Introduction: Navigating the Global Market for juntes de dilatació

In the dynamic world of construction and infrastructure, sourcing the right juntes de dilatación (expansion joints) can be a daunting task for international B2B buyers. With the potential for costly structural damage arising from improper installation or material selection, understanding the nuances of these critical components is essential. This guide is designed to illuminate the complexities surrounding expansion joints, providing a comprehensive resource on their various types, applications, and the best practices for supplier vetting.

Navigating the global market requires insight into regional preferences and standards, especially for buyers from diverse regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil. By delving into the different types of juntes de dilatación—ranging from sealed to open joints—and their specific applications in walls, pavements, and terraces, this guide empowers decision-makers to make informed choices.

Additionally, we will explore cost considerations, maintenance recommendations, and how to effectively assess potential suppliers to ensure quality and compliance with international standards. With this knowledge at hand, B2B buyers can confidently procure expansion joints that not only meet their project requirements but also enhance the longevity and safety of their constructions.

Table Of Contents

- Top 2 Juntes De Dilatació Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for juntes de dilatació

- Understanding juntes de dilatació Types and Variations

- Key Industrial Applications of juntes de dilatació

- 3 Common User Pain Points for ‘juntes de dilataci√≥’ & Their Solutions

- Strategic Material Selection Guide for juntes de dilatació

- In-depth Look: Manufacturing Processes and Quality Assurance for juntes de dilatació

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘juntes de dilataci√≥’

- Comprehensive Cost and Pricing Analysis for juntes de dilatació Sourcing

- Alternatives Analysis: Comparing juntes de dilatació With Other Solutions

- Essential Technical Properties and Trade Terminology for juntes de dilatació

- Navigating Market Dynamics and Sourcing Trends in the juntes de dilatació Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of juntes de dilatació

- Strategic Sourcing Conclusion and Outlook for juntes de dilatació

- Important Disclaimer & Terms of Use

Understanding juntes de dilatació Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open Expansion Joints | Allow for movement with unsealed spaces; prone to dirt accumulation. | Initial construction phases, large areas. | Pros: Cost-effective; Cons: Higher maintenance due to dirt. |

| Sealed Expansion Joints | Filled with elastic materials to prevent moisture and dirt intrusion. | High-traffic areas, commercial buildings. | Pros: Better durability; Cons: Higher initial cost. |

| Wall Expansion Joints | Designed for vertical and horizontal movement in walls. | High-rise buildings, retaining walls. | Pros: Prevents cracking; Cons: Requires precise installation. |

| Pavement Expansion Joints | Accommodate surface movement in pavements due to temperature changes. | Roads, parking lots, and sidewalks. | Pros: Reduces cracking; Cons: Needs regular inspection. |

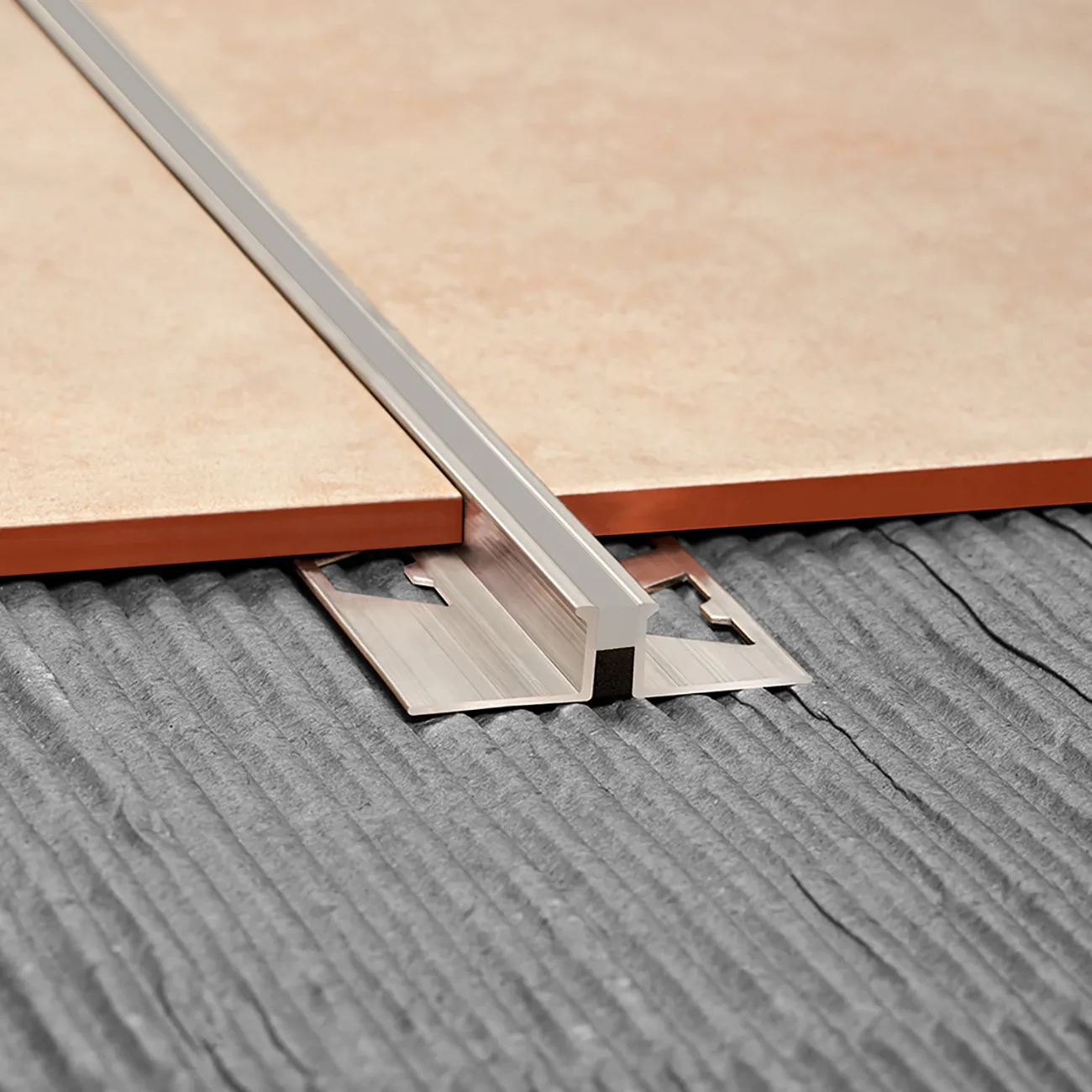

| Ceramic Tile Expansion Joints | Specifically designed for tile installations to manage dimensional changes. | Residential and commercial flooring. | Pros: Aesthetic finish; Cons: Limited to specific materials. |

What Are Open Expansion Joints and When Should They Be Used?

