quality Tests

Before finalizing your order, request samples of the hoses to conduct necessary quality tests. Evaluate their performance under pressure and environmental conditions similar to those they will face in use.

– Why It Matters: Testing samples ensures that the hoses meet your operational demands and can withstand the rigors of offshore environments.

Step 6: Inquire About After-Sales Support and Maintenance Services

Ask suppliers about their after-sales support, including maintenance services and hose re-inspection protocols. This can be crucial for the longevity and reliability of your hoses.

– What to Look For: A supplier that offers comprehensive support can save you time and costs in the long run, ensuring your hoses remain in optimal condition.

Illustrative image related to offshore transfers hoses

Step 7: Negotiate Terms and Conditions Clearly

Once you have selected a supplier, negotiate the terms and conditions of the purchase. Discuss pricing, delivery timelines, payment terms, and warranty provisions.

– Why It Matters: Clear agreements prevent misunderstandings and ensure that both parties are aligned on expectations, reducing the risk of disputes down the line.

By following this checklist, B2B buyers can streamline the procurement process for offshore transfer hoses, ensuring they make informed decisions that align with their operational needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for offshore transfers hoses Sourcing

Understanding the cost structure and pricing of offshore transfer hoses is crucial for international B2B buyers. This section delves into the various components influencing costs, pricing strategies, and valuable tips for optimizing procurement.

What Are the Key Cost Components in Offshore Transfer Hoses?

The cost structure for offshore transfer hoses typically includes several critical components:

-

Materials: The primary raw materials used in the production of offshore hoses include high-quality rubber, polyurethane, and other specialized compounds. The choice of material affects not only the performance but also the overall cost. For instance, fire-rated or chemical-resistant hoses generally incur higher material costs due to their enhanced properties.

-

Labor: Labor costs can vary significantly based on the region and the complexity of the hose manufacturing process. Skilled labor is essential for quality assurance during production, especially for custom solutions.

-

Manufacturing Overhead: This includes costs associated with factory operation, machinery maintenance, and utility expenses. Efficient production processes can help minimize these overhead costs, impacting the final pricing.

-

Tooling: Custom tooling for specific hose designs can be a significant upfront investment. This cost is often amortized over the production run, influencing the unit price.

-

Quality Control (QC): Rigorous testing and certification processes are crucial, especially for hoses used in critical applications. Compliance with international standards can lead to additional QC costs, reflected in the pricing.

-

Logistics: Transportation costs play a vital role in the overall cost structure. Factors such as distance, mode of transport, and shipping regulations can significantly affect pricing, especially for international buyers.

-

Margin: Suppliers will typically apply a margin that reflects their operational costs and desired profitability. Understanding the typical margins in your supplier’s market can aid in negotiation.

How Do Price Influencers Affect Offshore Transfer Hose Costs?

Several factors can influence the pricing of offshore transfer hoses:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly impact pricing. Larger orders often lead to volume discounts, making it essential for buyers to assess their needs and negotiate accordingly.

-

Specifications and Customization: Custom hoses tailored to specific applications or operational environments usually come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs.

-

Quality and Certifications: Hoses meeting specific certifications (like API or ISO standards) can command higher prices due to the assurance of quality and safety. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital for pricing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect the total landed cost of the hoses.

What Negotiation Tips Can Help Buyers Secure Better Pricing?

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing and ensure your negotiations are informed. Benchmarking against competitors can provide leverage.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operational efficiency, and potential downtime. This broader perspective can justify a higher initial investment for better quality.

-

Leverage Long-Term Relationships: Building a long-term relationship with suppliers can lead to better pricing and terms. Suppliers are often willing to offer discounts to loyal customers.

-

Be Transparent: Sharing your procurement needs and budget constraints can foster trust and encourage suppliers to provide more competitive offers.

-

Be Prepared to Walk Away: If a supplier’s terms do not meet your expectations, be prepared to explore alternatives. This approach can lead to better deals, as suppliers may revise their offers to retain your business.

Conclusion: What Should International Buyers Keep in Mind?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various complexities in sourcing offshore transfer hoses. Understanding cost components and the factors influencing pricing is essential for making informed decisions. Always consider local market conditions and supplier capabilities, as these can vary widely by region.

Disclaimer: The prices mentioned in this analysis are indicative and subject to change based on market conditions, currency fluctuations, and supplier negotiations.

