Introduction: Navigating the Global Market for floating pipe

In the evolving landscape of industrial applications, sourcing floating pipe solutions poses a significant challenge for B2B buyers across diverse markets. Floating pipes are essential for maintaining buoyancy and stability in critical operations such as dredging, oil and gas extraction, and marine construction. However, the variety of options available can make it difficult to identify the best products that align with specific project requirements and environmental conditions. This guide offers a comprehensive exploration of floating pipe systems, including various types, applications, and key considerations for supplier vetting and cost analysis.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including Nigeria and Germany, will find valuable insights tailored to their unique needs. By addressing factors such as durability, material specifications, and environmental resistance, this guide equips decision-makers with the knowledge needed to make informed purchasing decisions. Whether you are looking to enhance operational efficiency or ensure compliance with industry standards, understanding the nuances of floating pipe solutions is crucial. Through actionable insights and expert recommendations, this guide empowers you to navigate the global market confidently, securing the best floating pipe solutions for your business needs.

Table Of Contents

- Top 10 Floating Pipe Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for floating pipe

- Understanding floating pipe Types and Variations

- Key Industrial Applications of floating pipe

- 3 Common User Pain Points for ‘floating pipe’ & Their Solutions

- Strategic Material Selection Guide for floating pipe

- In-depth Look: Manufacturing Processes and Quality Assurance for floating pipe

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘floating pipe’

- Comprehensive Cost and Pricing Analysis for floating pipe Sourcing

- Alternatives Analysis: Comparing floating pipe With Other Solutions

- Essential Technical Properties and Trade Terminology for floating pipe

- Navigating Market Dynamics and Sourcing Trends in the floating pipe Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of floating pipe

- Strategic Sourcing Conclusion and Outlook for floating pipe

- Important Disclaimer & Terms of Use

Understanding floating pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modular Pipe Floats | Patented design, reusable for various sizes, corrosion-resistant | Dredging, marine construction, oil & gas | Pros: Versatile, easy to install; Cons: Initial cost may be higher. |

| Foam-Filled Pipe Floats | Lightweight, UV-resistant, foam-filled for added buoyancy | Water management, mining, dredging | Pros: Enhanced buoyancy, good impact resistance; Cons: Limited lifespan if punctured. |

| Clamp Tite Hose Floats | Non-slip technology, designed for secure attachment | Pumping, dredging, cable management | Pros: Reliable fit, reduces maintenance; Cons: May require specific installation tools. |

| Floating Pump Stations | Modular design, accommodates various pump types | Wastewater management, environmental projects | Pros: Customizable, durable; Cons: Higher initial investment. |

| Containment Booms | RF welded for durability, designed for environmental protection | Spill response, waterway management | Pros: Effective in controlling spills; Cons: Requires regular inspection and maintenance. |

What Are Modular Pipe Floats and Why Are They Essential?

Modular pipe floats feature a patented design that allows for easy customization and reuse across different projects. These floats can accommodate a wide range of pipe diameters, making them versatile for applications in dredging, marine construction, and oil and gas industries. Their corrosion-resistant materials ensure longevity in harsh environments, although the initial investment may be higher than traditional floats. Buyers should consider the adaptability and ease of maintenance that these floats offer.

How Do Foam-Filled Pipe Floats Enhance Performance?

Foam-filled pipe floats are characterized by their lightweight construction and added buoyancy from foam inserts. This design is particularly advantageous in water management, mining, and dredging applications, where stability is crucial. While these floats provide excellent impact resistance and can withstand UV exposure, puncturing can significantly shorten their lifespan. B2B buyers should weigh the benefits of enhanced buoyancy against potential replacement costs in demanding environments.

Why Choose Clamp Tite Hose Floats for Secure Attachment?

Clamp Tite hose floats are engineered with non-slip technology, ensuring a secure fit on hoses and cables. This feature is particularly beneficial in applications such as pumping and dredging, where slippage can lead to operational inefficiencies. While these floats reduce maintenance needs due to their secure attachment, they may require specialized installation tools. Buyers should consider the long-term reliability and reduced operational risks when evaluating these floats.

What Are the Benefits of Floating Pump Stations?

Floating pump stations are designed with a modular approach, allowing for the accommodation of various pump types. These stations are particularly useful in wastewater management and environmental projects, providing a durable and customizable solution for fluid management. However, they often come with a higher initial investment. B2B buyers should assess the long-term benefits of durability and customization against upfront costs.

How Do Containment Booms Function in Environmental Protection?

Containment booms are specifically designed to control spills and manage environmental hazards in waterways. Constructed using RF welding techniques, these booms are durable and effective in preventing the spread of contaminants. While they are crucial for spill response, they require regular inspection and maintenance to ensure effectiveness. Buyers in sectors like environmental management should prioritize the reliability of containment solutions when making purchasing decisions.

Key Industrial Applications of floating pipe

| Industry/Sector | Specific Application of Floating Pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Pipeline support in offshore drilling | Enhances safety and operational efficiency by keeping pipelines afloat, reducing risk of damage and leakage. | Look for UV-resistant materials and modular designs for adaptability in harsh environments. |

| Dredging and Mining | Dredge pump support | Ensures optimal flow and minimizes wear on hoses and pipes, increasing productivity and reducing maintenance costs. | Ensure compatibility with existing equipment and consider weight for ease of installation. |

| Water Management | Floating pump stations | Facilitates easy access and maintenance of pumps, improving water management efficiency in remote areas. | Consider durability and resistance to environmental factors, as well as ease of assembly. |

| Marine Construction | Floating walkways | Provides safe access to work areas over water, enhancing worker safety and operational efficiency. | Ensure the design is modular for easy transport and assembly, and check for compliance with safety regulations. |

| Environmental Protection | Containment booms | Prevents pollution and protects aquatic ecosystems by containing spills or debris in water bodies. | Look for high-impact resistance and UV protection to ensure longevity in various environmental conditions. |

How is Floating Pipe Used in the Oil and Gas Industry?

