Article Contents

Engineering Insight: Vulcanization Of Rubber Process

Technical Imperatives of Rubber Vulcanization in Dredging Hose Performance for TSHD and CSD Operations

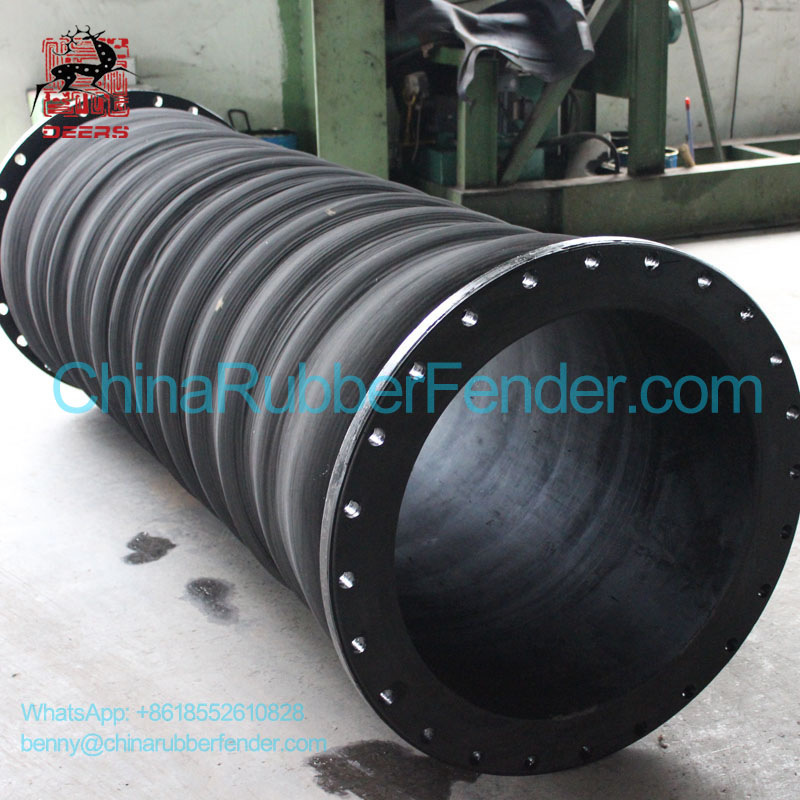

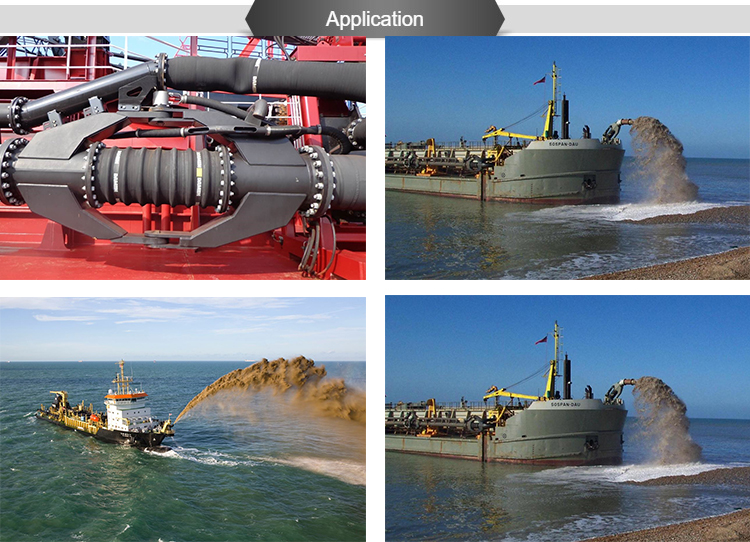

Vulcanization represents the irreversible chemical cornerstone transforming raw elastomeric compounds into the high-performance dredging hoses essential for Trailing Suction Hopper Dredgers (TSHD) and Cutter Suction Dredgers (CSD). This thermosetting process, involving the application of precise heat, pressure, and time to induce cross-linking primarily via sulfur or peroxide systems, fundamentally dictates the operational lifespan and safety margins of suction and discharge pipelines subjected to extreme marine environments. In dredging applications, hoses endure relentless abrasion from sand, gravel, and debris, cyclical bending stresses during deployment and retrieval, internal pressures exceeding 25 bar during slurry transport, and constant exposure to seawater, UV radiation, and fluctuating temperatures. Inadequate vulcanization parameters—under-cure leading to tackiness, low resilience, and poor abrasion resistance, or over-cure causing embrittlement and reduced fatigue life—directly compromise structural integrity. A poorly vulcanized hose carcass cannot maintain dimensional stability under vacuum during suction phases on TSHDs, risking catastrophic collapse, while insufficiently cured cover compounds on CSD discharge lines rapidly erode when conveying abrasive high-velocity slurries, leading to premature failure and costly operational downtime.