Illustrative image related to offshore transfers hoses

Alternatives Analysis: Comparing offshore transfers hoses With Other Solutions

Understanding Alternative Solutions for Offshore Transfers

In the offshore industry, the efficiency and safety of transferring fluids are paramount. While offshore transfer hoses are a popular choice, various alternative solutions exist that may suit specific operational needs. This section explores and compares offshore transfer hoses against other methods and technologies, helping B2B buyers make informed decisions.

| Comparison Aspect | Offshore Transfers Hoses | Rigid Piping Systems | Flexible Tubing Systems |

|---|---|---|---|

| Performance | High flexibility and adaptability for various applications. | Excellent flow rates and pressure handling; less flexibility. | Good flexibility and moderate pressure handling. |

| Cost | Moderate initial investment, but costs can accumulate with maintenance. | Higher upfront costs due to installation complexity. | Lower initial costs; however, may require more frequent replacements. |

| Ease of Implementation | Quick to deploy and easy to integrate into existing systems. | Requires significant engineering and installation time. | Simple installation; often requires less specialized knowledge. |

| Maintenance | Needs regular inspection and testing for safety compliance. | Low maintenance once installed; however, repairs can be costly. | Moderate maintenance; can be susceptible to wear and tear. |

| Best Use Case | Ideal for dynamic environments where flexibility is needed, such as ship-to-ship transfers. | Best for fixed installations with consistent fluid transport needs. | Suitable for temporary setups or applications requiring mobility. |

In-Depth Analysis of Alternatives

Rigid Piping Systems

Rigid piping systems are a conventional method for transporting fluids in offshore operations. They offer superior flow rates and pressure handling capabilities, making them suitable for high-volume applications. However, their installation can be complex and costly, requiring significant engineering resources and time. Once in place, they require minimal maintenance, but any repairs can be expensive and labor-intensive. This option is ideal for facilities with fixed installations where the fluid transport requirements are stable and predictable.

Flexible Tubing Systems

Flexible tubing systems provide a middle ground between offshore transfer hoses and rigid piping. They are characterized by their ease of installation and lower initial costs, making them a popular choice for temporary setups or applications that require mobility. However, they may not handle high pressure as effectively as offshore hoses or rigid pipes and can wear out faster, necessitating more frequent replacements. These systems are best suited for operations where flexibility and mobility are prioritized, such as in exploratory drilling or short-term projects.

Illustrative image related to offshore transfers hoses

Choosing the Right Solution for Your Offshore Operations

When selecting the best solution for offshore fluid transfers, B2B buyers must assess their specific needs, including the type of fluids being transported, pressure requirements, and installation constraints. Offshore transfer hoses offer significant flexibility and adaptability, making them suitable for dynamic environments. In contrast, rigid piping systems excel in stability and long-term efficiency but come with higher initial costs and complexity. Flexible tubing systems are ideal for temporary or mobile applications, providing cost-effective solutions with moderate performance.

Ultimately, the decision should align with operational requirements, budget constraints, and long-term maintenance capabilities. By carefully evaluating these aspects, businesses can ensure they choose the most effective and efficient solution for their offshore transfer needs.

Essential Technical Properties and Trade Terminology for offshore transfers hoses

Understanding the technical properties and industry terminology related to offshore transfer hoses is essential for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This knowledge ensures informed purchasing decisions that align with operational needs and regulatory compliance.

What Are the Key Technical Properties of Offshore Transfer Hoses?

1. Material Grade

Offshore transfer hoses are typically constructed from materials such as rubber, polyurethane, and thermoplastics. The choice of material affects durability, flexibility, and resistance to various chemicals and environmental conditions. For B2B buyers, selecting the appropriate material grade ensures that the hoses can withstand the harsh offshore environment, thereby minimizing downtime and maintenance costs.

2. Pressure Rating

The pressure rating indicates the maximum internal pressure the hose can safely handle. This specification is critical, as it must align with the operational pressures of the fluids being transferred. For businesses, understanding pressure ratings is vital to prevent hose failure, which could lead to spills and safety hazards, impacting both operational efficiency and environmental compliance.