In the oil and gas sector, floating pipes are essential for supporting offshore pipelines during drilling operations. These floats keep the pipelines buoyant, preventing them from sinking or becoming damaged by harsh marine conditions. This application is critical for ensuring safety and operational efficiency, as damaged pipes can lead to leaks and costly environmental disasters. International buyers should prioritize sourcing floats made from UV-resistant materials and modular designs that can adapt to varying pipeline sizes and conditions.

What Role Does Floating Pipe Play in Dredging and Mining?

Floating pipes are vital in dredging and mining operations, where they support dredge pumps. By keeping hoses and pipes afloat, they ensure optimal flow and reduce wear, leading to increased productivity and lower maintenance costs. In regions such as Africa and South America, where mining operations may be remote, sourcing durable floats that are compatible with existing equipment is crucial. Buyers should consider the weight of the floats for easy installation and transportation in challenging terrains.

How Do Floating Pump Stations Improve Water Management?

Floating pump stations utilize floating pipes to facilitate easy access and maintenance in water management projects. These systems are particularly beneficial in remote areas where traditional infrastructure may be lacking. By allowing pumps to be positioned on the water’s surface, they enhance efficiency and reduce downtime. Buyers in regions such as the Middle East should look for floats that offer durability and resistance to environmental factors, ensuring long-term performance.

What Are the Benefits of Floating Walkways in Marine Construction?

In marine construction, floating walkways provide safe access to work areas over water, significantly enhancing worker safety and operational efficiency. These modular systems can be quickly assembled and disassembled, making them ideal for temporary projects or changing worksite conditions. When sourcing floating walkways, it’s essential for buyers in Europe to ensure compliance with safety regulations and to consider designs that are easy to transport and install.

How Do Containment Booms Utilize Floating Pipe Technology?

Containment booms are crucial for environmental protection, as they use floating pipe technology to prevent pollution in aquatic ecosystems. By containing spills or debris, these booms safeguard water quality and wildlife. For international buyers, particularly in regions prone to industrial spills, sourcing floats with high-impact resistance and UV protection is vital to ensure that they withstand various environmental conditions over time.

3 Common User Pain Points for ‘floating pipe’ & Their Solutions

Scenario 1: Ensuring Stability in Rough Waters

The Problem: B2B buyers in marine construction often face the challenge of maintaining stability for floating pipes in turbulent water conditions. Factors such as waves, currents, and varying water levels can cause floating pipes to submerge or shift positions, leading to potential damage, operational delays, and increased costs. This instability can compromise the safety of operations, particularly when dealing with heavy equipment or critical infrastructure.

The Solution: To address these stability issues, buyers should invest in high-quality floating pipe systems that offer superior buoyancy and resistance to environmental factors. Choosing floats made from durable materials like UV-resistant polyethylene can ensure longevity and reliability. Additionally, opting for modular floating systems allows for easy adjustments based on the specific needs of the project. Implementing a system with a non-slip design and securely fastening the floats to the pipes with robust hardware (like stainless steel ratchets) can minimize movement in challenging conditions. Regular inspections and maintenance of the floating system will also help identify potential wear and tear before they lead to significant issues.

Scenario 2: Mitigating Slippage and Misalignment

The Problem: A common issue in floating pipe applications is the slippage and misalignment of hoses or cables, which can result in decreased efficiency and increased wear on the equipment. This is particularly problematic in dredging and mining operations where maintaining a consistent flow of materials is critical. Misalignment can lead to blockages, reduced pumping capacity, and costly downtime.

The Solution: Buyers should prioritize the selection of floating pipe systems equipped with innovative features that prevent slippage. For example, using floats with integrated clamp inserts can provide a snug fit around hoses and cables, ensuring they remain securely in place during operation. Additionally, choosing floats designed specifically for the diameter of the pipes being used can further minimize the risk of misalignment. Conducting thorough training for personnel on the proper installation and securing techniques will also enhance operational efficiency. It may also be beneficial to develop a routine maintenance schedule to check and adjust the positioning of the floats and connections, ensuring optimal performance.

Illustrative image related to floating pipe

Scenario 3: Cost Management Through Enhanced Durability

The Problem: Buyers often grapple with the high costs associated with replacing floating pipe systems due to wear and tear from harsh environmental conditions. Frequent replacements not only affect the bottom line but also lead to project delays and resource wastage. In regions with extreme weather or corrosive elements, the longevity of floating pipe materials becomes a significant concern.

The Solution: To manage costs effectively, it is essential to invest in floating pipe systems made from high-density, impact-resistant materials that can withstand harsh conditions. For instance, selecting products with UV inhibitors and corrosion-resistant properties will extend the lifespan of the floats significantly. Additionally, buyers can consider modular floating systems that allow for easy replacement of individual floats without needing to discard the entire assembly. This approach not only saves money but also reduces waste and supports sustainability efforts. Implementing a proactive maintenance plan that includes regular cleaning, inspections, and timely repairs will further enhance the durability and performance of floating pipe systems, leading to long-term savings.

Strategic Material Selection Guide for floating pipe

What Are the Key Materials Used in Floating Pipe Systems?