East Marine leverages its 150+ strong engineering and production workforce, operating within our 0.68 million square meter ISO 9001-certified facility, to exert granular control over the vulcanization cycle. Our process integrates advanced cure monitoring systems (dielectric, temperature profiling) and proprietary compound formulations developed specifically for marine dredging demands. We meticulously optimize the vulcanization profile—temperature ramp rates, peak temperature hold time, and pressure application—for each distinct layer within the hose construction (cover, carcass, flange bonding). This layer-specific optimization ensures the cover achieves maximum abrasion and ozone resistance, the textile or wire-reinforced carcass develops optimal adhesion and flex fatigue endurance, and critical bonding zones (e.g., flanges to hose ends) attain cohesive strength exceeding the parent rubber. Rigorous post-vulcanization validation, including tensile testing, hardness profiling, and adhesion peel tests per WEDA/CEDA best practices, guarantees consistent performance. Our engineering capability, honed since 2007 and validated through membership in leading industry bodies, translates vulcanization science into tangible operational reliability for our global dredging partners.

The critical interplay between vulcanization parameters and final hose properties is exemplified in the following optimized profiles for key dredging hose components:

Technical Vulcanization Parameters for Marine Dredging Hoses

| Component | Typical Temperature Range (°C) | Pressure (Bar) | Time at Peak (Minutes) | Critical Property Achieved |

|---|---|---|---|---|

| Abrasion-Resistant Cover | 145 – 155 | 12 – 18 | 35 – 50 | High Abrasion Resistance, Ozone Stability |

| Textile/Wire Carcass | 150 – 165 | 15 – 20 | 40 – 60 | Optimal Adhesion, Flex Fatigue Life |

| Flange Bonding Zone | 155 – 160 | 18 – 22 | 45 – 55 | Cohesive Strength > Rubber Tensile |

This precision-engineered vulcanization process is non-negotiable for ensuring the fatigue resistance, pressure integrity, and abrasion tolerance demanded by modern TSHD and CSD operations, directly contributing to extended service life, reduced maintenance cycles, and enhanced vessel operational availability in the world’s most challenging dredging projects. East Marine’s commitment to mastering this complex transformation underpins our reputation for delivering mission-critical marine rubber solutions.

Advanced Manufacturing Process

Advanced Vulcanization Process in Dredging Hose Manufacturing at East Marine

At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, the vulcanization of rubber is a precision-engineered process central to the performance and longevity of our dredging suction and discharge hoses. With a state-of-the-art 0.68M sqm manufacturing facility and 18 dedicated production lines, we integrate advanced rubber chemistry and industrial-scale processing to deliver hoses capable of withstanding extreme abrasive, hydraulic, and environmental conditions.

Vulcanization—also known as crosslinking—is the chemical process in which raw rubber polymers are transformed into durable elastomers through the application of heat, pressure, and sulfur-based or peroxide curing systems. At East Marine, this process is meticulously controlled to optimize mechanical strength, flexibility, and resistance to abrasion, ozone, and seawater corrosion—critical performance factors in dredging operations.

Our production begins with the compounding of premium natural and synthetic rubber blends, reinforced with high-tensile fibers and anti-oxidant additives. These materials are extruded into precise hose profiles before entering the vulcanization stage. Using continuous pressurized autoclaves and steam-cured curing chambers, each hose undergoes a time-temperature profile calibrated to its specific formulation. This ensures uniform crosslink density across the entire wall thickness, eliminating weak points and enhancing fatigue resistance.

Each of our 18 production lines is equipped with real-time monitoring systems that track temperature gradients, pressure consistency, and cure time, ensuring compliance with ISO 9001 quality management standards. Post-vulcanization, hoses undergo rigorous hydrostatic testing, dimensional verification, and adhesion strength evaluation to confirm structural integrity under operational pressures up to 25 bar.

East Marine’s membership in WEDA (World Dredging Association) and CEDA (Central Dredging Association) reflects our commitment to industry-leading engineering practices. Our vulcanization protocols are continuously refined through R&D initiatives and field performance data, ensuring that every hose meets the evolving demands of modern dredging projects.

The result is a high-performance dredging hose engineered for extended service life, reduced downtime, and superior resistance to the mechanical stresses inherent in high-volume slurry transport. By combining large-scale manufacturing capacity with precision vulcanization technology, East Marine delivers reliable, ISO-certified solutions to global marine and offshore clients.