Open expansion joints are characterized by their unsealed design, allowing for movement without obstruction. They are typically utilized during the initial construction phase, especially in large areas where significant expansion and contraction are anticipated. While they are cost-effective, their open nature can lead to dirt accumulation, necessitating more frequent maintenance. B2B buyers should consider the long-term maintenance implications when opting for this type.

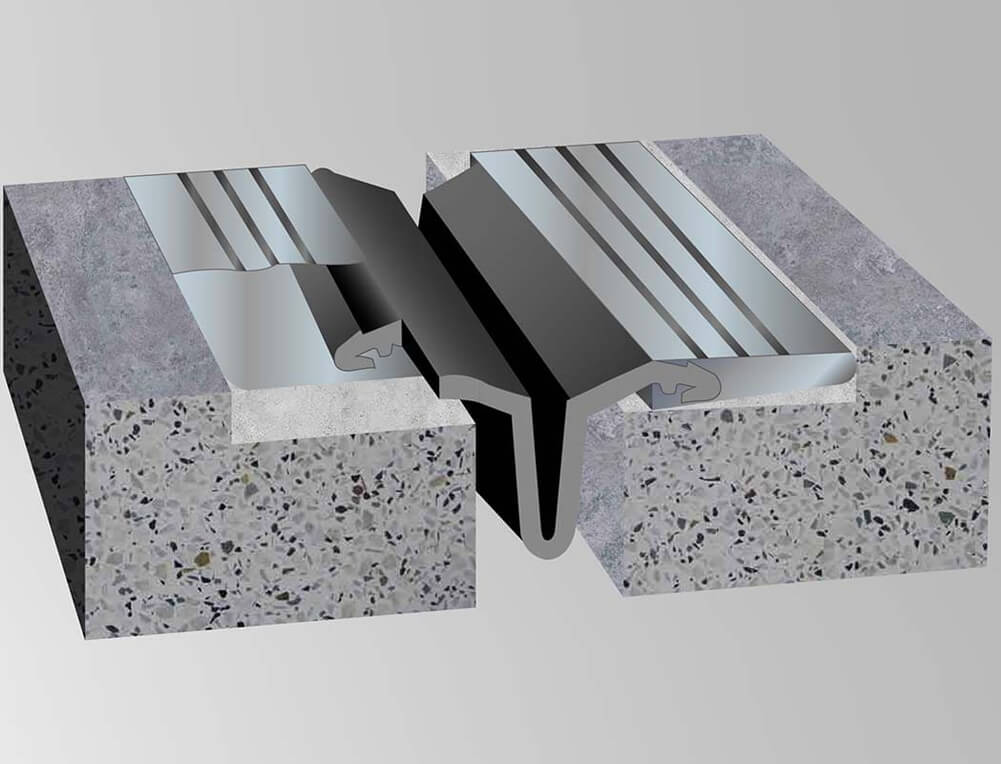

How Do Sealed Expansion Joints Enhance Structural Integrity?

Sealed expansion joints are filled with flexible materials that offer enhanced protection against moisture and dirt. These joints are particularly suitable for high-traffic areas in commercial buildings where durability is paramount. Although they come with a higher initial cost, their ability to withstand environmental factors makes them a wise investment for long-term structural integrity. Buyers should evaluate the potential savings in maintenance and repairs when considering this option.