When selecting materials for floating pipe systems, it’s critical to consider their properties, advantages, and limitations. This analysis will focus on four common materials: Polyethylene (PE), Polypropylene (PP), Steel, and Foam.

How Does Polyethylene (PE) Perform in Floating Pipe Applications?

Polyethylene is a widely used material for floating pipes due to its excellent buoyancy and resistance to UV rays and chemicals. It has a temperature rating of up to 80°C (176°F) and exhibits good impact resistance, making it suitable for demanding marine environments.

Illustrative image related to floating pipe

Pros: PE is lightweight, which simplifies transportation and installation. Its corrosion resistance extends the lifespan of floating systems, reducing maintenance costs. Additionally, it is recyclable, making it an environmentally friendly option.

Cons: While PE is durable, it can be susceptible to stress cracking under certain conditions. Its performance may degrade over time when exposed to extreme temperatures or harsh chemicals.

Impact on Application: Polyethylene floats are ideal for applications in dredging, mining, and water management, where buoyancy is crucial to prevent sinking or entanglement.

Considerations for International Buyers: Compliance with standards such as ASTM and ISO is essential. Buyers in regions like Africa and South America should ensure that the PE used is suitable for local environmental conditions and regulatory requirements.

What Advantages Does Polypropylene (PP) Offer for Floating Pipe Systems?

Polypropylene is another popular choice for floating pipes, known for its excellent chemical resistance and lower density compared to polyethylene. It can withstand temperatures up to 100°C (212°F) and is often used in industrial applications.

Pros: PP is highly resistant to fatigue and has a good strength-to-weight ratio, making it suitable for various applications. It is also less expensive than PE, offering a cost-effective solution for many projects.

Cons: Polypropylene is less UV resistant than polyethylene, which may lead to degradation if exposed to sunlight for extended periods. It also has a lower impact resistance.

Impact on Application: PP floats are particularly useful in chemical processing and wastewater management, where resistance to corrosive substances is critical.

Considerations for International Buyers: Buyers should verify compliance with regional standards like DIN and JIS, especially in Europe and the Middle East, where regulations can be stringent regarding chemical compatibility.

Illustrative image related to floating pipe

Why Is Steel Sometimes Used in Floating Pipe Systems?

Steel floats, while less common, are employed in specific applications requiring high strength and durability. They are typically coated to prevent corrosion and can handle extreme conditions.

Pros: Steel offers unmatched strength and can support heavy loads, making it suitable for large-scale industrial applications. It has a high resistance to punctures and physical damage.

Cons: The weight of steel makes transportation and installation more challenging. Additionally, it is prone to corrosion if not properly maintained, leading to higher long-term costs.

Impact on Application: Steel floats are ideal for heavy-duty applications, such as offshore oil drilling, where structural integrity is paramount.

Illustrative image related to floating pipe

Considerations for International Buyers: Buyers must consider the local availability of corrosion-resistant coatings and ensure compliance with international standards for marine applications.

How Does Foam Material Enhance Floating Pipe Systems?

Foam is often used as a buoyant filler in floating pipes, providing additional buoyancy and insulation. It is lightweight and can be molded into various shapes.

Pros: Foam is highly buoyant and provides excellent insulation. It is also cost-effective and can be easily integrated into various designs.

Cons: Foam can be susceptible to degradation from UV exposure and certain chemicals, which may limit its lifespan in harsh environments.

Illustrative image related to floating pipe

Impact on Application: Foam-filled floats are commonly used in temporary installations and applications where flexibility and lightweight properties are essential.

Considerations for International Buyers: Ensure that foam materials meet local environmental regulations, especially in regions with strict waste management policies.

Summary Table of Material Selection for Floating Pipe Systems

| Material | Typical Use Case for Floating Pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Dredging, mining, water management | Lightweight, corrosion-resistant | Susceptible to stress cracking | Medium |

| Polypropylene | Chemical processing, wastewater management | Excellent chemical resistance, cost-effective | Lower UV resistance | Low |

| Steel | Offshore oil drilling, heavy-duty applications | High strength and durability | Heavy, prone to corrosion | High |

| Foam | Temporary installations, flexible applications | Highly buoyant and cost-effective | Susceptible to UV and chemical degradation | Low |

This guide provides a comprehensive overview of material selection for floating pipe systems, enabling international B2B buyers to make informed decisions based on their specific project needs and regional considerations.

Illustrative image related to floating pipe

In-depth Look: Manufacturing Processes and Quality Assurance for floating pipe

What Are the Main Stages of the Manufacturing Process for Floating Pipes?

The manufacturing process for floating pipes involves several critical stages that ensure the final product meets industry standards for durability, performance, and safety. Each stage is designed to transform raw materials into a reliable flotation solution suitable for diverse applications, such as marine construction, dredging, and water management.

Material Preparation: What Materials Are Used and How Are They Prepared?

The primary materials used in the production of floating pipes typically include high-density polyethylene (HDPE) and various foam materials for added buoyancy. The preparation of these materials begins with sourcing high-quality resin or foam that meets specific performance criteria, such as UV resistance and impact strength.

During this stage, the raw materials are inspected for quality and consistency. Any non-compliant materials are discarded to maintain high production standards. Additionally, materials may undergo a pre-processing phase, where they are cut or shaped into manageable sizes for the subsequent manufacturing stages.

How Are Floating Pipes Formed and Assembled?

The forming process often involves advanced techniques such as extrusion or rotational molding, depending on the design specifications of the floating pipes.

-

Extrusion: In this method, the prepared resin is melted and forced through a die to create continuous lengths of pipe or float shapes. This technique allows for uniform thickness and high production efficiency.