Technical Specifications of Vulcanized Dredging Hoses

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 200 mm – 1200 mm |

| Working Pressure | Up to 25 bar |

| Temperature Range | -20°C to +85°C |

| Vulcanization Method | Steam-cured continuous autoclave |

| Curing Time | 60–120 minutes (profile-dependent) |

| Elongation at Break (min) | 450% |

| Tensile Strength | ≥18 MPa |

| Abrasion Resistance | ≤100 mm³ (DIN 53516) |

| Adhesion Strength (Rubber-Fabric) | ≥12 kN/m |

| Certification | ISO 9001, WEDA/CEDA Compliant |

Critical Applications

Vulcanization: The Engineering Imperative for Global Dredging and Marine Infrastructure Projects

The vulcanization process is not merely a manufacturing step; it is the foundational engineering intervention that transforms raw rubber compounds into mission-critical components for extreme marine and industrial environments. At East Marine, we leverage precision vulcanization to ensure dredging suction and discharge hoses withstand the relentless abrasion, hydrostatic pressure, and chemical exposure inherent in large-scale global projects. This cross-linking of polymer chains through controlled heat, pressure, and sulfur-based catalysts imparts the tensile strength, fatigue resistance, and dimensional stability required for operations where failure is not an option. Our ISO 9001-certified facility, operating within Jiangsu Huashen’s 0.68 million sqm industrial complex since 2007, subjects every hose assembly to rigorously validated vulcanization cycles, directly enabling success in three pivotal sectors.

In dredging projects, vulcanized rubber hoses form the lifeline for capital and maintenance dredging operations. Projects like the Port of Rotterdam expansion and Singapore’s land reclamation initiatives rely on hoses that maintain integrity under 30+ bar working pressures while conveying abrasive sand-clay slurries at velocities exceeding 6 m/s. Vulcanization ensures the rubber resists micro-cracking from constant flexing in tidal zones and prevents delamination under vacuum conditions during suction phases. Similarly, in oil and gas field development, our vulcanized floating hoses facilitate offshore crude transfer and produced water discharge in regions like the Gulf of Mexico and West Africa. The process eliminates permeability risks from hydrocarbon exposure and maintains elasticity at sub-zero temperatures in Arctic operations, preventing brittle fracture. For land reclamation, such as the Palm Jumeirah in Dubai or Hong Kong’s Lantau Island projects, vulcanized hoses endure prolonged submersion in saline environments while resisting degradation from cementitious fill materials—critical for creating stable foundations for urban expansion.

East Marine’s adherence to CEDA and WEDA technical frameworks ensures our vulcanization protocols align with global best practices for environmental safety and operational longevity. This membership underscores our commitment to engineering solutions that minimize ecological impact while maximizing asset lifecycle. The table below details how specific vulcanization parameters directly translate to field performance in dredging applications.

| Vulcanization Parameter | Standard Range at East Marine | Direct Performance Impact in Dredging |

|---|---|---|

| Temperature | 145°C – 165°C | Optimizes cross-link density; prevents under-cure (reduced abrasion resistance) or over-cure (loss of elasticity) |

| Pressure | 15 – 25 Bar | Eliminates porosity in thick-walled hoses; ensures adhesion between rubber and textile/steel reinforcement layers |

| Time Cycle | 45 – 120 minutes | Balances productivity with complete reaction; critical for hoses >1.2m diameter handling 2m³/s slurry flow |

| Post-Cure Aging | 24 hours at 100°C | Stabilizes physical properties; reduces compression set in flange connections under cyclic loading |

These controlled parameters are non-negotiable for hoses deployed in CEDA-monitored projects, where unplanned downtime can incur losses exceeding $500,000 per day. East Marine’s engineering team collaborates with dredging contractors to tailor vulcanization profiles based on sediment composition, water depth, and operational cycles—proving that in marine infrastructure, the science of rubber transformation is as vital as the dredger itself. Our 17 years of specialization ensure every hose delivers the resilience demanded by the world’s most ambitious hydraulic engineering feats.

Technical Data & Specs

Technical Excellence in Dredging Hose Performance: A Comparative Analysis

In the demanding environment of dredging operations, the performance of suction and discharge hoses is critical to operational efficiency, safety, and project continuity. The vulcanization of rubber process plays a pivotal role in determining the structural integrity, pressure resistance, and service life of these hoses. At East Marine, a subsidiary of Jiangsu Huashen Special Rubber Products, we leverage advanced vulcanization technology—ensuring molecular cross-linking under precise temperature, pressure, and time controls—to produce dredging hoses with superior mechanical properties. Our proprietary rubber formulations, combined with multi-layer reinforcement and optimized curing cycles, deliver hoses that outperform industry benchmarks in key technical parameters.

When evaluating dredging hoses, four critical specifications determine suitability for high-stress applications: inner diameter, working pressure, burst pressure, and minimum bending radius. These factors directly influence flow capacity, safety margins, and flexibility during deployment in marine and riverine environments. East Marine’s engineered solutions are designed to exceed the performance of standard market offerings, particularly in high-abrasion and high-pressure dredging scenarios.