Illustrative image related to juntes de dilatació

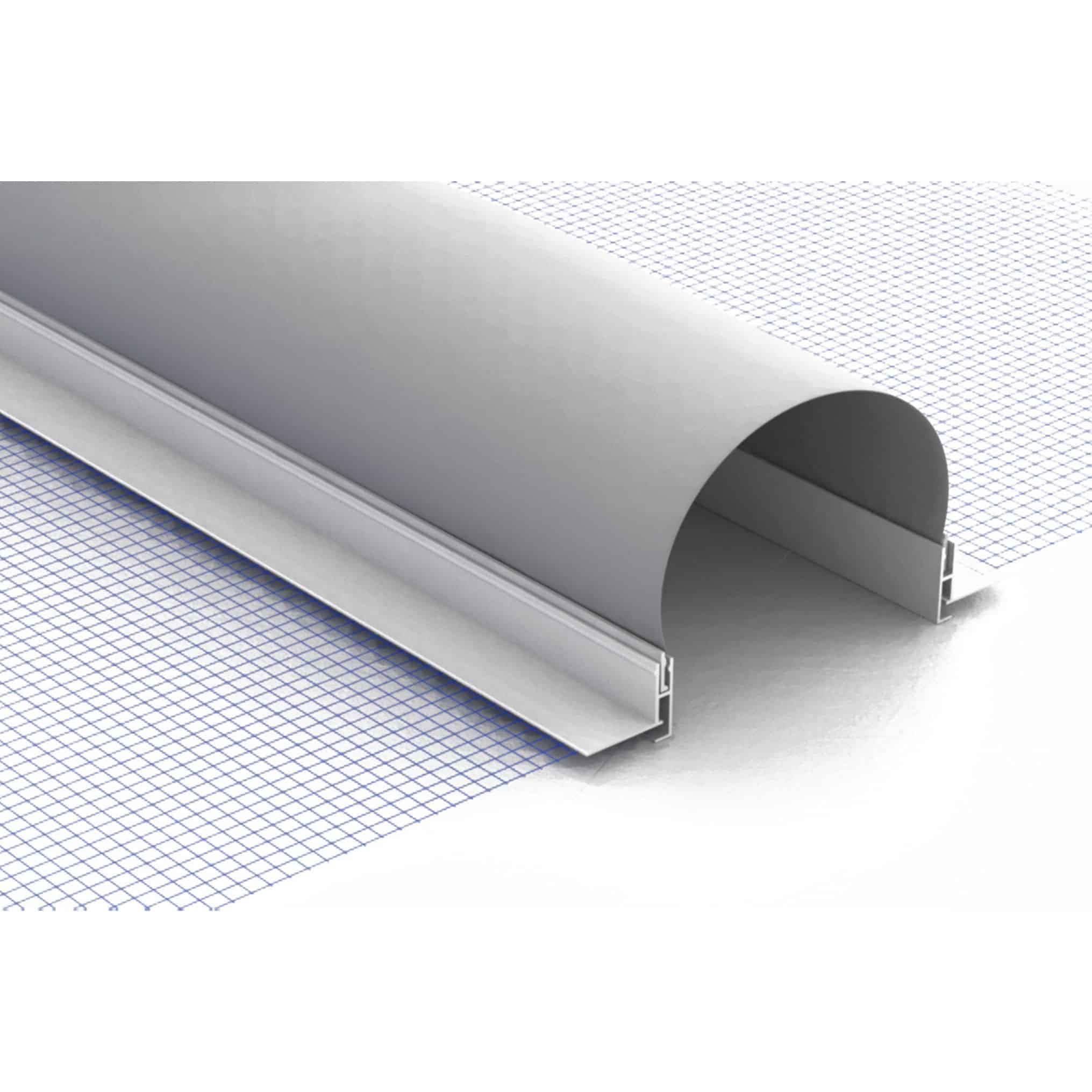

Why Are Wall Expansion Joints Critical for High-Rise Structures?

Wall expansion joints are essential for allowing both vertical and horizontal movement in structures, particularly in high-rise buildings and retaining walls. Their design helps prevent cracking and damage due to thermal expansion and contraction. However, they require precise installation to function effectively, which may necessitate specialized labor. B2B buyers should prioritize the experience and expertise of contractors when planning for wall expansion joint installations.

What Role Do Pavement Expansion Joints Play in Infrastructure?

Pavement expansion joints are crucial for accommodating surface movement in roads, parking lots, and sidewalks due to temperature fluctuations. They help reduce the likelihood of cracking and enhance the longevity of pavement structures. Regular inspections are necessary to ensure their effectiveness, which may add to maintenance costs. B2B buyers should factor in the lifecycle costs of pavement expansion joints when budgeting for infrastructure projects.

How Do Ceramic Tile Expansion Joints Contribute to Aesthetic and Functional Flooring?

Ceramic tile expansion joints are specifically designed to manage the dimensional changes of tiles, making them ideal for both residential and commercial flooring applications. They not only provide a visually appealing finish but also help prevent cracking and damage to the flooring system. However, their use is limited to specific materials, which may restrict design options. Buyers should assess their project requirements to determine the best fit for ceramic tile expansion joints.

Key Industrial Applications of juntes de dilatació

| Industry/Sector | Specific Application of juntes de dilatació | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Expansion joints in concrete structures | Prevents cracking and structural damage due to temperature changes | Ensure compliance with local building codes and standards |

| Infrastructure | Joints in roadways and bridges | Enhances durability and safety, reducing maintenance costs | Select materials that withstand local climate conditions |

| Manufacturing | Joints in industrial flooring | Reduces wear and tear, maintains operational efficiency | Consider load-bearing capacity and resistance to chemical exposure |

| HVAC | Expansion joints in ductwork systems | Minimizes noise and vibration, improving system efficiency | Ensure compatibility with various duct materials and sizes |

| Automotive | Joints in automotive assembly lines | Enhances production efficiency and product longevity | Source materials that meet automotive industry standards for durability |

How Are Juntas de Dilatación Used in the Construction Industry?

In the construction sector, juntas de dilatación are integral for managing the expansion and contraction of concrete structures. These joints are strategically placed to absorb movement caused by temperature fluctuations, thereby preventing cracks and structural failure. For international buyers, especially in regions with extreme temperatures, sourcing high-quality, durable materials that comply with local building codes is essential. Proper installation and maintenance of these joints can significantly reduce long-term repair costs.

What Role Do Juntas de Dilatación Play in Infrastructure Projects?

In infrastructure applications, such as roadways and bridges, juntas de dilatación are critical for ensuring safety and durability. They allow for the natural movement of materials without compromising structural integrity, which is especially important in areas prone to seismic activity or extreme weather conditions. Buyers must consider the specific environmental factors of their region when sourcing these materials, as well as their ability to withstand heavy traffic loads and harsh conditions, which can reduce maintenance requirements and extend the lifespan of the infrastructure.

Why Are Juntas de Dilatación Important in Manufacturing?

In manufacturing facilities, juntas de dilatación are commonly used in industrial flooring to accommodate thermal expansion and contraction. This application is crucial for maintaining operational efficiency and minimizing downtime due to flooring repairs. Businesses in this sector should prioritize sourcing joints that can handle the specific loads and chemical exposures typical of their production environments. Choosing the right materials can lead to reduced maintenance costs and increased safety for employees.

How Do Juntas de Dilatación Benefit HVAC Systems?

In HVAC applications, juntas de dilatación are utilized in ductwork systems to manage thermal expansion and contraction, minimizing noise and vibration. This not only improves system efficiency but also enhances comfort levels within buildings. For international buyers, it is vital to select joints that are compatible with various duct materials and sizes, ensuring they meet the specific requirements of the HVAC systems in different climates and building designs.

What Is the Significance of Juntas de Dilatación in Automotive Manufacturing?

In the automotive industry, juntas de dilatación are used in assembly lines to facilitate movement and accommodate thermal expansion. This application is essential for enhancing production efficiency and ensuring the longevity of vehicles. Buyers should consider sourcing materials that meet stringent automotive industry standards for durability and performance, as these factors can significantly impact the overall quality and reliability of the finished products.

3 Common User Pain Points for ‘juntes de dilataci√≥’ & Their Solutions

Scenario 1: Frequent Cracking in Structural Elements

The Problem: A construction company in Brazil is facing ongoing issues with cracking in concrete structures, particularly in large commercial buildings. These cracks not only compromise the aesthetic appeal of the structures but also pose significant safety risks. The team realizes that the lack of properly installed ‘juntes de dilatación’ is a primary contributor to this problem, as the concrete expands and contracts with temperature fluctuations. This situation leads to costly repairs and delays in project timelines, frustrating both the contractors and their clients.