-

Rotational Molding: For more complex shapes, rotational molding is employed. In this process, powdered resin is placed in a mold, which is then heated and rotated to ensure even coating and thickness throughout the mold.

Once the individual components are formed, the assembly phase follows. This may include attaching clamps, straps, or other fastening mechanisms that secure the floats to the pipes or hoses. The assembly process is crucial, as it ensures the stability and reliability of the entire system during operation.

Illustrative image related to floating pipe

What Finishing Techniques Are Applied to Enhance Performance?

After forming and assembly, floating pipes undergo various finishing processes to enhance their performance and durability. These may include:

- Surface Treatment: This involves applying coatings that improve UV resistance and abrasion resistance, ensuring the floats can withstand harsh environmental conditions.

- Quality Inspection: A thorough inspection is conducted to identify any defects or inconsistencies in the final product. This may include visual inspections and measurements to confirm that the dimensions and weights meet specifications.

What Quality Assurance Measures Are in Place for Floating Pipes?

Quality assurance is a pivotal aspect of the manufacturing process, ensuring that floating pipes meet international standards and industry-specific requirements. For B2B buyers, understanding these measures is essential for selecting reliable suppliers.

Which International Standards Should Buyers Be Aware Of?

Floating pipes are subject to various international quality standards, including:

- ISO 9001: This standard outlines criteria for a quality management system and is crucial for manufacturers aiming to ensure consistent quality and customer satisfaction.

- CE Marking: In Europe, products must meet certain safety and environmental protection requirements to be sold in the market. Compliance with CE marking signifies that the floating pipes meet these essential standards.

- API Standards: For manufacturers serving the oil and gas industry, adhering to American Petroleum Institute (API) standards is essential, particularly for products used in marine environments.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated at various stages of the manufacturing process to ensure compliance with standards. Key checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for quality and specifications before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are performed to monitor the production process and identify any deviations from specifications.

- Final Quality Control (FQC): Once the products are completed, a final inspection assesses their performance, durability, and compliance with international standards.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Several testing methods are employed to verify the quality and performance of floating pipes:

- Mechanical Testing: This includes tensile strength tests, impact resistance tests, and fatigue tests to ensure the materials can withstand operational stresses.

- Environmental Testing: Products are exposed to simulated environmental conditions, such as UV radiation and saltwater immersion, to assess their long-term durability.

- Dimensional Verification: Accurate measurements are taken to ensure that the dimensions of the floating pipes meet specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for risk mitigation. Here are some actionable steps:

Illustrative image related to floating pipe

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational integrity of the supplier.

- Requesting Quality Reports: Buyers should ask for documentation, including ISO certifications, test reports, and compliance certificates, to verify that the supplier adheres to international quality standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product reliability.

What Are the Nuances of Quality Control for International B2B Transactions?

When dealing with international suppliers, buyers must navigate additional complexities related to quality control:

- Regulatory Compliance: Different regions have varying regulations that may affect product compliance. Understanding these nuances is critical for ensuring that products meet local standards.

- Logistics and Shipping Considerations: Quality can also be affected by the shipping and handling of products. Buyers should ensure that suppliers have robust packaging and transport strategies to minimize damage during transit.

- Cultural and Communication Differences: Effective communication is vital for ensuring that quality expectations are clearly defined and understood across different cultural contexts.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for floating pipes can significantly enhance the decision-making process for B2B buyers. By focusing on the key stages of production, quality standards, and verification methods, buyers can ensure they are partnering with reputable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘floating pipe’

To effectively procure floating pipes, it’s essential to follow a structured approach that ensures you meet both operational and regulatory requirements. This checklist is designed to guide B2B buyers through the critical steps involved in sourcing floating pipes for various applications, from dredging to marine construction.

Illustrative image related to floating pipe

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the floating pipes you need. Consider factors such as the diameter, buoyancy needs, and environmental conditions (e.g., saltwater exposure, UV resistance). Defining these specifications helps streamline your sourcing process and ensures compatibility with your project needs.

- Diameter Requirements: Determine the size of pipes or hoses that will be used in conjunction with the floats.

- Environmental Considerations: Assess the conditions the floats will face, including temperature extremes and chemical exposure.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in floating pipes and related accessories. Look for companies with experience in your industry and positive customer reviews. A robust supplier base can provide you with various options and competitive pricing.

- Check Industry Experience: Focus on suppliers with a proven track record in your specific application area (e.g., dredging, oil and gas).

- Customer Testimonials: Seek out reviews or case studies from clients in similar sectors to gauge satisfaction and reliability.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that potential suppliers hold relevant industry certifications. Certifications ensure that products meet specific safety and quality standards, which is crucial for minimizing operational risks.

- ISO Certifications: Look for suppliers with ISO 9001 certification, indicating quality management practices.

- Environmental Standards: Ensure that suppliers comply with environmental regulations, particularly if operating in sensitive ecosystems.

Step 4: Request Samples for Testing

Ask suppliers for samples of their floating pipes to evaluate their quality and performance firsthand. This step allows you to assess buoyancy, durability, and overall suitability for your applications.

- Performance Testing: Test the samples under conditions similar to your operational environment to ensure they meet your specifications.

- Durability Assessment: Evaluate resistance to punctures, UV exposure, and other environmental factors.

Step 5: Review Pricing and Terms of Sale

Once you’ve narrowed down potential suppliers, compare pricing and terms of sale. Look beyond the base price; consider factors like shipping costs, bulk discounts, and warranty terms.

- Bulk Discounts: Inquire about pricing structures for large orders, as many suppliers offer competitive rates for bulk purchases.