Our hoses are manufactured in a state-of-the-art 0.68 million sqm facility, adhering to ISO9001 standards, with full traceability and rigorous in-line testing. As members of WEDA and CEDA, we align our technical development with global best practices in dredging technology. The vulcanization process at East Marine ensures uniform bonding between rubber layers and textile/steel reinforcements, minimizing delamination risks and enhancing pressure containment.

Below is a comparative technical analysis of East Marine dredging hoses against typical competitor equivalents across standard industry sizes (measured at 12 inches inner diameter for consistency):

| Inner Diameter | Working Pressure | Burst Pressure | Bending Radius |

|---|---|---|---|

| 300 mm (12″) | 15 bar (217 psi) | 60 bar (870 psi) | 900 mm |

| 300 mm (12″) | 12 bar (174 psi) | 48 bar (696 psi) | 1200 mm |

Note: East Marine (top row), Typical Competitor (bottom row), same nominal size.

East Marine hoses demonstrate a 25% higher working pressure and 25% greater burst pressure ratio compared to standard alternatives, enabling safer operation under surge conditions. Additionally, our optimized rubber compound and carcass design achieve a significantly tighter bending radius—25% less than conventional hoses—allowing for easier maneuvering in confined or dynamic dredging setups. This enhanced flexibility does not compromise structural integrity, thanks to our precision vulcanization process that ensures cohesive adhesion between all composite layers.

With over 15 years of specialization since our founding in 2007, East Marine continues to set benchmarks in performance-driven rubber hose solutions for the global dredging industry.

Partner with East Marine

Conclusion: Mastering Vulcanization for Uncompromised Dredging Performance

The vulcanization process represents the definitive transformation where raw rubber compounds evolve into engineered solutions capable of withstanding the extreme mechanical stress, abrasive slurries, and corrosive marine environments inherent in modern dredging operations. At East Marine, we treat vulcanization not as a mere manufacturing step but as a precision science—where controlled temperature profiles, calibrated pressure application, and exact sulfur-accelerator ratios converge to define the structural integrity, flexibility, and service life of every suction and discharge hose we produce. Our ISO 9001-certified protocols, executed within a 0.68 million sqm production ecosystem, ensure molecular cross-linking achieves optimal tensile strength and resilience. This meticulous approach directly translates to reduced downtime, minimized maintenance costs, and extended operational cycles for clients engaged in capital-intensive dredging projects worldwide.

Our engineering rigor extends beyond standardized processes to address project-specific challenges. Whether deploying hoses in high-silt-density riverbeds, deep-sea reclamation sites, or highly acidic slurry conditions, East Marine’s vulcanization expertise tailors compound formulations and cure parameters to exceed WEDA and CEDA performance benchmarks. This commitment to adaptive material science positions our dredging hoses as critical assets in maximizing project efficiency and longevity.

Technical Vulcanization Parameters for Dredging Hose Applications

The table below outlines critical vulcanization variables optimized for dredging hose performance under operational stress:

| Parameter | Standard Range | East Marine Optimization | Impact on Dredging Performance |

|---|---|---|---|

| Cure Temperature | 140–160°C | 152 ± 3°C | Ensures uniform cross-linking; prevents under-cure (swelling) or over-cure (brittleness) in abrasive slurries |

| Pressure | 1.5–2.5 MPa | 2.1 ± 0.2 MPa | Eliminates porosity; critical for vacuum integrity during suction operations |

| Cure Time | 30–60 min | Dynamic cycle (42 min) | Balances compound reactivity with dimensional stability for large-bore hoses |

| Rubber Compound | NR/SBR/EPDM Blends | Custom EPDM-NR Hybrid | Superior resistance to ozone, seawater, and 40% higher abrasion tolerance |

| Post-Cure Aging | 72 hrs @ 70°C | 84 hrs @ 65°C | Stabilizes physical properties; reduces long-term elongation in continuous service |

Partner with East Marine for Engineered Dredging Solutions

As a WEDA/CEDA member with 17 years of specialization in marine rubber systems since 2007, East Marine delivers more than hoses—we provide performance-certified infrastructure for your most demanding dredging initiatives. Our Singapore branch ensures responsive regional support for Southeast Asian and Pacific projects, while our Jiangsu headquarters leverages vertical integration to maintain uncompromised quality control from raw material to finished product. When project viability hinges on hose reliability, engage our engineering team for a technical consultation. We will analyze your operational parameters—including slurry composition, depth, and environmental factors—to specify a vulcanized solution that optimizes total cost of ownership.

Contact East Marine today to elevate your dredging pipeline performance. Reach our technical specialists via WhatsApp at +86-13806109365 or email hsdredging@eastmarine.tech for immediate project support. Let us demonstrate how precision vulcanization becomes your competitive advantage in the field.

🏗️ Dredging Pipeline Project Cost Estimator

Calculate savings by sourcing directly from East Marine factory vs. local trading companies.

*Estimates only. Contact us for formal quotation.