Illustrative image related to juntes de dilatació

The Solution: To address this issue, the company should adopt a comprehensive approach to specifying and installing ‘juntes de dilatación.’ First, they need to conduct a thorough analysis of the construction site, considering factors such as local climate conditions, building materials, and anticipated temperature variations. The recommended distance between joints in concrete structures is generally between 20 to 30 meters, but this should be adapted based on specific project needs.

Investing in high-quality, elastic joint fillers is crucial. Products like Boquiflex offer superior elongation properties, ensuring that the joints can accommodate movement without compromising structural integrity. Regular training for installation teams on the proper application techniques, including the use of sealants, can help maintain the effectiveness of these joints. Conducting periodic inspections and maintenance will also ensure that any wear and tear are addressed before they develop into significant issues.

Scenario 2: Water Infiltration Issues in Exterior Applications

The Problem: A general contractor in Germany is tasked with completing a series of outdoor projects, including terraces and pavements. After a few months of service, they notice that water is seeping through the joints, leading to mold growth and structural deterioration. This not only compromises the quality of the work but also risks the safety of users, leading to potential liability claims. The contractor realizes that inadequate sealing of ‘juntes de dilatación’ is a primary culprit, exacerbated by the region’s frequent rain and temperature shifts.

The Solution: To solve water infiltration issues, the contractor must prioritize the selection and application of appropriate sealing materials for ‘juntes de dilatación.’ They should choose sealants designed for outdoor use, such as those that are UV-resistant and flexible to allow for movement without cracking.

Training installation teams to ensure that joints are properly filled and sealed is essential. The use of a primer before applying the sealant can significantly enhance adhesion and durability. Additionally, incorporating drainage solutions around the joints can help manage water flow, reducing the risk of infiltration. Regular maintenance checks should be scheduled to inspect the condition of the joints and sealants, ensuring they remain intact throughout their service life.

Illustrative image related to juntes de dilatació

Scenario 3: Delays Due to Incorrect Joint Placement

The Problem: A construction firm in South Africa is experiencing delays in their project timelines due to incorrect placement of ‘juntes de dilatación’ during the initial phases of construction. The team discovers that the spacing and alignment do not meet the structural specifications, leading to a need for rework. This situation not only increases costs but also affects relationships with clients who are eager for timely completion.

The Solution: To prevent such delays in future projects, the construction firm should implement a robust planning phase that emphasizes the correct placement of ‘juntes de dilatación.’ Utilizing advanced software for structural modeling can help visualize the correct placement and spacing based on the building design and expected environmental conditions.

Additionally, establishing clear communication channels between architects, engineers, and the construction team can ensure everyone is aligned on specifications. Providing ongoing training to staff about the importance of joint placement and the specific guidelines for various materials will enhance overall project execution. A checklist for joint placement during inspections can serve as a practical tool to ensure compliance and accuracy before moving forward with subsequent construction phases.

Strategic Material Selection Guide for juntes de dilatació

What Are the Key Properties of Common Materials Used for Juntas de Dilatación?

When selecting materials for juntas de dilatación, it is essential to consider their properties to ensure optimal performance in various applications. The most common materials include silicone, polyurethane, asphalt, and rubber. Each material has unique characteristics that influence its suitability for specific environments and applications.

How Does Silicone Compare as a Material for Juntas de Dilatación?

Silicone is widely recognized for its excellent flexibility and temperature resistance, typically rated for use in environments ranging from -60°C to 200°C. Its high elasticity allows it to accommodate significant movement, making it ideal for areas with frequent thermal expansion and contraction.

Pros: Silicone exhibits outstanding durability and resistance to UV light, moisture, and many chemicals, making it suitable for both indoor and outdoor applications. It is also easy to apply and can be painted over after curing.

Cons: However, silicone can be more expensive than other materials and may not adhere well to certain substrates without proper priming. Additionally, it can be less effective in high-pressure applications compared to other sealants.

Impact on Application: Silicone’s compatibility with various media, including water and many solvents, makes it a versatile choice for construction projects across different sectors.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with local standards such as ASTM or DIN, as silicone formulations may vary significantly between manufacturers.

What Advantages Does Polyurethane Offer for Juntas de Dilatación?

Polyurethane is another popular choice for juntas de dilatación due to its robust mechanical properties and resistance to abrasion and chemicals. It generally performs well in a temperature range of -40°C to 80°C.

Pros: This material offers excellent adhesion to a variety of substrates and is highly durable, making it suitable for high-traffic areas. It is also resistant to moisture and can withstand harsh environmental conditions.

Cons: On the downside, polyurethane can be more challenging to apply than silicone and may require specific conditions for curing. It can also be more costly, particularly for high-performance grades.

Impact on Application: Polyurethane’s compatibility with both water and oil-based media enhances its applicability in industrial settings, where exposure to various substances is common.

Considerations for International Buyers: Buyers should verify compliance with local regulations and standards, particularly in regions like Africa and South America, where product specifications may differ.

Why Is Asphalt a Viable Option for Juntas de Dilatación?

Asphalt is often used in construction for sealing joints due to its flexibility and ability to withstand temperature fluctuations. It is typically rated for use in environments ranging from -30°C to 70°C.

Pros: The primary advantage of asphalt is its cost-effectiveness and ease of application. It provides a reliable seal against moisture and is suitable for outdoor applications, particularly in pavements and roads.

Cons: However, asphalt can degrade over time when exposed to UV light and may require regular maintenance. It also has a limited temperature range compared to silicone and polyurethane.

Impact on Application: Asphalt is particularly effective in applications involving heavy traffic and exposure to the elements, making it a common choice for infrastructure projects.

Illustrative image related to juntes de dilatació

Considerations for International Buyers: Buyers should be aware of local standards and practices, especially in Europe, where asphalt formulations may need to meet specific performance criteria.

What Role Does Rubber Play in Juntas de Dilatación?

Rubber, particularly in the form of elastomeric compounds, is used in various construction applications for its flexibility and resilience. It can typically handle temperatures from -50°C to 100°C.