- Warranty and Support: Ensure that the terms include adequate warranty coverage and customer support for troubleshooting.

Step 6: Confirm Delivery and Lead Times

Discuss delivery timelines and logistics with your chosen supplier. Understanding lead times is essential for planning your project schedule and avoiding potential delays.

- Logistics Planning: Confirm whether the supplier can meet your delivery requirements, particularly for international shipments.

- Contingency Plans: Discuss options for expedited shipping in case of unexpected delays.

Step 7: Establish a Long-term Relationship

After successfully sourcing your floating pipes, consider establishing a long-term relationship with the supplier. Consistent communication and collaboration can lead to better pricing, priority support, and tailored solutions for future projects.

- Regular Reviews: Schedule periodic evaluations of supplier performance and product quality.

- Feedback Loop: Provide feedback on product performance to help suppliers improve their offerings.

By following this checklist, you can streamline the procurement process for floating pipes, ensuring that you select the right products and suppliers for your business needs.

Comprehensive Cost and Pricing Analysis for floating pipe Sourcing

What Are the Key Cost Components in Floating Pipe Sourcing?

When sourcing floating pipes, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Illustrative image related to floating pipe

-

Materials: The choice of materials significantly impacts the overall cost. High-density polyethylene (HDPE) and foam-filled options are common due to their lightweight and corrosion-resistant properties. The price can vary based on the quality and sourcing of these materials.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and installation. Regions with lower labor costs may offer more competitive pricing, but it’s essential to consider the quality of workmanship, which can vary widely.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and equipment depreciation. Efficient production processes can help minimize these costs, impacting the final price.

-

Tooling: Custom tooling for specialized designs can be a significant upfront investment. For standard floating pipe sizes, tooling costs are typically lower, allowing for a more flexible pricing structure.

-

Quality Control (QC): Rigorous quality control measures ensure that the floating pipes meet industry standards. While this adds to the cost, it is crucial for reducing the risk of product failure, which can lead to costly operational disruptions.

-

Logistics: Transportation costs can vary based on the location of the supplier and the buyer. Factors like shipping method, distance, and freight charges need to be carefully evaluated to manage logistics costs effectively.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and the perceived value of their product offerings.

What Factors Influence Floating Pipe Prices?

Several factors can influence the pricing of floating pipes:

-

Volume/MOQ: Bulk purchasing often results in lower per-unit costs. Suppliers are more willing to negotiate on price for larger orders, which is beneficial for buyers looking to source for extensive projects.

-

Specifications and Customization: Customized solutions tailored to specific project needs can lead to higher costs. Buyers should weigh the necessity of customization against the added expense.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but offer better durability and compliance with international standards, which is essential for certain industries.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge a premium for their products due to their track record and service reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can impact the total cost. Understanding whether the price includes freight, insurance, and other logistical considerations is vital for accurate budgeting.

What Are the Best Negotiation Tips for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for effective negotiation:

-

Research Market Prices: Familiarize yourself with the typical pricing for floating pipes in your region. This knowledge will empower you during negotiations and help you identify fair offers.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs, including maintenance, durability, and the impact of operational downtime. This holistic view can justify higher upfront costs if they lead to savings over time.

-

Leverage Volume Discounts: If you anticipate future needs, negotiate bulk pricing for current and upcoming projects. Suppliers often provide better rates for commitments to larger orders.

-

Be Aware of Regional Variances: Pricing can vary significantly based on geographic location and local market conditions. Tailor your negotiation strategy to reflect these dynamics.

-

Clarify Payment Terms: Ensure that payment terms align with your cash flow requirements. Flexible payment options can improve your purchasing power and help manage expenses better.

Conclusion

Understanding the cost structure and pricing influences of floating pipes is essential for international B2B buyers. By focusing on the key cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can optimize their sourcing decisions and achieve better value in their procurement processes. Always consider obtaining quotes from multiple suppliers to compare options effectively, keeping in mind that indicative prices may fluctuate based on market conditions.

Alternatives Analysis: Comparing floating pipe With Other Solutions

In the quest for efficient and effective buoyancy solutions in industrial applications, various alternatives to floating pipe systems exist. Each option has its unique advantages and disadvantages, making it essential for B2B buyers to carefully evaluate which solution best meets their specific operational needs.

| Comparison Aspect | Floating Pipe | Modular Hose Floats | Steel Pontoons |

|---|---|---|---|

| Performance | High buoyancy and stability; adjustable for various pipe sizes | Excellent for diverse applications; modular design allows for customization | Strong support; however, heavier and less flexible |

| Cost | Moderate initial investment with long-term savings on maintenance | Competitive pricing; reusable, reducing overall costs | Higher upfront costs; significant maintenance expenses |

| Ease of Implementation | Quick installation; lightweight for easy handling | Simple assembly; modular nature allows for easy adjustments | Labor-intensive installation; requires heavy machinery |

| Maintenance | Low maintenance; durable materials resist corrosion | Low maintenance; reusable and easy to repair | High maintenance; prone to rust and structural issues |

| Best Use Case | Ideal for dredging and marine operations needing flexibility | Suitable for various industrial applications, including water management | Best for large-scale projects needing robust support |

What are the Advantages and Disadvantages of Modular Hose Floats?

Modular hose floats, such as those offered by companies like EZ Connect and Neptune, provide a flexible solution for buoyancy needs. Their modular design allows for easy adjustments, making them suitable for various pipe sizes and applications, from dredging to marine construction. They are typically made from durable, UV-resistant polyethylene, ensuring longevity in harsh environments. The key advantage is their reusability and low maintenance requirements, making them cost-effective over time. However, they may not provide the same level of structural support as a floating pipe system in extremely demanding conditions.