3. Temperature Tolerance

Temperature tolerance refers to the range of temperatures that a hose can endure without degrading. Offshore conditions can involve extreme temperatures, so selecting hoses with appropriate tolerance ensures reliability and longevity. This is particularly important for buyers in regions with fluctuating climates, as it affects the operational lifecycle of the hoses.

4. Diameter and Length Specifications

Hoses come in various diameters and lengths, which must be tailored to specific applications. The diameter affects flow rates, while the length impacts pressure loss and installation feasibility. For B2B buyers, understanding these specifications is crucial for ensuring that the hoses fit seamlessly into existing systems, optimizing performance, and reducing installation costs.

5. Coupling and Fitting Compatibility

Compatibility with couplings and fittings is essential for ensuring leak-proof connections. Buyers should consider the type of connections needed for their specific applications, as improper fittings can lead to operational inefficiencies and safety concerns. Ensuring compatibility can also simplify maintenance and replacement procedures.

6. Compliance and Certification

Hoses used in offshore applications must comply with various industry standards and certifications, such as those from the American Petroleum Institute (API) or ISO. Compliance ensures that the hoses meet safety and performance benchmarks. For B2B buyers, selecting certified hoses not only enhances operational safety but also fulfills legal and regulatory obligations.

Illustrative image related to offshore transfers hoses

What Are Common Trade Terms Related to Offshore Transfer Hoses?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify trusted suppliers and gauge the quality of hoses based on their manufacturing origins.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of a product that a supplier is willing to sell. For B2B buyers, being aware of MOQ is crucial for budgeting and inventory planning. It can also affect negotiations and supply chain logistics, especially for smaller companies or those just starting.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details about specific products. This process helps buyers compare options and negotiate terms. For companies looking to optimize costs and ensure quality, mastering the RFQ process is essential.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping, liability, and delivery obligations, facilitating smoother international trade processes.

5. Lead Time

Lead time refers to the duration from placing an order to receiving it. Understanding lead times is crucial for project planning and inventory management. For B2B buyers, minimizing lead time can enhance operational efficiency and responsiveness to market demands.

6. Inspection and Testing Standards

These standards refer to the procedures used to assess the quality and safety of hoses before they are deployed. Being knowledgeable about inspection and testing standards is vital for ensuring that hoses meet required performance specifications, thereby reducing risks associated with equipment failure.

By comprehensively understanding these technical properties and trade terminology, B2B buyers can make more informed decisions when procuring offshore transfer hoses, ultimately enhancing operational efficiency and compliance.

Navigating Market Dynamics and Sourcing Trends in the offshore transfers hoses Sector

What are the Current Market Dynamics and Key Trends for Offshore Transfer Hoses?

The offshore transfer hoses market is experiencing significant growth driven by increasing oil and gas exploration activities, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for efficient and safe transfer of fluids between vessels and offshore platforms is propelling advancements in hose technology. Key trends include the rise of high-pressure hoses designed for extreme conditions, the development of floating hoses that enhance operational flexibility, and the integration of smart technologies for monitoring and maintenance.

Illustrative image related to offshore transfers hoses

Emerging B2B technologies are also reshaping sourcing practices. Companies are increasingly leveraging digital platforms for procurement, allowing buyers to access a wider array of suppliers and products. This shift is particularly relevant for international buyers who seek to streamline their supply chains and reduce lead times. Additionally, the adoption of custom-made solutions is on the rise, as businesses require hoses tailored to specific operational needs, such as varying diameters and lengths for different offshore applications.

Another dynamic shaping the market is regulatory compliance. International standards for safety and environmental protection are compelling suppliers to ensure that their hoses meet rigorous testing and certification processes. For B2B buyers, understanding these regulations is crucial for making informed purchasing decisions.

How is Sustainability Influencing Sourcing Decisions in the Offshore Hoses Sector?

Sustainability is becoming an integral aspect of sourcing strategies in the offshore transfer hoses sector. The environmental impact of oil and gas operations has led to increased scrutiny from governments and stakeholders, prompting companies to adopt more sustainable practices. This includes sourcing hoses that utilize eco-friendly materials and manufacturing processes.

Ethical supply chains are gaining importance as buyers prioritize partnerships with suppliers who demonstrate a commitment to sustainability. This trend is particularly relevant for international buyers from regions like Africa and South America, where environmental regulations are evolving rapidly. Suppliers that can provide green certifications and materials, such as recyclable or biodegradable options, will have a competitive advantage in the marketplace.