Pros: Rubber offers excellent resistance to weathering, ozone, and UV light, making it suitable for outdoor applications. It also provides good sound insulation and vibration dampening.

Cons: The primary limitation of rubber is its susceptibility to certain chemicals, which can degrade its performance over time. Additionally, it may not be as cost-effective as asphalt or some synthetic options.

Impact on Application: Rubber’s flexibility makes it ideal for applications requiring significant movement, such as in seismic zones or areas with heavy foot traffic.

Illustrative image related to juntes de dilatació

Considerations for International Buyers: Buyers should consider the specific chemical exposure of their applications and ensure compliance with relevant standards in their regions, such as those in Germany or Brazil.

Summary Table of Material Selection for Juntas de Dilatación

| Material | Typical Use Case for juntas de dilatación | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Indoor and outdoor applications | Excellent flexibility and durability | Higher cost and adhesion issues | High |

| Polyurethane | High-traffic areas and industrial settings | Robust mechanical properties | Challenging application | Med |

| Asphalt | Pavements and roads | Cost-effective and easy to apply | Degrades under UV exposure | Low |

| Rubber | Seismic zones and outdoor applications | Good weather resistance | Susceptible to certain chemicals | Med |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their choices for juntas de dilatación, ensuring they select the most suitable material for their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for juntes de dilatació

What Are the Main Stages of Manufacturing Juntas de Dilatación?

The manufacturing process for juntas de dilatación (expansion joints) involves several key stages that ensure the final product meets the durability and performance requirements essential for construction applications. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Juntas de Dilatación?

Material preparation is the first step in manufacturing juntas de dilatación. High-quality raw materials such as elastomers, metals, and composites are sourced based on their specific properties, including flexibility, tensile strength, and resistance to environmental factors. Suppliers must ensure that materials meet relevant industry standards, such as ISO 9001 for quality management systems.

Once the materials are selected, they undergo a rigorous quality check (IQC – Incoming Quality Control) to verify their compliance with specifications. This may include testing for physical properties, chemical composition, and moisture content to prevent defects in the final product.

What Techniques Are Used in Forming Juntas de Dilatación?

The forming stage employs various techniques depending on the type of junta de dilatación being produced. Common methods include:

Illustrative image related to juntes de dilatació

-

Molding: For elastomeric joints, materials are often molded using compression or injection techniques. This allows for precise shapes and dimensions while maintaining the material’s integrity.

-

Extrusion: This technique is commonly used for continuous profiles, where material is forced through a die to create long sections of expansion joint material.

-

Cutting and Machining: For metal components, machining and cutting processes are employed to achieve the required tolerances and surface finishes. This ensures that the joints fit seamlessly into construction applications.

These techniques must be closely monitored during production (IPQC – In-Process Quality Control) to ensure adherence to design specifications.

How Are Juntas de Dilatación Assembled and Finished?

The assembly process involves bringing together various components of the juntas de dilatación. This may include integrating metal plates, elastomeric seals, and other structural elements. The assembly must be performed in a controlled environment to prevent contamination and ensure precision.

Finishing touches include surface treatment and coating applications that enhance durability, such as corrosion resistance for metal components or UV protection for elastomeric materials. The final product undergoes Final Quality Control (FQC) to ensure it meets all design and performance criteria before packaging.

What Are the Relevant International Standards for Quality Assurance?

Quality assurance in the manufacturing of juntas de dilatación is governed by several international standards. Key standards include:

- ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent quality and continuous improvement in manufacturing processes.

- CE Marking: In Europe, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: The American Petroleum Institute (API) sets standards for the oil and gas industry, which may apply to certain types of expansion joints used in these sectors.

B2B buyers must ensure that their suppliers adhere to these standards to guarantee the quality and reliability of the products.

What Quality Control Checkpoints Are Important for Juntas de Dilatación?

Implementing quality control checkpoints throughout the manufacturing process is critical to ensuring product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): Verification of raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing monitoring during production to catch defects early and ensure compliance with design specifications.

- Final Quality Control (FQC): A thorough inspection of the finished product to ensure it meets all quality standards before shipment.

Common testing methods include tensile testing, elongation tests, thermal cycling tests, and resistance to environmental factors. These tests help assess the performance and durability of the joints in real-world conditions.

Illustrative image related to juntes de dilatació

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are some actionable steps:

- Conduct Supplier Audits: Periodic audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

- Request Quality Assurance Reports: Suppliers should provide documentation demonstrating compliance with relevant standards and results from testing and inspections.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality management practices and product performance.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must be aware of certain nuances regarding quality control and certification. For example, while some regions may have strict regulatory requirements, others may be less stringent. Buyers should familiarize themselves with local standards and regulations applicable to their specific market to ensure compliance.

Additionally, understanding the certification process can aid in supplier selection. Not all suppliers may have the same certifications, and those that do may vary in terms of their relevance to specific applications. Thus, engaging in thorough due diligence is essential for mitigating risks associated with quality and performance.

Conclusion

The manufacturing processes and quality assurance protocols for juntas de dilatación are critical for ensuring the longevity and reliability of construction projects. By understanding these processes, B2B buyers can make informed decisions, verify supplier quality, and ultimately select products that meet their specific needs. Investing time in evaluating manufacturers and their quality assurance practices can lead to successful partnerships and high-quality outcomes in construction projects across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘juntes de dilataci√≥’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of ‘juntes de dilatación’ (expansion joints). Understanding the critical aspects of sourcing these components will ensure that your construction projects are resilient and compliant with industry standards. This checklist provides actionable steps to streamline the procurement process, helping you make informed decisions that can save time and resources.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider the specific requirements of your project, including the type of materials, dimensions, and environmental conditions where the expansion joints will be installed. This clarity will help you communicate effectively with potential suppliers.

- Material Requirements: Identify whether you need rubber, asphalt, or other materials based on durability and application.

- Size and Design: Specify the dimensions and design features necessary for your project’s structural integrity.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify reputable suppliers who specialize in expansion joints. Look for companies with a proven track record in the industry and positive customer reviews.

- Industry Experience: Prioritize suppliers with experience in your specific sector, whether it be construction, civil engineering, or infrastructure.