How Do Steel Pontoons Compare to Floating Pipe Systems?

Steel pontoons have been a traditional choice for buoyancy in industrial applications due to their strength and stability. They excel in providing robust support, particularly for large-scale projects. However, they come with significant drawbacks, including high initial costs and extensive maintenance requirements. Steel pontoons are prone to corrosion, which can lead to structural failures over time, necessitating frequent inspections and repairs. While they are suitable for specific heavy-duty applications, their weight and installation complexity can hinder operational efficiency.

Conclusion: How Can Buyers Select the Right Solution for Their Needs?

Selecting the appropriate buoyancy solution involves assessing your specific operational requirements, budget constraints, and environmental conditions. Floating pipes offer a versatile and efficient option for industries requiring flexibility and low maintenance. Modular hose floats present an adaptable and cost-effective alternative for varied applications, while steel pontoons may be suitable for large projects needing robust support despite their maintenance challenges. By evaluating these factors, B2B buyers can make informed decisions that align with their operational objectives and budgetary considerations.

Essential Technical Properties and Trade Terminology for floating pipe

What Are the Key Technical Properties of Floating Pipe?

When evaluating floating pipe solutions, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Floating pipes are typically constructed from high-density polyethylene (HDPE) or other durable plastics. These materials are known for their UV resistance and corrosion durability, making them ideal for marine environments. For B2B buyers, selecting the right material grade ensures longevity and minimizes maintenance costs, especially in harsh conditions.

Illustrative image related to floating pipe

2. Buoyancy Capacity

Buoyancy capacity refers to the float’s ability to support weight while remaining above water. This property is vital for preventing submerged pipes or hoses from becoming damaged or causing operational failures. Buyers should assess buoyancy ratings in relation to their specific application requirements, ensuring the floats can support the intended load effectively.

3. Impact Resistance

The ability of floating pipes to withstand physical impacts is critical, particularly in dynamic environments like marine operations. High impact resistance reduces the risk of damage from boat collisions or debris. For B2B clients, investing in floats with superior impact resistance can lead to reduced downtime and lower replacement costs.

4. Temperature Tolerance

Temperature tolerance indicates how well the floating pipe can perform under varying thermal conditions. This property is essential for applications in regions with extreme temperatures, whether hot or cold. Buyers should ensure that the floating pipe chosen can maintain its integrity and performance in their specific operational climate.

5. Modular Design

A modular design allows for the easy addition or removal of float units to accommodate various pipe sizes and configurations. This flexibility is particularly beneficial for projects with changing specifications. B2B buyers can optimize their inventory and reduce costs by selecting floats that can be reused across multiple projects.

6. Weight and Portability

The weight of the floating pipe affects its transport and installation. Lightweight options are easier to handle, reducing labor costs and installation time. Buyers should prioritize portable solutions, especially for projects in remote or challenging locations, where logistics can significantly impact overall project timelines.

Illustrative image related to floating pipe

What Common Trade Terminology Should B2B Buyers Know?

Familiarizing oneself with industry jargon can facilitate smoother negotiations and better decision-making. Here are some common terms relevant to floating pipe procurement:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for buyers who need compatibility and quality assurance in their floating pipe systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, especially for businesses that may not require large quantities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain pricing and terms for products. It’s a critical step for buyers to ensure they receive competitive offers and understand the full scope of costs involved.

Illustrative image related to floating pipe

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery obligations.

5. Lead Time

Lead time is the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for project planning and ensuring timely delivery of floating pipe systems to avoid operational delays.

6. Warranty

A warranty is a promise from the manufacturer regarding the quality and longevity of the product. Knowing the warranty terms helps buyers assess the risk and reliability of their floating pipe investments.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, ensuring they select the best floating pipe solutions for their operational needs.

Illustrative image related to floating pipe

Navigating Market Dynamics and Sourcing Trends in the floating pipe Sector

What Are the Current Market Dynamics and Key Trends in the Floating Pipe Sector?

The global floating pipe sector is witnessing transformative growth, driven by increasing demand in industries such as dredging, oil and gas, and marine construction. One of the primary market drivers is the need for efficient and sustainable solutions for managing pipelines and hoses in aquatic environments. With a focus on reducing operational costs and enhancing safety, companies are turning to advanced materials such as high-density polyethylene (HDPE) and modular float designs that allow for easy installation and adaptability to various pipe sizes.

Emerging B2B technology trends include the adoption of modular and reusable floating systems. These innovations not only improve shipping efficiency but also reduce waste, aligning with modern sustainability goals. Furthermore, the integration of smart technology, such as sensors that monitor float performance and environmental conditions, is gaining traction, offering companies real-time data for better decision-making. For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed procurement decisions that align with both operational needs and sustainability initiatives.

How Is Sustainability Shaping the Sourcing of Floating Pipes?

Sustainability is increasingly becoming a cornerstone of sourcing strategies in the floating pipe sector. Buyers are not just looking for high-performance products; they are also prioritizing environmental impact and ethical sourcing. The production of floating pipes involves considerable resource use, and manufacturers are responding by adopting greener practices. This includes utilizing recyclable materials and minimizing waste through efficient manufacturing processes.