Moreover, the focus on sustainability extends to lifecycle management. Companies are investing in hoses designed for durability, reducing the frequency of replacements and minimizing waste. This shift not only lowers operational costs but also enhances brand reputation among environmentally conscious consumers and partners.

How Has the Offshore Transfer Hoses Sector Evolved Over Time?

The offshore transfer hoses sector has evolved significantly over the past few decades. Initially, the focus was primarily on basic functionality and durability, with limited attention paid to safety and environmental considerations. However, as the offshore industry expanded and environmental concerns grew, the demand for high-performance hoses that could withstand harsh marine conditions increased.

Illustrative image related to offshore transfers hoses

Technological advancements have played a crucial role in this evolution. The introduction of synthetic materials and innovative design features has enabled the development of hoses that are not only more resilient but also capable of handling a broader range of fluids, including chemicals and hydrocarbons. Furthermore, the incorporation of smart technologies for monitoring hose conditions has enhanced safety and operational efficiency.

As the market continues to mature, international B2B buyers are encouraged to stay informed about these trends and innovations, ensuring that their sourcing strategies align with both current demands and future developments in the offshore transfer hoses sector.

Frequently Asked Questions (FAQs) for B2B Buyers of offshore transfers hoses

1. How do I solve issues with hose compatibility for offshore transfers?

To address compatibility issues with offshore transfer hoses, first identify the specific requirements of your operation, including the type of fluid being transferred, pressure ratings, and environmental conditions. Consult with suppliers who specialize in offshore hoses, as they can provide insights on materials and designs suited for your needs. Additionally, ensure that the hoses meet relevant industry standards and regulations. A thorough review of technical specifications alongside supplier expertise will help ensure optimal compatibility.

2. What is the best type of offshore transfer hose for crude oil transportation?

The best type of offshore transfer hose for crude oil transportation is typically a flexible, reinforced marine hose designed for high-pressure applications. Look for hoses made from materials resistant to oil and abrasion, such as rubber or synthetic compounds. These hoses should also be compliant with international standards like ISO 1823 for marine applications. For added safety, consider hoses that have been fire-tested and certified, especially when operating in high-risk environments.

3. What factors should I consider when selecting a supplier for offshore transfer hoses?

When selecting a supplier for offshore transfer hoses, consider their industry experience, reputation, and certifications. Look for suppliers who offer a range of products tailored to your specific needs, including customization options. It’s also essential to evaluate their quality assurance processes and after-sales support, such as inspection and maintenance services. Request references from other clients and assess their responsiveness to inquiries as part of your vetting process.

Illustrative image related to offshore transfers hoses

4. What are the typical minimum order quantities (MOQ) for offshore transfer hoses?

Minimum order quantities (MOQ) for offshore transfer hoses can vary significantly based on the supplier and the specific hose type. Generally, MOQs can range from 500 meters to several thousand meters, depending on the material and customization requirements. Suppliers often have a minimum order amount to ensure profitability, which may be around €2,000 or equivalent. Always confirm MOQs with your supplier before placing an order to avoid unexpected costs.

5. How can I ensure the quality of offshore transfer hoses before purchase?

To ensure the quality of offshore transfer hoses, request detailed product specifications, including material composition, pressure ratings, and compliance with international standards. Ask for samples and certifications from recognized testing organizations. Additionally, inquire about the supplier’s quality assurance processes, including any testing protocols they follow before shipping products. A reputable supplier will provide documentation such as pressure test reports for new hoses.

6. What payment terms are typically offered for international orders of offshore transfer hoses?

Payment terms for international orders of offshore transfer hoses can vary widely among suppliers. Common terms include a percentage deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment upon receipt, depending on the buyer’s creditworthiness. Always clarify payment terms during negotiations and ensure they align with your financial capabilities and risk management strategies.

7. What are the logistics considerations for shipping offshore transfer hoses internationally?

When shipping offshore transfer hoses internationally, consider factors such as shipping methods, customs regulations, and lead times. Ensure that the supplier can provide documentation for customs clearance, including invoices and certificates of origin. Evaluate shipping options, such as sea freight for bulk orders, which is cost-effective but may have longer transit times. Additionally, coordinate with logistics providers to manage delivery schedules and mitigate potential delays.