- Geographic Reach: Consider suppliers that have a strong presence in your target markets, such as Africa, South America, or Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step will help you gauge the supplier’s reliability and expertise.

- Quality Assurance: Inquire about their quality control processes and certifications to ensure compliance with international standards.

- Customer Support: Assess their responsiveness and willingness to provide technical assistance or advice.

Step 4: Request Samples and Product Specifications

Always request samples of the expansion joints to evaluate their quality firsthand. Understanding the product specifications will help you assess whether they meet your project’s requirements.

- Performance Testing: Check if the samples have undergone relevant performance tests for durability, flexibility, and resistance to environmental factors.

- Documentation: Ensure that product datasheets and installation guidelines are available to facilitate proper usage.

Step 5: Compare Pricing and Payment Terms

Once you have narrowed down your options, compare pricing structures and payment terms among your shortlisted suppliers. A comprehensive understanding of costs will enable you to make a budget-conscious decision.

- Total Cost of Ownership: Consider not just the purchase price but also installation and maintenance costs.

- Payment Flexibility: Look for suppliers offering favorable payment terms, such as credit options or discounts for bulk purchases.

Step 6: Negotiate Contracts and Terms

Engage in discussions to negotiate contracts that protect your interests. Ensure that all agreed-upon terms, such as delivery timelines, warranties, and after-sales support, are clearly documented.

- Legal Review: Have your legal team review contracts to ensure compliance with local regulations and industry standards.

- Performance Guarantees: Request performance guarantees to safeguard against defects and ensure product reliability.

Step 7: Plan for Ongoing Support and Maintenance

Once the procurement process is complete, establish a plan for ongoing support and maintenance. This will help ensure the longevity and effectiveness of the expansion joints in your projects.

- Regular Inspections: Schedule periodic inspections to identify any potential issues early.

- Supplier Communication: Maintain open lines of communication with your supplier for future needs or replacement parts.

By following this checklist, B2B buyers can streamline their sourcing process for ‘juntes de dilatación,’ ultimately leading to more successful and sustainable construction projects.

Comprehensive Cost and Pricing Analysis for juntes de dilatació Sourcing

What Are the Key Cost Components for Juntas de Dilatación?

The cost structure for juntas de dilatación encompasses several critical components that significantly influence overall pricing. The primary elements include:

-

Materials: The type and quality of materials used are pivotal in determining cost. Common materials include elastomers, sealants, and specialized asphalt. Higher-quality materials typically incur a higher price but offer enhanced durability and performance.

-

Labor: Labor costs vary based on geographical location and the complexity of installation. Skilled labor is essential for ensuring proper installation, which can prevent costly repairs in the future.

-

Manufacturing Overhead: This includes expenses related to production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead costs, allowing for competitive pricing.

-

Tooling: Investment in specialized tooling for the production of various joint types can influence costs. Custom tooling may be necessary for bespoke solutions, impacting both initial and ongoing expenses.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and compliance with international standards. While this adds to the cost, it is crucial for minimizing defects and enhancing customer satisfaction.

-

Logistics: Transportation costs can vary widely based on the distance from the manufacturer to the buyer and the mode of transport. Efficient logistics management can help mitigate these costs.

-

Margin: Suppliers typically add a profit margin to cover business expenses and profit objectives. This margin can vary significantly based on market dynamics and the competitive landscape.

How Do Price Influencers Affect Juntas de Dilatación Pricing?

Several factors can influence the pricing of juntas de dilatación, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in bulk can lead to significant cost savings. Suppliers often offer lower per-unit prices for larger orders, making it beneficial for buyers with high-volume needs.

-

Specifications and Customization: Customized solutions, while often necessary for specific projects, can increase costs. Standardized products typically offer more competitive pricing.

-

Material Quality and Certifications: The presence of certifications (e.g., ISO, CE) can add to costs but is vital for ensuring compliance with local regulations and enhancing product credibility.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge a premium, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers in shipping, which can affect overall costs, including freight and insurance.

What Are the Best Tips for Negotiating Juntas de Dilatación Prices?

B2B buyers should consider the following strategies to optimize their sourcing of juntas de dilatación:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery timelines. A clear understanding of your needs can foster better negotiations.

-

Evaluate Total Cost of Ownership (TCO): Assess not just the initial purchase price but also the long-term costs associated with installation, maintenance, and potential failures. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Understand Pricing Nuances: Pricing can vary significantly by region. For buyers in Africa, South America, the Middle East, and Europe, being aware of local market conditions, currency fluctuations, and import tariffs is essential for effective budgeting.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive products.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of juntas de dilatación is vital for B2B buyers seeking to make informed purchasing decisions. By considering the key cost components, price influencers, and negotiation strategies, buyers can enhance their sourcing efficiency and ensure optimal project outcomes.

Alternatives Analysis: Comparing juntes de dilatació With Other Solutions

Exploring Alternatives to Juntes de Dilatación

In the construction industry, the choice of materials and methods for managing structural movement is critical. Juntes de dilatación, or expansion joints, are designed to accommodate the thermal expansion and contraction of building materials. However, several alternative solutions exist that may better suit specific project requirements or budget constraints. This analysis compares juntes de dilatación with other viable alternatives, providing B2B buyers with insights to make informed decisions.

Comparison Table

| Comparison Aspect | Juntes De Dilatación | Foam Expansion Joint | Rubber Expansion Joint |

|---|---|---|---|

| Performance | Excellent for thermal expansion, preventing cracks | Good for minor movements, less effective under heavy loads | Strong performance under both thermal and mechanical stress |

| Cost | Moderate cost, varies by material | Generally lower cost | Higher initial cost but longer lifespan |

| Ease of Implementation | Requires precise installation and planning | Easy to install, flexible | Moderate complexity, requires proper alignment |

| Maintenance | Low maintenance with regular inspections | Minimal maintenance needed | Requires occasional inspection for wear |

| Best Use Case | Ideal for large structures with significant thermal changes | Suitable for residential projects or smaller structures | Best for industrial applications with heavy machinery |

Detailed Breakdown of Alternatives

Foam Expansion Joint

Foam expansion joints are a cost-effective alternative commonly used in residential and light commercial construction. They offer adequate flexibility to accommodate minor movements caused by temperature changes. The ease of installation is a significant advantage, as these joints can be cut to size and placed directly into the joint space. However, foam joints may not provide sufficient support for heavy loads, making them less suitable for large-scale industrial applications.