Moreover, certifications for environmentally friendly products are gaining importance. Buyers are encouraged to seek out floating pipe solutions that come with certifications such as ISO 14001, which indicates a commitment to sustainable practices. These ‘green’ materials not only help in compliance with regulatory frameworks but also enhance a company’s brand reputation in a market that increasingly values corporate social responsibility. For buyers in developing regions, such as Nigeria or South America, aligning procurement with sustainability goals can also open doors to funding and support from international organizations focused on environmental conservation.

What Is the Evolution of Floating Pipe Technology?

The floating pipe sector has evolved significantly over the past few decades, transitioning from traditional materials like steel to more advanced polymers. Initially, floating systems were largely limited by the durability and weight of materials, which restricted their applications. However, advancements in plastic engineering have led to the development of lightweight, high-density polyethylene floats that offer superior buoyancy and resistance to environmental stressors.

The introduction of modular designs has further revolutionized the market, allowing for customizable solutions that can adapt to various projects and conditions. These advancements not only enhance operational efficiency but also reduce the overall cost of ownership for businesses. As the industry continues to innovate, the focus on sustainability and ethical sourcing is likely to shape the next phase of evolution, ensuring that floating pipe solutions are both effective and environmentally responsible.

Frequently Asked Questions (FAQs) for B2B Buyers of floating pipe

-

How do I solve issues with floating pipe slippage during operations?

To mitigate slippage, choose floating pipes with integrated clamp systems, such as Clamp Tite™ inserts, which secure the floats firmly to the pipes or hoses. Additionally, ensure that the floats are designed for a snug fit and are made from high-density materials that prevent movement. Regularly inspect the float systems for wear and replace any damaged components immediately to maintain operational integrity. If slippage persists, consider consulting with the manufacturer for customized solutions tailored to your specific operational conditions. -

What is the best material for floating pipes in harsh environments?

For harsh environments, polyethylene (PE) is often the best choice due to its UV resistance, lightweight nature, and high impact strength. These properties ensure durability against extreme weather conditions and marine environments. Additionally, consider floats made with foam filling, as they provide added buoyancy and stability. Always inquire about the specific environmental tests conducted on the products to ensure they meet the requirements of your project location, whether in Africa, South America, or Europe. -

How can I customize floating pipe solutions for my project?

Many manufacturers offer customization options for floating pipe solutions, including size, buoyancy capacity, and color. Engage directly with suppliers to discuss your project requirements and any specific features you need, such as additional buoyancy or modular designs. Request samples or prototypes to evaluate their effectiveness in your operational setting. Ensure that the customization aligns with industry standards and regulations applicable in your region. -

What are the minimum order quantities (MOQs) for floating pipe products?

Minimum order quantities can vary significantly between suppliers, often depending on the product type and customization level. Typically, standard products may have lower MOQs, while custom solutions might require larger orders. It’s advisable to inquire directly with suppliers about their MOQs to ensure they align with your project needs. Establishing a relationship with the supplier may also allow for negotiation on MOQs, especially for repeat orders or long-term partnerships. -

What payment terms should I expect when sourcing floating pipe?

Payment terms vary by supplier and often depend on factors such as order size, relationship history, and regional practices. Common terms include deposits upfront, with the balance due upon shipment or delivery. Some suppliers may offer credit terms for established customers. Always clarify payment methods accepted, such as wire transfers or letters of credit, and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance (QA) for floating pipe products?

To ensure quality assurance, request certifications from the supplier that demonstrate compliance with industry standards. Inquire about their manufacturing processes and whether they conduct regular quality checks. Some manufacturers may provide third-party testing results, which can give you confidence in the product’s durability and performance. Establishing a clear QA process in your contract can also help hold the supplier accountable for product quality. -

What logistics considerations should I keep in mind when sourcing floating pipe internationally?

When sourcing internationally, consider shipping methods, lead times, and customs regulations in your country. Ensure that the supplier can provide accurate shipping estimates and track the shipment until delivery. Familiarize yourself with import duties and taxes that may apply. Engaging a logistics partner experienced in international trade can streamline this process and help mitigate potential delays or additional costs. -

How do I vet suppliers for floating pipe products?

To vet suppliers, research their industry reputation through online reviews, case studies, and testimonials from previous clients. Verify their manufacturing capabilities and experience in your specific industry. Request references and reach out to past customers to gauge their satisfaction. Additionally, consider visiting the supplier’s facility if possible or requesting a virtual tour to assess their operations and quality control processes. Ensure they comply with international standards relevant to your project.

Top 10 Floating Pipe Manufacturers & Suppliers List

1. EZ Connect – Modular Floats for Hoses and Pipelines

Domain: ezconnectfloats.com

Registered: 2022 (3 years)

Introduction: EZ Connect Floats are patented modular one-size-fits-all floats designed for hoses, pipelines, pipes, cables, and umbilicals. They are made of bright red polyethylene material, easy to see, and withstand extended wear in water and direct sunlight. The floats are reusable for any size diameter from 1 to 40 inches and can be quickly installed using nylon straps and stainless-steel ratchets that are …

2. PipeFloat – Pipe Floats & Mooring Buoys

Domain: pipefloat.com

Registered: 2011 (14 years)

Introduction: {“Pipe Floats/Hose Floats & Cable Floats”: {“material”: “UV resistant PE”, “features”: “Clamp Tite TM inserts to prevent slippage”}, “Mooring Buoys”: {“size range”: “13’’ to 48’’”, “features”: “foam filled, available with eye or rope channel”}, “Regulatory Buoys”: {“also known as”: “Spar Buoys or Channel Marker Buoys”, “features”: “impact resistant, molded with handles for lifting”}, “Floating Wal…

3. DAE Pumps – Polyethylene Pipe and Hose Floats

Domain: daepumps.com

Registered: 2018 (7 years)

Introduction: DAE Pumps offers ultra-durable polyethylene pipe and hose floats designed for dredging applications. Key features include:

– Made from lightweight, high-density polyethylene for flexibility and impact resistance.