8. Are there customization options available for offshore transfer hoses?

Yes, many suppliers offer customization options for offshore transfer hoses to meet specific operational needs. This may include variations in length, diameter, and material composition, as well as features like color coding for identification or specialized fittings. Discuss your requirements with the supplier early in the sourcing process to explore available options. Customization can enhance performance and ensure that the hoses fit seamlessly into your existing systems.

Top 6 Offshore Transfers Hoses Manufacturers & Suppliers List

1. Continental – High Performance Offshore Hoses

Domain: continental-industry.com

Registered: 2018 (7 years)

Introduction: This company, Continental – High Performance Offshore Hoses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Ridderflex – Offshore Hoses

Domain: ridderflex.com

Registered: 2007 (18 years)

Introduction: Ridderflex supplies a wide range of hoses for the offshore industry, including: Bulk transfer hose, Bunkering hose, Chemical hose, Discharge hose, Fire rated hose, Floating hose, High pressure hose, Hydraulic hose, Marine hose, RIG Supply hose, Sea-water intake systems, STS hose (ship-to-ship), Suction hose, Utility hose. Hoses can be assembled in various lengths, diameters, and types, and can be …

3. Rubber Worx – Petroleum Transfer Hoses

Domain: rubberworxhose.com

Registered: 2020 (5 years)

Introduction: Petroleum transfer hoses are specifically designed for the demands of oil and fuel transfer, suitable for diesel, petroleum, gasoline, and oily water. Key types include: 1. 150 PSI Petroleum Transfer Hose: Designed for discharge and suction applications in tank car and truck transfers of petroleum-based products. Made of oil-resistant Nitrile tubing with a cover that resists hydrocarbons, ozone, a…

4. Offspring International – Fluid Transfer Hoses

Domain: offspringinternational.com

Registered: 2000 (25 years)

Introduction: Offspring International offers a range of hoses for fluid transfer applications including oil suction & discharge, LPG suction & discharge, and fuel transfer. All hoses are manufactured and tested according to industry standards such as OCIMF GMPHOM 2009 and certified by the American Bureau of Shipping (ABS). The range includes:

1. Single Carcass Hoses: Available in diameters of 6-24″ (150-600mm)…

5. Offshore Marine Hoses – STS Offshore Hoses

Domain: offshoremarinehoses.com

Registered: 2023 (2 years)

Introduction: STS (Ship-to-Ship) Offshore Hoses are designed for transporting fluids such as crude oil, petroleum products, liquefied natural gas (LNG), chemicals, and potable water between two vessels at sea. Key features include:

– Adaptability to various fluids, ensuring compatibility to prevent contamination.

– Safety measures are crucial, requiring strict adherence to protocols to minimize spills and acc…

6. JW Roberts – Industrial Hoses for Offshore Applications

Domain: jwroberts.com

Registered: 1998 (27 years)

Introduction: Industrial hoses for offshore applications are designed to withstand harsh conditions such as sea water, vibrations, and fluctuating temperatures. They are used for transferring materials like fresh water, raw water, mud, dredging slurry, vessel fuel, lubrication oil, and chemicals. Key features include heavy-duty construction, specialized safety features like safety breakaway couplings, and compl…

Strategic Sourcing Conclusion and Outlook for offshore transfers hoses

As the offshore industry continues to evolve, strategic sourcing of transfer hoses becomes increasingly critical for international B2B buyers. Understanding the diverse applications—ranging from bulk transfer to specialized chemical handling—enables companies to select the right products that meet stringent safety and performance standards. Engaging with reliable suppliers who offer customized solutions and rigorous inspection services can enhance operational efficiency and reduce downtime.

Moreover, regional considerations are vital. Buyers from Africa, South America, the Middle East, and Europe must navigate unique regulatory environments and market demands. Establishing partnerships with manufacturers who understand these dynamics can lead to cost-effective solutions that align with local needs.

Looking ahead, the demand for innovative and sustainable hose solutions will only grow. Companies should prioritize suppliers who are committed to sustainability and can provide advanced materials suitable for emerging energy sectors, such as renewables and hydrogen.

By taking proactive steps in sourcing offshore transfer hoses, businesses can not only enhance their supply chain resilience but also position themselves for future growth in an increasingly competitive landscape. Explore your options today and connect with trusted suppliers to secure your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.