Rubber Expansion Joint

Rubber expansion joints are designed to handle both thermal expansion and mechanical stress, making them ideal for industrial environments. They offer superior durability and flexibility, which allows them to absorb vibrations and accommodate significant movement. While the initial investment is higher than that of foam options, their longevity often justifies the cost. Regular inspections are necessary to ensure they remain effective, as wear and tear can occur over time, particularly in high-traffic areas.

Conclusion: Choosing the Right Solution for Your Project

When selecting a solution for managing structural movement, B2B buyers should consider the specific needs of their projects, including performance requirements, budget constraints, and ease of implementation. Juntes de dilatación provide excellent performance in large-scale applications, while alternatives like foam and rubber expansion joints may offer benefits in terms of cost and installation simplicity for smaller projects. Ultimately, understanding the unique demands of each project will guide buyers in making the most informed and effective choice.

Essential Technical Properties and Trade Terminology for juntes de dilatació

What Are the Key Technical Properties of Juntas de Dilatación?

When considering juntas de dilatación, or expansion joints, several technical properties are critical to ensure their effectiveness in construction. Understanding these specifications can help B2B buyers make informed decisions about their projects.

1. Material Grade

The material used in juntas de dilatación significantly impacts their durability and performance. Common materials include elastomeric compounds, metals, and concrete. Each material offers unique properties such as flexibility, temperature resistance, and load-bearing capacity. For instance, elastomeric joints provide excellent flexibility and can accommodate significant movement, making them suitable for dynamic environments.

2. Tolerance Levels

Tolerance refers to the allowable deviation in the dimensions of the joint. Tight tolerances are critical in environments subject to heavy loads or extreme temperatures, as they ensure that the joints function correctly without compromising structural integrity. B2B buyers should consider the specific requirements of their projects to ensure that the tolerance levels align with industry standards and regulations.

Illustrative image related to juntes de dilatació

3. Elongation Capacity

Elongation capacity measures the ability of the joint material to stretch and compress without breaking. This property is essential for accommodating thermal expansion and contraction. A high elongation capacity indicates that the joint can handle significant movement without failing, which is crucial in regions with extreme temperature fluctuations.

4. Compression Set

Compression set is the ability of a material to return to its original thickness after being compressed. A low compression set value is desirable as it indicates that the joint will maintain its effectiveness over time, resisting deformation. This is particularly important for joints in high-traffic areas where repeated compression occurs.

5. Weather Resistance

Weather resistance encompasses the material’s ability to withstand environmental factors such as moisture, UV radiation, and temperature variations. Materials that exhibit high weather resistance will ensure longevity and reliability of the juntas de dilatación, making them a worthwhile investment for B2B buyers looking for sustainable solutions.

What Are Common Trade Terms Related to Juntas de Dilatación?

Familiarity with industry jargon can streamline communication and negotiations. Here are some essential terms relevant to juntas de dilatación:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of juntas de dilatación, understanding whether a supplier is an OEM can help buyers assess the quality and authenticity of the products they are considering.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum amount of product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers as it helps in budgeting and inventory planning, ensuring that they can meet their project requirements without excess expenditure.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products. This term is crucial for B2B transactions involving juntas de dilatación, as it sets the stage for negotiations and procurement processes.

Illustrative image related to juntes de dilatació

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify aspects such as shipping costs, risk transfer, and delivery points. Understanding Incoterms is essential for B2B buyers engaging with international suppliers of juntas de dilatación, as it helps in managing logistics and compliance.

5. Lead Time

Lead time is the period between the initiation of an order and its delivery. In construction projects, understanding lead times for juntas de dilatación can help buyers plan their project schedules effectively, minimizing delays.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies for juntas de dilatación, ensuring they select the right products for their construction needs.

Navigating Market Dynamics and Sourcing Trends in the juntes de dilatació Sector

What Are the Key Market Dynamics Driving the Juntas de Dilatación Sector?

The global market for juntas de dilatación (expansion joints) is influenced by several key drivers, including urbanization, infrastructure development, and increasing awareness of construction quality standards. In regions such as Africa and South America, rapid urbanization is prompting the construction of new buildings and infrastructure, which significantly boosts demand for reliable expansion joints. In Europe, particularly in Germany, strict building regulations and standards necessitate the use of high-quality materials, including expansion joints, to ensure structural integrity and longevity.

Illustrative image related to juntes de dilatació

Emerging technologies, such as advanced materials and innovative sealing solutions, are also shaping the industry. For instance, the development of flexible sealants like Boquiflex, which offer superior elongation and resistance to environmental factors, is attracting attention from international buyers. Additionally, the rise of digital platforms for sourcing and procurement is transforming how B2B buyers engage with suppliers, enabling them to access a wider range of products and services more efficiently.

Moreover, increasing competition in the market is pushing manufacturers to invest in research and development to enhance the performance and durability of their products. As a result, buyers are presented with an array of choices, making it crucial to evaluate suppliers based on quality, reliability, and technological advancements.

How Is Sustainability and Ethical Sourcing Shaping the Juntas de Dilatación Market?

Sustainability is becoming a pivotal factor in the sourcing of juntas de dilatación, with an increasing focus on minimizing environmental impact and promoting ethical supply chains. B2B buyers are now more discerning, seeking suppliers that prioritize sustainable practices, such as using recycled materials and reducing waste in production processes.

The demand for ‘green’ certifications is rising as buyers look for products that meet environmental standards. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 for environmental management are becoming critical in the purchasing decisions of international buyers. Products made from eco-friendly materials not only help in reducing the carbon footprint but also enhance the reputation of businesses committed to sustainability.

Furthermore, ethical sourcing practices are gaining traction, with buyers increasingly interested in transparency throughout the supply chain. This includes understanding the sourcing of raw materials and ensuring fair labor practices. Suppliers who can demonstrate their commitment to ethical standards are likely to gain a competitive advantage in the market.