– Prevents slippage and misalignment on cables, hoses, and pipes.

– High corrosion and UV resistance for longer product life.

– High impact strength to withstand rough conditions.

– Light…

4. CDSR – Pipe Float

Domain: cdsr-tech.com

Registered: 2022 (3 years)

Introduction: Product Name: Pipe Float (Float for Dredging Pipes)\nManufacturer: CDSR\nComposition: Steel pipe, flotation jacket, outer cover, retaining rings at both ends\nMain Function: Provides buoyancy to steel pipes for floating on water\nMaterials: Q235, PE foam, natural rubber\nFeatures: \n1. Good rigidity\n2. Straight pipe, easy to install\n3. Good floating performance with high reserve buoyancy\n4. Exc…

5. Pedredgepipe – HDPE Floating Pipelines

Domain: pedredgepipe.com

Registered: 2021 (4 years)

Introduction: HDPE floating pipelines are designed for various applications including dredging, offshore oil and gas operations, and water transport in challenging terrains. They utilize high-density polyethylene (HDPE) for buoyancy and stability, making them suitable for both freshwater and saltwater environments. The pipelines consist of HDPE pipes and pipe floats, which can be adjusted for different water le…

6. China Rubber Fender – Pipe Floats

Domain: chinarubberfender.com

Registered: 2011 (14 years)

Introduction: Pipe Floats – Used in combined pipeline and dredge equipment. Features: 1. Lightweight, easy installation, secure nut bolts system and tightening belts. 2. Quick online maintenance without taking off line. 3. Marine grade galvanized accessories. 4. Thick PE shell with eco-friendly PU filling for maximum impact resistance. 5. Superb flexible system for rough sea conditions. 6. Excellent weathering …

7. Barr Plastics – Neptune Industrial Pipe Floats

Domain: barrplastics.com

Registered: 2004 (21 years)

Introduction: Neptune Industrial Pipe Floats are designed for dredging, mining, de-watering, pumping, and other industrial projects. They are molded from tough, impact-resistant high-density polyethylene and are foam-filled. Key features include a low profile for stability and reduced resistance to waves, currents, ice, and winds, the ability to withstand sub-zero temperatures, and UV stabilizers for sunlight r…

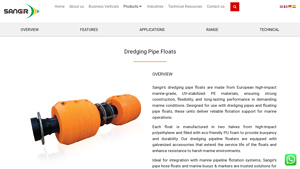

8. Sangir – Dredging Pipe Floats

Domain: sangir.com

Registered: 2011 (14 years)

Introduction: Dredging Pipe Floats Overview: Sangir’s dredging pipe floats are made from European high-impact marine-grade, UV-stabilized PE materials, ensuring strong construction, flexibility, and long-lasting performance in demanding marine conditions. Designed for use with dredging pipes and floating pipe floats, these units deliver reliable flotation support for marine operations. Each float is manufacture…

9. Pipefloats – Large Range Pipefloats

Domain: pipefloats.com

Registered: 2000 (25 years)

Introduction: {‘product_name’: ‘Large Range Pipefloats’, ‘made_in’: ‘100% Australian Made & Designed’, ‘applications’: [‘Dredging’, ‘Mining’, ‘Marine’, ‘Aqua Farming’, ‘Boating’], ‘specifications’: [{‘model’: ‘PIPEFLOAT 400mm’, ‘length’: ‘1,160mm’, ‘weight’: ’60 kg’, ‘reserve_buoyancy’: ‘700.0 kg’}, {‘model’: ‘PIPEFLOAT 560mm’, ‘length’: ‘1,160mm’, ‘weight’: ’60 kg’, ‘reserve_buoyancy’: ‘620.0 kg’}, {‘model’: ‘…

10. IADC Dredging – Floating Pipelines

Domain: iadc-dredging.com

Registered: 1998 (27 years)

Introduction: Pipelines fall into three main categories: floating pipelines, submerged or “sinker” lines, and land or “shore” lines.

1. Floating Pipelines:

– Formed of steel pipes supported by buoyancy units or surrounded by a buoyant case, or made of buoyant material.

– Must be flexible to endure sea movement and currents.

– Flexibility achieved by inserting ball joints or adding flexible pressur…

Strategic Sourcing Conclusion and Outlook for floating pipe

Why is Strategic Sourcing Essential for Floating Pipe Solutions?

In the dynamic landscape of floating pipe solutions, strategic sourcing emerges as a critical factor for businesses aiming to enhance operational efficiency and reduce costs. By leveraging innovative products such as modular floats and advanced materials, companies can ensure durability and reliability in challenging environments. The ability to adapt float systems for various applications—from dredging to marine construction—underscores the importance of sourcing flexible solutions that meet diverse needs.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the latest advancements in floating pipe technology can lead to significant operational advantages. Prioritizing suppliers that offer high-quality, environmentally friendly products not only enhances project outcomes but also aligns with sustainability goals increasingly important in today’s market.

Illustrative image related to floating pipe

What’s Next for Your Floating Pipe Needs?

As you consider your options, focus on suppliers who demonstrate a commitment to innovation and customer service. Request quotes and explore customizable solutions that fit your specific applications. The future of floating pipe systems is bright, and by making informed sourcing decisions today, you position your business for success in tomorrow’s competitive landscape. Reach out to trusted manufacturers and take the first step towards optimizing your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to floating pipe

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.