What Is the Historical Context of Juntas de Dilatación in Construction?

The use of juntas de dilatación in construction has evolved significantly over the decades. Historically, the concept of expansion joints can be traced back to ancient civilizations that recognized the need for structural flexibility to accommodate temperature changes and movement. As construction materials evolved, so did the technology behind expansion joints.

In the 20th century, advancements in materials science led to the development of more sophisticated joint designs that improved performance and durability. The introduction of elastomers and polymers allowed for better flexibility and resistance to environmental factors, which are crucial for modern infrastructure. Today, the evolution of juntas de dilatación continues, driven by innovations that address the challenges of contemporary construction, including climate resilience and sustainability.

This historical context underscores the importance of understanding the technical specifications and requirements for expansion joints in various applications, allowing B2B buyers to make informed decisions that align with industry standards and project needs.

Frequently Asked Questions (FAQs) for B2B Buyers of juntes de dilatació

-

How do I solve issues with cracking in concrete due to temperature changes?

To mitigate cracking in concrete caused by temperature fluctuations, it’s essential to incorporate the appropriate expansion joints (juntas de dilatación). These joints allow for the natural expansion and contraction of materials, preventing undue stress on the concrete. Ensure that the distance between joints is consistent with local building codes and project specifications, typically ranging from 3 to 5 meters for slabs. Regular maintenance and inspections are also crucial to identify any potential issues before they escalate. -

What is the best type of expansion joint for outdoor applications?

For outdoor applications, particularly in areas exposed to varying weather conditions, sealed expansion joints are recommended. These joints utilize elastic materials to accommodate significant movement while protecting against moisture, dirt, and other environmental factors. Products like Boquiflex are particularly effective due to their flexibility, UV resistance, and low VOC content, making them suitable for high-traffic areas and installations that require durability against outdoor elements. -

What factors should I consider when sourcing expansion joints from suppliers?

When sourcing expansion joints, consider the supplier’s reputation, product quality, and experience in the industry. Request samples to evaluate their performance in your specific application. Additionally, inquire about the supplier’s compliance with international standards and certifications, as well as their ability to provide customized solutions tailored to your project needs. It’s also beneficial to check customer reviews and case studies to gauge reliability and service quality. -

How can I ensure the quality of expansion joints before purchasing?

To ensure quality, request detailed product specifications, including material composition, performance data, and any applicable certifications. Conduct a factory visit if possible to observe production processes and quality control measures. Additionally, consider third-party testing results and ask for references from other clients who have used their products in similar applications. Establishing clear communication about your quality expectations with the supplier is also crucial. -

What are the minimum order quantities (MOQ) typically required for expansion joints?

Minimum order quantities (MOQ) for expansion joints can vary widely depending on the supplier and the specific product type. Generally, MOQs can range from a few hundred to several thousand units. It’s advisable to discuss your project requirements with potential suppliers to negotiate favorable terms, especially if you have a smaller project or are testing a new product line. Some suppliers may offer flexible MOQs for new clients or larger contracts. -

What payment terms are standard in international B2B transactions for expansion joints?

Standard payment terms in international B2B transactions often include options such as advance payment, letters of credit, or payment upon delivery. Terms like 30% upfront and 70% upon completion are common, but this can vary based on the supplier’s policies and your relationship with them. It’s crucial to clarify payment expectations and any potential tariffs or import duties that may apply to your order to avoid unexpected costs. -

How should I handle logistics and shipping for expansion joints?

Effective logistics management is vital for timely delivery. Coordinate with your supplier to choose the best shipping method—air freight for speed or sea freight for cost-effectiveness. Ensure you have the necessary documentation for customs clearance, and consider using a freight forwarder to navigate international shipping complexities. Tracking shipments and establishing a clear communication line with your supplier will help mitigate delays and ensure that you receive your products on schedule. -

What customization options are available for expansion joints?

Many suppliers offer customization options for expansion joints to meet specific project requirements. This can include variations in size, material, and design to accommodate different environmental conditions and load specifications. Discuss your needs with potential suppliers to determine available customization options, including color choices and branding. Customization can enhance performance and aesthetic appeal, ensuring that the product fits seamlessly into your project design.

Top 2 Juntes De Dilatació Manufacturers & Suppliers List

1. Cemix – Juntas de Dilatación

Domain: cemix.com

Registered: 1997 (28 years)

Introduction: Las juntas de dilatación son espacios destinados a permitir el movimiento de las estructuras o piezas, evitando la fragmentación de los materiales ante cambios de temperatura. Existen diferentes tipos de juntas de dilatación:

1. Juntas de dilatación Abiertas: permiten la expansión y contracción de las piezas cerámicas, dejando algunos milímetros sin sellar.

2. Juntas de dilatación Selladas: util…

2. Alumacer – Juntas de Dilatación

Domain: alumacer.com

Registered: 2013 (12 years)

Introduction: Las juntas de dilatación son elementos fundamentales en la construcción que permiten la expansión y contracción de los materiales debido a cambios de temperatura, humedad y cargas aplicadas. Existen varios tipos de juntas de dilatación: 1. Juntas de dilatación estructurales, utilizadas en grandes estructuras como puentes y edificios altos. 2. Juntas de dilatación de pavimento, que se instalan en s…

Strategic Sourcing Conclusion and Outlook for juntes de dilatació

In conclusion, strategic sourcing of juntes de dilatación is essential for international B2B buyers seeking to enhance construction quality and longevity. Understanding the various types of expansion joints, such as open and sealed joints, allows businesses to make informed decisions tailored to specific project needs. Effective sourcing not only mitigates the risks of structural damage due to temperature fluctuations but also optimizes maintenance costs over time.

As businesses expand across diverse markets in Africa, South America, the Middle East, and Europe, the demand for high-quality materials and reliable suppliers is paramount. Engaging with trusted manufacturers who prioritize innovation and sustainability will ensure that your projects meet both aesthetic and functional requirements.

Moving forward, we encourage B2B buyers to leverage these insights to build strategic partnerships that enhance their supply chains. By investing in quality juntes de dilatación, you are not just purchasing a product but securing the foundation for future growth and stability in your construction endeavors. Embrace the opportunity to connect with suppliers who share your vision for quality and excellence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.